Page 1

Hammer Drill

MODEL MT810

MODEL MT811

MODEL MT812

MODEL MT813

DOUBLE

INSULATION

INSTRUCTION MANUAL

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

001690

Page 2

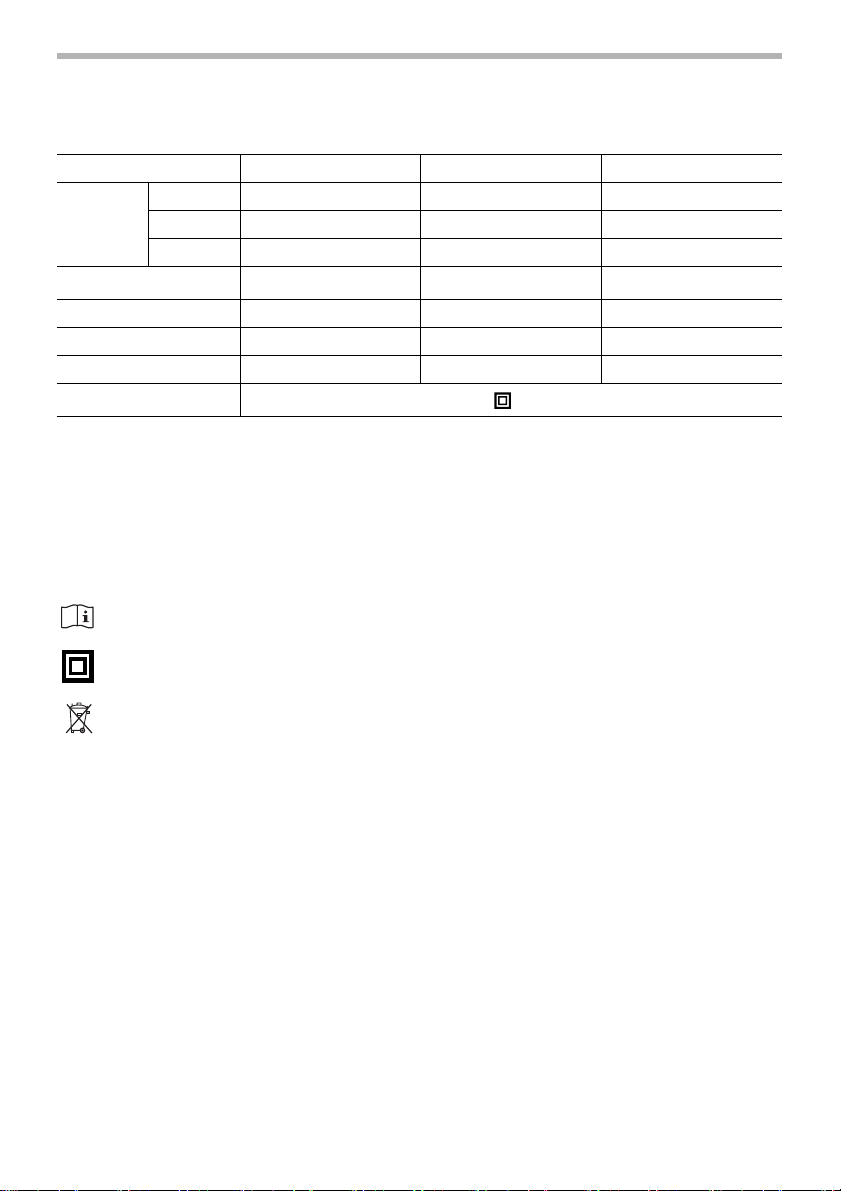

SPECIFICATIONS

Model MT810 MT811/MT812 MT813

Concrete 10 mm 13 mm 16 mm

Capacities

No load speed (Min

Blows per minute 0 - 30,800 0 - 30,800 0 - 45,000

Overall length 258 mm 272 mm 297 mm

Net weight 1.4 kg 1.6 kg 2.0 kg

Safety class

• Manufacturer reserves the right to change specifications without notice.

• Specifications may differ from country to country.

SYMBOLS

The following show the symbols used for the

tool. Be sure that you understand their

meaning before use.

...............Read instruction manual.

...............DOUBLE INSULATION

..............Only for EU countries

Wood 18 mm 18 mm 30 mm

Steel 10 mm 13 mm 13 mm

-1

)

0 - 2,800 0 - 2,800 0 - 3,000

/II

END201-2

Intended use

The tool is intended for impact drilling in

brick, concrete and stone as well as for drilling without impact in wood, metal, ceramic

and plastic.

Power supply

The tool should be connected only to a

power supply of the same voltage as indicated on the nameplate, and can only be

operated on single-phase AC supply. They

Do not dispose of electric

equipment together with

household waste material!

are double-insulated in accordance with

European Standard and can, therefore, also

be used from sockets without earth wire.

For Model MT810/MT811/MT812

In observance of European

Directive 2002/96/EC on

waste electric and electronic

equipment and its implementation in accordance with

national law, electric equipment that have reached the

end of their life must be collected separately and

returned to an environmentally compatible recycling

facility.

For European countries only

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 95 dB (A)

sound power level: 106 dB (A)

Uncertainty: 3 dB

– Wear ear protection. –

The typical weighted root mean square

acceleration value is 10 m/s

These values have been obtained according

to EN60745.

2

2

.

Page 3

For Model MT813

For European countries only

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 98 dB (A)

sound power level: 109 dB (A)

Uncertainty: 3 dB

– Wear ear protection. –

The typical weighted root mean square

acceleration value is 10 m/s2.

These values have been obtained according

to EN60745.

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility

that this product is in compliance with the

following standards of standardized documents, EN60745, EN55014, EN61000 in

accordance with Council Directives, 89/336/

EEC, 98/37/EC.

Yasuhiko Kanzaki CE 2005

Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer:

Makita Corporation Anjo Aichi Japan

GENERAL SAFETY RULES GEA001-3

WARNING:

Read all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury. The term

“power tool” in all of the warnings listed below refers to your mainsoperated (corded) power tool or battery-operated (cordless) power

tool.

SAVE THESE INSTRUCTIONS

Work area safety

1. Keep work area clean and well lit. Cluttered

and dark areas invite accidents.

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Powe r

tools create sparks which may ignite the dust

or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

3

Page 4

Electrical safety

4. Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

5. Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

6. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

8. When operating a power tool outdoors,

use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

Personal safety

9. Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

10. Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the

switch is in the off-position before plugging in. Carrying power tools with your finger

on the switch or plugging in power tools that

have the switch on invites accidents.

12. Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

13. Do not overreach. Keep proper footing

and balance at all times. This enables bet-

ter control of the power tool in unexpected situations.

14. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing,

and gloves away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

15. If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust-

related hazards.

Power tool use and care

16. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

17. Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

18. Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety mea-

sures reduce the risk of starting the power

tool accidentally.

19. Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained

users.

20. Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that

may affect the power tools operation. If

4

Page 5

damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

21. Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp cutting edges are less likely to bind and are

easier to control.

22. Use the power tool, accessories and tool

bits etc. in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into

account the working conditions and the

work to be performed. Use of the power tool

for operations different from those intended

could result in a hazardous situation.

Service

23. Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

24. Follow instruction for lubricating and

changing accessories.

25. Keep handles dry, clean and free from oil

and grease.

SPECIFIC SAFETY RULES GEB003-2

DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to hammer drill safety

rules. If you use this power tool unsafely or incorrectly, you can

suffer serious personal injury.

1. Wear ear protectors with impact drills.

Exposure to noise can cause hearing loss.

2. Use auxiliary handles supplied with the

tool. Loss of control can cause personal

injury.

3. Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will make exposed metal parts of the tool

“live” and shock the operator.

4. Always be sure you have a firm footing.

Be sure no one is below when using the

tool in high locations.

5. Hold the tool firmly with both hands.

6. Keep hands away from rotating parts.

7. Do not leave the tool running. Operate the

tool only when hand-held.

8. Do not touch the bit or the workpiece

immediately after operation; they may be

extremely hot and could burn your skin.

9. Some material contains chemicals which

may be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material supplier safety data.

5

Page 6

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

6

Page 7

ASSEMBLY

1

2

5

1. Grip base

2. Side grip(auxiliary handle)

3. Teeth

4. Protrusion

5. Loosen

6. Tighten

3

4

6

001691

Installing side grip (auxiliary handle)

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the side grip.

Always use the side grip to ensure operating safety. Install

the side grip so that the teeth on the grip fit in between the

protrusions on the tool barrel. Then tighten the grip by turning clockwise at the desired position. It may be swung 360°

so as to be secured at any position.

001692

Installing or removing drill bit

1

1. Drill chuck

2. Chuck key

1

1. Sleeve

2. Ring

2

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the bit.

For Model MT810/MT811/MT813

To install the bit, place it in the chuck as far as it will go.

Tighten the chuck by hand. Place the chuck key in each of

the three holes and tighten clockwise. Be sure to tighten all

three chuck holes evenly. To remove the bit, turn the chuck

key counterclockwise in just one hole, then loosen the chuck

by hand.

After using the chuck key, be sure to return it to the original

position.

For Model MT812

004365

Hold the ring and turn the sleeve counterclockwise to open

the chuck jaws. Place the bit in the chuck as far as it will go.

Hold the ring firmly and turn the sleeve clockwise to tighten

the chuck.

To remove the bit, hold the ring and turn the sleeve counter-

2

clockwise.

7

Page 8

1

1. Side grip

2. Depth gauge

3. Grip base

FUNCTIONAL

DESCRIPTION

1

2

1. Switch trigger

2. Lock button

001693

2

3

001694

Depth gauge (optional accessory)

The depth gauge is convenient for drilling holes of uniform

depth. Loosen the side grip and insert the depth gauge into

the hole in the grip base. Adjust the depth gauge to the

desired depth and tighten the side grip.

NOTE:

The depth gauge cannot be used at the position where the

depth gauge strikes against the gear housing.

Switch action

CAUTION:

• Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the “OFF”

position when released.

To start the tool, simply pull the switch trigger. Tool speed is

increased by increasing pressure on the switch trigger.

Release the switch trigger to stop. For continuous operation,

pull the switch trigger and then push in the lock button. To

stop the tool from the locked position, pull the switch trigger

fully, then release it.

A

B

1

1. Reversing switch lever

001695

Reversing switch action

This tool has a reversing switch to change the direction of

rotation. Move the reversing switch lever to the position (A

side) for clockwise rotation or to the position (B side) for

counterclockwise rotation.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation before

the tool stops may damage the tool.

8

Page 9

001696

Selecting the action mode

This tool has an action mode change lever. For rotation with

hammering, slide the action mode change lever to the right

( symbol). For rotation only, slide the action mode change

lever to the left ( symbol).

1

1. Action mode changing lever

OPERATION

CAUTION:

• Always slide the action mode change lever all the way to

your desired mode position. If you operate the tool with

the lever positioned halfway between the mode symbols,

the tool may be damaged.

Hammer drilling operation

CAUTION:

• There is tremendous and sudden twisting force exerted

on the tool/bit at the time of hole break-through, when

the hole becomes clogged with chips and particles, or

when striking reinforcing rods embedded in the

concrete. Always use the side grip (auxiliary handle) and

firmly hold the tool by both side grip and switch handle

during operations. Failure to do so may result in the loss

of control of the toll and potentially serve injury.

When drilling in concrete, granite, tile, etc., slide the action

mode change lever to the position of symbol to use “rota-

tion with hammering” action. Be sure to use a tungsten-carbide tipped bit. Do not apply more pressure when the hole

becomes clogged with chips or particles. Instead, run the

tool at an idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out.

After drilling the hole, use the blow-out bulb to clean the dust

out of the hole.

Drilling operation

When drilling in wood, metal or plastic materials, slide the

action mode change lever to the position of symbol to use

“rotation only” action.

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide screw

makes drilling easier by pulling the bit into the workpiece.

9

Page 10

Drilling in metal

To prevent the bit from slipping when starting a hole, make

an indentation with a center-punch and hammer at the point

to be drilled. Place the point of the bit in the indentation and

start drilling. Use a cutting lubricant when drilling metals. The

exceptions are iron and brass which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve to

damage the tip of your bit, decrease the tool

performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at the

time of hole break through. Hold the tool firmly and exert

care when the bit begins to break through the workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar holddown device.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by an Makita

Authorized Service Center.

10

Page 11

Memo

11

Page 12

884431C225

Makita Corporation Anjo, Aichi, Japan

Loading...

Loading...