Makita Maktec MT925, Maktec MT925G Technical Information

T

ECHNICAL INFORMATION

PRODUCT

P 1/ 7

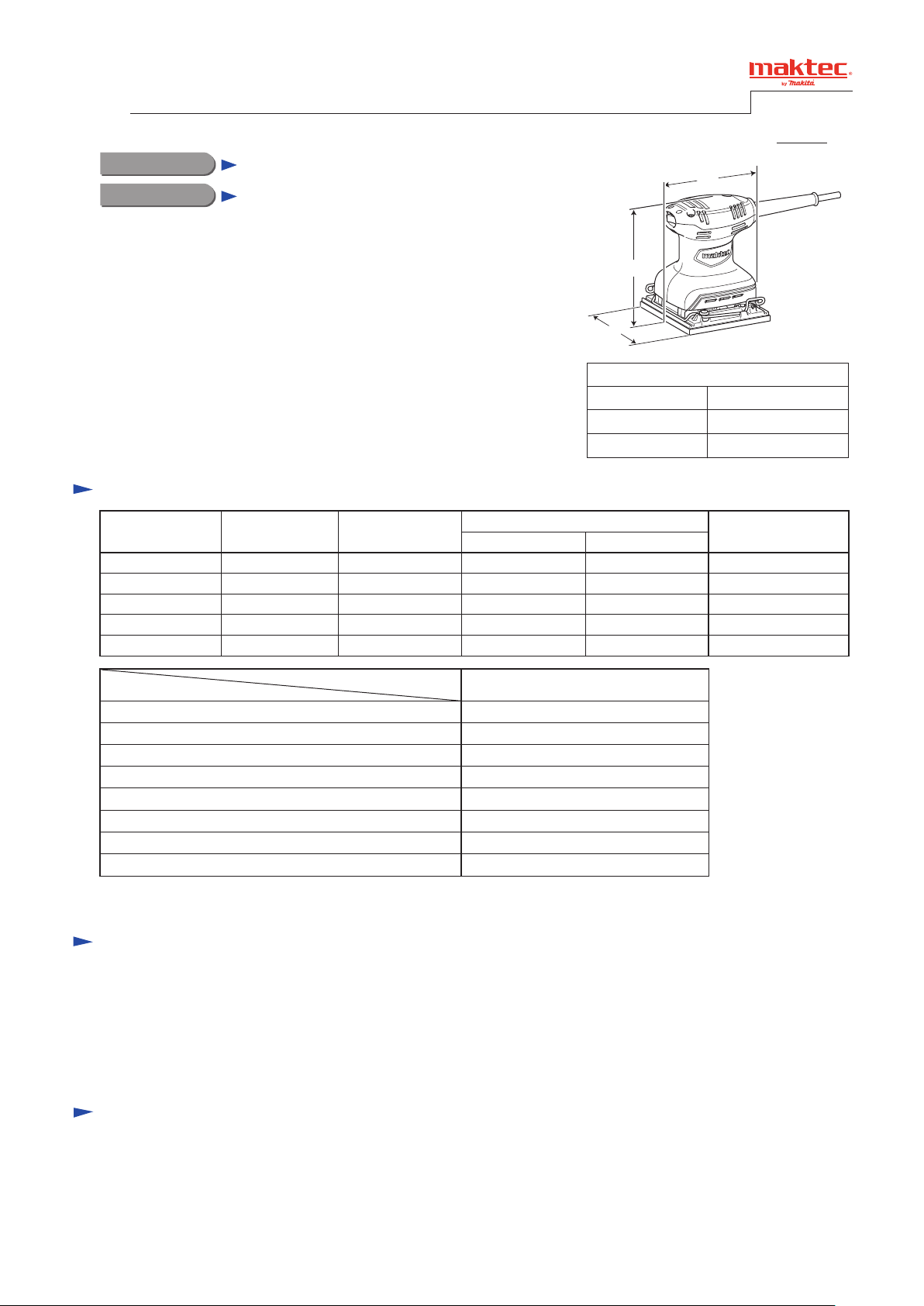

Model No.

MT925, MT925G

Description Finishing Sander

CONCEPT AND MAIN APPLICATIONS

Model MT925 has been developed as the cosmetic change

model of maktec finishing sander MT920, featuring:

• Slim grip for easy horizontal and overhead applications

• Industrial performance and durability at less expense

Model MT925G is Green housing model exclusively developed

for Korean market.

Specification

Voltage (V)

110

220

230 0.9 50/60 180 5025

240

Current (A)

1.7

0.9

0.8

Cycle (Hz)

50/60

50/60

50/60

H

W

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

180

180

180

25

25120 1.6 50/60 --- 50

25

25

L

110 (4-5/16)

112 (4-3/8)

133 (5-1/4)

Max. Output (W)

50

50

50

Specification

Orbits per minute: opm= min.ˉ¹

Sanding strokes: spm= min.ˉ¹

Abrasive paper size: mm (")

Pad size: mm (")

Orbit diameter: mm (")

Protection from electric shock Double insulation

Power supply cord: m (ft)

Weight according to EPTA-Procedure 01/2003: kg (lbs)

Model

MT925/ MT925G

14,000

28,000

114 x 140 (4-1/2 x 5-1/2)

112 x 102 (4-3/8 x 4)

ø1.5 (1/16)

2.0 (6.6)

0.89 (2.0)

Standard equipment

Abrasive paper 114-60 ....................... 2

Abrasive paper 114-100 ..................... 2

Abrasive paper 114-150 ..................... 2

Note: The standard equipment for the tool shown above may vary by country.

Optional accessories

TBA

P 2/ 7

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

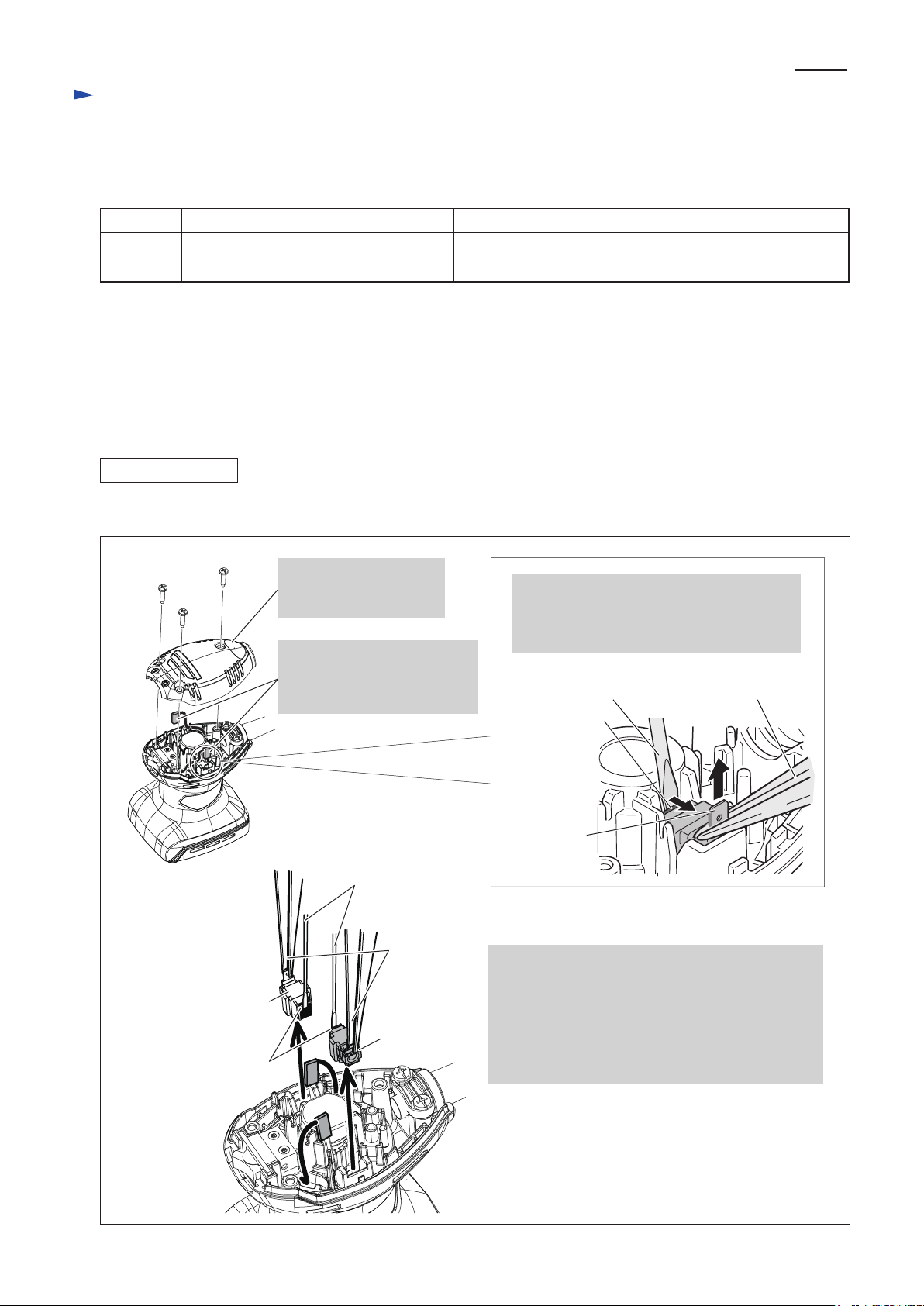

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R027 Bearing setting pipe 18-10.2 removing Armature

1R269 Bearing extractor removing Ball bearings 629DDW, 606ZZ

[2] LUBRICATION

Lubrication is not required for this product because no gear is used for transmission.

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature

DISASSEMBLING

(1) Remove Carbon brushes and Brush holders from Motor housing as drawn in Fig. 1.

Fig. 1

Brush holder

Carbon brushes

1. Remove Top cover by

unscrewing three 4x18

Tapping screws.

2. Disconnect Field lead wires

by pulling off Receptacles

from the terminals of Brush

holders.

Small slotted

Screwdriver

Long nose

pliers

Brush holder

3. Insert a small slotted screwdriver between

Armature’s commutator and Carbon brush

carefully, and hold the terminal of Brush

holder with Long nose pliers.

Small slotted

Screwdriver

Carbon brush

Terminal of

Brush holder

4. Then, lift up Brush holder vertically together with

Carbon brush while pressing Carbon brush with

the screwdriver.

Remove the other Brush holder and Carbon brush

in the same manner.

Note: Do not bend terminals of Brush holders.

Do not scratch the commutator of Armature.

Long nose

pliers

Repair

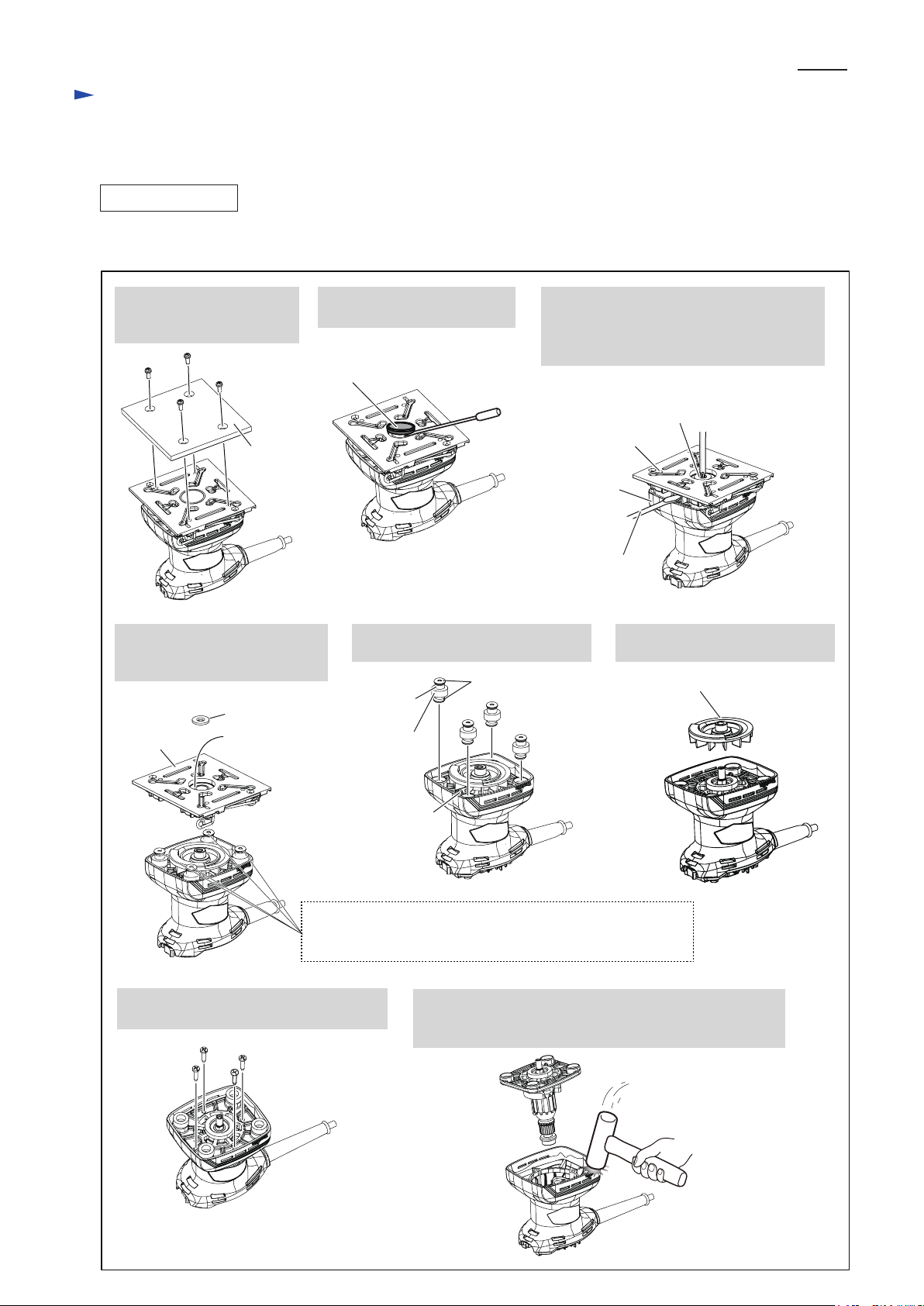

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature (cont.)

DISASSEMBLING

(2) Disassemble the parts in bottom section and remove Armature from Motor housing as drawn in Fig. 2.

Fig. 2

P 3/ 7

1. Remove Pad complete

by unscrewing four

M4x10 +Pan head screws.

Pad complete

4. After removing Flat washer 6,

Base is removed together with

Ball bearing 6001ZZ.

Flat washer 6

Base

Ball bearing

6001ZZ

2. Remove Cap 28 by levering

up with slotted screwdriver.

Cap 28

5. Remove Sponge sleeves and Foots

with O rings 4 from Bearing box.

Foot

(4 pcs.)

Sponge

sleeve

(4 pcs.)

O ring 4 (8 pcs.)

3. While holding Fan 65 by inserting slotted

screwdriver from the gap between Motor

housing and Base, remove M4x10

+Countersunk head screw.

M4x10 +Countersunk

head screw

Base

Motor

housing

Slotted

screwdriver

6. Remove Fan 65 from Armature

shaft.

Fan 65

Bearing box

Caution:

Sponge sleeves, Foots and O rings may be left to Base.

Be careful not to lose them when Base is turned upside down.

7. Remove four 4x18 Tapping screws that

fasten Bearing box to Motor housing.

4x18 Tapping

screws

8. Disassemble Armature assembly and Bearing box from

Motor housing by tapping the skirt portion of Motor

housing with plastic hammer.

Loading...

Loading...