Makita MAKSTAR DC18RA Technical Information

T

ECHNICAL INFORMATION

Models No.

Description

DC18RA

Charger

CONCEPT AND MAIN APPLICATIONS

Considering the future demand for slide type 7.2V Li-ion and Ni-MH

battery, the above product has been launched with wider changeable range.

This new face contains trickle charging function.

Its brief benefits are mentioned below.

1. Only 22 minutes for full-charge of 3.0 Ah Li-ion Battery

2. Innovative computer controlled charging system realized most suitable

charge by making the digital communication between charger and battery.

3. Cooling system to keep the ideal temperature for charge.

4. Power display for battery; It displays the charging amounts of battery

in two steps. (less than 80% or more than 80% of charge)

5. The adapter ADP04 (optional accessory) enables to charge the existing

Ni-Cd and Ni-MH batteries.

6. The adapter ADP03 (optional accessory) enables to refresh inactive

batteries

7. Selectable melody sound of completed charging

Specification

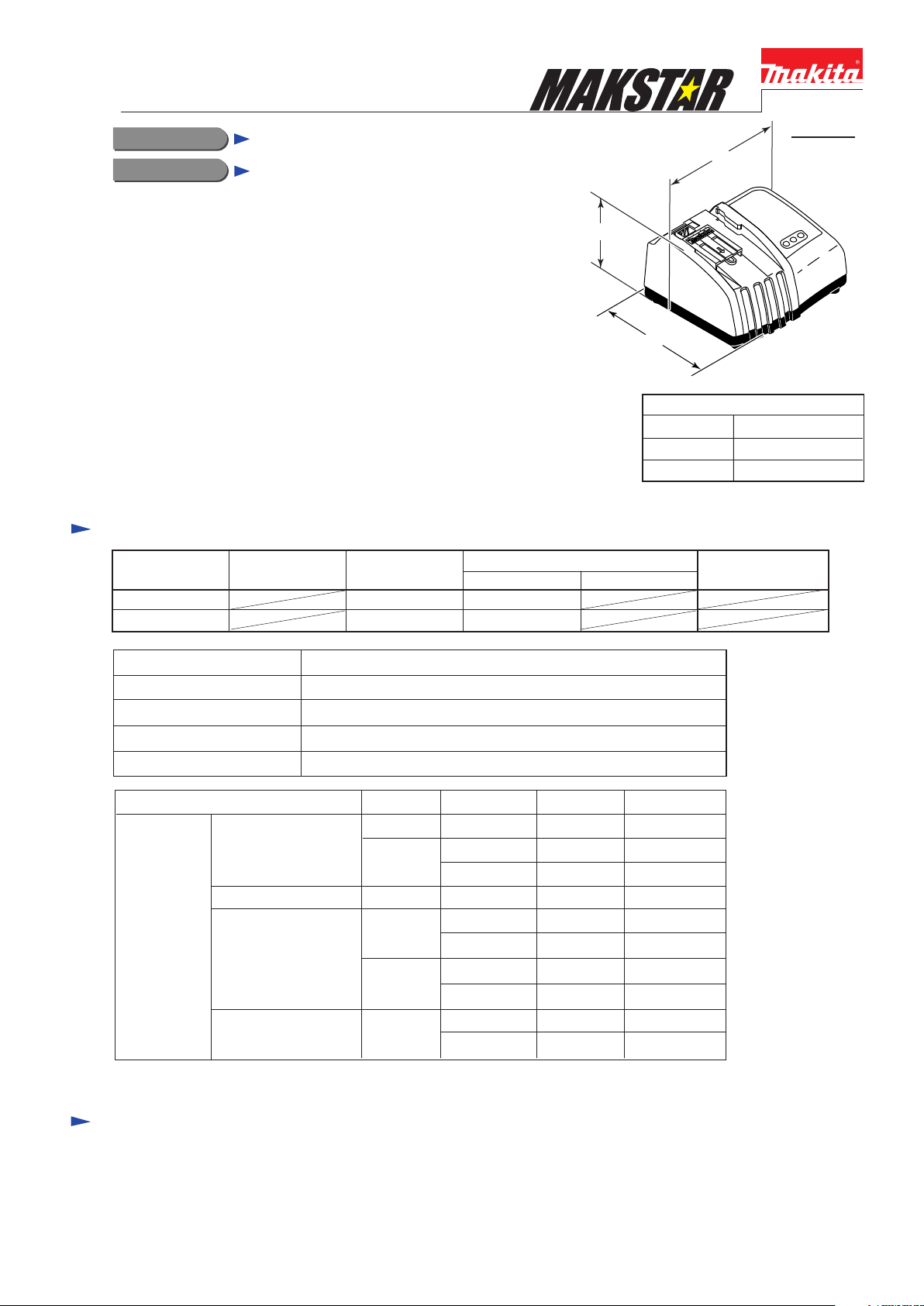

H

W

L

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

PRODUCT

P 1 / 5

164 (6-1/2)

190 (7-1/2)

106 (4-3/16)

Voltage (V) Cycle (Hz)

110-120

220-240

Output voltage : V

Output current : A

Power Supply Cord: m ( ft )

Net weight: Kg (lbs)

Charging

Time

Current (A)

Approx. 15 min.

Approx. 20 min.

Approx. 22 min.

Approx. 30 min.

50 - 60

50 - 60

Cell Voltage: VCapacity: Ah

Li-ion BL1815

Ni-MH

Ni-MH

Li-ion

Ni-MH

Ni-MH

Continuous Rating (W)

Input Output

240

240

DC 7.2 - 18

DC 9.0

YesDouble Insulation

2.0 (6.6)

1.0 (2.2)

1.5

2.0

2.0

2.0

3.3

18

14.4

12

9.6

183.0

14.43.0

12

14.43.3

9.6 BH90333.3

9.6

Max. Output(W)

Battery

BH1420

BH1220 / C

BH9020 / A

BL1830

BL1430 / A

BH1233/ C

BH1433

BH9033A3.3

< Note > The above figures about charging time may differ from condition to condition on batteries' temperature

or room temperature.

Optional accessories

* ADP03 Automatic Refreshing Adapter

* ADP04 Interchangeable Adapter

Repair

CAUTION: Disconnect the charger from the power source for safety

before repair/ maintenance !

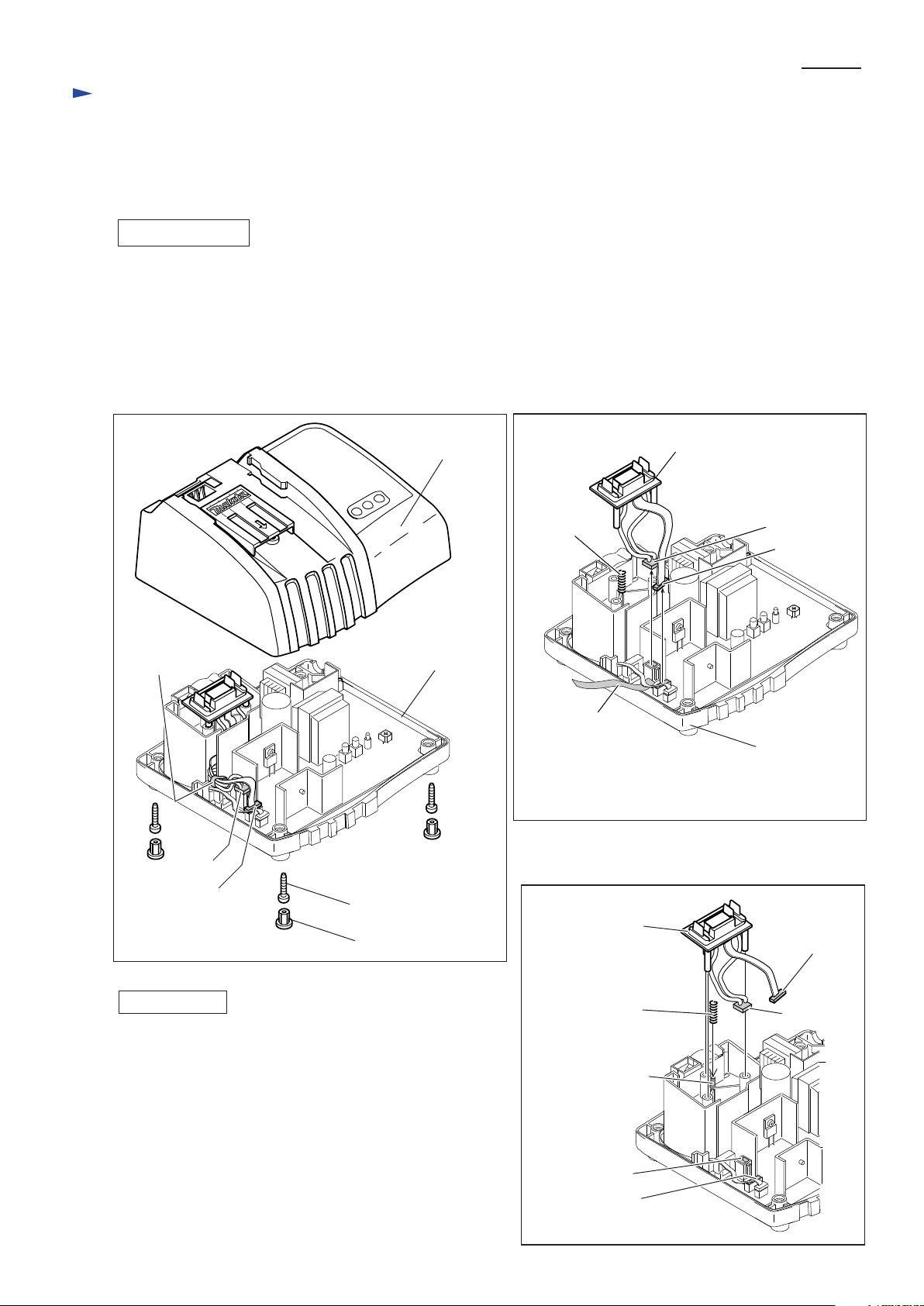

[1] DISASSEMBLY/ASSEMBLY

[1] -1. Terminal Unit

DISASSEMBLING

1. Remove four caps 13 and four 4x20 tapping screws. Consequently, charger case complete can be separated

from charger case cover. (Fig. 1)

< Note >

When removing charger case complete from charger case cover, be sure to put the product on the work bench, with

charger case complete faced to the upper side.

2. Loosen band with which bundles lead wires of terminal unit and that of cirocco fan. Disconnect connector 1 and

connector 2, and remove terminal unit from charger case cover. (Fig. 2)

Fig. 1 Fig. 2

P 2 / 5

Band

Connector 1

Connector 2

Charger Case

Complete

Charger Case

Cover

Tapping

Screw 4x20: 4 pcs.

Cap 13: 4 pcs.

Compression

Spring 4

Fig. 3

Terminal Unit

Terminal Unit

Connector 1

Connector 2

Band

Charger Case

Cover

Connector 2

ASSEMBLING

1. Insert compression spring 4 over the boss for accepting

the compression spring. (Fig. 3)

2. Insert three legs of terminal unit into the three bosses

of charger case cover. (Fig. 3)

3. Connect the connector 1 to the joint for connector 1 and

connector 2 to the joint for the connector 2. (Fig. 3)

4. Bundle the lead wires with band. Refer to Fig. 1.

5. Put the lead wires by the rib and wall of charger case cover

as instructed [2] Wiring Diagram in page 5.

6. Assemble charger case complete with four 4 x20 tapping

screws and four caps 13 firmly.

Compression

Spring 4

Boss for accepting

the compression

spring

Joint for

the connector 1

Joint for

the connector 2

Connector 1

Loading...

Loading...