Makita MAKSTAR BTW250 Series, MAKSTAR BTW251 Series, MAKSTAR BTW250Z, MAKSTAR BTW250RFE, MAKSTAR BTW251Z Technical Information

...

T

ECHNICAL INFORMATION

Models No.

BTW250, BTW251

PRODUCT

P 1 / 8

Description

Cordless Impact Wrench

CONCEPT AND MAIN APPLICATIONS

Models BTW250 and BTW251 are compact and lightweight

cordless impact wrenches, featuring maximum fastening torque

of 230N.m (170ft.lbs).

BTW250 is powered by Model BL1430 14.4V Li-ion battery,

and BTW251 by Model BL1830 18V Li-ion battery.

These products are available in the following variations:

BTW250

Model No.

BTW250Z

BTW250RFE 2

BTW251

Model No.

BTW251Z

BTW251

BTW251RFE

Charger

Charger

Battery

type quantity

No No

BL1430DC18RA

Battery

type quantity

No No

BL1830DC18RA

No

No

2

Plastic

carrying case

No

Yes

Plastic

carrying case

No All countries

Yes

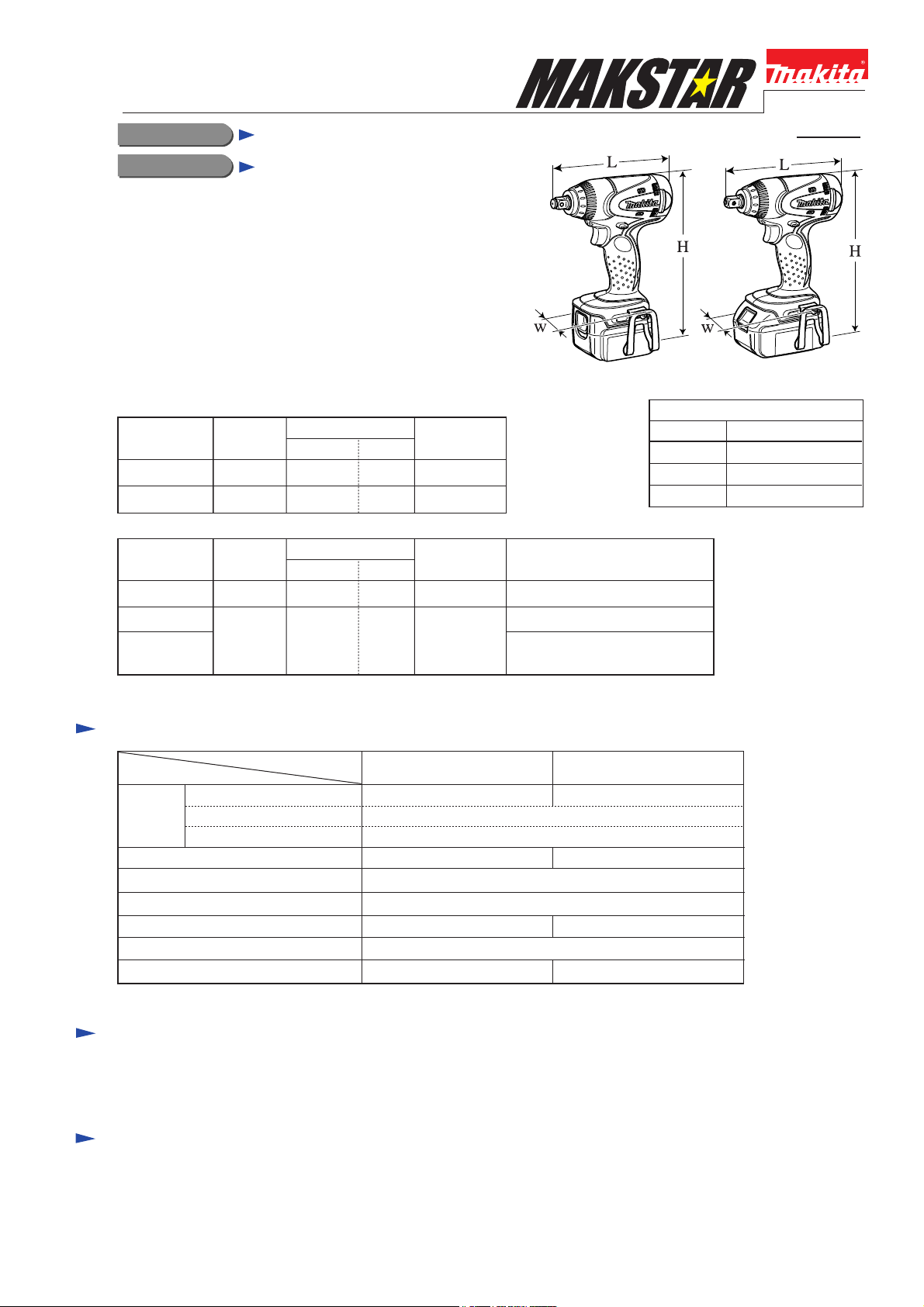

BTW250 BTW251

Dimensions: mm (")

Model BTW250, BTW251

Length (L) 165 (6-1/2)

Width (W)

Height (H)

Offered to

USA, Canada, Mexico, Panama

All countries other than

the four listed above

79 (3-1/8)

234 (9-1/4)

The items listed below in "Standard Equipment" also come with the above items.

Specification

Specification

Voltage: V

Battery

Max output (W)

Driving shank

Impacts per min.: min.-1=ipm

No load speed: min.-1=rpm

Max. fastening torque*: N.m (in.lbs) 230 (2,040)

Net weight**: kg (lbs)

*catalog value (torque at 6 seconds after seating) **with battery

Capacity: Ah

Cell

Model

BTW250 BTW251

14.4

3.0

Li-ion

235 280

12.7mm (1/2") Square

0 - 3,200

0 - 2,200 0 - 2,100

1.6 (3.5)

Standard equipment

Belt clip ................................... 1

Plastic carrying case ................ 1

Note: The standard equipment for the tool shown above may differ by country.

18

1.7 (3.7)

Optional accessories

Sockets

Extension bar

Universal joint

Bit adapter assembly

Battery BL1430 (for BTW250 only)

Battery BL1830 (for BTW251 only)

Fast charger DC18RA

Charger DC24SA

Charger DC24SC (for BTW250 only)

Repair

CAUTION: Remove the battery from the machine for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

P 2 / 8

Code No.

1R045

1R346 Center attachment for 1R045

1R288 Screwdriver magnetizer

1R041 Vise plate (2 pcs)

1R223 Torque wrench shaft

1R224 Ratchet head

Gear extractor (Large)

Socket 32-50 (2 pcs)134848-9

Description

Disassembling Hammering mechanism

Magnetizing screwdriver for removing Steel balls

Removing Hammer case complete

[2] LUBRICATION

Apply the following grease to protect parts and product from unusual abrasion:

Makita grease N. No.2 to the portions designated with the black triangle

Makita grease FA. No.2 to the portions designated with the gray triangle

Item No.

15

17

21

23

Description

Anvil Surface that contacts Hammer case complete

Whole surfaceSteel ball 3.5 (24 pcs)

Whole surfaceSteel ball 5.6 (2 pcs)

Spindle

Put 2g of Makita grease N. No.2 in the hole.

Surface that contacts Anvil

Portion to lubricate Grease

Use for

Fig. 1

Hammer case complete

15

Hammer

17

21

23

Armature

Repair

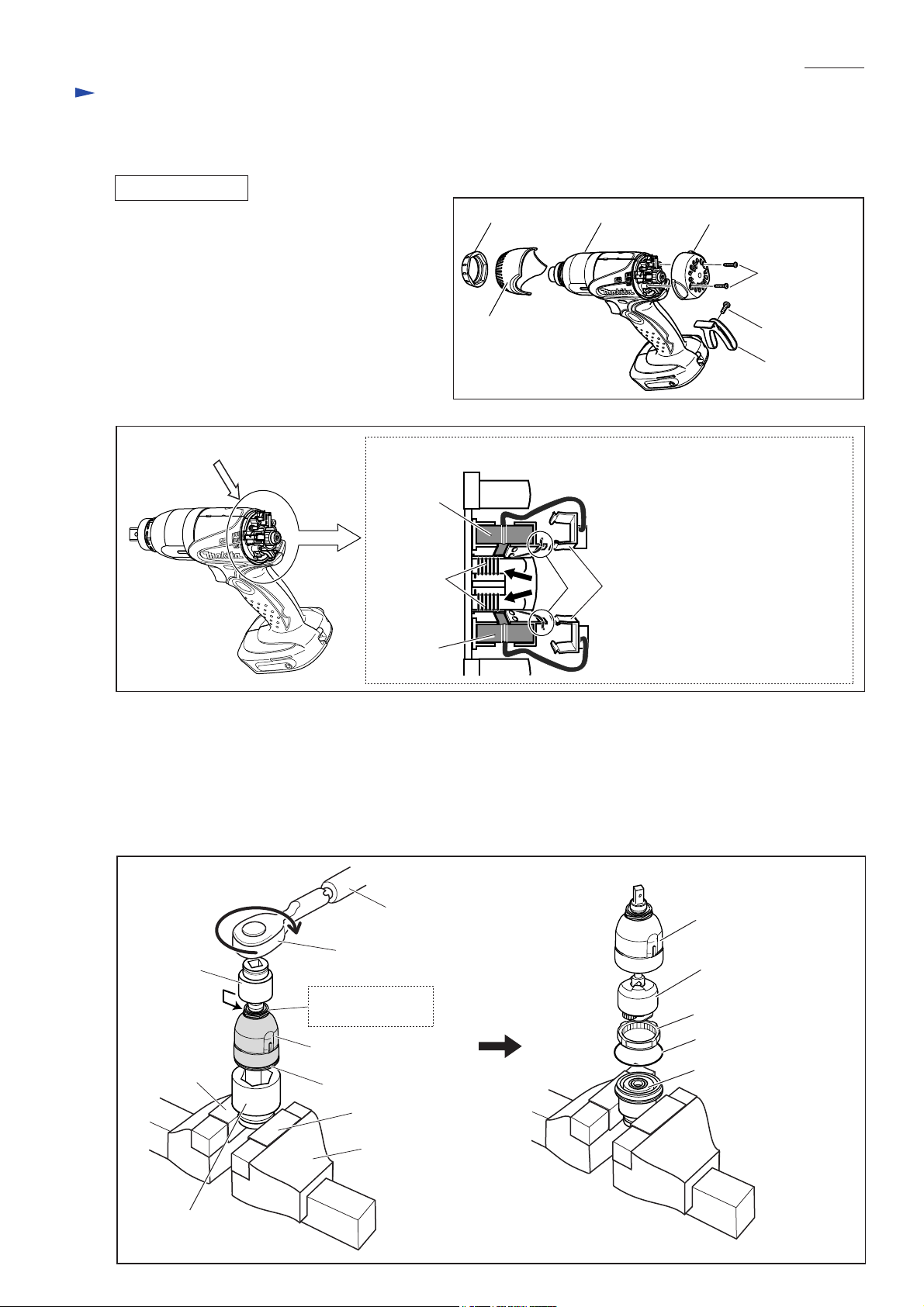

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Disassembling/Assembling Hammering Mechanism

P 3 / 8

DISASSEMBLING

1) Remove Belt clip by unscrewing Screw M4x12.

Remove Bumper and Hammer case cover by hand,

Remove Rear cover by unscrewing two PT3x16

Tapping screws. (Fig. 2)

2) Disconnect Carbon brush from Commutator

as illustrated in Fig. 3.

Fig. 3

A

[Brush holder section (Viewed from A)]

Carbon

brush

Torsion

spring

Carbon

brush

Fig. 2

Bumper

Hammer case cover

Hammer case

1. Move the tail of Torsion spring

onto the notch of Brush holder.

2. Then pull off Receptacle from

Brush holder.

Note:

1 2

Do the above steps while pushing

Torsion spring in the direction of

the arrow so that it cannot slip

out of position.

Rear cover

Tapping screw

PT3x16 (2 pcs)

Screw M4x12

Belt clip

3) Separate Housing (R) from Housing (L) by removing eight PT3x16 Tapping screws.

4) Remove the assembly of Hammer case section and Motor section from Housing (L), and separate Hammer case

section from Motor section.

5) See Fig. 4. Attach 1R041 (2 pcs) to vise. Fix 134848-9 in vise securely. Put Hammer case section on 134848-9

while fitting the hexagonal portion of Bearing box complete in 134848-9. Fit another 134848-9 over the hexagonal

portion of Hammer case complete. By turning 134848-9 clockwise with 1R223 and 1R224, the Hammer case section

can be disassembled as illustrated to right.

Fig. 4

134848-9

1R041

1R223

1R224

Fit 134848-9 over

this hex portion.

Hammer case section

Bearing box complete

1R041

Vise

Hammer case complete

Hammering mechanism

Internal gear 51

O ring 40

Bearing box complete

134848-9

Loading...

Loading...