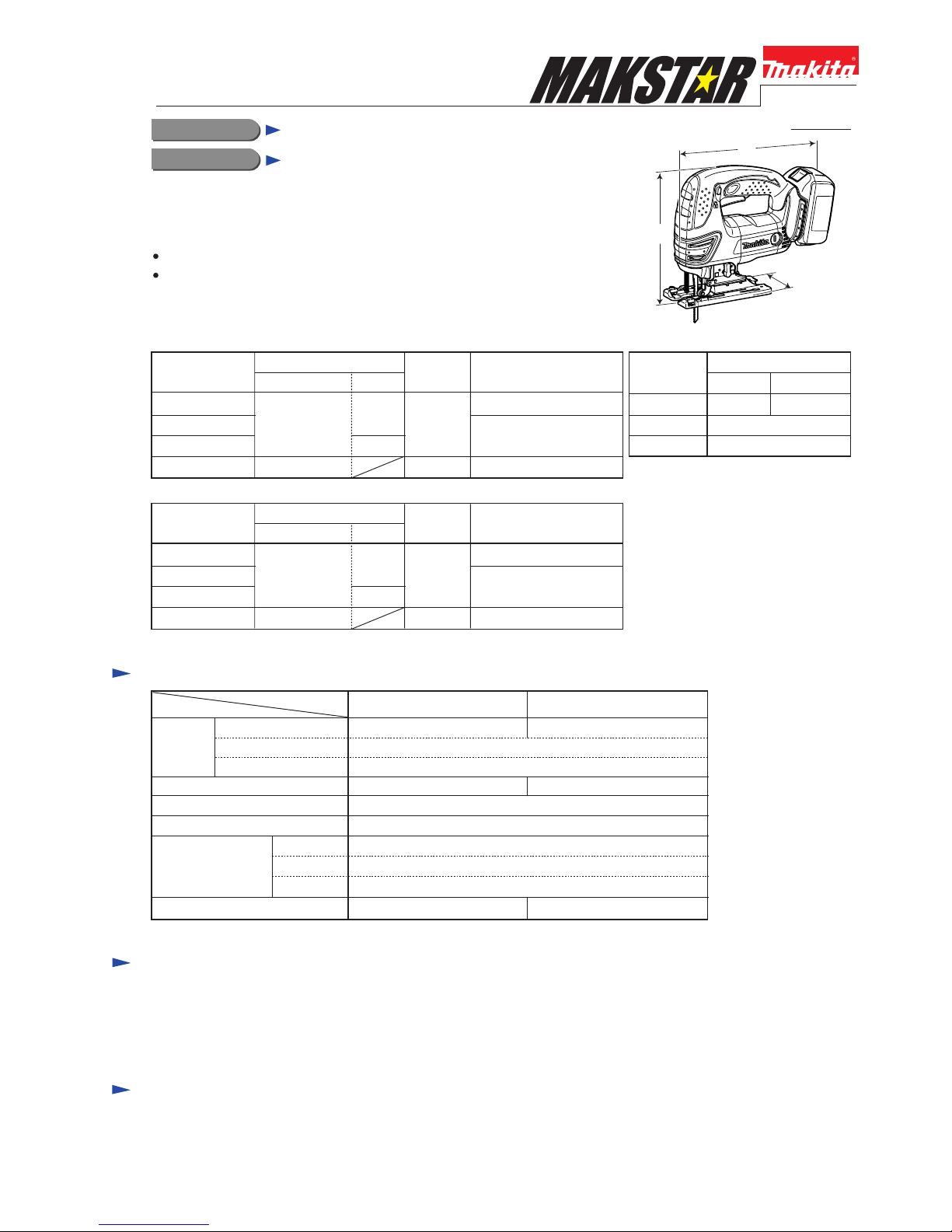

Makita Makstar BJV140, Makstar BJV180 Technical Information

Models No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

P 1 /13

Note: The standard equipment for the tool shown above may differ by country.

BJV140, BJV180

Cordless Jig Saw

Models BJV140 and BJV180 are MAKSTAR cordless jig saws powered by

3.0Ah Li-ion battery, featuring;

Compact and lightweight design

The same mechanism as used for the popular AC jig saw Model 4340FCT

Jig saw blade assortment ......... 1 set*3

Cover plate ............................... 1 pc

Anti-splintering device ............ 1 pc

Hex wrench 4 ........................... 1 pc

Dust nozzle .............................. 1 pc (for European countries only)

Plastic carrying case ................ 1 pc

Jig saw blades

Guide rule set

Guide rail

Guide rail adapter set

Anti-splintering device

Hose complete 28-5

Dust nozzle

Battery BL1430 (for BJV140 only)

Battery BL1830 (for BJV180 only)

Fast charger DC18RA

Charger DC18SC

Charger DC24SA (for North America only)

Charger DC24SC (for all countries except North America)

Battery

Specification

Net weight*2: kg (lbs)

Capacity: Ah

Cell

Voltage: V

18

No load speed: strokes per min.

SteelCapacities: mm (")

Wood*1

10 (3/8)

Aluminum 20 (25/32)

135 (5-5/16)

2.8 (6.1)

14.4

2.7 (5.9)

3.0

Li-ion

250 340

0 - 2,600

Length of stroke: mm (") 26 (1)

*1 when cutting with optional blade No.B-16L *2 with battery

Max output (W)

Model

BJV140 BJV180

L

H

W

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 255 (10) 257 (10-1/8)

BJV140 BJV180

73 (2-7/8)

208 (8-3/16)

T

ECHNICAL INFORMATION

These products available in the following variations.

All models also include the accessories listed below in "Standard equipment".

BJV140

BJV140RFE

BJV140Z

BJV140

BL1430

(Li-ion 3.0Ah)

DC18RA

No No

Model No.

type quantity

Charger Offered to

All countries

North America

All countries other than

North America

2

BJV140RF 1

Battery

BJV180

BJV180RFE

BJV180Z

BJV180

BL1830

(Li-ion 3.0Ah)

DC18RA

No No

Model No.

type quantity

Charger Offered to

All countries

North America

All countries other than

North America

2

BJV180RF 1

Battery

(Illustrated above is BJV180.)

*3 includes each 2 pcs of B-10, BR-13, B-22

P 2 /13

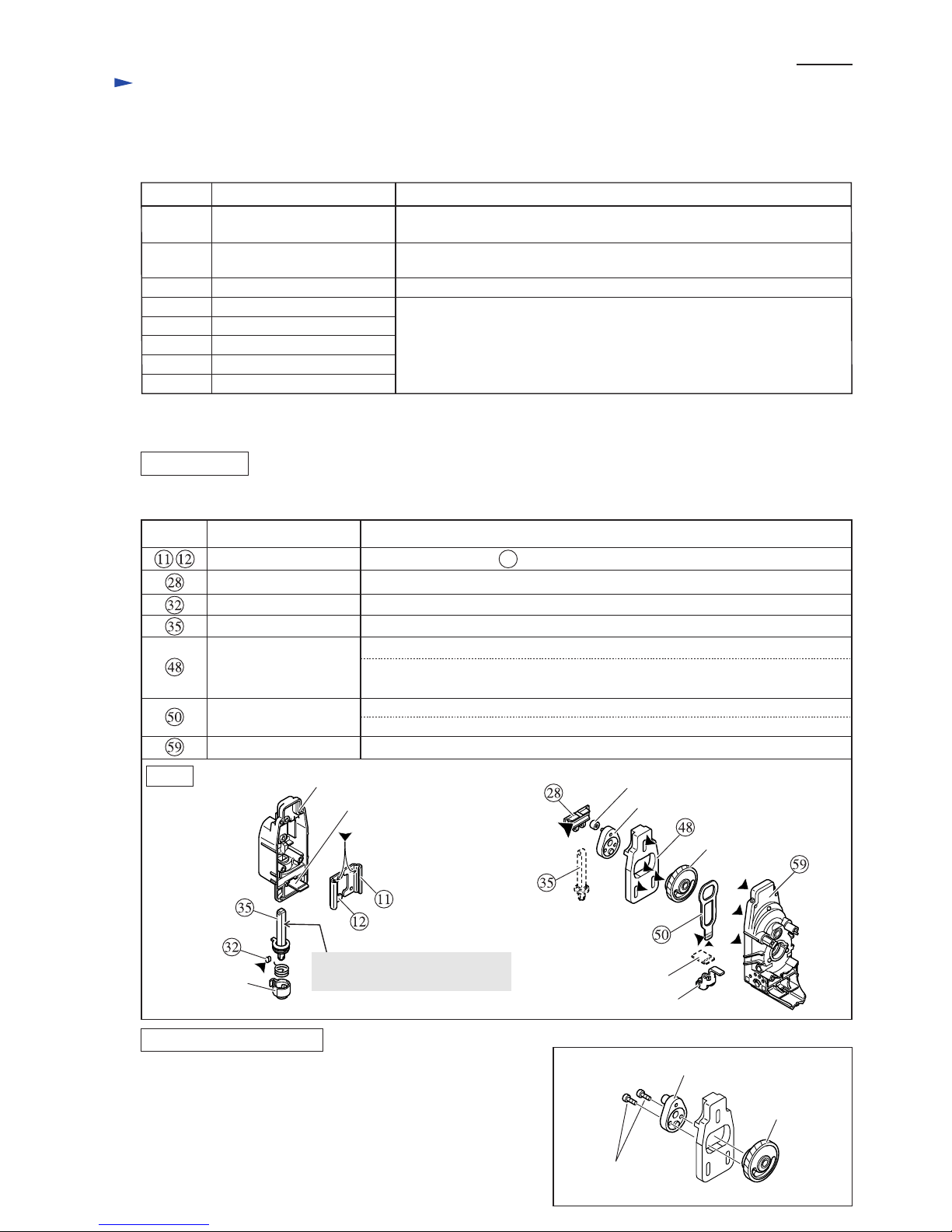

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the jig saw blade from the machine for safety before repair/ maintenance,

in accordance with the instruction manual!

Repair

1R235 Round bar for arbor 6-100

Locking Crank complete when removing/fastening

M4x12 Hex socket head bolt

1R291 Retaining ring S and R pliers

Removing/installing Retaining ring S-8 from/on the shaft portion

of Gear housing Complete

1R220 Ratchet head 9.5

1R222 Socket adaptor

1R254 Torque wrench shaft 2-6N.m

Removing/fastening M4x12 Hex socket head bolt from/to Crank complete

A-33750 Bit adaptor assembly

1R228* 1/4 Hex shank bit M4

1R311 Retaining ring pliers Removing/installing Retaining ring R-18 from/on Blade holder

DescriptionCode No. Use for

Fig. 1

Linear guide Groove portion where 28 Slider slides

Seal plate

Seal plate

Retainer

Blade holder

Gear housing cover complete

Needle bearing 407

Gear complete

Crank complete

Balance plate

Push plate

Gear housing complete

Push pin Whole surface

Surface that contacts Gear housing cover complete

Surface that contacts Retainer

Upper, middle and lower portions of gear room

Surface that contacts Seal plate when Push plate moves downward

Inside surface of the large elliptic hole that contacts Gear complete

Each inside surface of the three small elliptic holes that contacts

corresponding pin on Gear housing complete

Slider

Rod

Groove portion where Needle bearing 407 slides

Item No. Description Portion to lubricate

*1R014 (1/4 Hex shank bit M4) can also be used.

[2] LUBRICATION and ADHESIVE APPLICATION

Apply Makita grease FA. No.2 to the following portions designated with the black triangle

to protect parts and product from unusual abrasion.

If you remove M4x12 Hex socket head bolt from Crank complete,

be sure to apply Loctite 241/242 or Threebond 1321/1342 to the bolt

when reinstalling. (Fig. 2)

LUBRICATION

ADHESIVE APPLICATION

Fig. 2

Gear complete

Crank complete

Hex socket head

bolt M4x12

Apply machine oil #120 here

for smooth reciprocating of Rod.

P 3 /13

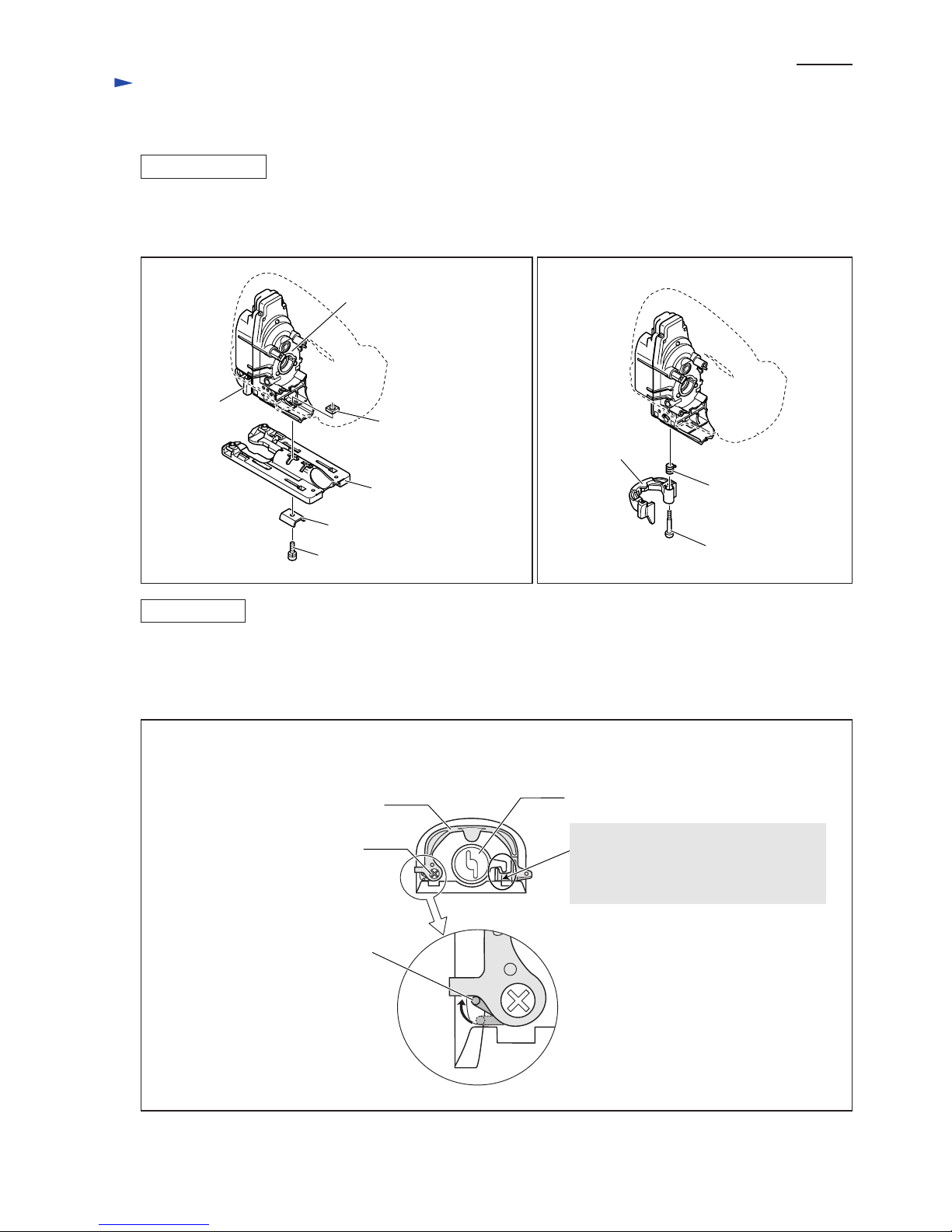

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Tool Opener

Repair

ASSEMBLING

1) Remove Base from Gear housing cover complete by unscrewing M5x18 Hex socket head bolt. (Fig. 3)

2) By unscrewing M4 + Pan head screw, Tool opener can be disassembled from Gear housing cover complete together

with Torsion spring 6. (Fig. 4)

1) Put Torsion spring 6 in the through hole of Tool opener, then fasten Tool opener to Gear housing cover complete

with M4 + Pan head screw. (Fig. 4)

2) Set the end of Torsion spring 6 in place by turning clockwise (viewed from the side of Base) with a small slotted

screwdriver or the like. (Fig. 5)

Tool opener

Torsion spring 6

+ Pan head screw M4

Fig. 3 Fig. 4

Fig. 5

Tool opener assembled to Gear housing cover complete

(viewed from Base side)

Blade holder

Tool opener

end of Torsion spring 6 set in place

Base

Square nut M5-8

Gear housing cover complete

Clamp plate

Hex socket head bolt M5x18

Tool opener

+ Pan head screw M4

Be sure to engage this end of Tool opener

with the hook of Blade holder.

Otherwise, you can not turn Blade holder

with Tool opener when changing blade.

DISASSEMBLING

P 4 /13

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear Housing Cover Section

Repair

1) Remove seven Tapping screws that fasten Handle (R) to Handle (L). (Fig. 6)

2) Remove Handles (R) and (L) from Motor housings (R) and (L) as illustrated in Fig. 6A.

3) Separate Gear housing cover section from Gear housing complete by unscrewing four CT4x16 Tapping screws.

(Fig. 7)

Fig. 6

Fig. 7

Tapping screw CT4x16 (4 pcs)

Gear housing cover section

Packing

Gear housing complete

Motor housing (R)

Motor housing (L)

Gear housing

cover section

Gear housing cover section side

Handle (R)

Handle (L)

Motor housing (L)

Fig. 6A

Motor housing (R)

A

Tapping screws that fasten

Handle (R) to Handle (L):

A: Tapping screw 4x18 (5 pcs)

B: Tapping screw 4x40 (1 pc)

C: Tapping screw 4x50 (1 pc)

B

C

A

By pulling Handles (R) and (L)

towards Gear housing cover

section side, each hook portion

of Handles (R) and (L) can be

disengaged from the notch between

Motor housings (R) and (L).

If you are disassembling Gear housing cover section

without removing Tool opener, unscrew this Tapping

screw while opening Tool opener fully.

DISASSEMBLING

Loading...

Loading...