Makita Maktec MT241 Technical Information

T

Models No.

ECHNICAL INFORMATION

MT241

PRODUCT

P 1/ 9

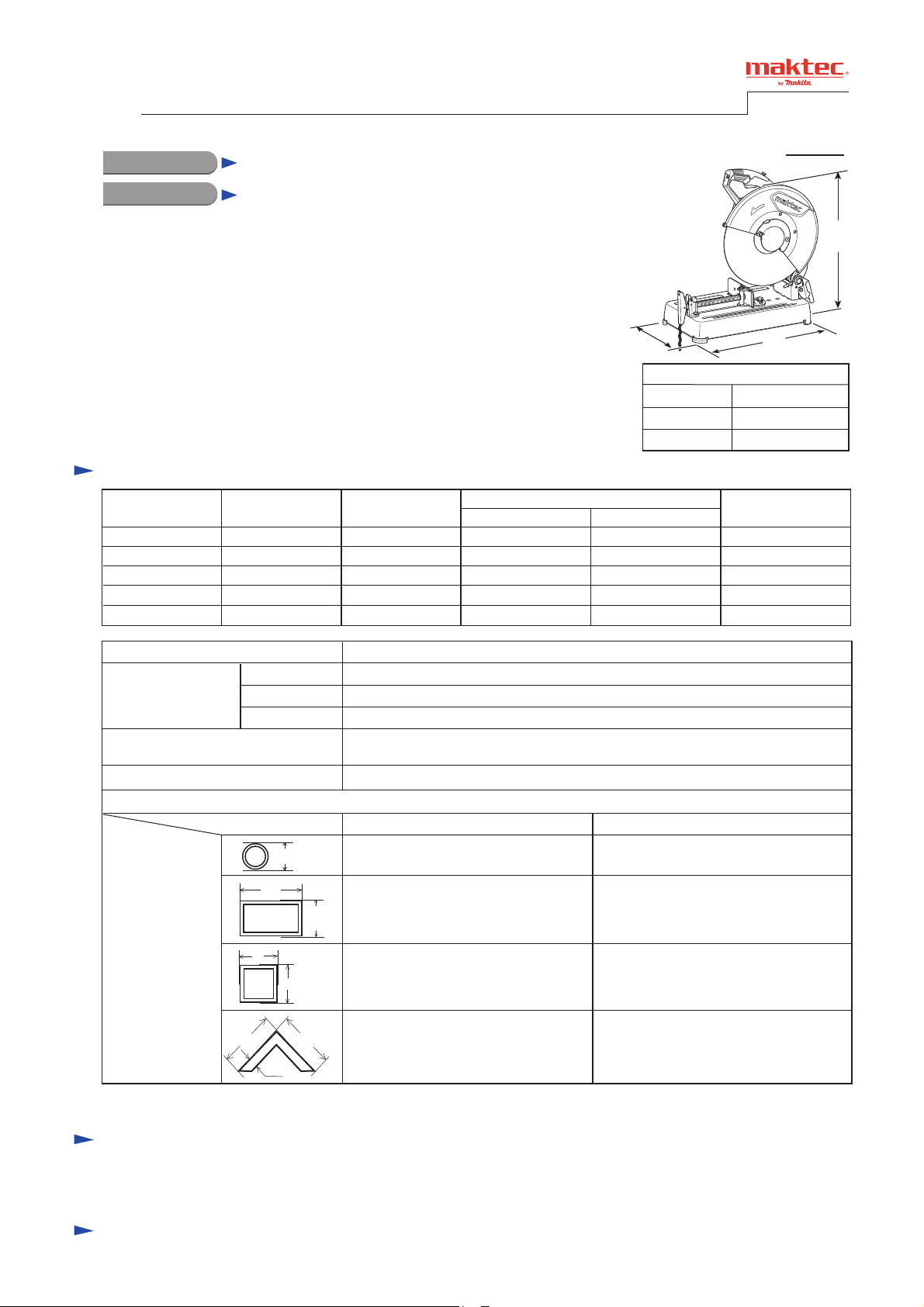

Description

355mm (14") Portable Cut-Off

CONCEPT AND MAIN APPLICATIONS

Model MT241 has been developed as the aesthetic change model

of maktec MT240, featuring industrial performance and durability

at less expense.

Specification

Voltage (V) Cycle (Hz)

110

120 15.0

220

230

240

Current (A)

15.0

9.6

9.2

8.8

50/60

50/60

50/60

50/60

50/60

W

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

1,650

--2,000 1,400 3,000

2,000 1,400 3,000

2,000 1,400 3,000

L

500 (19-3/4)

280 (11)

620 (24-3/8)

Max. Output(W)

2,500900

2,500900

H

No load speed: min-1= rpm.

Diameter

Wheel size: mm (")

Weight according to

EPTA-Procedure 01/2003*

Cord length: m (ft)

Capacity: mm (")

Form of materials

D: Diameter

W: Width

H: Height

S: Side

T: Thickness

*1 with Abrasive cut-off wheel 355

*2 Weight shown above is the model with Center cap.

Arbor

Thickness

1: kg (lbs)

Miter angle

D

W

W

H

S S

T

2.0 (6.6) for Brazil, 2.5 (8.2) for Oceania, 3.0 (9.8) for other countries

H x W: 102 (4) x 194 (7-5/8)

H

H x W: 70 (2-3/4) x 233 (9-1/8)

H x W: 119 (4-11/16) x 119 (4-11/16) H x W: 106 (4-3/16) x 106 (4-3/16)

S x S: 137 (5-3/8) x 137 (5-3/8),

3,800

355 (14)

25.4 (1)

3 (1/8)

15.7 (34.6)*

0°

ø115 (4-1/2) ø115 (4-1/2)

T: 10 (3/8)

2

45°

H x W: 115 (4-1/2) x 103 (4-1/16)

S x S: 100 (4) x 100 (4),

T: 10 (3/8)

Standard equipment

Socket wrench 17 ................................ 1

Abrasive cut-off wheel 355 ............................... 1

Note: The standard equipment for the tool shown may vary by country.

Optional accessories

No

P 2/ 9

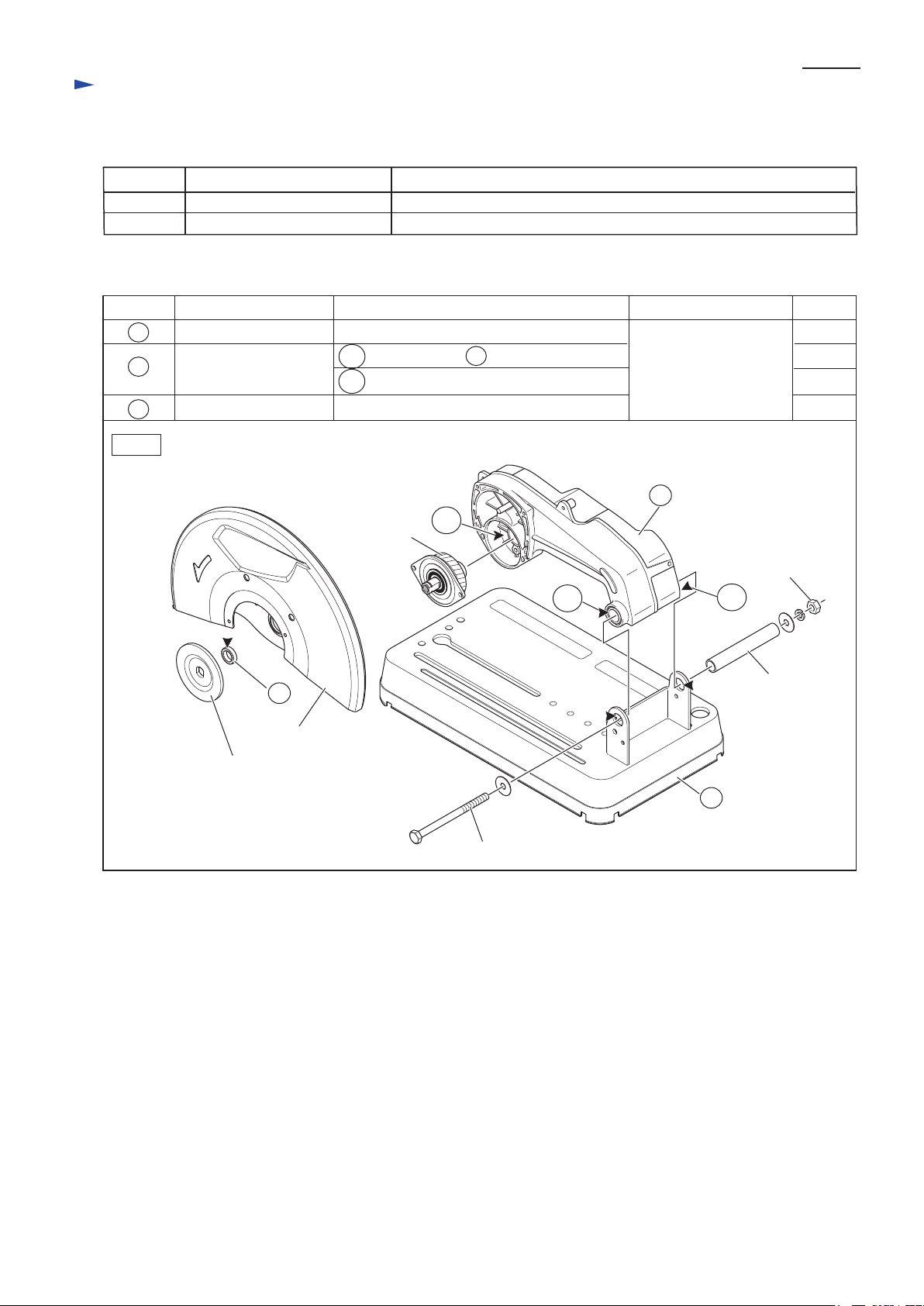

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R003 Retaining Ring S Pliers ST-2N Removing Pipe 20-128

1R269 Bearing extractor Removing Ball bearing 6000ZZ from spindle

[2] LUBRICATIONS

Apply the following grease to the portions pointed with triangles to protect parts and product from unusual abrasion.

Item No.

16

57

86

Fig. 1

Description

Ring 17

Gear housing complete

Base

16

Safety cover

Outside where Safety cover contacts

57a Surface where 86 Base contacts

57b Gear room where Helical gear 49 rotates

Punched hole for Pipe 20-128 passing

57b

Helical gear 49

57a

Lubricant AmountPortion to lubricate

Makita Grease N No.1

57

M10-17 Hex nut

57a

Pipe 20-128

a little

2 g

25 g

a little

Inner flange

86

M10x140 Hex bolt

Repair

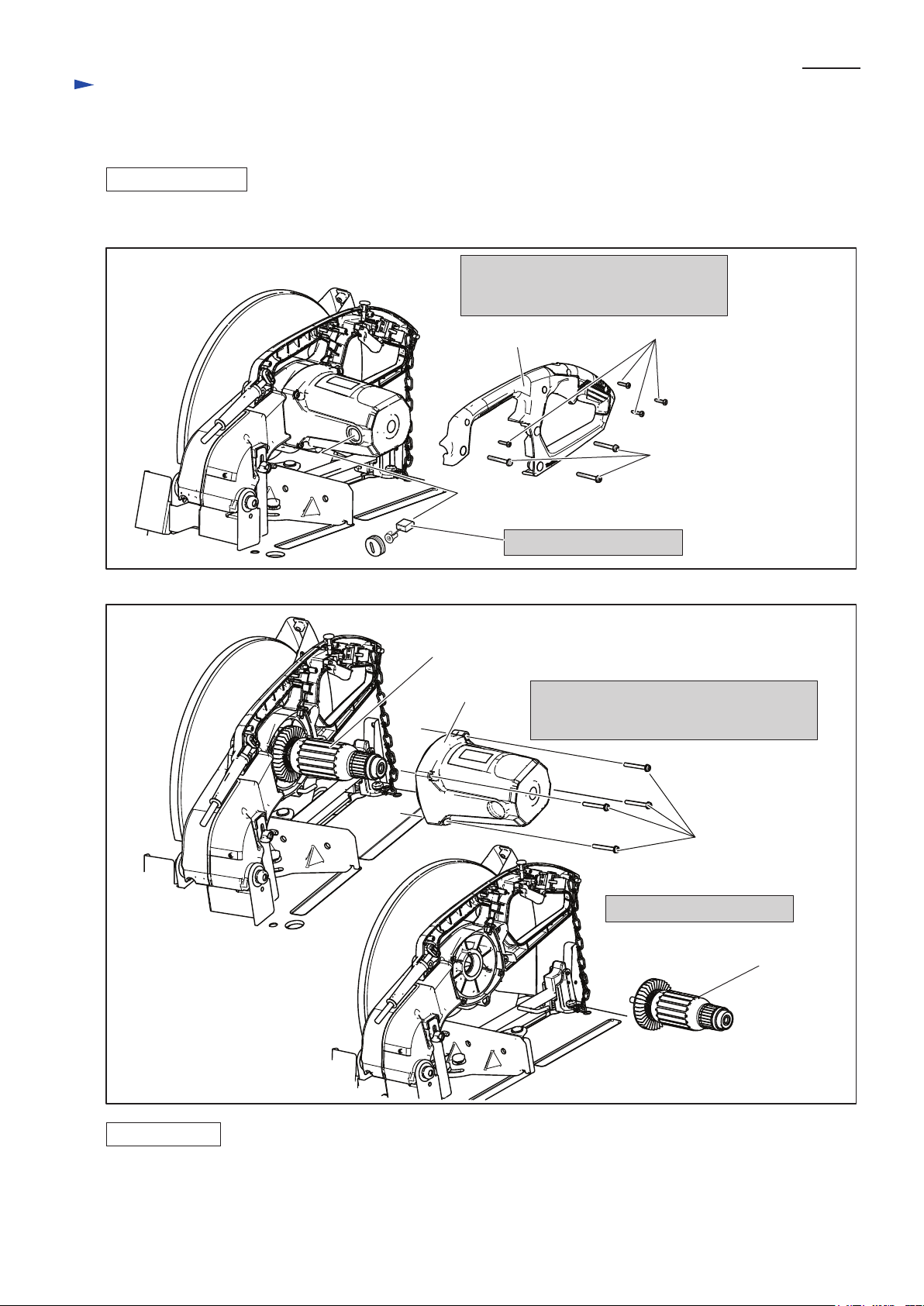

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Armature

DISASSEMBLING

Disassemble Armature (Fig. 2, Fig. 3).

Fig. 2

P 3/ 9

1. Remove Handle (L) by unscrewing

four Tapping screws and three M5x30

Pan head screws.

4x18 Tapping screw (4 pcs.)

Handle (L)

M5x30 Pan

head screw (3pcs.)

Fig. 3

Armature

Motor housing

2. Remove carbon brushes.

3. Unscrew four M5x30 Pan head screws

and remove Motor housing.

Now, Armature comes into your sight.

M5x30 Pan

head screw (4pcs.)

4. Armature can be replaced.

Armature

ASSEMBLING

Take the reverse step of Disassembling (Fig. 3, Fig. 2).

Loading...

Loading...