Makita MLT100 User Manual

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Table Saw

Scie de table

Sierra de Banco

MLT100

009024

DOUBLE INSULATION

DOUBLE ISOLATION

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l'utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la

herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

DOBLE AISLAMIENTO

1

ENGLISH

SPECIFICATIONS

Model MLT100

Arbor hole 15.88 mm (5/8")

Blade diameter 255 mm (10")

Max. cutting capacities

Maximum dado capacity 9.5 mm (3/8")

No load speed (RPM) 4300/min

Table size (L x W)

Dimensions (L x W x H) with table not extended

Net weight 35 kg (77.2 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

• Note: Specifications may differ from country to country.

For Your Own Safety Read

Instruction Manual

Before Operating Tool

Save it for future reference

GENERAL SAFETY

PRECAUTIONS

(For All Tools)

1. KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the tool's applications

and limitations, as well as the specific

potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working

order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

4. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

5. DO NOT USE IN DANGEROUS ENVIRONMENT.

Do not use power tools in damp or wet

locations, or expose them to rain. Keep work

area well lighted. Do not use tool in presence

of flammable liquids or gases.

90° 90.5 mm (3-9/16")

45° 63 mm (2-1/2")

(685 mm - 835 mm) x (955 mm - 1,155 mm)

(27" - 32-7/8") x (37-1/2" - 45-1/2")

726 mm x 984 mm x 333 mm

28-1/2" x 38-3/4" x 13-1/8"

USA007-2

6. KEEP CHILDREN AWAY. All visitors should be

kept safe distance from work area.

7. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

8. DO NOT FORCE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE RIGHT TOOL. Do not force tool or

attachment to do a job for which it was not

designed.

10. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair.

11. ALWAYS USE SAFETY GLASSES. Also use

face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold

work when practical. It's safer than using your

hand and it frees both hands to operate tool.

13. DO NOT OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits,

cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off position

before plugging in.

2

17. USE RECOMMENDED ACCESSORIES.

Consult the owner's manual for recommended

accessories. The use of improper accessories

may cause risk of injury to persons.

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of

the blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing, use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of

electric shock, this appliance has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper

outlet. Do not change the plug in any way.

VOLTAGE WARNING: Before connecting the tool to

a power source (receptacle, outlet, etc.) be sure the

voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage

greater than that specified for the tool can result in

SERIOUS INJURY to the user- as well as damage to

the appliance. If in doubt, DO NOT PLUG IN THE

APPLIANCE. Using a power source with voltage less

than the nameplate rating is harmful to the motor.

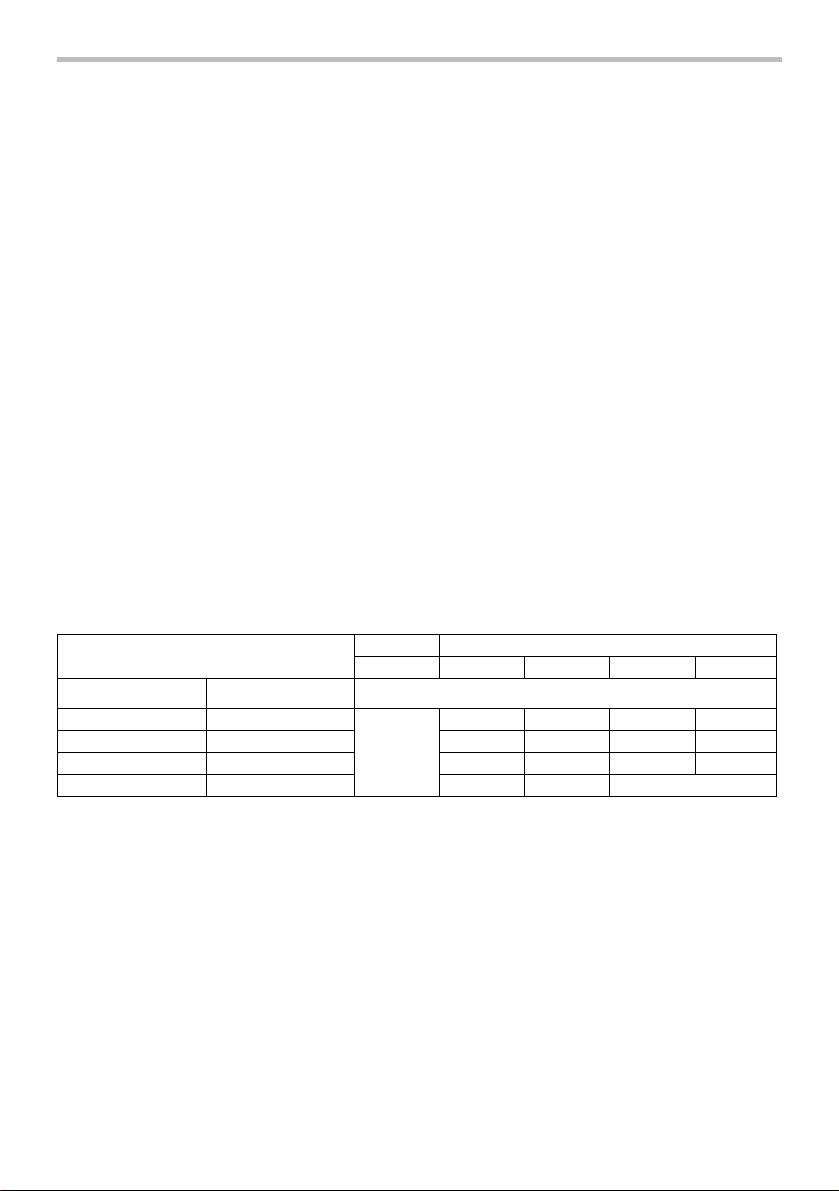

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the gage number,

the heavier the cord.

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

18 16 14 12610

10 12 16 16 14 12

000173

ADDITIONAL SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to table saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious

personal injury.

1. Wear eye protection.

2. Do not use the tool in presence of flammable

3. NEVER use the tool with an abrasive cut-off

12 16 14 12

USB059-1

liquids or gases.

wheel installed.

4. Check the blade carefully for cracks or

damage before operation. Replace cracked or

damaged blade immediately.

5. Clean the spindle, flanges (especially the

installing surface) and hex nut before

installing the blade. Poor installation may

cause vibration/wobbling or slippage of the

blade.

6. Use saw-blade guard and spreader for every

operation for which it can be used, including

all through sawing operations. Always

assemble and install the blade guard following

the step by step instructions out-lined in this

manual. Through sawing operations are those

in which the blade cuts completely through

3

Not Recommended

the workpiece as in ripping or cross cutting.

NEVER use the tool with a faulty blade guard

or secure the blade guard with a rope, string,

etc. Any irregular operation of the blade guard

should be corrected immediately.

7. Immediately reattach the guard and spreader

after completing an operation which requires

removal of the guard.

8. Do not cut metal objects such as nails and

screws. Inspect for and remove all nails,

screws and other foreign material from the

workpiece before operation.

9. Remove wrenches, cut-off pieces, etc. from

the table before the switch is turned on.

10. NEVER wear gloves during operation.

11. Keep hands out of the line of the saw blade.

12. NEVER stand or permit anyone else to stand in

line with the path of the saw blade.

13. Make sure the blade is not contacting the

spreader or workpiece before the switch is

turned on.

14. Before cutting an actual workpiece, let the tool

run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced blade.

15. NEVER make any adjustments while tool is

running. Disconnect tool before making any

adjustments.

16. Use a push stick when required. Push sticks

MUST be used for ripping narrow workpieces

to keep your hands and fingers well away from

the blade.

17. Pay particular attention to instructions for

reducing risk of KICKBACK. KICKBACK is a

sudden reaction to a pinched, bound or

misaligned saw blade. KICKBACK causes the

ejection of the workpiece from the tool back

towards the operator. KICKBACKS CAN LEAD

TO SERIOUS PERSONAL INJURY. Avoid

KICKBACKS by keeping the blade sharp, by

keeping the rip fence parallel to the blade, by

keeping the spreader, antikickback pawls and

blade guard in place and operating properly,

by not releasing the workpiece until you have

pushed it all the way past the blade, and by

not ripping a workpiece that is twisted or

warped or does not have a straight edge to

guide along the fence.

18. Do not perform any operation freehand.

Freehand means using your hands to support

or guide the workpiece, in lieu of a rip fence or

miter gauge.

19. NEVER reach around or over saw blade.

NEVER reach for a workpiece until the saw

blade has completely stopped.

20. Avoid abrupt, fast feeding. Feed as slowly as

possible when cutting hard workpieces. Do

not bend or twist workpiece while feeding. If

you stall or jam the blade in the workpiece,

turn the tool off immediately. Unplug the tool.

Then clear the jam.

21. NEVER remove cut-off pieces near the blade

or touch the blade guard while the blade is

running.

22. Knock out any loose knots from workpiece

BEFORE beginning to cut.

23. Do not abuse cord. Never yank cord to

disconnect it from the receptacle. Keep cord

away from heat, oil, water and sharp edges.

24. Some material contains chemicals which may

be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material

supplier safety data.

25. The guard can be lifted during workpiece

setup and for ease of cleaning. Always make

sure that guard hood is down and flat against

sawtable before plugging in the tool.

SAVE THESE INSTRUCTIONS.

WARNING:

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

INSTALLATION

Positioning table saw

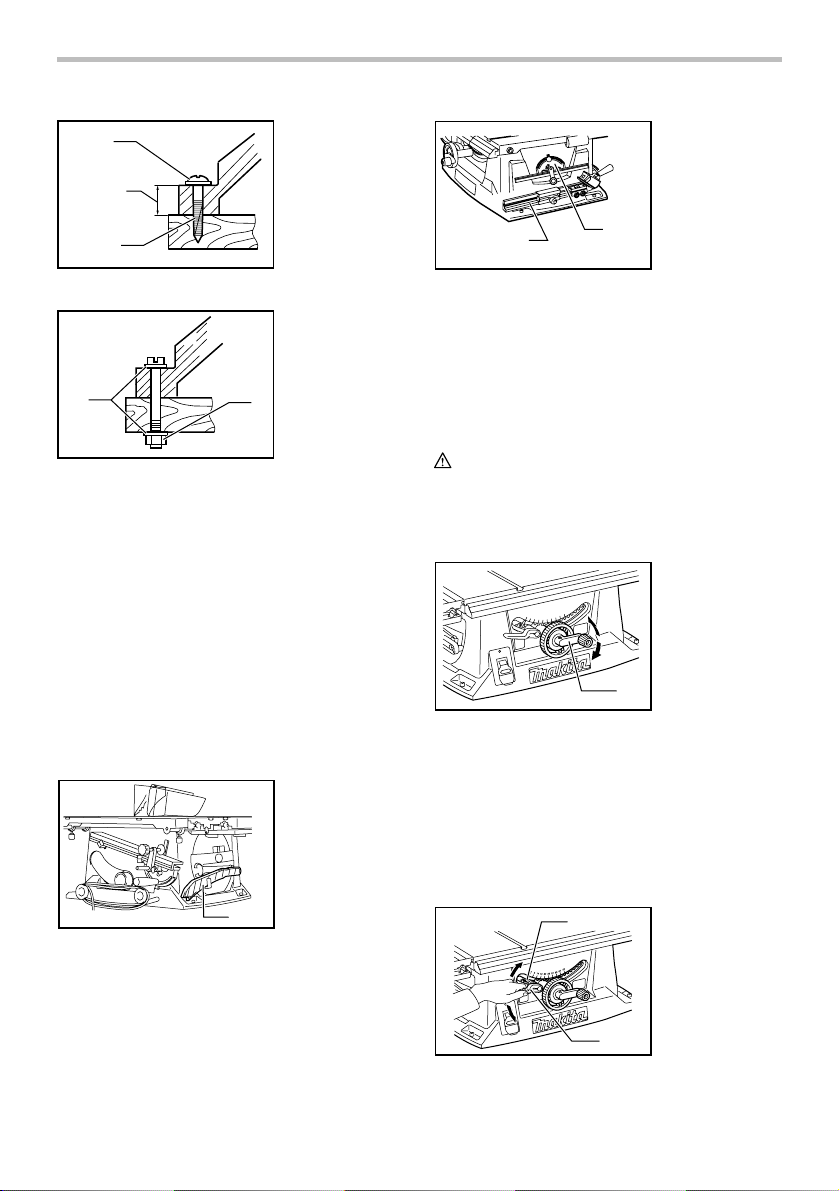

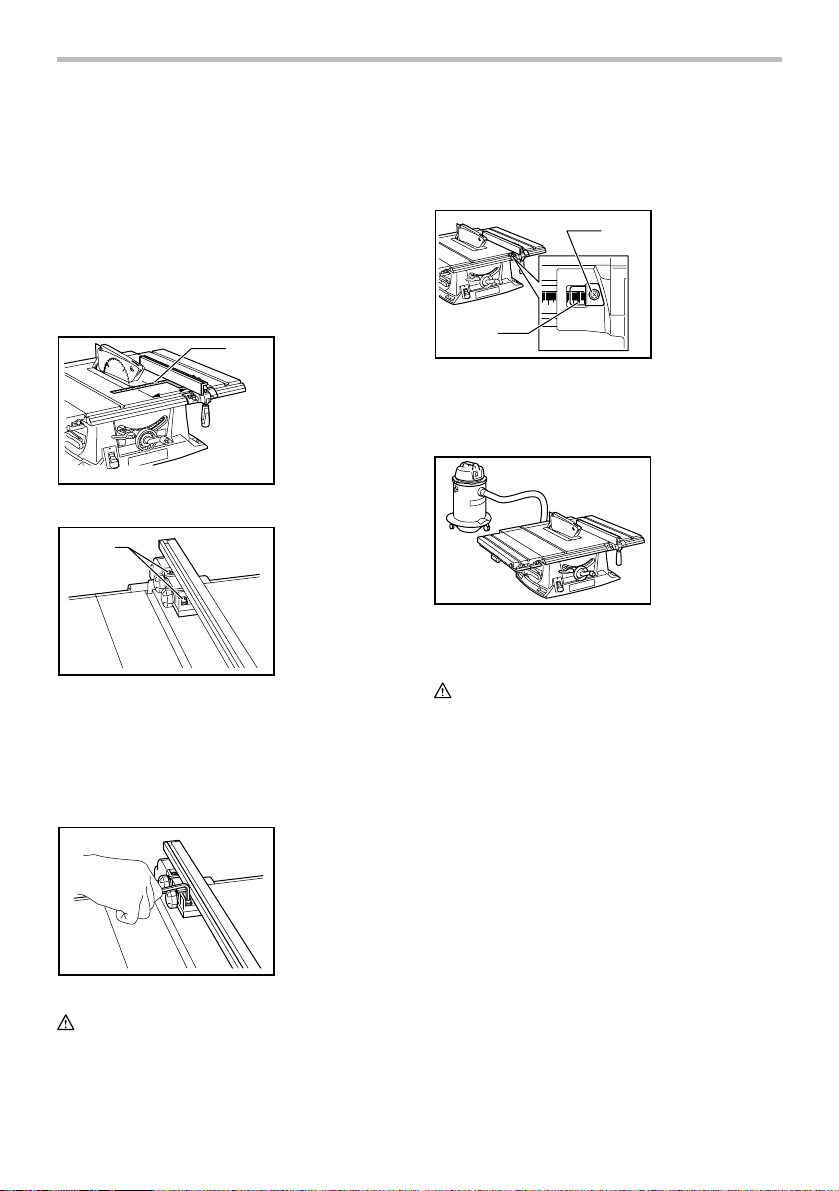

1. Hole diameter 8

mm (5/16")

588 mm

(23-1/8")

1

(13-3/8")

340 mm

008792

4

1. 6 mm (1/4") Std.

washer

2. No.10 wood

screw 40 mm

(1-1/2") min.

length

17 mm

008793

1

(11/16")

2

1. 6 mm (1/4") Std.

washer

2. 6 mm (1/4")

Mounting bolt &

1

008794

Nut tighten

securely

2

Locate the table saw in a well lit and level area where

you can maintain good footing and balance. It should be

installed in an area that leaves enough room to easily

handle the size of your workpieces. The table saw

should be secured with four screws or bolts to the work

bench or table saw stand using the holes provided in the

bottom of the table saw. When securing the table saw on

the work bench, make sure that there is an opening in

the top of the work bench the same size as the opening

in the bottom of the table saw so the sawdust can drop

through.

If during operation there is any tendency for the table

saw to tip over, slide or move, the work bench or table

saw stand should be secured to the floor.

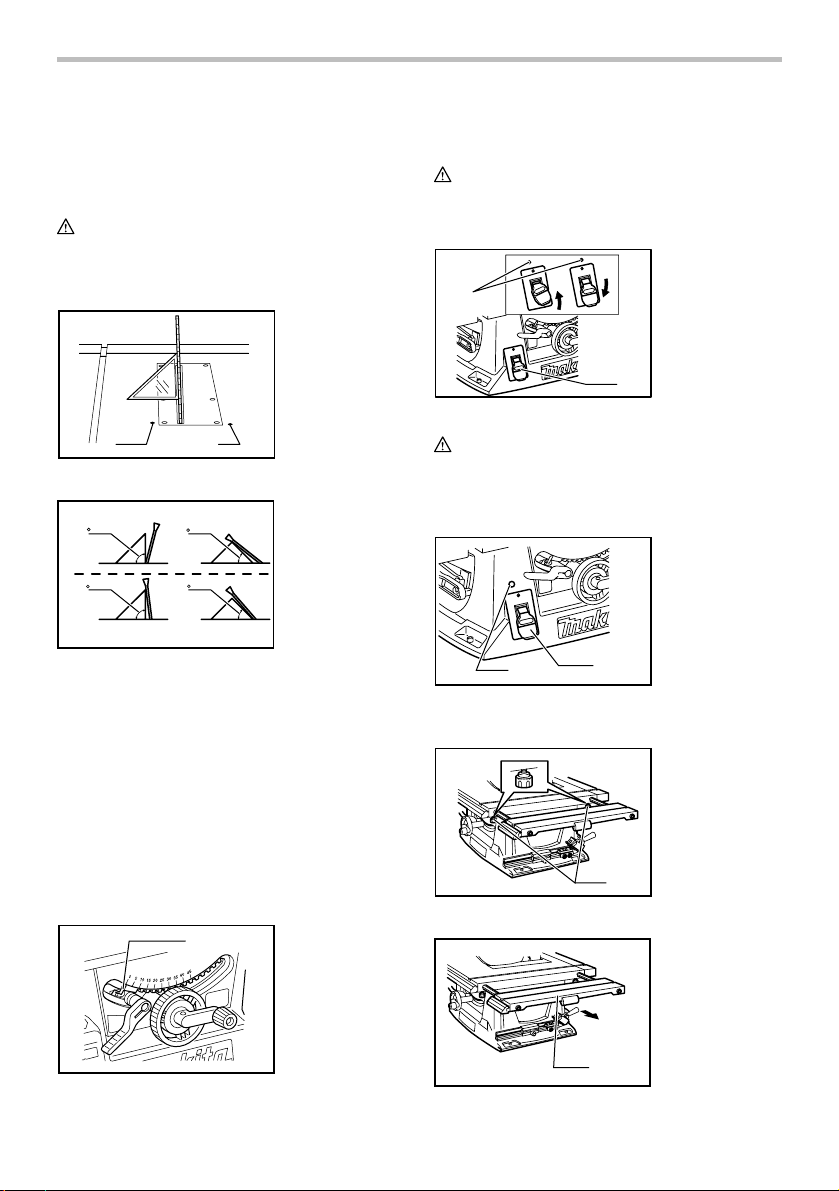

Storing accessories

1. Push stick

1

009025

1. Rip fence

(Guide rule)

2. Miter gauge

1

008759

2

Push stick, Triangular rule, blade and wrenches can be

stored on the left side of the base and the rip fence and

miter gauge can be stored at the right side of the base.

The blade guard to be removed in dado cutting can be

stored at the rear.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

Adjusting the depth of cut

1. Handle

1

009026

The depth of cut may be adjusted by turning the handle.

Turn the handle clockwise to raise the blade or

counterclockwise to lower it.

NOTE:

• Use a shallow depth setting when cutting thin

materials in order to obtain a cleaner cut.

Adjusting the bevel angle

1

1. Arrow pointer

2. Lock lever

5

009027

2

Loosen the lock lever counterclockwise and turn the

handwheel until the desired angle (0° - 45°) is obtained.

The bevel angle is indicated by the arrow pointer.

After obtaining the desired angle, tighten the lock lever

clockwise to secure the adjustment.

CAUTION:

• After adjusting the bevel angle, be sure to tighten

the lock lever securely.

Adjusting positive stops

1. 90 ゚ adjusting

screw

2. 45 ゚ adjusting

screw

12

008762

(A)

90

90

45

45

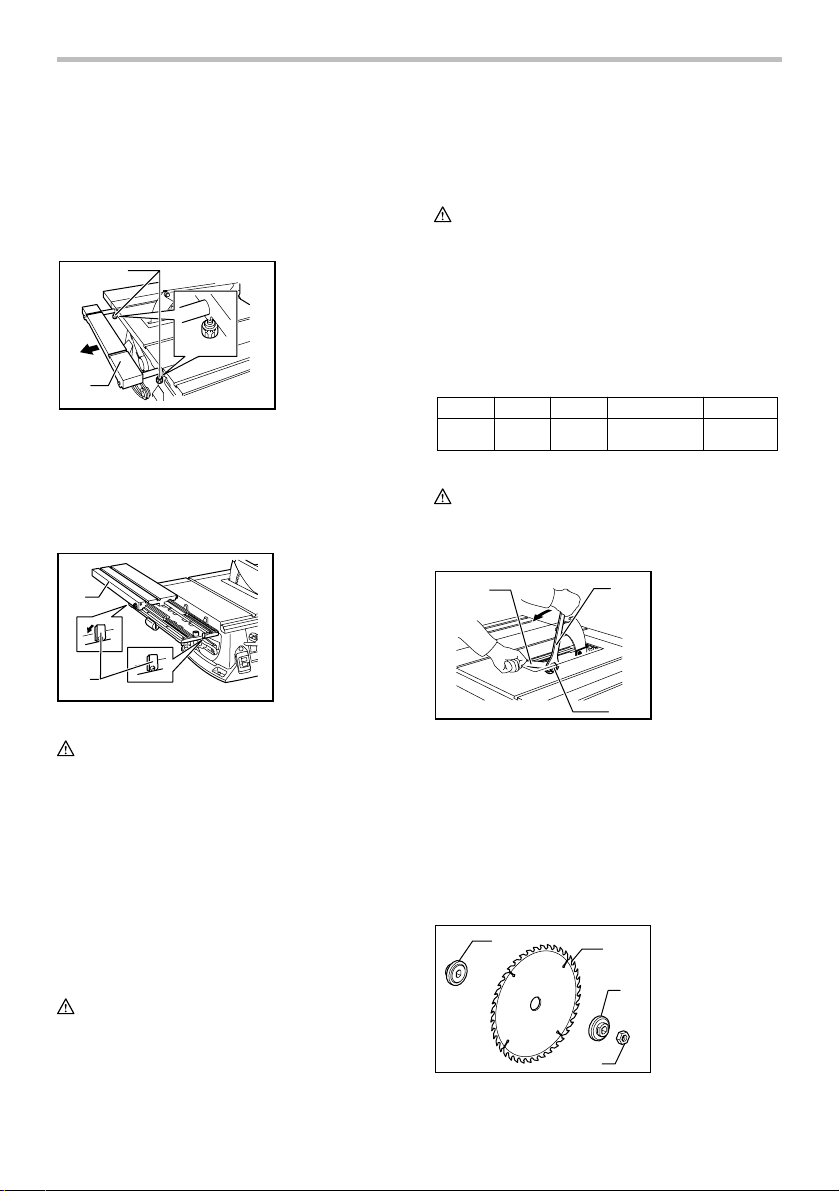

Switch action

CAUTION:

• Remove workpiece from the table.

• Switch off the tool and then press in the restart

button.

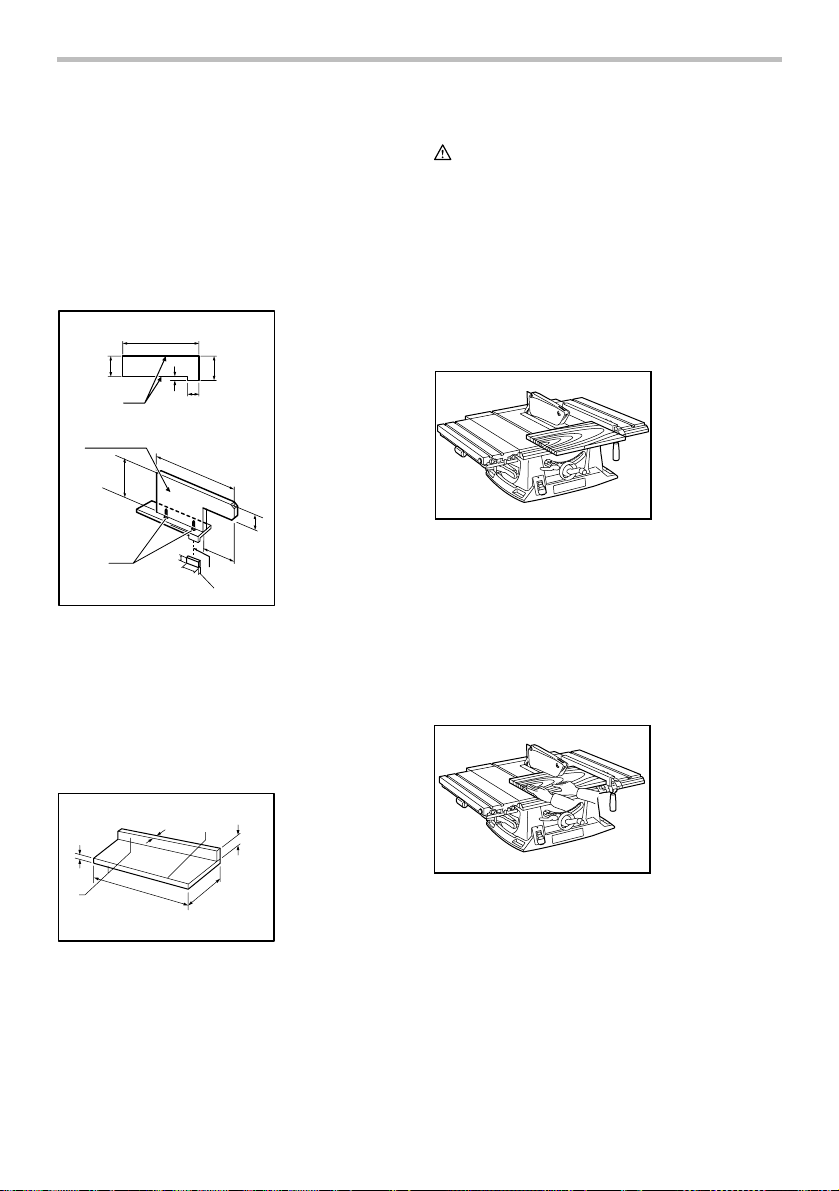

1. Switch

2. Restart button

1

009028

2

ON

OFF

CAUTION:

• Before plugging in the tool, always be sure that the

tool is switched off.

To start the tool, raise the switch lever. To stop it, lower

the switch lever.

1. Switch

2. Restart button

(B)

006157

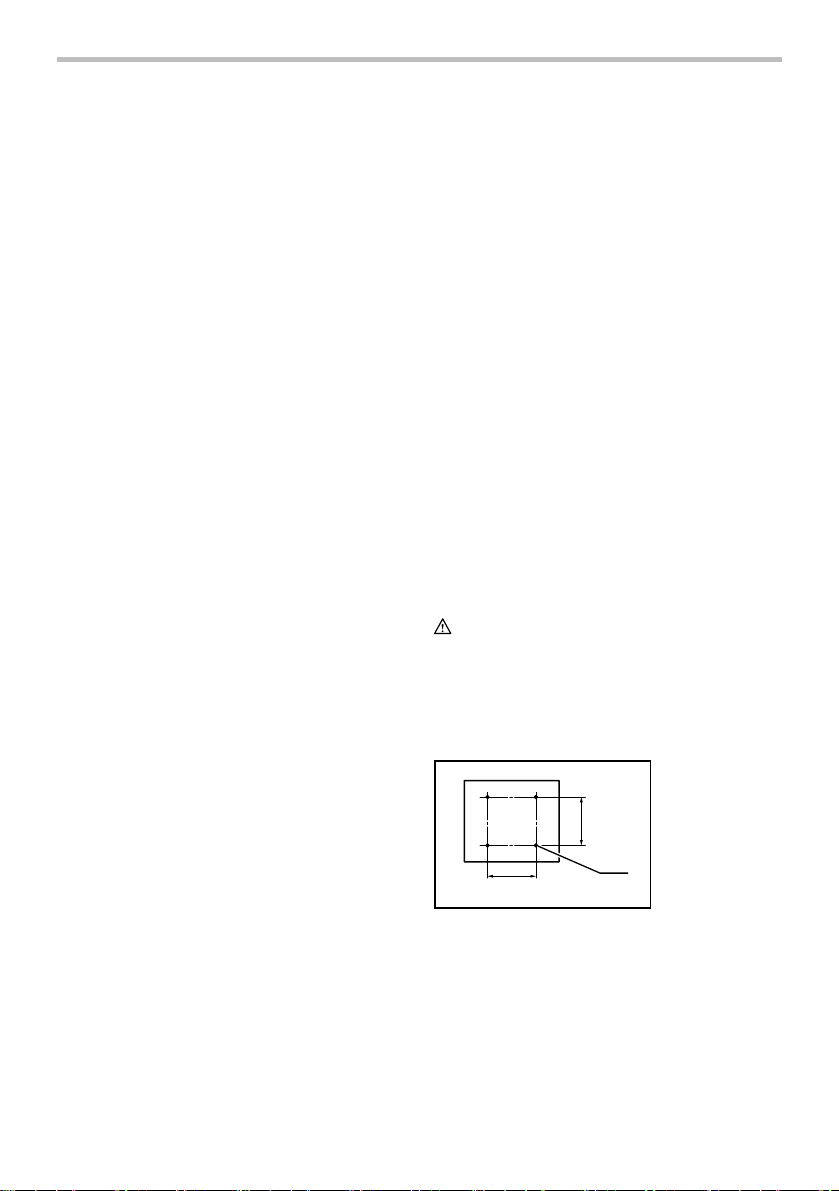

The tool is equipped with positive stops at 90° and 45° to

the table surface. To check and adjust the positive stops,

proceed as follows:

Move the handwheel as far as possible by turning it.

Place a triangular rule on the table and check to see if

the blade is at 90° or 45° to the table surface. If the blade

is at an angle shown in Fig. A, turn the adjusting screws

clockwise; if it is at an angle shown in Fig. B, turn the

adjusting screws counterclockwise to adjust the positive

stops.

After adjusting the positive stops, set the blade at 90° to

the table surface. Then adjust the arrow pointer so that

its right edge is aligned to the 0° graduation.

1

008763

1. Arrow pointer

009046

Sub table (R)

008765

008766

6

2

1

1. Screws

1

1. Sub table (R)

1

This tool is provided with the sub table (R) on the right

side of the main table. To use the sub table (R), loosen

two screws on the right side counterclockwise, pull out

the table (R) fully and then tighten the two screws to

secure it.

Sub table (back)

1

2

008768

To use the sub table (back), loosen the screws on the left

and right hand sides under the table and pull it out

backwards to the desired length. At the desired length,

tighten the screw securely.

1. Screws

2. Sub table (back)

Slide table

1. Slide table

2. Locking plate

1

2

008767

CAUTION:

• After using slide table, be sure to lock it by moving

the locking plate to the vertical position.

This tool is provided with the slide table on the left side.

The slide table slides back and forth. Pivot the locking

plates on the back and front sides to the horizontal

position before using it.

Hold workpiece firmly with the miter gauge using a

clamp on the miter gauge and slide the workpiece

together with the slide table at the time of cutting

operation.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

The tool is shipped from the factory with the saw blade

and blade guard not in the installed condition. Assemble

as follows:

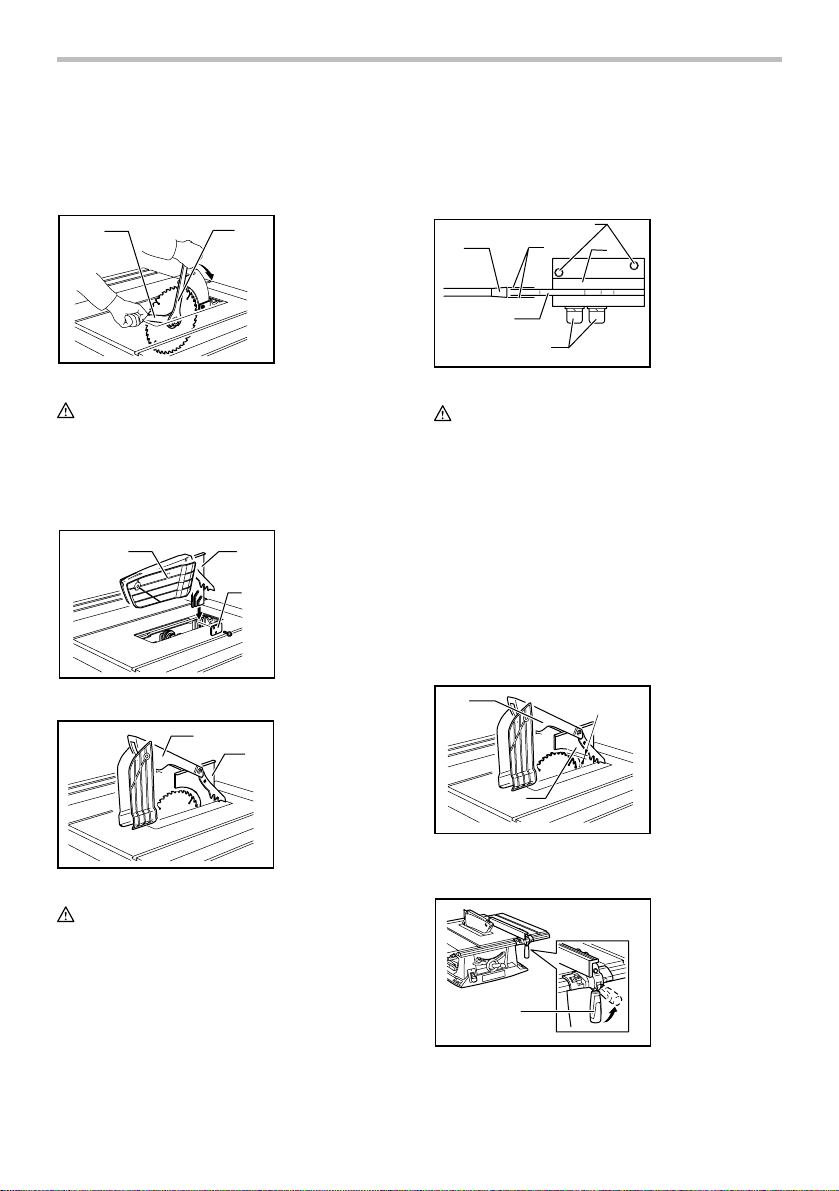

Installing or removing saw blade

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

• Use only the Makita socket wrench provided to

install or remove the blade. Failure to do so may

result in overtightening or insufficient tightening of

the hex bolt. This could cause an injury.

• Use the following saw blade. Do not use saw

blades which do not comply with the

characteristics specified in these instructions.

For Model

Max. dia. Min. dia. Blade thickness Kerf

260 mm

230 mm

MLT100

009110

(10")

(9-3/32")

1.8 mm (5/64")

or less

2 mm (3/32")

or more

CAUTION:

• Check the arbor hole diameter of the blade before

installing the blade. Always use the correct ring for

the arbor hole of the blade you intend to use.

12

008769

1. Wrench

2. Wrench

3. Hex nut

3

Remove the table insert on the table. Hold the outer

flange with the wrench and loosen the hex nut

counterclockwise with the wrench. Then remove the

outer flange.

Assemble the inner flange, saw blade, outer flange and

hex nut onto the arbor, making sure that the teeth of the

blade are pointing down at the front of the table. Always

install the hex nut with its recessed side facing the outer

flange.

1

4

009047

1. Inner flange

2

2. Saw blade

3. Outer flange

4. Hex nut

3

7

(B)

To secure the blade in place, hold the outer flange with

the offset wrench, then tighten the hex nut clockwise

with the wrench. BE SURE TO TIGHTEN THE HEX NUT

SECURELY.

1. Wrench

1

008771

2

2. Wrench

CAUTION:

• Be sure to hold the hex nut carefully with the

wrench. If your grip should slip, the wrench may

come off the hex nut, and your hand could strike

the sharp blade edges.

Installing blade guard

1. Blade guard

1

009029

2

2. Riving knife

3. Blade guard

mounting

3

portion (stay)

1

1. Blade guard

2. Riving knife

2

However, if they are not in a straight line, loosen the hex

bolts (B) and adjust the blade guard mounting portion

(stay) so that the riving knife is aligned directly behind

the blade. Then tighten the hex bolts (B) to secure the

stay.

1. Blade

2. These two

3

clearances

should be equal.

3. Blade guard

mounting portion

(stay)

4. Riving knife

5. Hex bolts (A)

6. Hex bolts

1

008776

6

2

4

5

CAUTION:

• If the blade and riving knife are not aligned properly,

a dangerous pinching condition may result during

operation. Make sure they are properly aligned.

You could suffer serious personal injury while using

the tool without a properly aligned riving knife.

• NEVER make any adjustments while tool is

running. Disconnect the tool before making any

adjustments.

There must be a clearance of about 4 - 5 mm

(5/32"-3/16") between the riving knife and the blade

teeth. Adjust the riving knife accordingly and tighten the

hex bolts (A) securely. Attach the table insert on the

table, then check to see that the blade guard works

smoothly before cutting.

1

4 mm-5 mm

(5/32"-3/16")

1. Blade guard

2. Riving knife

009030

CAUTION:

• Before installing the blade guard, adjust the depth

of cut to its maximum elevation.

Remove the center cover. Insert the riving knife into the

blade guard mounting portion (stay). Tighten the hex

bolts (A) with the provided wrench.

For both European and non-European type blade

guards

The riving knife installing location is factory-adjusted so

that the blade and riving knife will be in a straight line.

2

009033

Installing and adjusting rip fence

1. Lever

1

009034

Install the rip fence so that the fence holder engages

8

with the nearmost guide rail.

To secure the rip fence, pivot fully the lever on the fence

holder.

To check to be sure that the rip fence is parallel with the

blade, secure the rip fence 2 - 3 mm (5/64"-1/8") from

the blade. Raise the blade up to maximum elevation.

Mark one of the blade teeth with a crayon. Measure the

distance (A) and (B) between the rip fence and blade.

Take both measurements using the tooth marked with

the crayon. These two measurements should be

identical. If the rip fence is not parallel with the blade,

proceed as follows:

1. Scale

1

Bring the rip fence up flush against the side of the blade.

Make sure that the guideline on the fence holder points

to the 0 graduation. If the guideline does not point to the

0 graduation, loosen the screw on the scale plate and

adjust the scale plate.

1. Guideline

2

2. Screw

1

009036

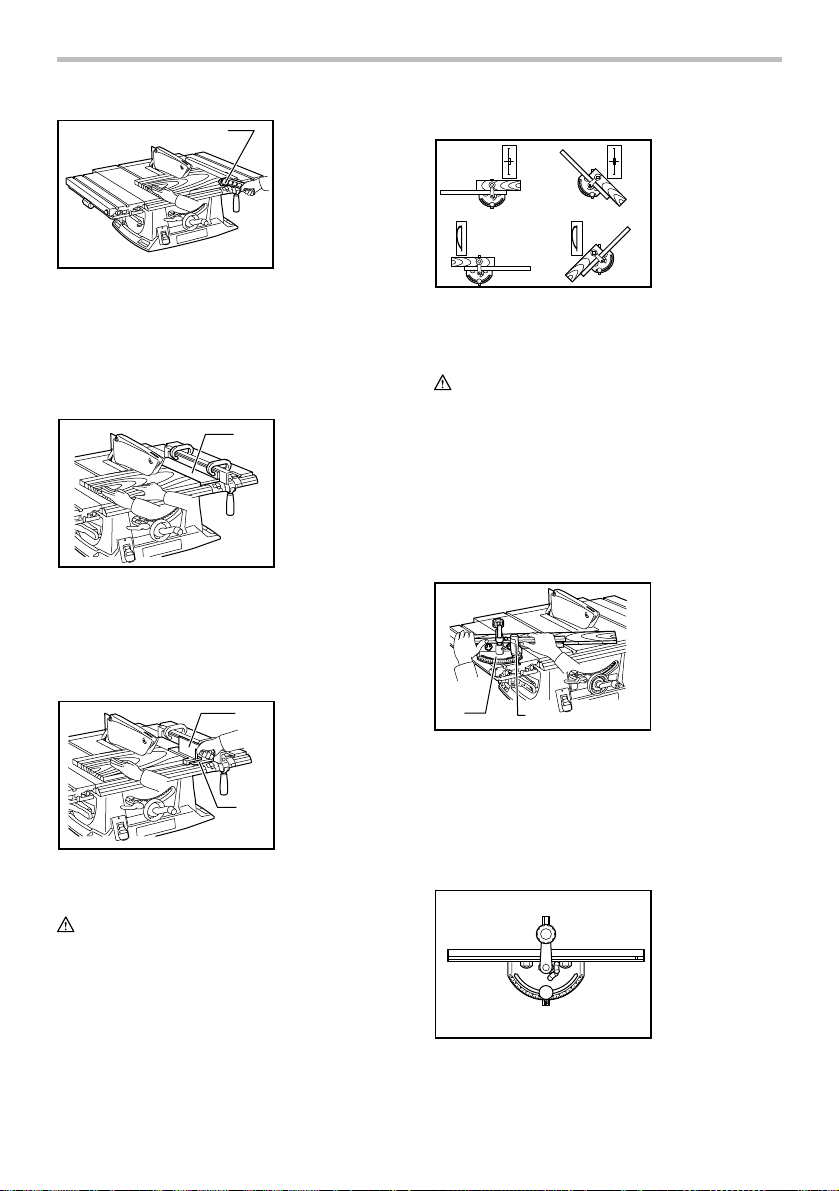

Connecting to vacuum cleaner

Cleaner operations can be performed by connecting the

tool to Makita vacuum cleaner or dust collector.

009035

1

008780

1. Hex bolts

1. Secure the rip fence by lowering the lever on it.

2. Loosen the two hex bolts on the rip fence with the

hex wrench provided.

3. Adjust the rip fence until it becomes parallel with

the blade.

4. Tighten the two hex bolts on the rip fence.

008781

CAUTION:

• Be sure to adjust the rip fence so that it is parallel

with the blade, or a dangerous kickback condition

may occur.

009037

OPERATION

CAUTION:

• Always use "work helpers" such as push sticks and

push blocks when there is a danger that your

hands or fingers will come close to the blade.

• Always hold the workpiece firmly with the table and

the rip fence or miter gauge. Do not bend or twist it

while feeding. If the workpiece is bent or twisted,

dangerous kickbacks may occur.

• NEVER withdraw the workpiece while the blade is

running. If you must withdraw the workpiece before

completing a cut, first switch the tool off while

holding the workpiece firmly. Wait until the blade

has come to a complete stop before withdrawing

the workpiece. Failure to do so may cause

dangerous kickbacks.

• NEVER remove cut-off material while the blade is

running.

• NEVER place your hands or fingers in the path of

the saw blade. Be especially careful with bevel

cuts.

• Always secure the rip fence firmly, or dangerous

kickbacks may occur.

9

• Always use "work helpers" such as push sticks and

push blocks when cutting small or narrow

workpieces, or when the dado head is hidden from

view while cutting.

Work helpers

Push sticks, push blocks or auxiliary fence are types of

"work helpers". Use them to make safe, sure cuts

without the need for the operator to contact the blade

with any part of the body.

Push block

1. Face/edge

parallel

2. Handle

3. Wood screw

4. Glue together

120mm

(4-3/4")

1

300mm(12")

6mm

(1/4")

130mm(5")

50mm(2")

Ripping

CAUTION:

• When ripping, remove the miter gauge from the

table.

• When cutting long or large workpieces, always

provide adequate support behind the table. DO

NOT allow a long board to move or shift on the

table. This will cause the blade to bind and

increase the possibility of kickback and personal

injury. The support should be at the same height as

the table.

1. Adjust the depth of cut a bit higher than the

thickness of the workpiece.

2

006219

130mm

(5")

3

300mm(12")

9.5mm

(3/8")

50mm

(2") 8mm(5/16")

50mm

(2")

100mm

4

(4")

Use a 19 mm (3/4")piece of plywood.

Handle should be in center of plywood piece. Fasten

with glue and wood screws as shown. Small piece 9.5

mm (3/8")x 8 mm (5/16") x 50 mm (2") of wood must

always be glued to plywood to keep the blade from

dulling if the operator cuts into push block by mistake.

(Never use nails in push block.)

Auxiliary fence

9.5mm

(3/8")

1

006211

19mm

(3/4")

460mm

(18")

120mm

(4-3/4")

140mm

(5-1/2")

1. Face/edge

parallel

40mm

(1-1/2")

Make auxiliary fence from 9.5 mm (3/8") and 19 mm

(3/4") plywood pieces.

009038

2. Position the rip fence to the desired width of rip

and lock in place by pivoting the grip.

3. Turn the tool on and gently feed the workpiece

into the blade along with the rip fence.

(1) When the width of rip is 150 mm (5-15/16")

and wider, carefully use your right hand to

feed the workpiece. Use your left hand to

hold the workpiece in position against the rip

fence.

009039

(2) When the width of rip is 65 mm - 150 mm

wide, use the push stick to feed the

workpiece.

10

1

009040

1. Push block

(3) When the width of rip is narrower than 65 mm,

the push stick cannot be used because the

push stick will strike the blade guard. Use the

auxiliary fence and push block. Attach the

auxiliary fence to the rip fence with two "C"

clamps.

1. Auxiliary fence

1

009041

Feed the workpiece by hand until the end is

about 25 mm from the front edge of the table.

Continue to feed using the push block on the

top of the auxiliary fence until the cut is

complete.

1. Push block

1

2. Auxiliary fence

2

009042

Cross cutting

CAUTION:

• When making a crosscut, remove the rip fence

from the table.

• When cutting long or large workpieces, always

provide adequate support to the sides of the table.

The support should be at the same height as the

table.

• Always keep hands away from path of blade.

Miter gauge

1. Cross cutting

2. Mitering

3. Bevel cutting

4. Compound

mitering

(angles)

008788

1

3

2

4

Use the miter gauge for the 4 types of cutting shown in

the figure.

CAUTION:

• Secure the knob on the miter gauge carefully.

• Avoid creep of workpiece and gauge by firm

workholding arrangement, especially when cutting

at an angle.

• NEVER hold or grasp the intended "cut-off" portion

of the workpiece.

• Always adjust the distance between the end of the

miter gauge and the saw blade not to exceed 15

mm (19/32").

Use of miter gauge

1. Miter gauge

2. Knob

1

009043

2

Slide the miter gauge into the thick grooves in the table.

Loosen the knob on the gauge and align to desired

angle (0° to 60°). Bring stock flush up against fence and

slide table, secure it with the clamp on the miter gauge

and feed gently forward into the blade.

Auxiliary wood facing (miter gauge)

008790

11

To prevent a long board from wobbling, fit the miter

gauge with an auxiliary fence board. Fasten with

bolts/nuts after drilling holes, but fasteners must not

protrude from the face board.

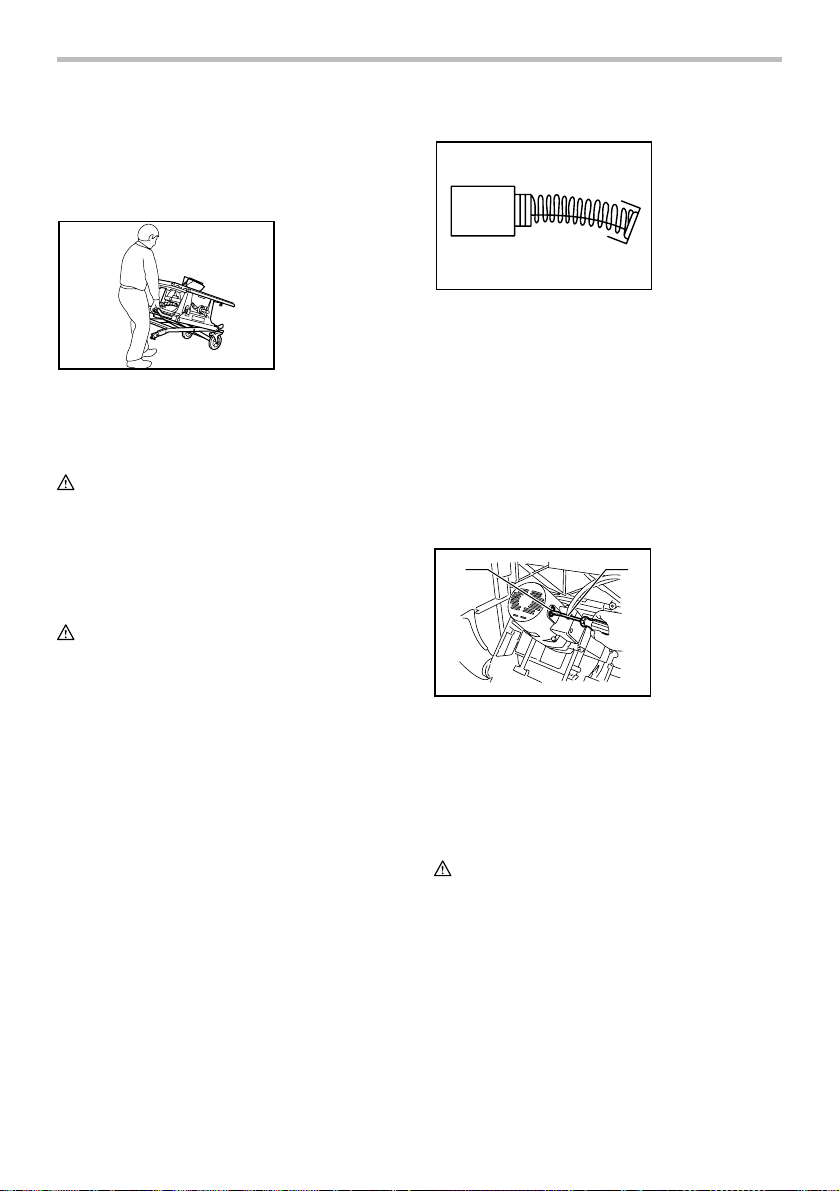

Carrying tool

Replacing carbon brushes

009044

Make sure that the tool is unplugged.

Carry the tool by holding the tool part shown in the

figure.

CAUTION:

• Always secure all moving portions before carrying

the tool.

• Always make sure that the blade guard is installed

in place before the carrying the tool.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

Cleaning

Clean out sawdust and chips from time to time. Carefully

clean the blade guard and moving parts inside the table

saw.

Lubrication

To keep the table saw in tip-top running condition, and to

assure maximum service life, oil or grease the moving

parts and rotating parts from time to time.

Lubrication places:

• Threaded shaft to elevate the blade

• Hinge to rotate the frame

• Elevation guide shafts on motor

• Gear to elevate the blade

007834

Remove and check the carbon brushes regularly.

Replace when they wear down to 3 mm (1/8") in length.

Keep the carbon brushes clean and free to slip in the

holders. Both carbon brushes should be replaced at the

same time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. To

replace the carbon brushes, remove the blade guard

and blade and then loosen the lock lever, tilt the saw

head and secure it at 45° bevel angle. Carefully lay the

tool on itself backward. Then loosen the brush holder

cap. Remove the worn carbon brushes, insert the new

ones and secure the brush holder caps.

1. Brush holder

1

006173

2

cap

2. Screwdriver

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Rip fence

• Miter gauge

• Wrench 24

• Hex wrench 5

12

Loading...

Loading...