Makita Maktec MT961, Maktec MT962, Maktec MT963 Technical Information

T

ECHNICAL INFORMATION

PRODUCT

P 1/ 10

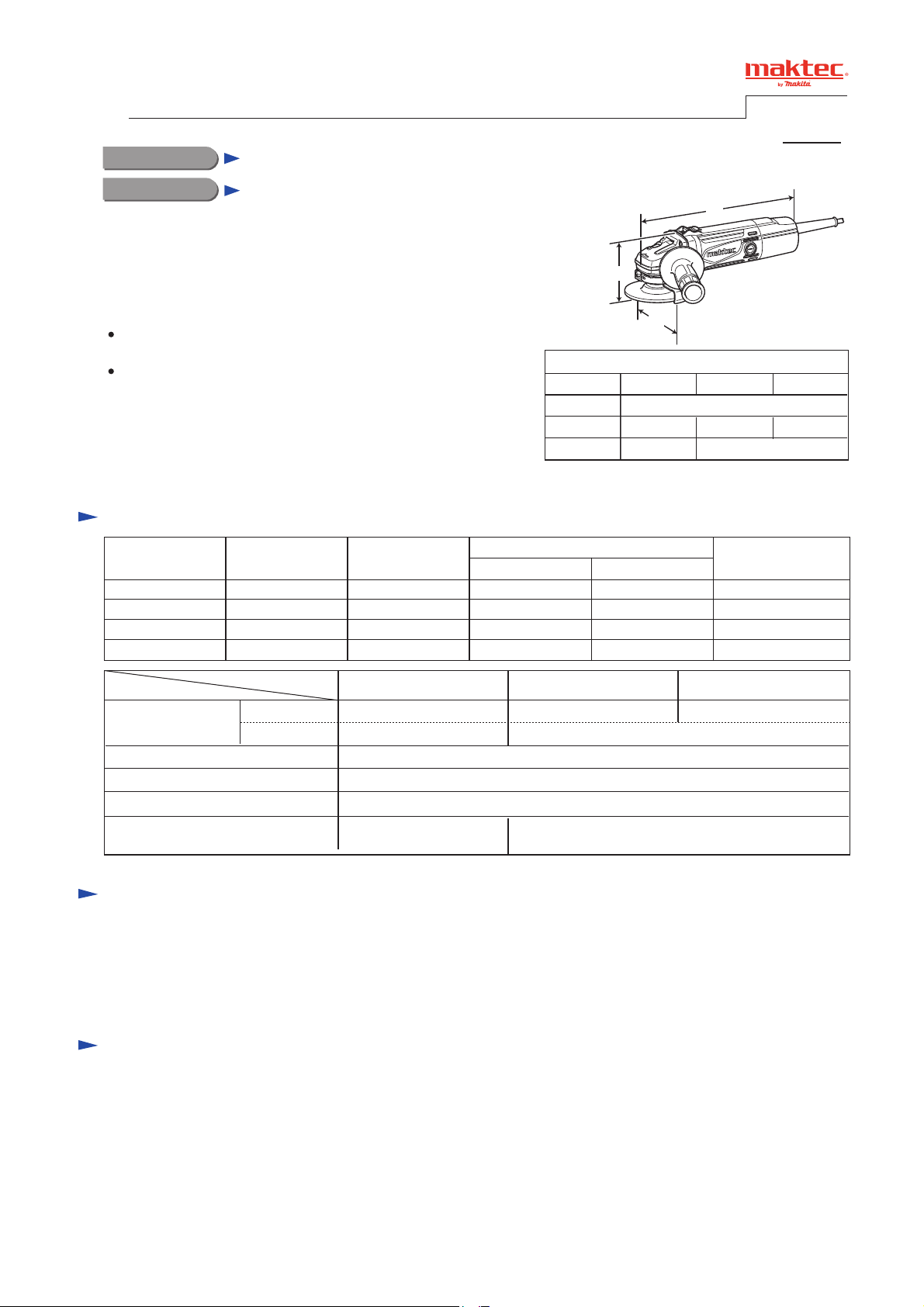

Model No.

Description

MT961, MT962, MT963

Angle Grinders 100mm (4"), 115mm (4-1/2"), 125mm (5")

CONCEPT AND MAIN APPLICATIONS

These new angle grinders have been developed as the aesthetic

change models of the predecessors MT951/ MT952/ MT953.

Their main features are:

New slide switch (two action safety switch) and wheel cover

in compliance with the requirements of the new regulations

Industrial performance and durability at less expense

Specification

Voltage (V) Cycle (Hz)

110

120

220

230-240

Current (A)

5.5

5.0

2.7

2.5

50/60

50/60

50/60

50/60

H

W

Dimensions: mm (")

Model No.

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

570

---

570

570

MT961

118 (4-5/8)

96 (3-3/4)

320

320

350

350

L

MT962 MT963

270 (10-5/8)

129 (5-1/8)

Max. Output (W)

139 (5-1/2)

105 (4-1/8)

550

550

650

650

Specification

Wheel size: mm (")

No load speed: min.

Protection against electric shock

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003*: kg (lbs)

* With Side grip, Wheel cover, Inner flange, Lock nut

Model No.

Diameter

Hole diameter

-1 = rpm

MT961

100 (4)

16 (5/8)

1.9 (4.1) 2.0 (4.4)

MT962

115 (4-1/2)

11,000

Double insulation

2.0 (6.6)

Standard equipment

Lock nut wrench 20 ...................... 1 (for MT961)

Lock nut wrench 35 ...................... 1 (for MT962/ MT963)

Side grip ....................................... 1

Note: The standard equipment for the tool shown above may vary by country.

Optional accessories

Wheel cover for Cut-off wheel

MT963

125 (5)

22.23 (7/8)

P 2/ 10

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

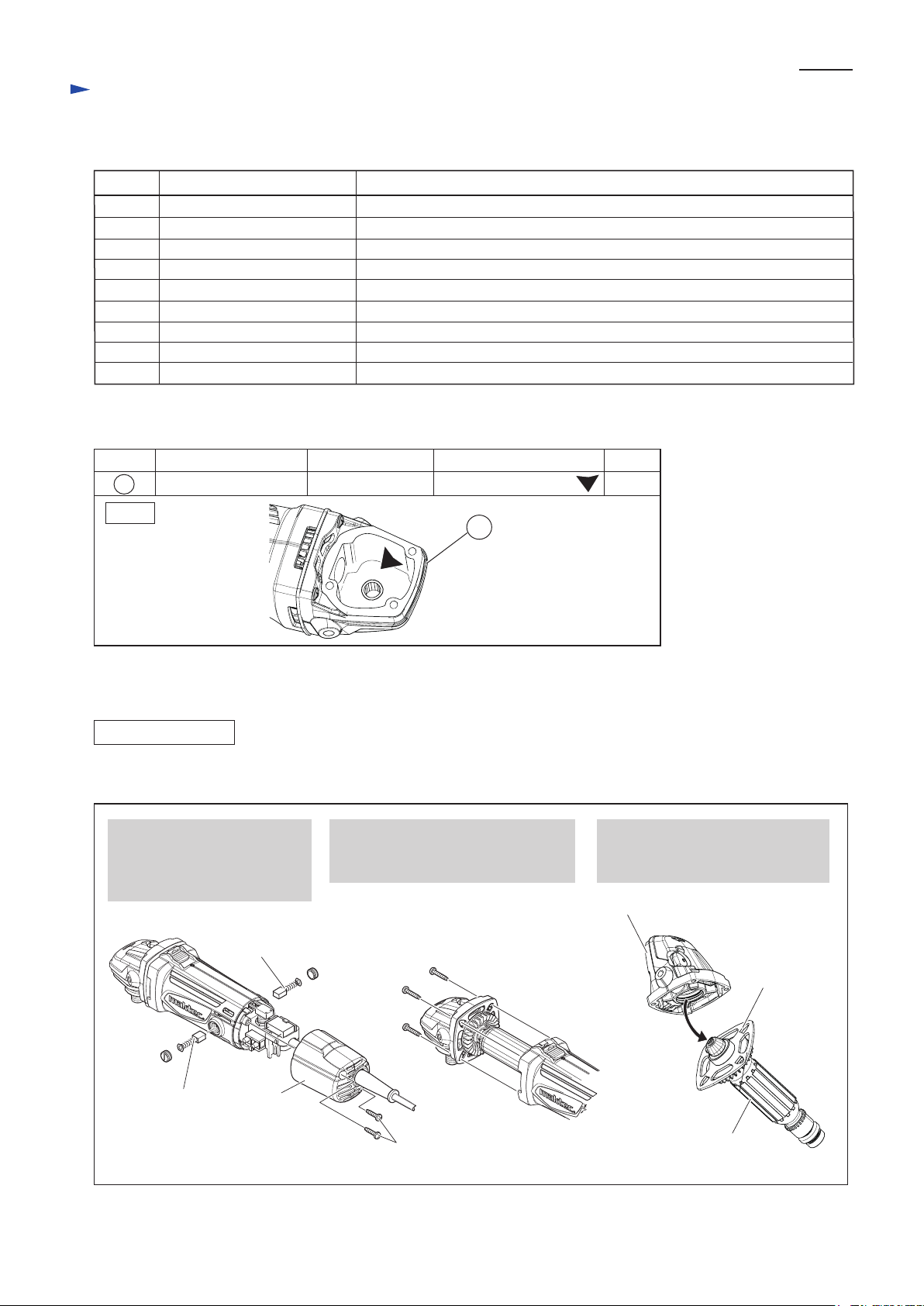

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R004 Retaining ring S pliers ST-2N removing Ring spring 11 from Spindle

1R005 Retaining ring R pliers RT-2N removing Retaining ring R-32 from Bearing box

1R026 Bearing setting pipe 16-8.2 removing Spindle from Spiral bevel gear 36

1R232 Pipe 30 supporting Bearing box when removing Spindle

1R268 Spring pin extractor 3 disassembling Shaft lock mechanism

1R269 Bearing extractor removing Ball bearing

1R281 Round bar for arbor 7-50 locking Switch knob when separating Switch lever from Switch knob

1R282 Round bar for arbor 8-50 removing Spindle

1R291 Retaining ring S and R pliers removing / assembling Retaining ring S-6 from / to Armature shaft

[2] LUBRICATIONS

Apply the following lubricant to protect parts and product from unusual abrasion.

Item No.

17

Description

Gear housing complete

Gear room

Lubricant

Makita grease N No.1

AmountPortion to lubricate

10g

Fig. 1

17

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Armature, Spiral bevel gear 11, Ball bearings 6000ZZ and 607ZZ

DISASSEMBLING

(1) Remove Armature. (Fig. 2)

Fig. 2

1. Remove Carbon brushes and

two 4x18 Tapping screws,

and then remove Rear cover

from Motor housing.

Carbon brush

2. Remove four 4x22 Tapping screws

and Gear housing section from

Motor housing.

4x22 Tapping screw (4pcs.)

3. Remove Armature together with

Bearing box from Gear housing

complete.

Gear housing complete

Carbon brush

Rear cover

4 x 18 Tapping screw

(2pcs.)

Bearing box

Armature

epair

R

[3] DISASSEMBLY/ASSEMBLY

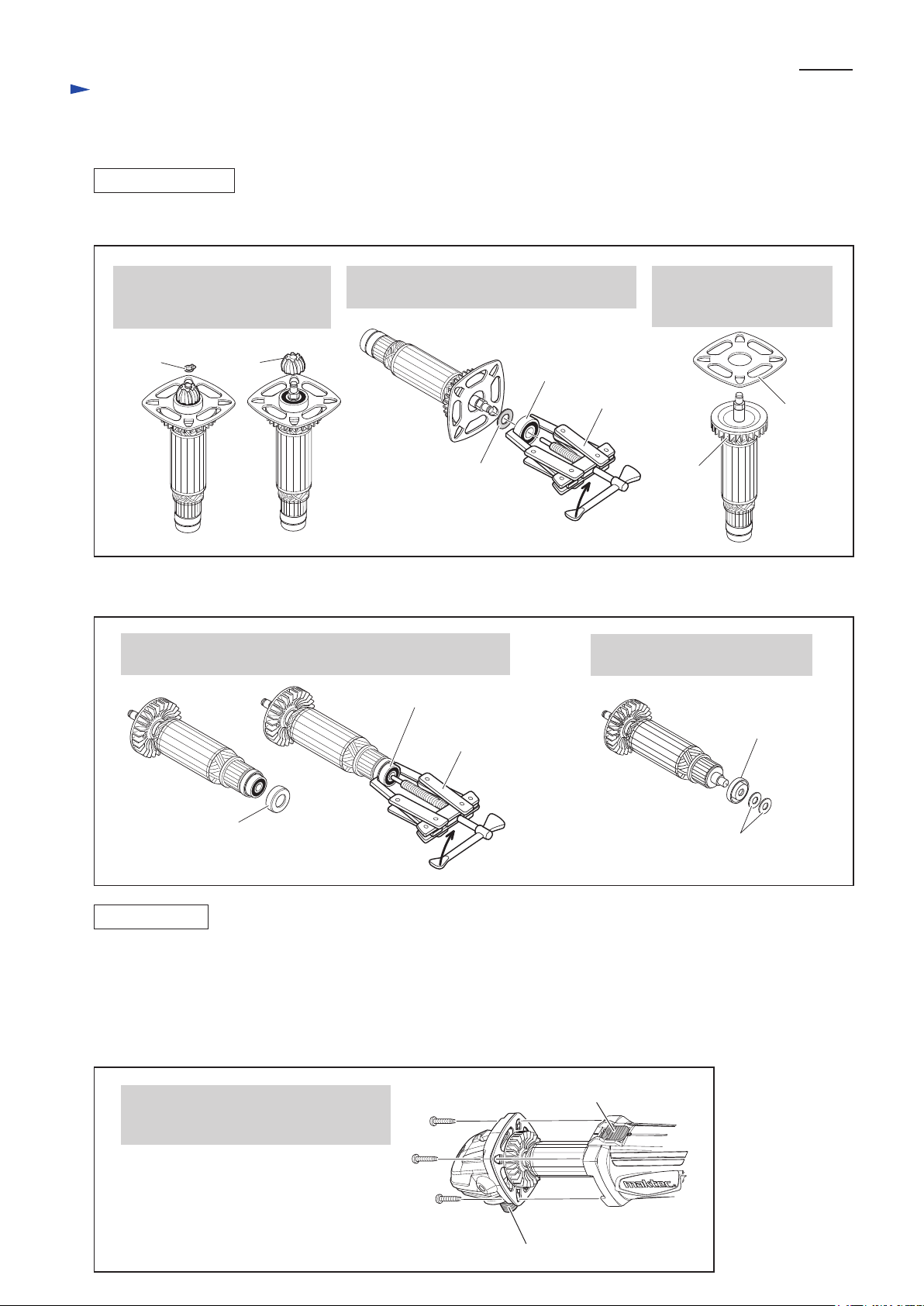

[3]-1. Armature, Spiral bevel gear 11, Ball bearings 6000ZZ and 607ZZ (cont.)

DISASSEMBLING

(2) Remove Helical gear 11, Ball bearing 6000ZZ and Bearing retainer 69 from Armature. (Fig. 3)

Fig. 3

P 3/ 10

4. Remove Retaining ring S-6

with 1R291. Helical gear 11

can now be removed by hand.

Retaining

ring S-6

(3) Remove Ball bearing 607ZZ from the commutator end of Armature. (Fig. 4)

Fig. 4

After removing Rubber ring 19, remove Ball bearing 607ZZ

with 1R269.

Helical

gear 11

5. Remove Ball bearing 6000ZZ with 1R269,

and then remove Flat washer 10.

Ball bearing

6000ZZ

Flat washer 10

Ball bearing 607ZZ

1R269

6. Armature can be now

removed from Bearing

retainer 69.

1R269

Armature

Remove two Flat washers 7 and

Insulation washer.

Insulation

washer

Bearing

retainer 69

Rubber ring 19

Flat washer 7 (2pcs.)

ASSEMBLING

(1) Do the reverse of the disassembling steps. (Figs. 4, 3, 2)

Note:

a. Do not forget to put two Flat washer 7 before assembling Ball bearing 607ZZ. (right in Fig. 4)

b. Put Flat washer 10, before assembling Ball bearing 6000ZZ. (center of Fig. 3)

c. Be sure to use new Retaining ring S-6 because removed one was damaged in the removal process. (left in Fig. 3)

d. Assemble Gear housing section to Motor housing by screwing four 4 x 22 Tapping screws. (Fig. 5)

Fig. 5

Spindle face from Gear housing section

to the opposite side of Switch knob of

Motor housing.

Spindle

Switch knob

Loading...

Loading...