Makita MT904, MT905 Technical Information

OFFICIAL USE

for ASC & Sales Shop

T

ECHNICAL INFORMATION

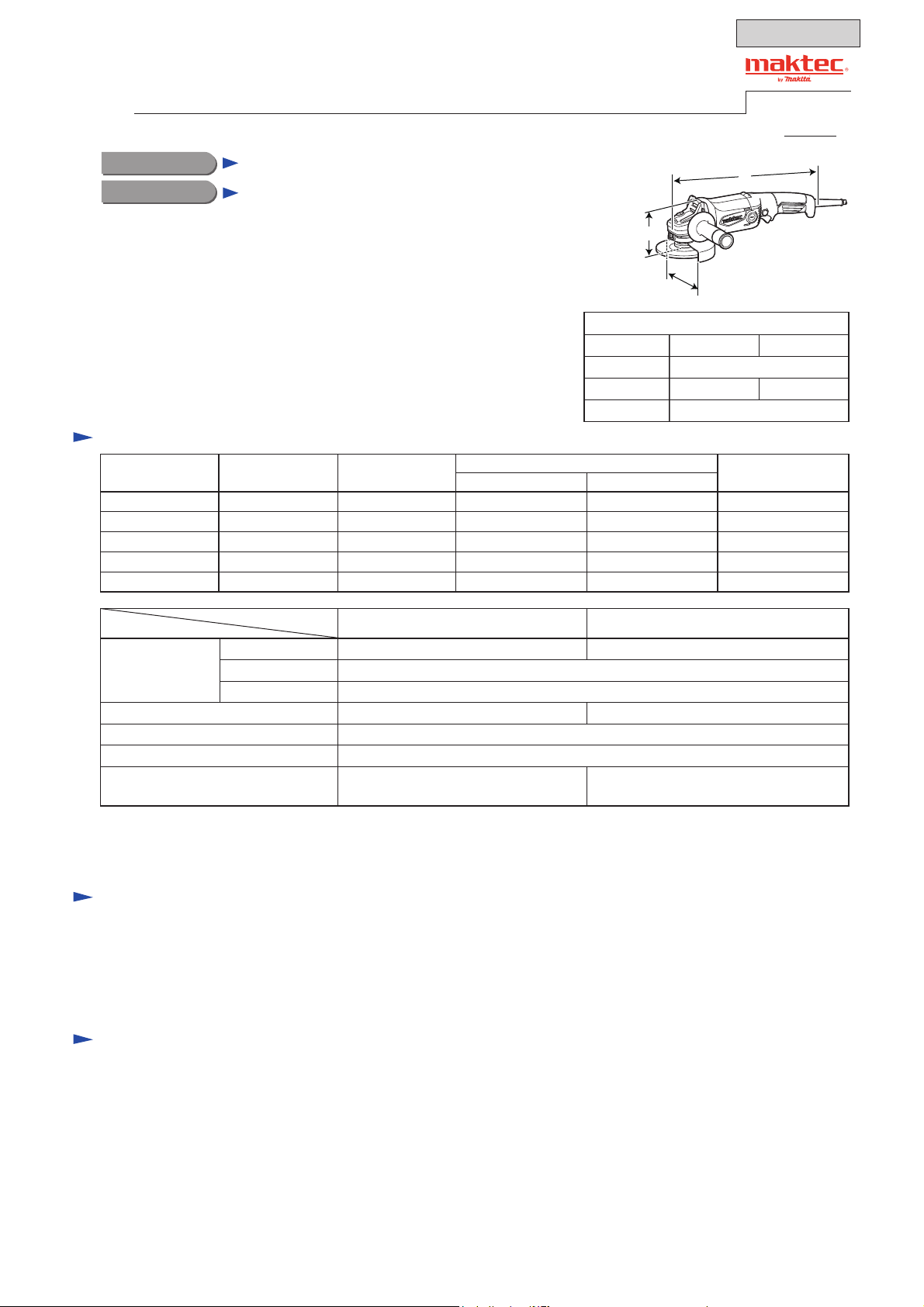

Model No.

Description

MT904/ MT905

Angle Grinders 125mm (5") /150mm (6")

CONCEPT AND MAIN APPLICATIONS

Moldes MT904/ MT905 are easy to handle, lightweight maktec Angle grinders.

Their features are as follows:

• Similar performance as Makita GA5010/GA6010

• New cosmetic design

• Industrial performance and durability at less expense

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240 4.6 50/60 1,050 1,700

Current (A)

10

10.5

5

4.8

50/60

50/60

50/60

50/60

Continuous Rating (W)

Input Output

1,050

1,050

1,050

PRODUCT

P 1/ 10

L

H

W

Dimensions: mm (")

Model No. MT904 MT905

Length (L)

Width (W)

Height (H)

700

900--700

700

700

361 (14-1/4)

140 (5-1/2) 171 (6-3/4)

124 (4-7/8)

Max. Output (W)

1,600

1,600

1,700

1,700

Specification

Wheel size:

mm (")

No load speed: min.ֿ ¹= rpm

Weight according to

EPTA-Procedure 01/2003*: kg (lbs)

* With Inner flange, Lock nut, Wheel cover, and Side grip

Diameter

Hole diameter

Max. thickness

Model

MT904 MT905

125 (5)

11,000 10,000

Double insulationProtection against electric shock

2.8 (6.1) 2.8 (6.2)

Standard equipment

Side grip ........................................................1

Lock nut wrench ............................................1

Note: The standard equipment may vary by country or model variation.

Optional accessories

Wheel cover

150 (6)

22.23 (7/8)

6 (1/4)

2.0 (6.6)Power supply cord: m (ft)

P 2/ 10

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R004 Retaining ring pliers ST-2

1R028

1R035

1R037

1R268

1R269

1R280

1R291

1R350

Bearing setting pipe 20-12.2

Baring setting plate 15.2

Bearing setting plate 20.2 assemble large Spiral bevel gear to Spindle

Spring pin extractor M3 disassembling Spindle lock mechanism

Bearing extractor removing Ball bearings 608ZZ and 696ZZ

Retaining ring S and R pliers removing / assembling Retaining ring R-26

Ring 60

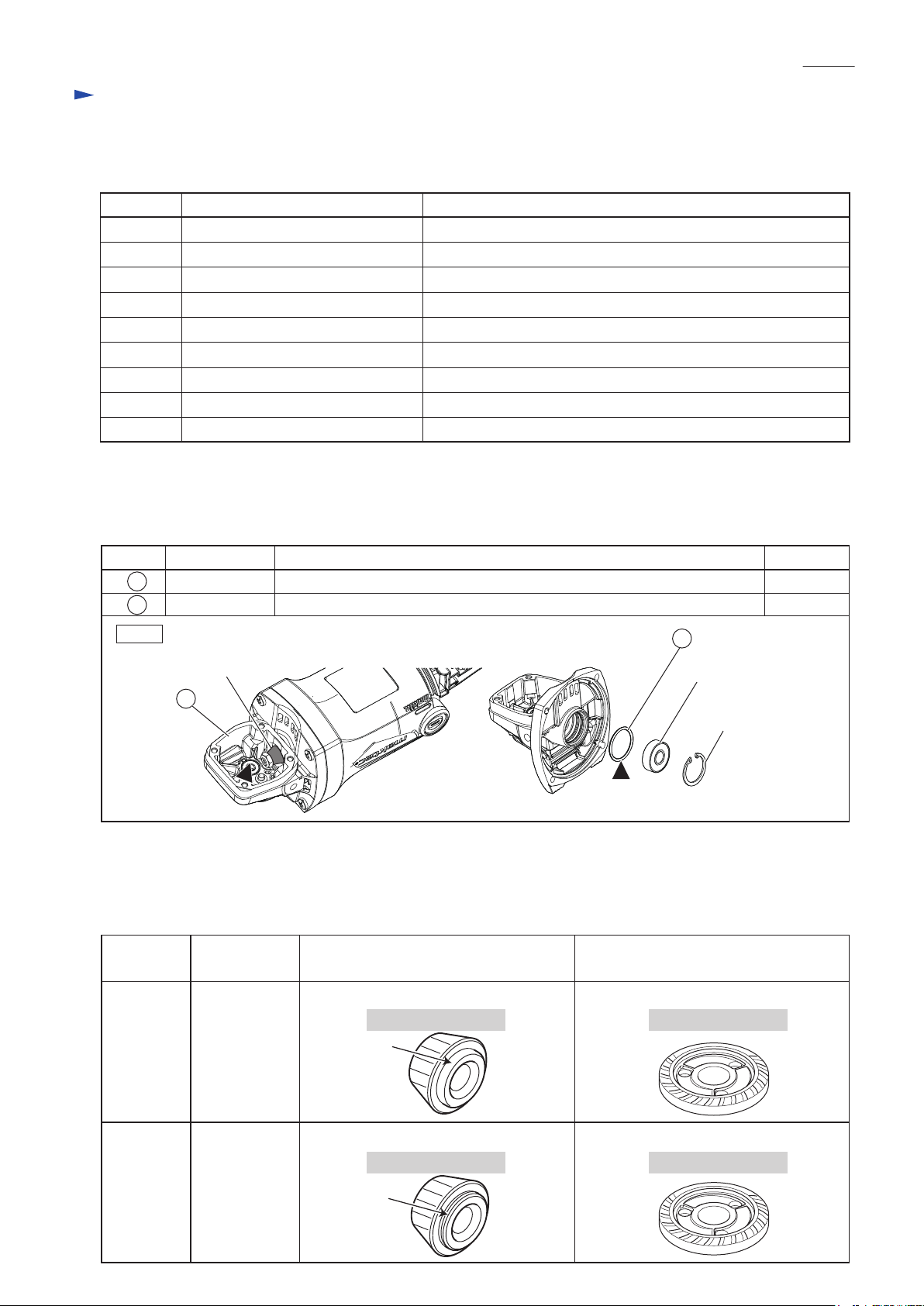

[2] LUBRICATION

removing / assembling Ring spring 13 from / to Spindle

removing Ball bearing 6202DDW from Bearing box

holding Spindle when assembling large Spiral bevel gear

removing Spindle from large Spiral bevel gearRound bar for Arbor 6-50

support Gear housing when disassembling Spindle lock

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect parts and product

from unusual abrasion.

Item No.

4 Gear housing Gear room where small and large Spiral bevel gears engage.

5 O ring 26 whole portion

Fig. 1

Description

Spiral bevel gear

(small)

4

Portion to lubricate

Amount

18g approx.

a little

5

Ball bearing 6000DDW

Retaining ring R-26

[3] DISASSEMBLY/ASSEMBLY

Important: As listed below, different gears are used for MT904/ MGA504 and MT905/ MGA600, and they are not

interchangeable between the models. Be careful not to confuse them.

Model No.

No load speed

(rpm)

Small spiral bevel gear

(Gear on Armature shaft)

Large spiral bevel gear

(Gear on Spindle)

MT904/

MGA504

MT905/

MGA600

11,000 rpm.

10,000 rpm.

Spiral bevel gear 11 Spiral bevel gear 35A

Number of teeth : 11

not grooved

Spiral bevel gear 11A Spiral bevel gear 38

Number of teeth : 11

grooved

Number of teeth : 35

Number of teeth : 38

Repair

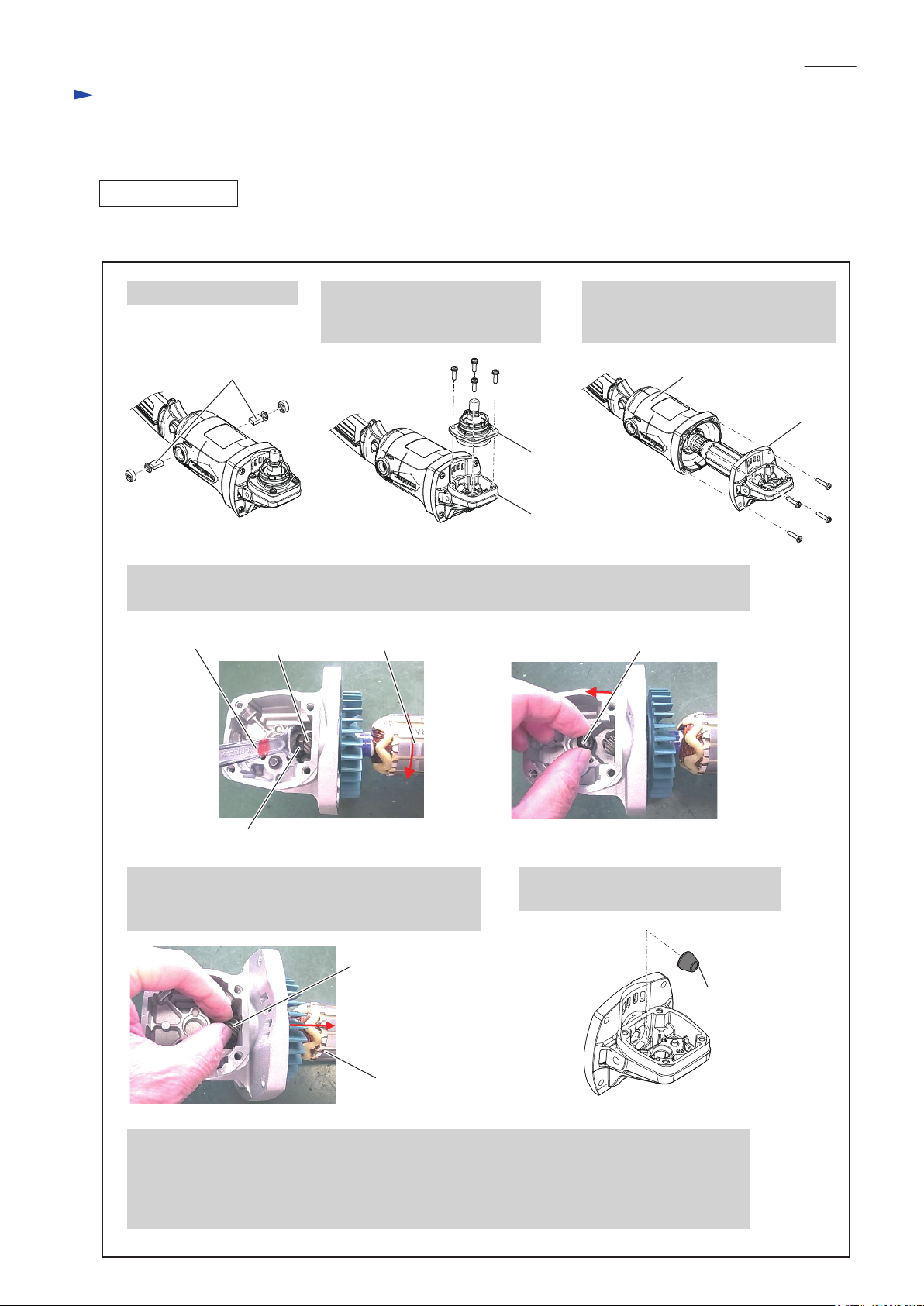

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature, Spiral bevel gear (small), Ball bearings 6000DDW, 608ZZ

DISASSEMBLING

(1) Disassemble Armature and small Spiral bevel gear from Gear housing as drawn in Fig. 2.

Fig. 2

P 3/ 10

1. Remove Carbon brush.

Carbon brush (2 pcs.) M5x18 Pan head

4. While holding M7 Hex nut with Wrench 11, turn Armature counterclockwise to remove the nut

from Armature assembly.

Wrench 11

Spiral bevel gear

(small)

2. Remove four M5x18 Pan head

screws, then separate Bearing

box section from Gear housing.

screw (2 pcs.)

Bearing box

Gear housing

Armature

3. Remove four 5x25 Tapping screws,

then separate Gear housing from

Motor housing.

Motor housing

M5x25 Pan head

screw (4 pcs.)

M7 Hex nut

Gear housing

M7 Hex nut

5. Pull off Armature from Gear housing while holding

small Spiral bevel gear by hand so that the gear

does not fall off from Gear housing.

Small Spiral bevel gear

Armature

Note in Disassembling:

If it is difficult to pull off Armature by hand, do the following steps.

1. Lubricate small spiral bevel gear and Armature shaft with spray lubricant.

2. Wrap the gear with a cloth to protect the gear teeth.

3. Using water pump pliers or the like, firmly grip the gear wrapped with cloth, then turn the gear.

6. Remove small Spiral bevel gear from

Gear housing.

Small Spiral bevel gear

Loading...

Loading...