Makita Maktec MT362 Technical Information

T

ECHNICAL INFORMATION

Model No.

Description

MT362

Router 12mm (1/2")

CONCEPT AND MAIN APPLICATIONS

Model MT362 has been developed as the cosmetic change model of

maktec router MT360.

Its main features are:

• Industrial performance and durability at less expense

• Ergonomically contoured knob style handles with rubberized soft grip

Specification

H

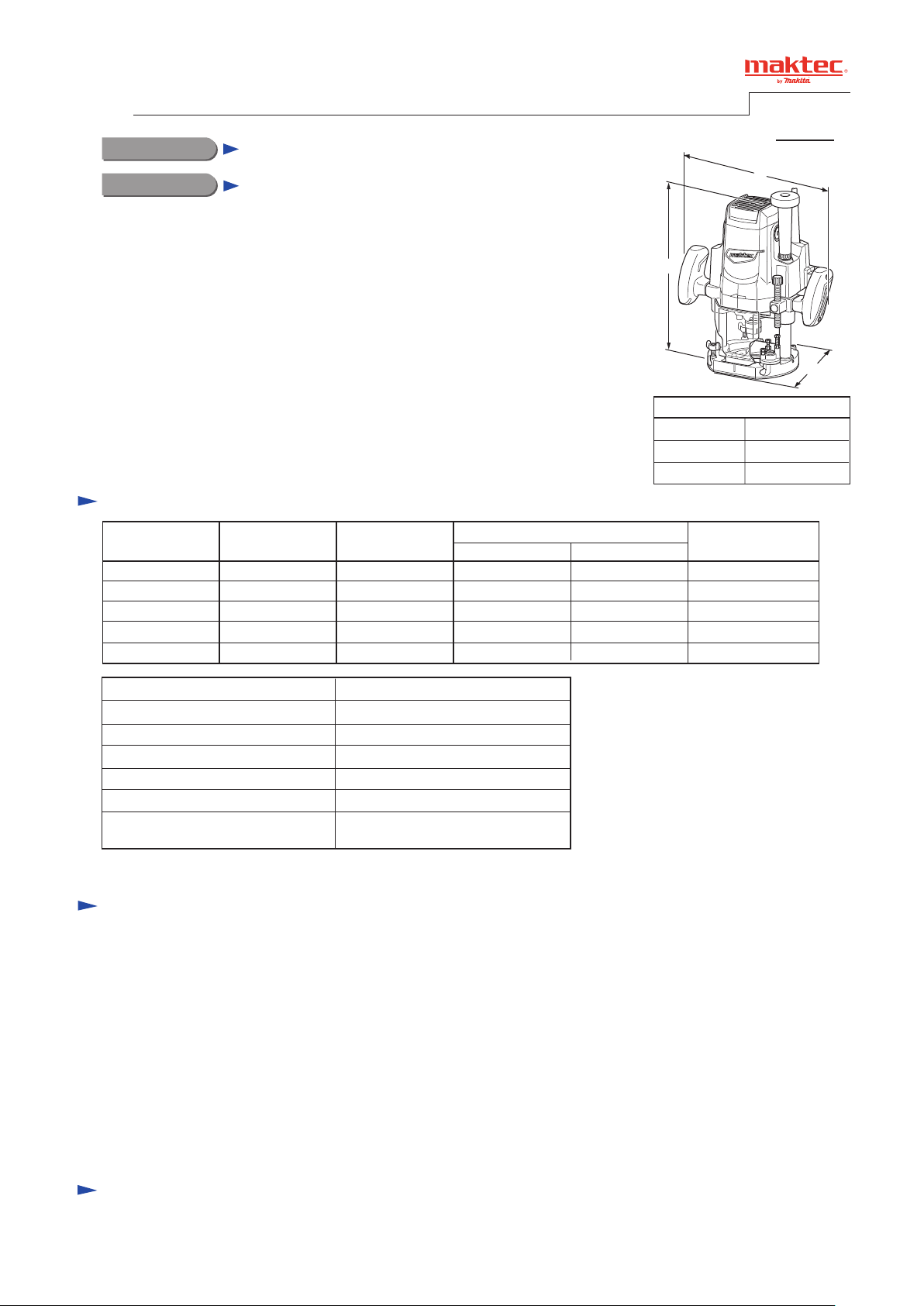

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

PRODUCT

P 1/ 9

L

W

284(11-1/8)

148 (5-7/8)

300 (11-3/4)

Voltage (V) Cycle (Hz)

110

120

220

230

240

No load speed: min.ˉ¹= rpm.

Collet capacity*

Plunge capacity: mm (")

Switch type

Protection from electric shock Double insulation

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

* Collet capacity may vary by country.

Current (A)

15

15

7.9

7.6

7.2

50-60

50-60

50-60

50-60

50-60

22,000

12mm (15/32") or 1/2" (12.7mm)

0 - 60 (0 - 2-3/8)

Toggle

2.0 (6.6)

5.5 (12.2)

Continuous Rating (W)

Input Output

1,650

-

1,650

1,650

1,650

1,000

1,000

1,000

1,000

1,000

Standard equipment

Wrench 8 - 24 ................................................. 1

Collet sleeve 6mm or 1/4" .............................. 1

Collet sleeve 8mm or 3/8" .............................. 1

Templet guide 16 ............................................ 1

Guide holder assembly ................................... 1

Straight guide ................................................. 1

Trimmer guide assembly ................................ 1

Dust cover ..................................................... 1 (only for the specifications with knob 50)

Straight bit 12E or 12 ..................................... 1

Dust nozzle ..................................................... 1 (for European countries only)

Note: The standard equipment for the tool shown above may vary by country.

Max. Output (W)

2,200

2,200

2,200

2,200

2,200

Optional accessories

Dust nozzle

P 2/ 9

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R269 Bearing extractor removing Ball bearing 629ZZ

1R233 Round bar for arbor 4-100 removing Cap 11

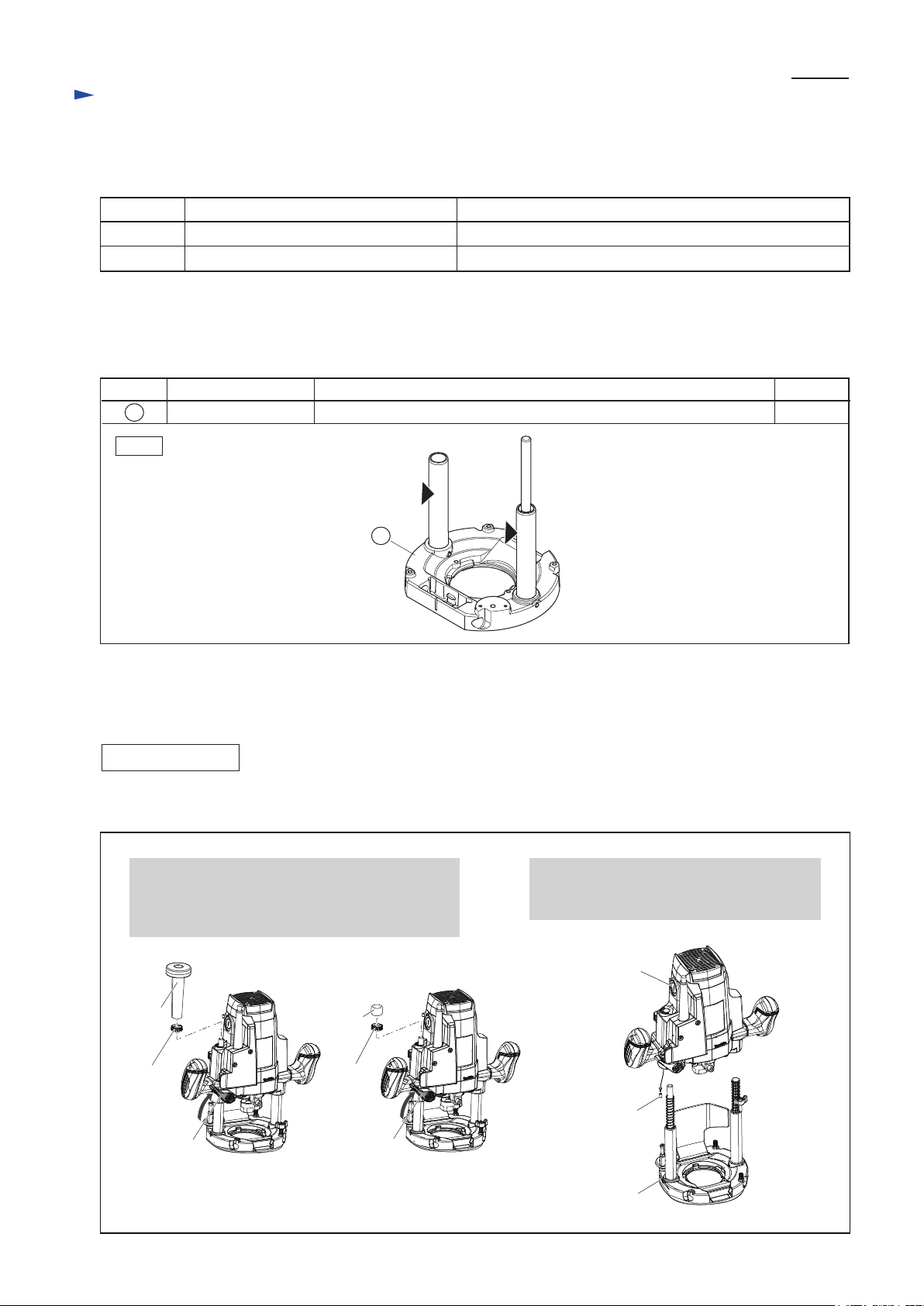

[2] LUBRICATION

Apply lubricating oil VG100 to the following portions designated with the black triangle to protect parts and product

from unusual abrasion.

Item No. Description AmountPortion to lubricate

52 a littleBase complete Pipe section for smooth plunge action

Fig. 1

52

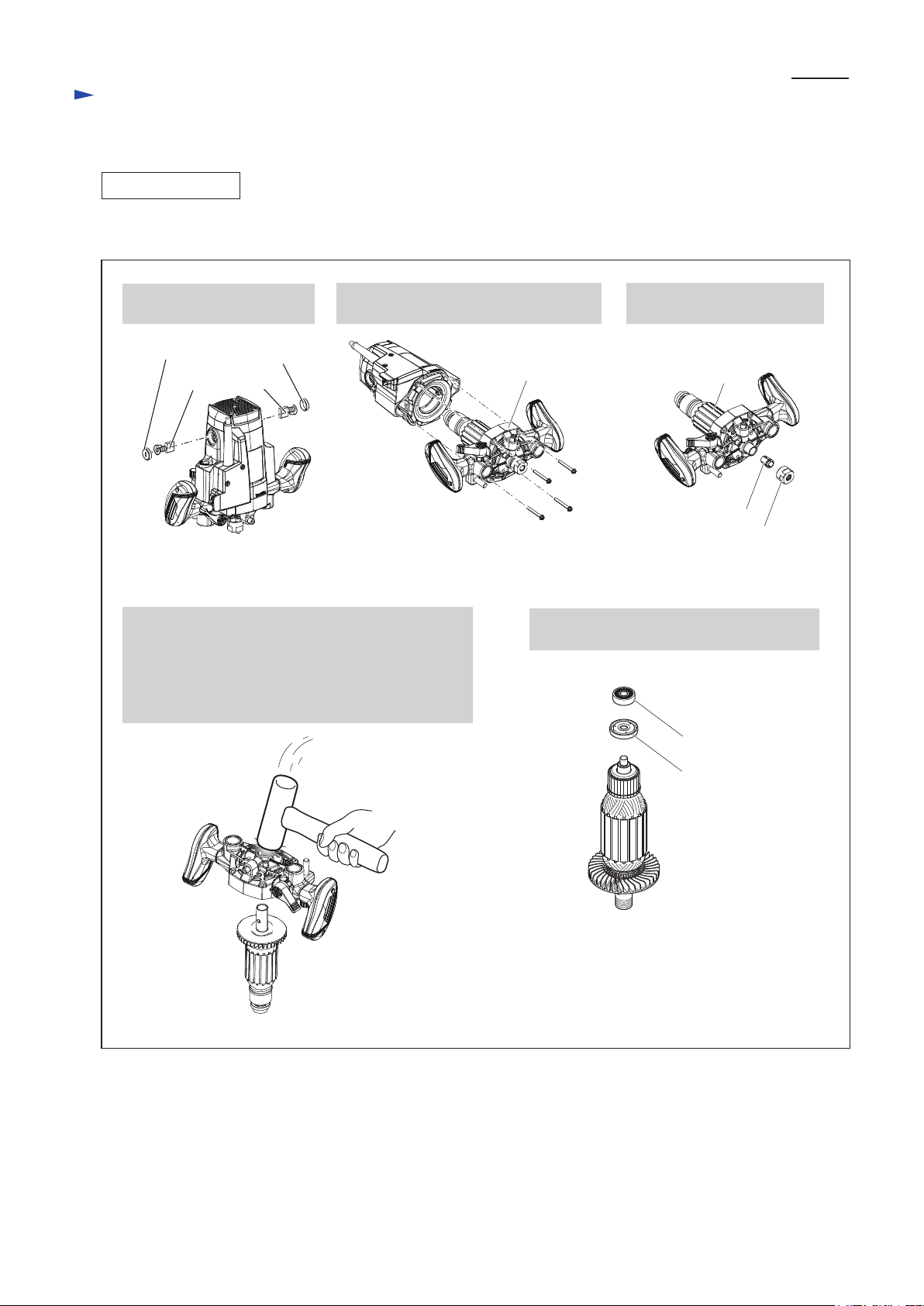

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature

DISASSEMBLING

(1) Separate Motor section from Base complete. (Fig. 2)

Fig. 2

1. MT362: Remove Knob 50 and M10 Nylon nut,

and then release Lock lever.

MRP102: Remove Cap 15 and M10 Nylon nut,

and then release Lock lever.

2. Separate Base complete from the machine.

Note: Be careful not to lose Lock pin

in this step.

Motor section

Knob 50

M10

Nylon

nut

Lock lever

[MT362]

Cap 15

M10

Nylon

nut

Lock lever

Lock pin

[MRP102]

Base

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature (cont.)

DISASSEMBLING

(2) Disassemble Armature from Motor section. (Fig. 3)

Fig. 3

P 3/ 9

1. Remove Brush holder caps

and Carbon brushes.

Brush holder caps

Carbon brushes

4. Remove Armature from Motor bracket by tapping

the drive end of Armature with plastic hammer,

or by pressing the same portion of Armature with

Arbor press.

Note: Ball bearing 6004ZZ on Armature’s drive end

remains in Motor bracket in this step.

2. Separate Motor bracket by unscrewing

four M5x45 Pan head screws.

Motor bracket

M5x45 Pan head screw

(4 pcs.)

5. Remove Ball bearing 629ZZ with 1R269,

and then remove Insulation washer.

3. Remove Collet nut and

Collet cone from Armature.

Armature

Collet cone

Collet nut

Ball bearing 629ZZ

Insulation washer

Loading...

Loading...