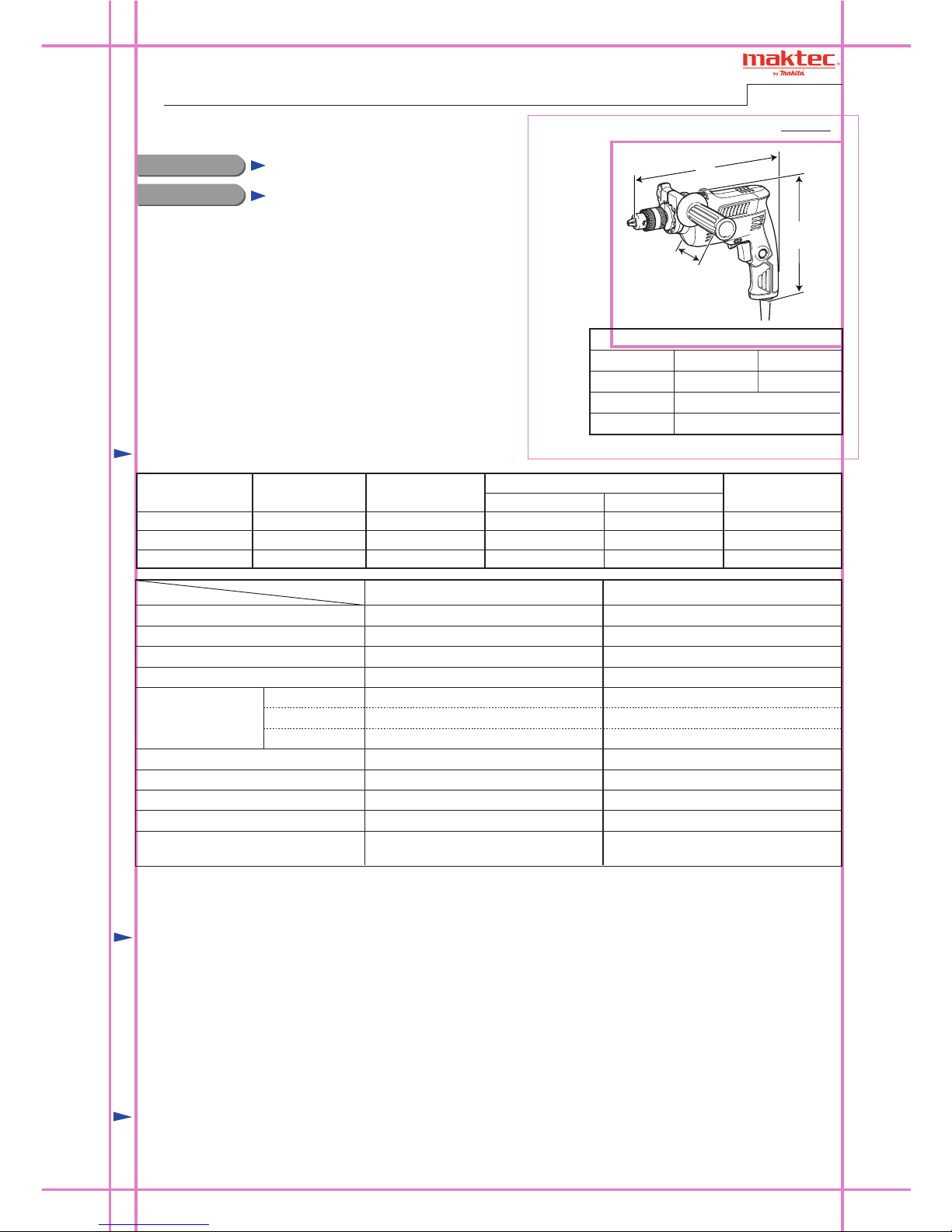

Makita MT80A, MT80B Technical Information

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 12

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

Model No.

Description

MT80A, MT80B

Hammer Drills 10mm (3/8"), 16mm (5/8")

Models MT80A/ MT80B have been developed as maktec brand

hammer drills 10mm (3/8")/ 16mm (5/8"), mainly for the emerging

countries.

New maktec design is employed to eliminate white printing and

polygonal line from maktec logo/ elastomer from handle for the cost

effectiveness.

Depth gauge

230

240

50/60

50/60

2.3

2.2

500

500

250

250

350

220 50/602.4 500 250 350

350

Continuous Rating (W)

Voltage (V) Cycle (Hz)

Input Output

Max. Output (W)Current (A)

Dimensions: mm ( " )

Width (W)

Height (H)

Length (L)

262 (10-3/8)

MT80B

254 (10)

MT80A

196 (7-3/4)

70 (2-3/4)

Chuck capacity: mm (")

Chuck type

Reverse switch

Impacts per min.: min.

ˉ¹= ipm

Capacities: mm (") Steel

Concrete

Wood

Protection against electric shock

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003*: kg (lbs)

0 - 2,900

Model No.

MT80B

0 - 43,500

Keyed

1.5 - 13 (1/16 - 1/2)

16 (5/8)

13 (1/2)

20 (13/16)

Yes

Double insulation

1.7 (3.7)

2.0 (6.6)

Variable speed control by trigger Yes

0 - 2,900

MT80A

0 - 43,500

Keyed

1.5 - 10 (1/16 - 3/8)

10 (3/8)

10 (3/8)

20 (13/16)

Yes

Double insulation

1.6 (3.4)

2.0 (6.6)

Yes

* with Side grip

Chuck key S10 (MT80A) ........................................ 1

Chuck key S13 (MT80B) ........................................ 1

Key holder 10 .......................................................... 1 (for some countries only)

Side grip .................................................................. 1

Plastic carrying case (MT80B) ............................... 1 (for “K model” only)

No load speed: min.

ˉ¹=rpm

Specification

T

ECHNICAL INFORMATION

W

L

H

P 2/ 12

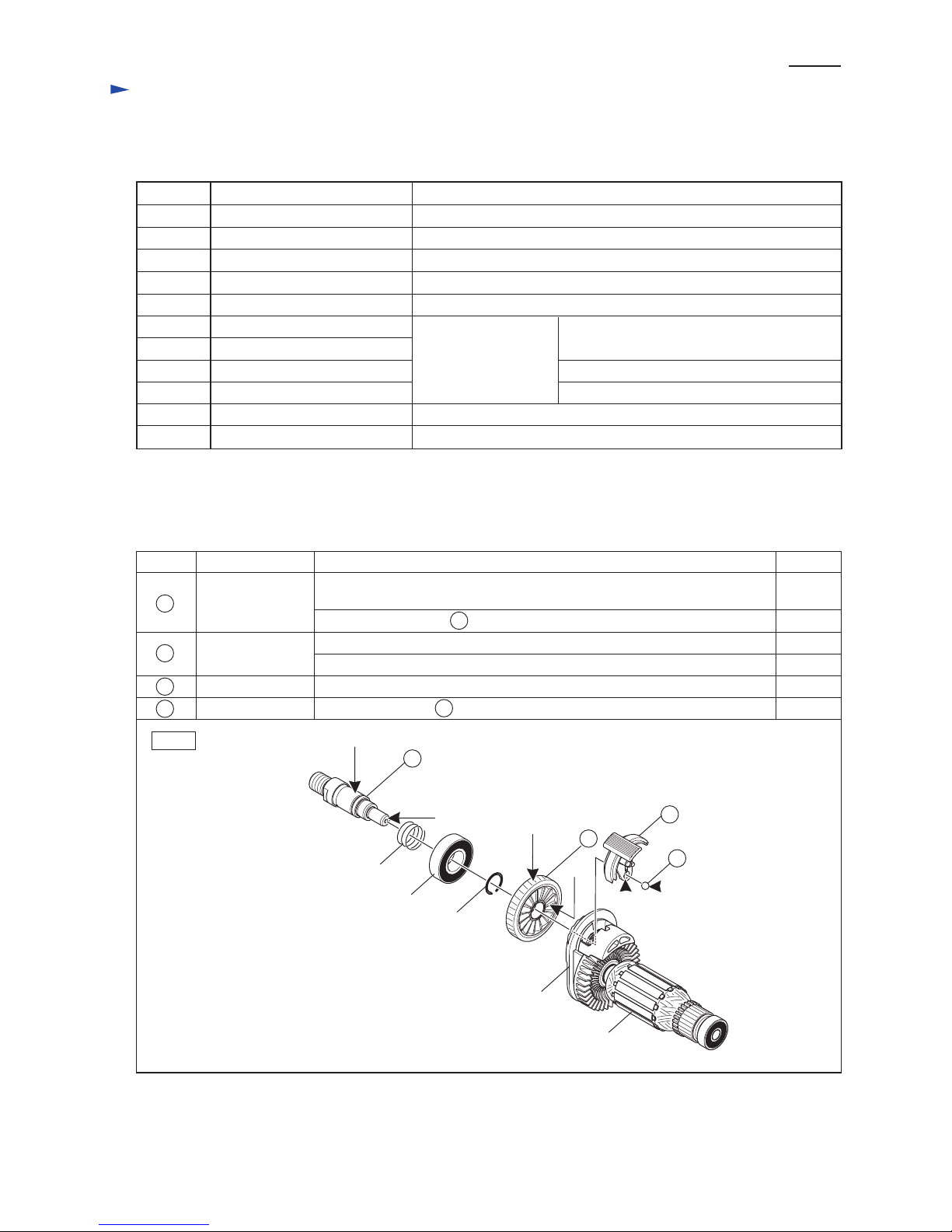

Repair

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No. Description Use for

1R004 Retaining ring pliers ST-2

Ratchet head 12.7 (for 1R223)

1/4” Hex. shank bit for M8

removing / mounting Ring spring 13

1R029

1R031

1R139

1R165

1R223

1R224

1R231

1R258

1R278

1R298

Bearing setting pipe 23-15.2 assembling Helical gear 39 to Spindle

Bearing setting pipe 28-20.2 assembling Cam complete to Cam holder

fixing Spindle when removing / mounting Drill chuck

holding Helical gear 39 when separating Spindle from Helical gear 39

holding Cam holder when disassembling/ assembling Cam complete

removing / assembling

Drill chucks

for both 10 mm and 13 mm Drill chucks

for 13 mm Drill chuck

for 10 mm Drill chuck

[2] LUBRICATION

Apply Makita grease N. No.2 to the following portions designated with the black triangle to protect parts and product

from unusual abrasion.

Fig. 1

Item No. Description

Spindle

a little

a little

3.0g

1.7g

a little

a little

a: Drum portion for smooth hammering in the inner ring

of Ball bearing 6002LLB

b: Spindle end where 10 Steel ball 5 contacts

Steel ball 5

Change lever

accepting hole for 10 Steel ball 5

Helical gear 39

c: Teeth portion for smooth engaging with Armature’s gear

d: Cam portion for smooth engaging with Cam on Cam holder complete

Whole portion

AmountPortion to lubricate

5

b

c

d

a

5

9

9

10

10

Ball bearing 6002LLB

Compression spring 16

Ring spring 13

Armature

Cam holder

complete

12

12

Drill chuck extractor

Ring spring setting tool B

Torque wrench shaft 20-90N·m

Round bar for arbor 4-50

Hex bar 10 with square socket

V block

disassembling Cam complete from Cam holder

P 3/ 12

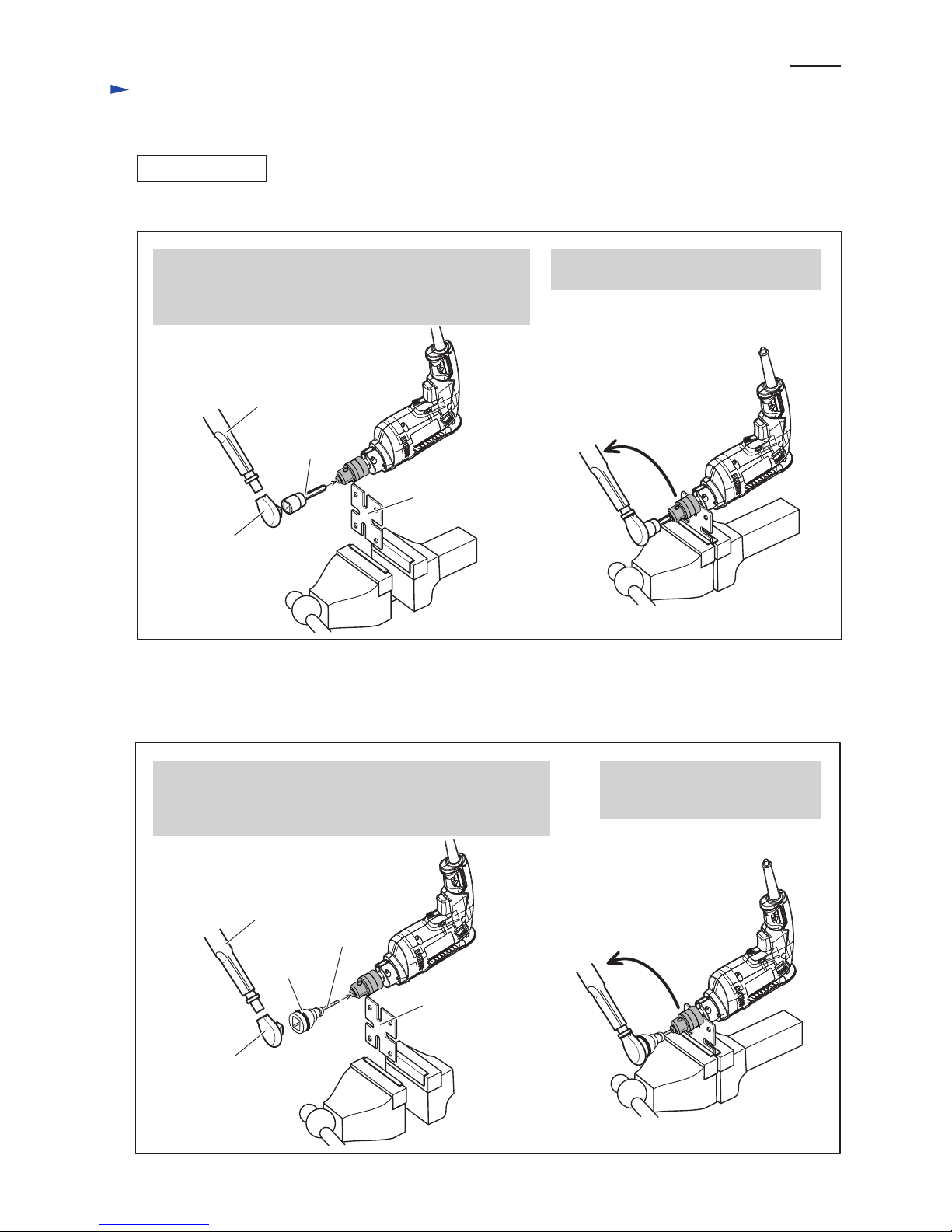

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1A. 13mm Drill Chuck of model MT80B

DISASSEMBLING

Remove 13mm Drill chuck as drawn in Fig. 2A.

Remove 10mm Drill chuck as drawn in Fig. 2B.

1. Fix 1R139 firmly with vise. Then attach 1R298 to

13mm Drill chuck, and then fix the machine to 1R139

by fitting the flat portion of Spindle to the groove of 1R139.

2. Attach 1R224 to 1R223 and set them to 1R298.

3. Turn 1R223 counter clockwise to remove

13mm Drill chuck from the machine.

1R139

1R298

1R224

1R223

Fig. 2A

Fig. 2B

[3] -1B. 10mm Drill Chuck of model MT80A

1R139

1R224

1R231

Bit adapter

1R223

1. Fix 1R139 firmly with vise. Then attach 1R231 and Bit adapter

to 10mm Drill chuck, and then fix the machine to 1R139

by fitting the flat portion of Spindle to the groove of 1R139.

2. Attach 1R224 to 1R223 and set them Bit adapter.

3. Turn 1R223 counter clockwise

to remove 10mm Drill chuck

from the machine.

P 4/ 12

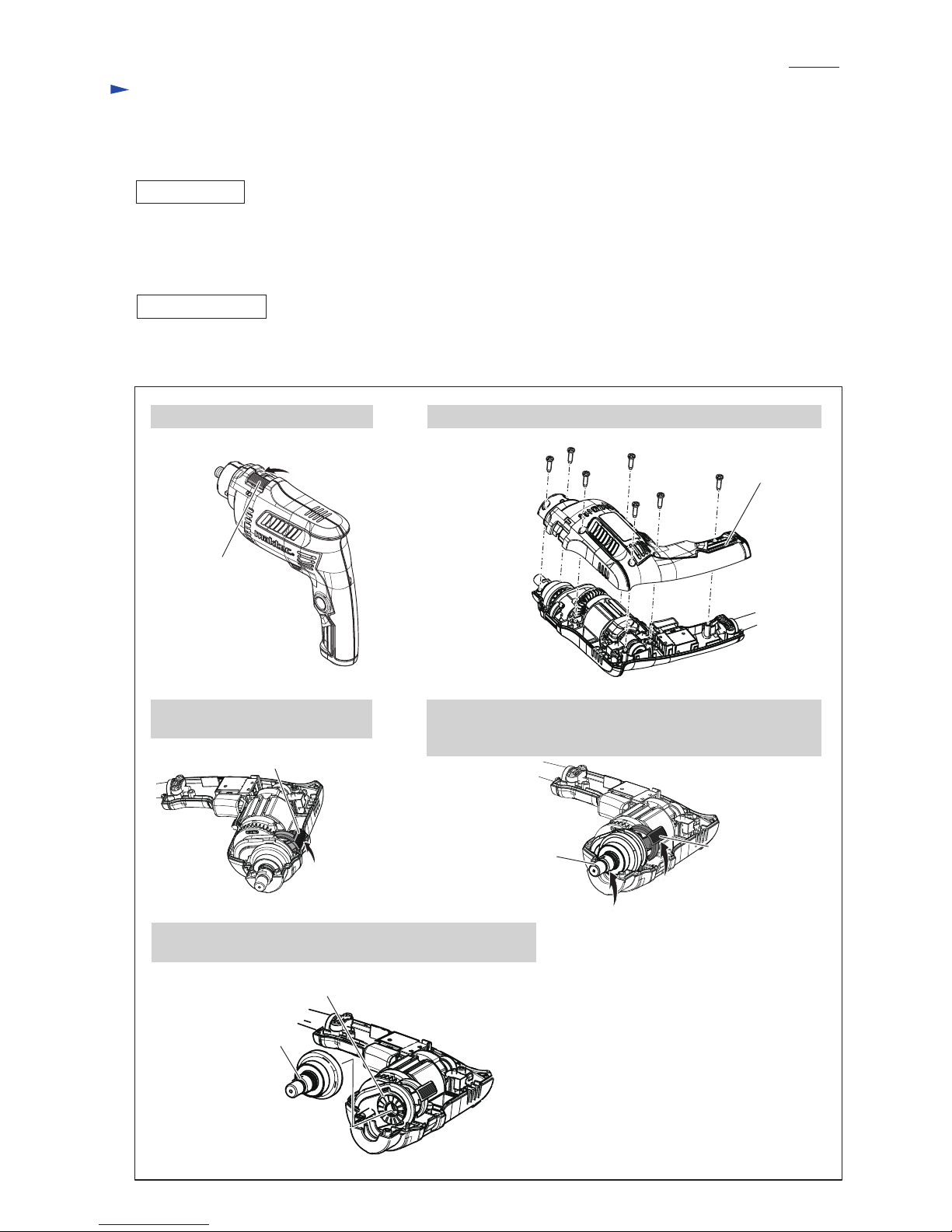

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1A. 13mm Drill Chuck of model MT80B (cont.)

-1B. 10mm Drill Chuck of model MT80A (cont.)

ASSEMBLING

[3] -2. Helical Gear 39, Ball Bearing 6002LLB

DISASSEMBLING

Assemble by reversing the disassembly procedure. Refer to Fig. 2A or Fig. 2B.

Note: Set the fastening torque of 1R223 to 24.5N·m ~ 29.4 N·m (250 Kg f·cm ~ 300 Kg f·cm) and turn 1R223 clockwise.

(1) Remove Drill chuck as drawn in Fig. 2A or Fig. 2B.

(2) Remove Spindle section from the machine as illustrated in Fig. 3.

Fig. 3

3. Shift Change lever to Hammer

drill mode

1. Shift Change lever to Drill mode. 2. Remove Housing (R) by loosening seven 4x18 Tapping screws.

4. Hold Spindle and Change lever by hand, then Lift up Spindle

and Change lever while turning them counter clockwise

viewing them from Drill chuck side.

5. Pull off the Spindle section (Spindle, Ball bearing 6002LLB,

Compression spring 16) from Cam holder complete.

Change lever

Cam holder complete

Housing (R)

4x18 Tapping screw

(7 pcs.)

Change lever

Spindle

Change

lever

Spindle section

Loading...

Loading...