Makita Makstar BSS610 Technical Information

T

ECHNICAL INFORMATION

Models No.

BSS610

PRODUCT

P 1 / 7

Description

Cordless Circular Saw 165mm (6-1/2")

CONCEPT AND MAIN APPLICATIONS

Model BSS610 has been developed as our first cordless circular saw that is

powered by 18V/3.0Ah Li-ion battery.

Main features are:

Powerful 360W maximum output, yet still with the extra-lightweight and

compact design achieved by using Lithium-ion battery as power unit

Smooth and powerful cutting at the high rotational speed of 3,700 rpm

delivered from enhanced motor

Easy to trace cutting line with:

a) LED job light

b) Built-in blow-off nozzle that directs sawdust away from cutting line

This new product will be available in the following variations.

Model No.

BSS610SF

BSS610SFE*

BSS610Z No

*Offered as Model BSS610 to USA, Canada, Mexico, and Panama

Battery

type quantity

BL1830

No

1

2

Charger

DC18SC

No

Blade

Yes

carrying case

Plastic

Yes

No

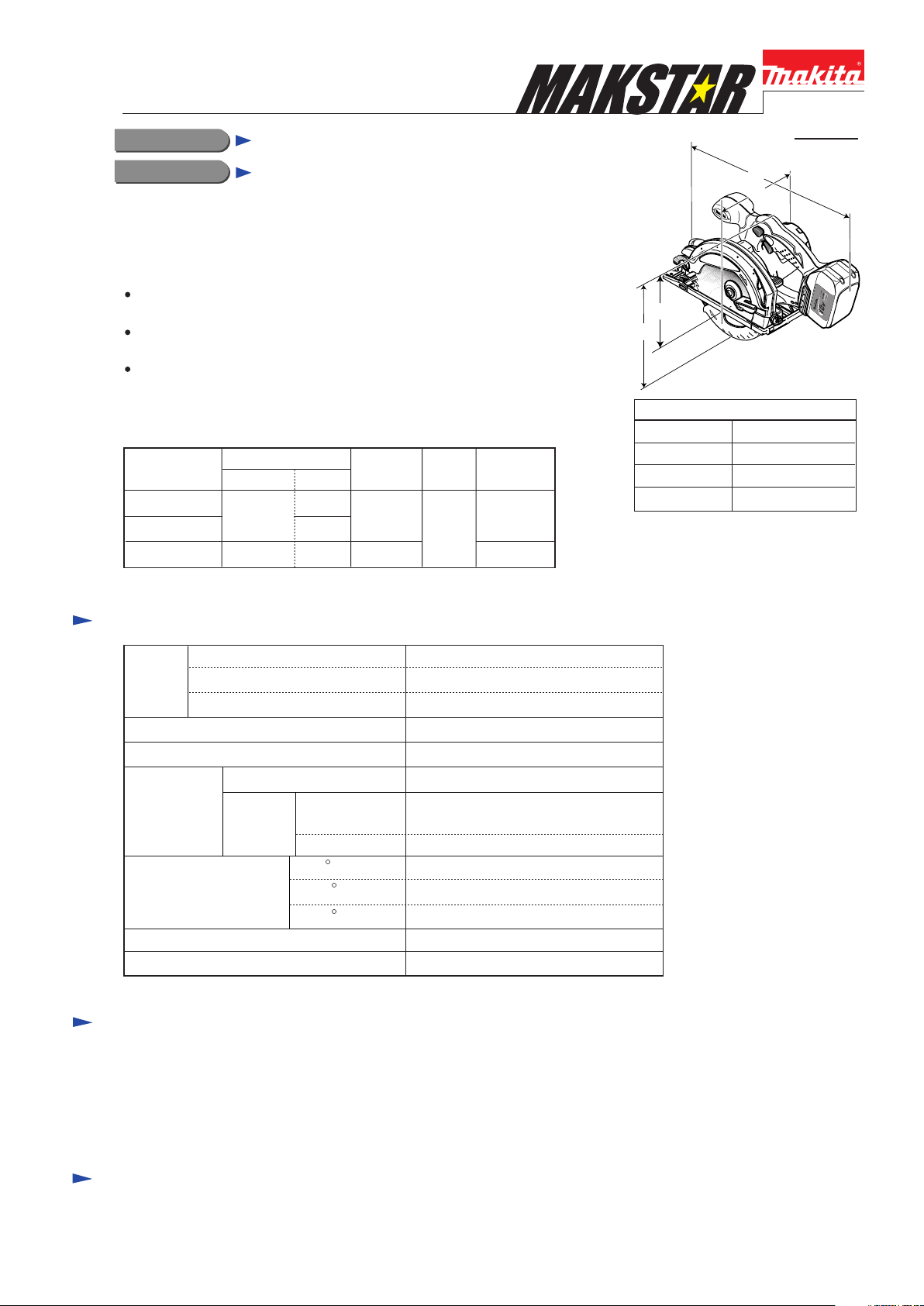

H2

H1

Dimensions: mm (")

Length (L)

Width (W)

Height 1 (H1)

Height 2 (H2)

L

W

347 (13-5/8)

202 (8)

228 (9)

166 (6-1/2)

Specification

Voltage: V

Battery

Max output (W) 360

No load speed: min-1=rpm

Size of blade:

mm (")

Max cutting capacities:

mm (")

Electric brake

Net weight*: kg (lbs)

*Includes battery BL1830

Capacity: Ah

Cell

Diameter

Hole

diameter

Canada, USA,

Mexico, Panama

The others

at 0 57 (2-1/4)

at 45

at 50

18

3.0

Li-ion

3,700

165 (6-1/2)

15.88 (5/8)

20 (13/16)

40 (1-9/16)

36 (1-7/16)

Yes

3.2 (7.1)

Standard equipment

TCT Saw blade 165mm (6-1/2") .................................. 1 pc

Hex wrench 5 ................................................................ 1 pc

Guide rule ..................................................................... 1 pc

Dust nozzle ( exclusively for European countries) ....... 1 pc

Plastic carrying case .................................................... 1 pc

Note: The standard equipment for the tool shown above may differ from country to country.

Optional accessories

Charger DC18SC

Charger DC24SA

Charger DC24SC

TCT Saw blade 165mm (6-1/2")

Li-ion battery BL1830

Repair

CAUTION: Remove Saw blade, Inner flange 40, Outer flange 40, Hex socket head bolt and

Battery cartridge from the machine for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

P 2 / 7

Makita Part No.

1R003 Retaining ring pliers ST-2N

1R026 Bearing setting pipe 16-8.2

1R208 90 Degree set square

1R232 Pipe 30

1R263 Bearing extractor

1R269 Bearing extractor

1R291 Retaining S & R pliers

1R340 Bearing retainer wrench

Descriptions Purpose

Removing / Mounting retaining ring

Removing helical gear 52

Adjusting the right angle of saw blade to base plate

Holding bearing box, when removing helical gear 52

Bearing extractor

Bearing extractor

Removing / Mounting retaining ring

Removing / Mounting bearing retainer

Triangular rule

Adjust the saw blade's angle of 45 degree to base plate

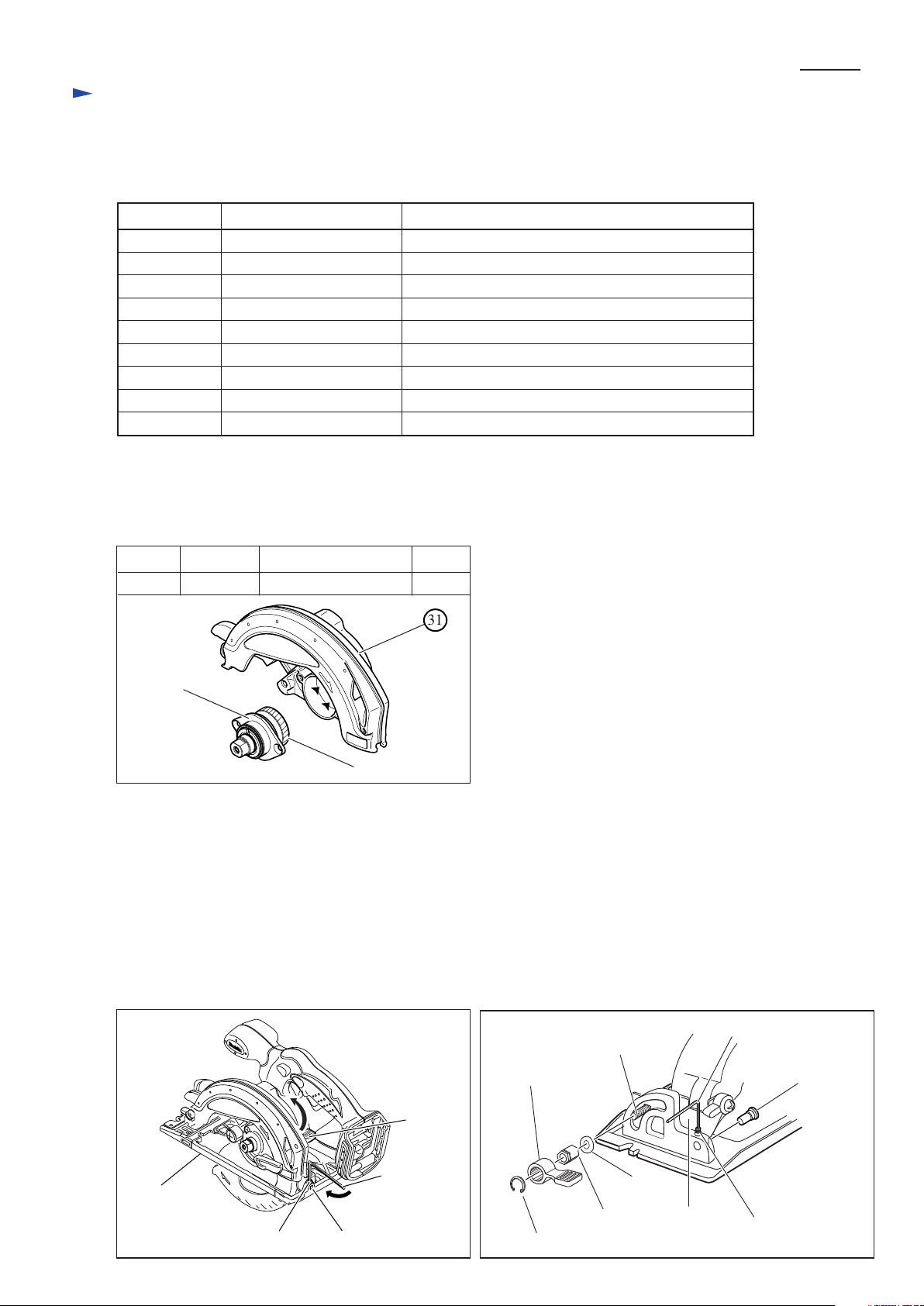

[2] LUBRICATION

Put Makita grease N. No.1 into the gear room indicated by the black triangle to protect parts and product from unusual

abrasion. See Fig.1.

Fig.1

Item No. Parts item Portion to be lubricated

31 Blade case

Gear room

Amount

6g

Bearing box

Helical gear 52

[3] Replacing Base complete

1. Loosen M5x6 Hex socket head set screw for fixing Depth guide to Base complete. See Fig.2.

Loosen Lever 40 and remove Shoulder pin 6-7 for connecting Depth guide and Base complete.

2. Remove the following parts as shown in Fig.3. Base complete can be separated from the machine.

A) Shoulder pin 6-7 for connecting Angular guide and Base complete

B) Stop ring E-8, M6 Hex nut, Flat washer 6 and M6x20 Cap square neck bolt for securing Lever 30

3. Reuse the above parts (for example, Mx6 Hex socket head screws) to replace the current base complete by the new one.

Note: M6 Hex nut in Lever 30 is not interchangeable with M6 Hex nut in Lever 40.

The former has left handed threads, the latter has right handed threads.

Fig. 2

Lever 40

Fig. 3

Lever 30

Cap square

neck bolt M6x20

Hex wrench

Shoulder pin 6-7

Base complete

Hex. wrench

M5x6 Hex socket set screw Shoulder pin 6-7

Stop ring E-8

Flat washer 6

Hex nut M6

Angular guide

Hex socket head

set screw M5x6

Repair

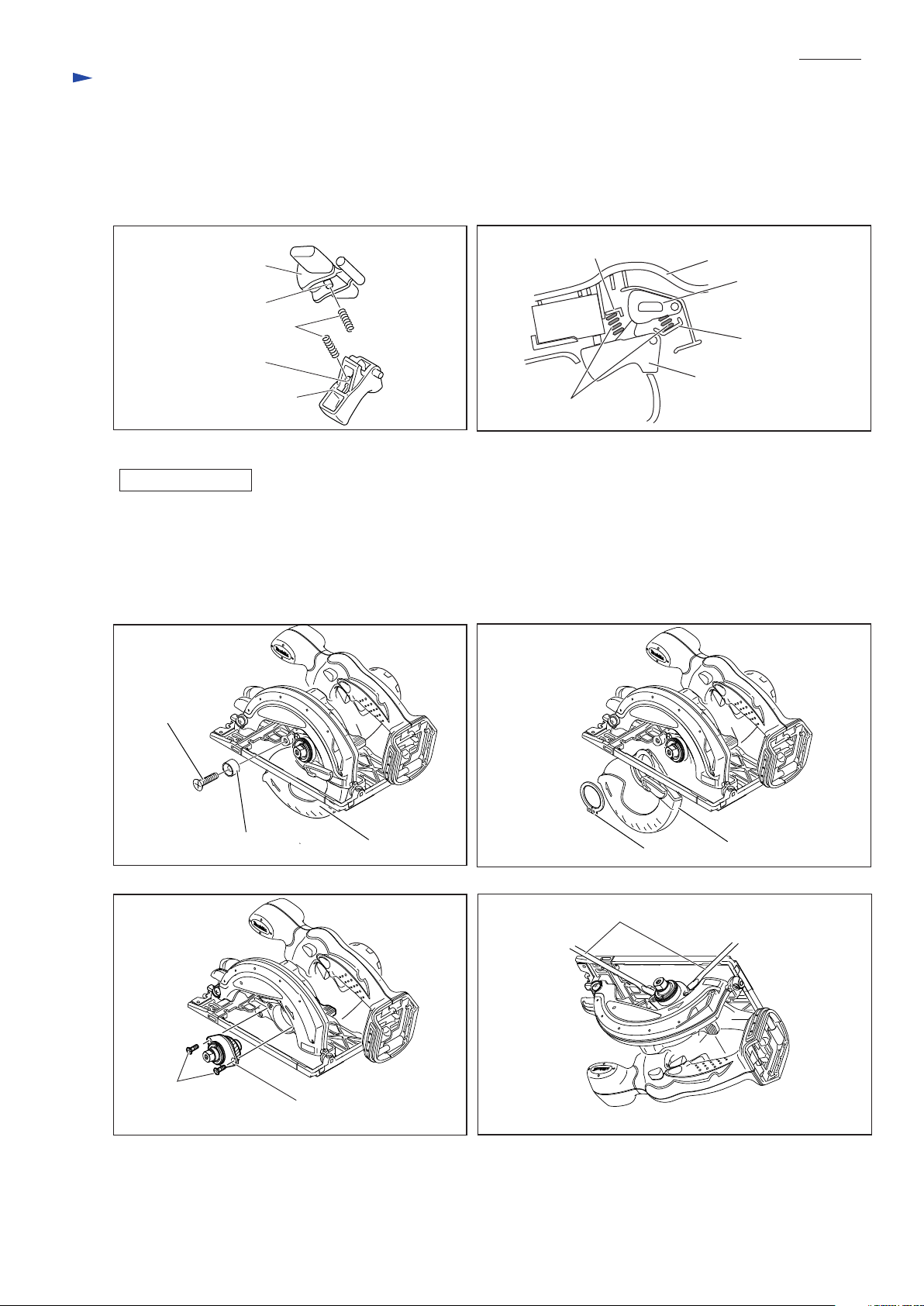

[4] Assembling Lock Off Lever and Switch Lever

1. Compression spring 4 for Lock off lever and Compression spring 4 for switch lever are the same.

Insert the bosses of Lock off lever and Switch lever into the compression springs 4 as illustrated in Fig.4.

2. Put their assembled parts into places as illustrated in Fig.5 so that the Compression springs 4 can perform well

between the bosses and the Ribs of Housing L.

Fig.4

Fig.5

P 3 / 7

Housing L

Lock Off lever

Rib

Switch lever

Lock off lever

Boss

Compression spring 4

Boss

Switch lever

Rib

Switch

Compression spring 4

[5] Disassembling/Asssembling Safety Cover and Bearing Box (Gear Section)

DISASSEMBLING

1. Remove Rubber ring 6 together with M6 countersunk head screw as illustrated in Fig.6.

2. Remove retaining ring S-34 with No.1R003 "Retaining pliers ST-2N". Safety cover can be separated from the machine

as illustrated in Fig.7.

3. Remove Bearing box by unscrewing two M5x16 countersunk head screws as shown in Fig.8. If it is difficult to remove

the Bearing box by hand, lever it up with 1R263 "Bearing extractor" as shown in Fig.9.

Fig.7Fig.6

Countersunk

head screw M6

Fig. 8

Countersunk head

screw M5x16

Rubber ring 6

Bearing box

Safety cover

Fig. 9

Retaining ring S-34

1R263 Bearing extractor

Safety cover

Loading...

Loading...