Makita MAKSTAR BJR240SH, MAKSTAR BJR240SF Technical Information

Models No.

Description

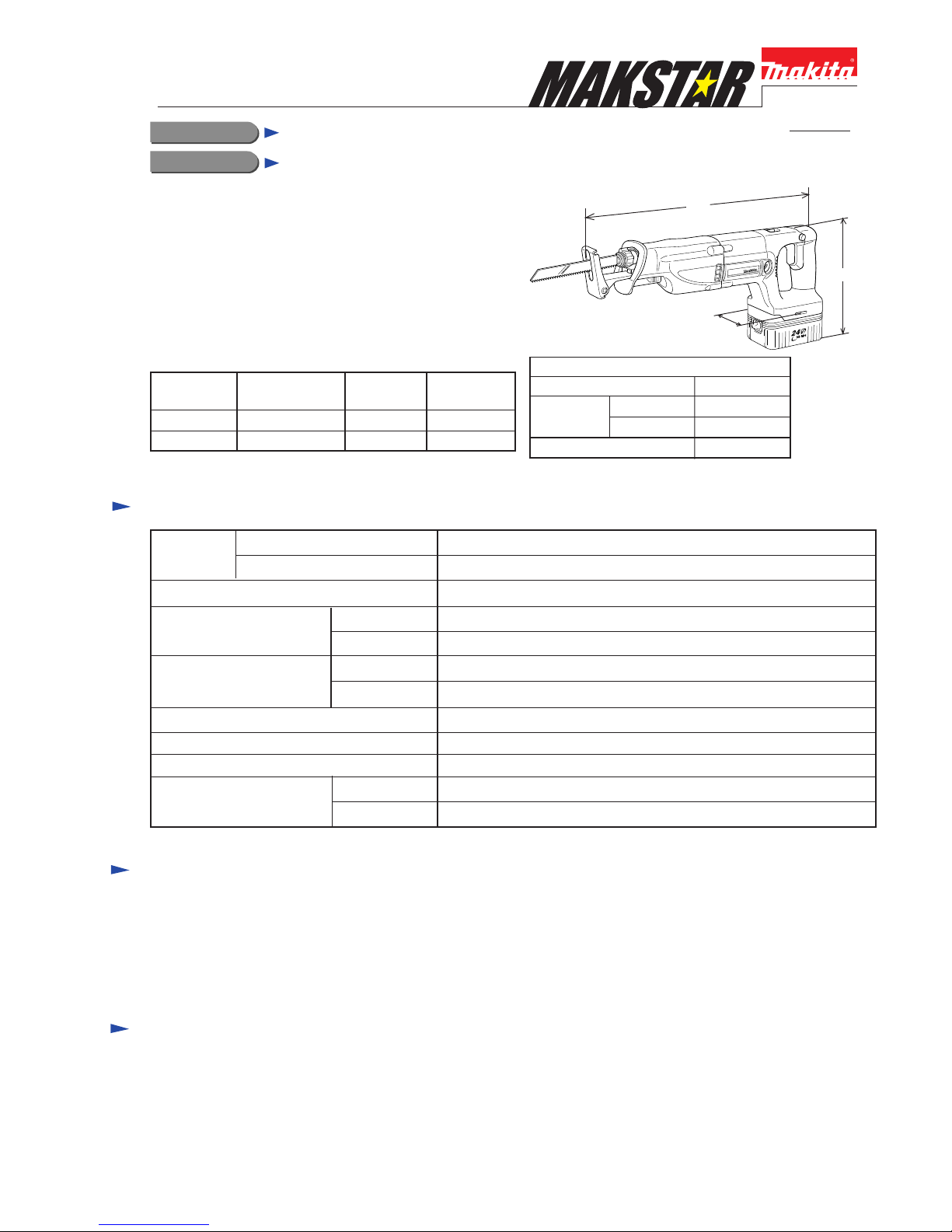

PRODUCT

T

ECHNICAL INFORMATION

CONCEPTION AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 /15

BJR240

Cordless Recipro Saw

Dimensions : mm ( " )

Width ( W )

Height ( H )

Length ( L )

469 (18-1/2)

230 (9)

255 (10)

88 (3-1/2)

L

W

H

The above model has been developed to be added to MAKSTAR

series models which are featuring New Charging System.

Other features and benefits are

* The fastest cutting speed among the cordless recipro saws

* Incredible low vibration with counterbalancing system

in its gear unit.

* Tool-less features for easy and rapid changing recipro saw blade

and for easy adjusting shoe

The variations of this model are listed below.

w /B2430

w /B2417

Battery

Voltage : V

Capacity : Ah

Length of Stroke

Strokes per Minute

:spm.(min-1)

High

Low

Cutting

capacity: mm (")

Pipe

Wood

Electric brake

Variable switch

Speed change

Net Weight : Kg (lbs)

with B2417

with B2430

32 mm (1-1/4")

0 - 2,700

0 - 2,300

24

4.4 (9.7)

4.9 (10.8)

ø 90 (3-1/2)

90 (3-1/2) in thickness

1.7 with Battery B2417 3.0 with Battery B2430

Yes

Yes

Yes (Electric 2 speed)

Model No.

BJR240SH B2417 (1.7Ah) DC24SA

Battery Charger

Q'ty of

Battery

1 pc.

BJR240SF B2430 (3.0Ah) DC24SA

1 pc.

* Recipro saw blade No.21 for steel ......................... 1 pc.

* Recipro saw blade No.22 for steel ......................... 1 pc.

* Recipro saw blade No.23 for wood ....................... 1 pc.

* Plastic carrying case ............................................... 1 pc

* Various recipro saw blades

* Charger DC24SA

* Battery B2417

* Battery B2430

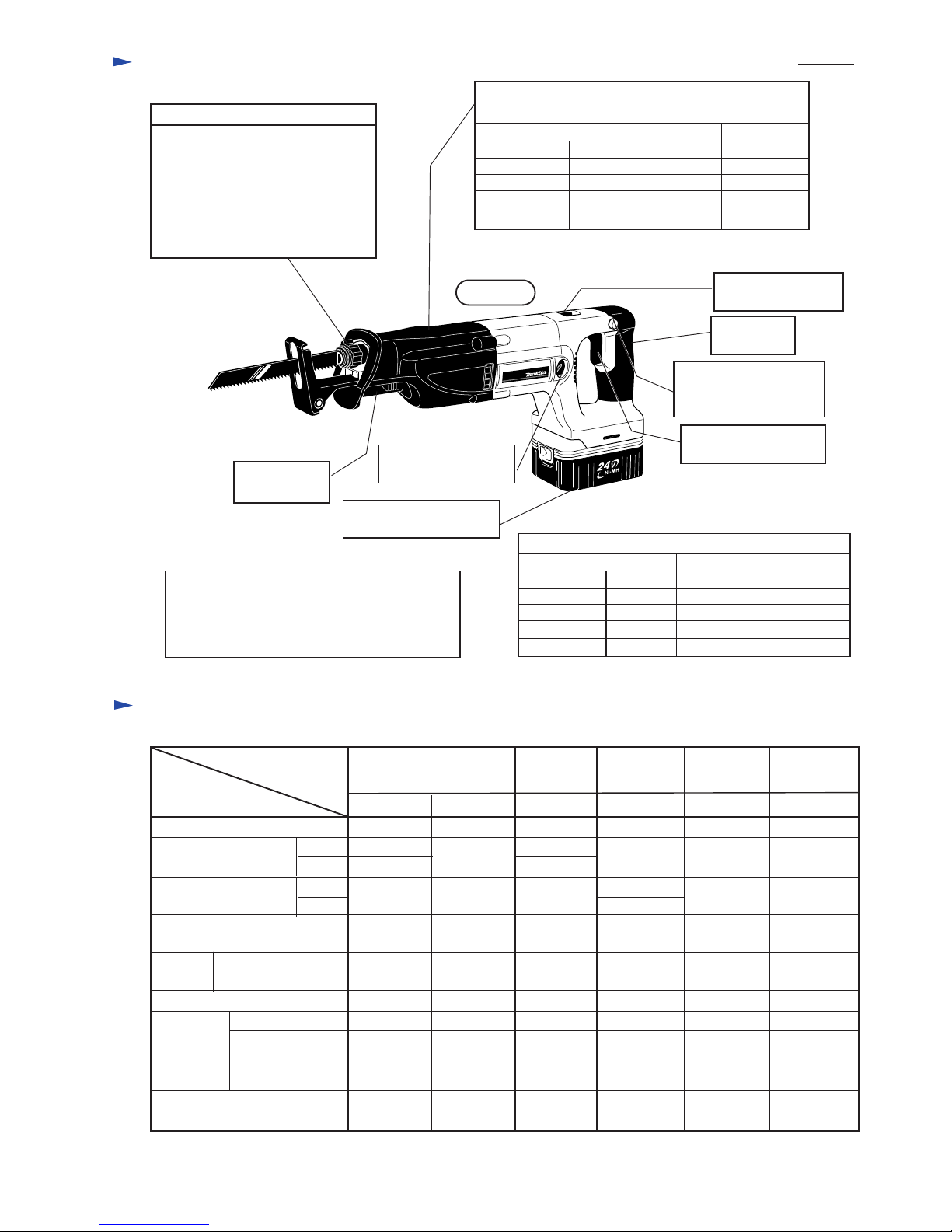

Features and benefits

P 2 / 15

BJR240

Incredible low vibration with counterbalancing

system in its gear unit.

Model No.

LoadedNo loaded

BJR240 8.7m/sec.2 10.3m/sec.2

Mod. A 11.5m/sec.2 19.8m/sec.2

Mod. B 20.4m/sec.2 20.9m/sec.2

Mod. C 14.4m/sec.2 16.2m/sec.2

Mod. D

8.1m/sec.2 9.4m/sec.2

MAKITA

Lower noise level

Comparison of the specifications

Model No.

LoadedNo loaded

BJR240 82 dB 94 dB

85 dB 94 dB

85 dB

85 dB

94 dB

97 dB

95 dB91 dB

MAKITA

BJR240

MAKITA

The figures on loaded condition are based on

the cutting of chip board 19mm in thickness.

The figures on loaded condition are based on

the cutting of chip board of 19mm in thickness.

Push-in Lock System has

made it possible to install

the blade quickly.

New tool-less blade change system

Lock off push-out system has

enabled to take off the hot saw

blade of just after work, without

touching it.

Externally accessible

carbon brush

Tool-less shoe

adjustment

Electric High /Low

speed change switch

Palm fitting

soft grip

Lock off button can be

pushed from both of left

and right.

Switch with big trigger

for easy operation

24V Ni-MH Battery with

new charging system

The fastest cutting speed among

the cordless recipro saws.

See the graph in "Comparison of Products"

at page 3.

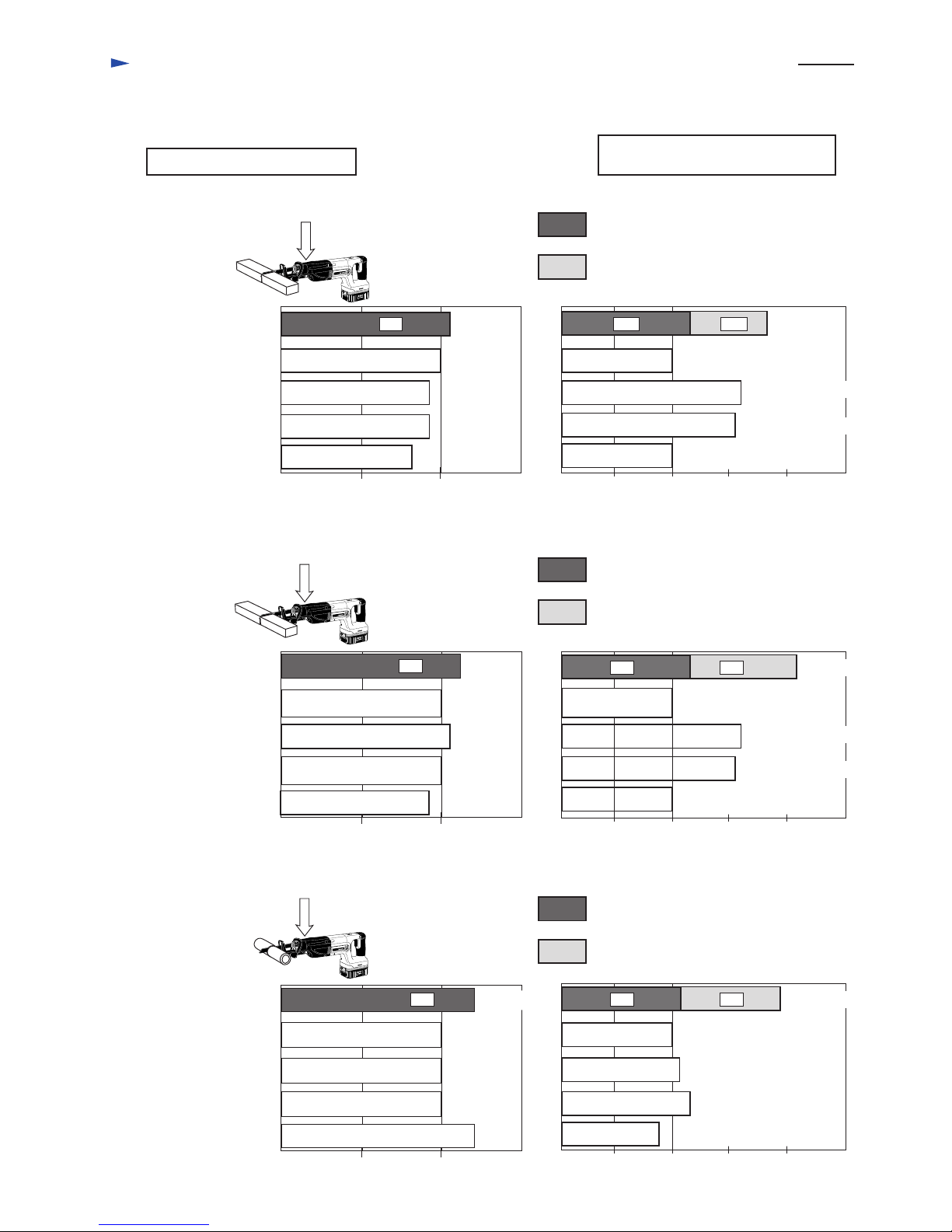

Comparison of products

Model No.

Specifications

Voltage

Tool-less

system

Length of Stroke

: mm (1-1/4")

Strokes per

Minute :spm.(min-1)

High

Dimensions

including

battery

Weight including

battery :Kg (lbs)

Low

High

Low

Suppressing the vibration

Externally accessible brush

for replacing blade

for adjusting shoe

Palm fitting soft grip

Height : mm(")

Width : mm(")

Length : mm(")

32 (1-1/4)

0 - 2,700

0 - 2,300

24

Yes

Yes

Yes

Yes

Yes

469 (18-1/2)

230 (9)

*255 (10)

88 (3-1/2)

4.4 (9.7)

*4.9 (10.8)

29 (1-1/8) 28 (1-1/8) 25 (1)

0 - 2,900

0 - 2,900

0 - 2,400

24

Yes

Yes

Yes

463 (18-1/4)

232 (9-1/8)

80 (3-1/8)

3.9 (8.6)

JR180D

23 (7/8)

0 - 2,700

18

No No

No

Yes

No

Yes

Yes

NoYes

Yes

Yes

No

447 (17-5/8)

206 (8-7/8)

95 (3-3/4)

3.5 (7.7)

32 (1-1/4)

19 (3/4)

0 - 2,300 0 - 2,600

24 24 19.2

No No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

495 (19-1/2)

213 (8-3/8)

76 (3)

448 (17-5/8)

240 (9-1/2)

83 (3-1/8)

3.9 (8.6) 4.3 (9.5)

393 (15-1/2)

202 (8)

76 (3)

4.5 (9.9)

*255 (10) and *4.9 (10.8) are the data when battery B2430 is attached.

Competitor A

Competitor B

Competitor C

Competitor D

Mod. A

Mod. B

Mod. C

Mod. D

Mod. D

Competitor A

Competitor B

Competitor C

Competitor D

Mod. A

Competitor

A

Competitor

B

Competitor

C

Competitor

D

Mod. B Mod. C

Comparison of products

P 3 / 15

Comparison of the cuting speed

Comparison of the working amount

per one full charged battery pack

Testing conditions

Material : Spruce (Wood) 2" x 10"

Pressure load ; 5 kg.f

Testing conditions

Material : Spruce (Wood) 2" x 10"

Pressure load ; 7 kg.f

Testing conditions

Material : Steel Pipe ø 1"

Pressure load ; 5 kg.f

MAKITA

BJR240

Competitor C

Model C

Model D

Competitor D

Competitor A

Model A

Competitor B

Model B

0 50 100 50 100150 150 200 250

100 100

100

165

160

100

165

160

MAKITA

BJR240

0 50 100 150

100

100

MAKITA

BJR240

0 50 100 150

100

100

100

80

105

95

95

(7.5 sec.)

(5.5 sec.)

110

105

105

95

120

120

Numbers in graph below are relative values when setting capacity of competitor A's model as 100.

(21 sec.)

50 100 150 200 250

100

50 100 150 200 250

100

110

120

80

: Amount with 1.7Ah battery B2417

: Whole amount with 3.0Ah battery B2430

: Amount with 1.7Ah battery B2417

: Whole amount with 3.0Ah battery B2430

: Amount with 1.7Ah battery B2417

: Whole amount with 3.0Ah battery B2430

120

120

110

180

210

195

with 1.7Ah battery

with 1.7Ah battery

with 1.7Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

with 2.0Ah battery

< Note > The data mentioned below may differ depending on the conditions of batteries' temperature,

room temperature, materials,etc.

27 / 47cuts

29 / 51cuts

11 / 19cuts

Competitor C

Model C

Model D

Competitor D

Competitor A

Model A

Competitor B

Model B

Competitor C

Model C

Model D

Competitor D

Competitor A

Model A

Competitor B

Model B

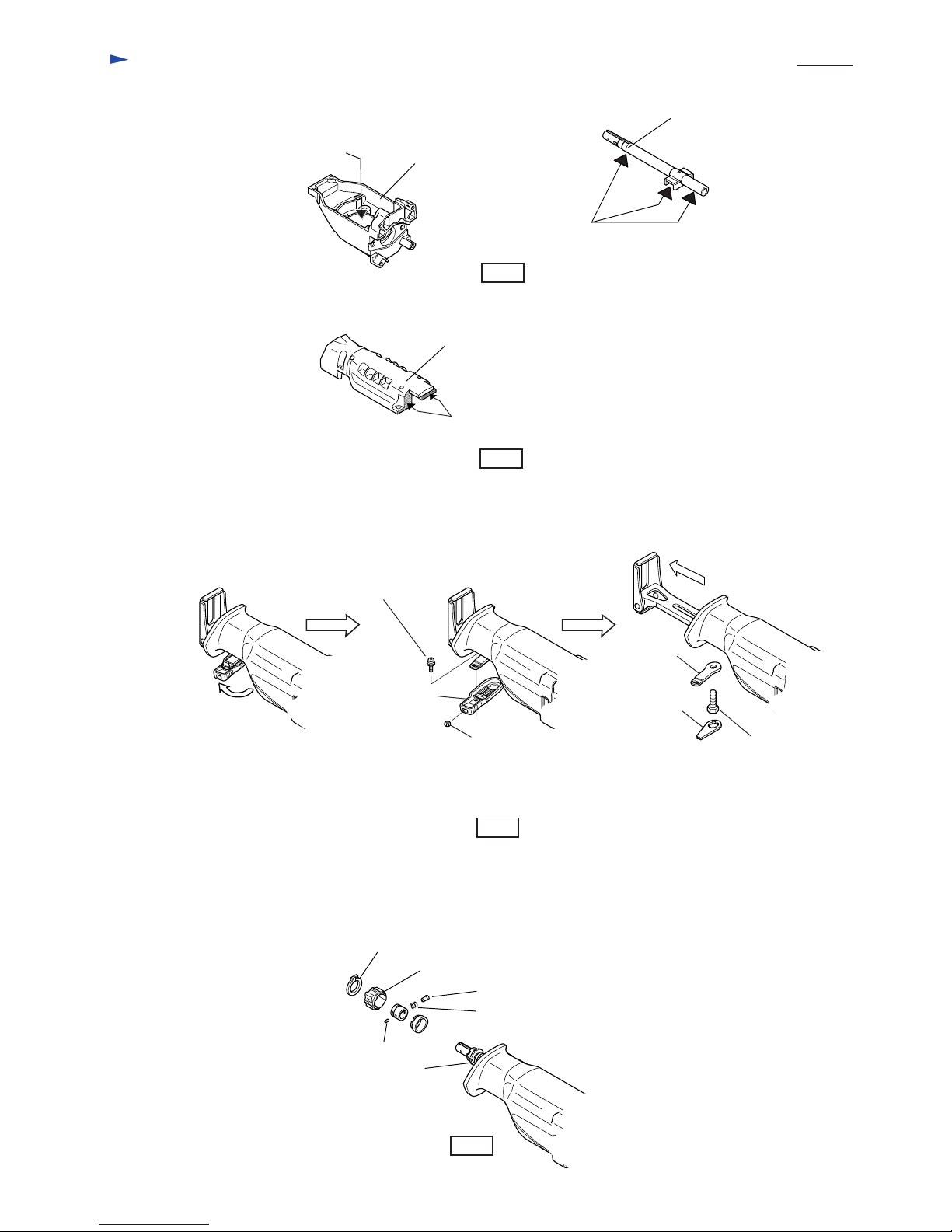

Repair

P 4 / 15

< 1 > Lubrication

Apply MAKITA grease N No.1 to the following portions marked with black triangle to protect parts and machine

from unusual abrasion. See Fig. 1.

< 2 > Sealing

< 3 > Disassembling and assembling

Apply three bond 1215 to the following portion of gear housing cover which joins to gear housing, when assembling.

See Fig. 2.

(1) Removing shoe

Turn lever 60 (adjusting lever for shoe), and take off pan head screw M4x10. Then, lever 60 can be removed.

Take off hex bolt M8x25 (This hex bolt can be unscrewed by using lock lever as a wrench.), and inner plate.

Remove shoe by pulling out. See Fig. 3.

(2) Disassembling blade clamp section

Remove shoe as mentioned above. Pull out the blade clamp section, if it stays near gear housing.

1. Take off retaining ring S-18 with No.1R291 "Snap ring plier".

2. Take off driving sleeve, shoulder pin 5, compression spring 6,

pin 3, guide sleeve and driving sleeve guide from slider.

Apply 7g.

Slider

Apply 12g.

Gear housing

Apply here three bond 1215

for sealing.

Gear housing cover

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Turn lever 60

(adjusting lever for shoe).

Take off pan head screw M4x10.

<Note> Be careful, not to lose

hex nut M4 in lever 60.

Pan head screw

M4x10

Lever 60

Hex nut M4

Lock lever

Inner plate

Hex bolt M8x25

Pull out shoe.

Retaining ring S-18

Driving sleeve

Compression spring 6

Shoulder pin 5

Pin 3

Sleeve

Repair

P 5 / 15

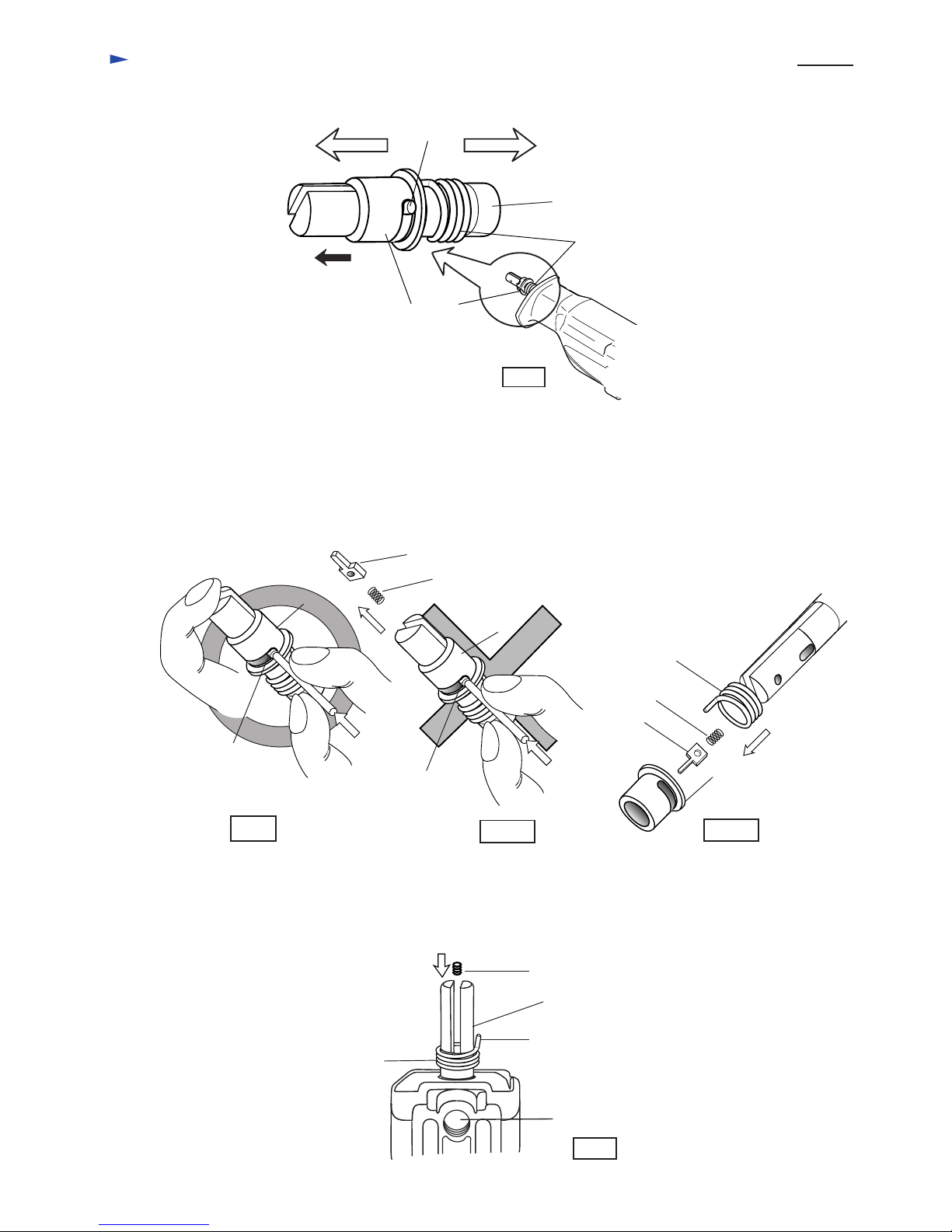

3. Sleeve is in the lock position. In order to free from lock position, pull sleeve toward the blade installing side.

(When the sleeve is free from lock, pin 3 (long) is at the position illustrated in Fig. 5.

4. Holding the top of slider with your finger, remove sleeve by pushing pin 3 (long) with a small sticker

through slider as illustrated in Fig. 6.

< Note > When removing sleeve, always hold the top of slider with your finger as illustrated in Fig. 6.

Otherwise, push plate and compression spring 2 can spring out from slider as illustrated in Fig. 6A,

and they will get lost.

After removing sleeve, take off push plate, compression spring 2 and torsion spring 17 from slider

as illustrated in Fig. 6B.

Fig. 5

Sleeve

Pin 3 (long)

Torsion spring 17

Slider

Blade installing side

Gear housing side

Pull the sleeve to this

direction.

Fig. 6

Fig. 6A

Push plate

Compression spring 2

Fig. 6B

Torsion spring 17

Compression spring 2

Push plate

Sleeve

Sleeve

Pin 3

Pin 3

Sleeve

(3) Assembling blade clamp section

1. Assemble torsion spring 17 to slider. And then, set compression spring 2 into slider.

<Note> Pay attention to the position of the tail of torsion spring 17. It has to come to the right side

in the view from the side of shoe adjusting bolt M8x25, as illustrated in Fig. 7.

Torsion spring 17

Slider

The tail of

torsion spring 17

Compression spring 2

Threaded hole for hex bolt M8x25

Fig. 7

Loading...

Loading...