Makita BTD129, LXDT08 Series Technical Information

Models No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 12

BTD129 (LXDT08)*1

Cordless Impact Driver

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

See the model variation list in the next page.

Model BTD129 (LXDT08*

1) Cordless Impact Driver has been developed specially for

light to medium duty fastening applications.

This model is equipped with a basic BLDC motor (BrushLess DC motor) specially

designed to provide, above all, more work amount on a single full battery charge.

This product is powered by 18V-1.3(1.5*4)Ah/ 3.0Ah Li-ion batteries BL1815/ BL1830,

and available in the variations listed in the next page.

Battery

No load speed: min.

ˉ¹=rpm

Impacts per min.: min.

ˉ¹=ipm

Max. fastening torque

*5:

N.m (kgf.cm/ in.lbs)

Charging time (approx.): min.

Capacities

Electric brake

Reverse switch

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

Variable speed control by trigger

Capacity: Ah

Cell

Voltage: V

18V

0 - 2,500

0 - 3,200

160 (1,630/ 1,420)

Standard bolt

High tensile bolt

Machine screw

Driving shank

M5 - M14 (3/16 - 9/16")

M5 - M12 (3/16 - 1/2")

Coarse thread screw

22 - 125mm (7/8 - 4-7/8")

M4 - M8 (5/32 - 5/16")

Yes

Yes

Yes

LED job light

Yes

1.3 (2.9)/ 1.5 (3.4)

1.3 (1.5*

4)/ 3.0

Energy capacity: Wh

24 (2.7*

4)/ 54

Li-ion

220

15/ 22 with DC18RC (DC18RA*

4)

6.35mm (1/4") Hex

Max output (W)

*

4 for some countries only

*5 The fastening torque at 3 seconds after seating, when fastening M14 high tensile bolt

*

1 Model number for North and Central American countries

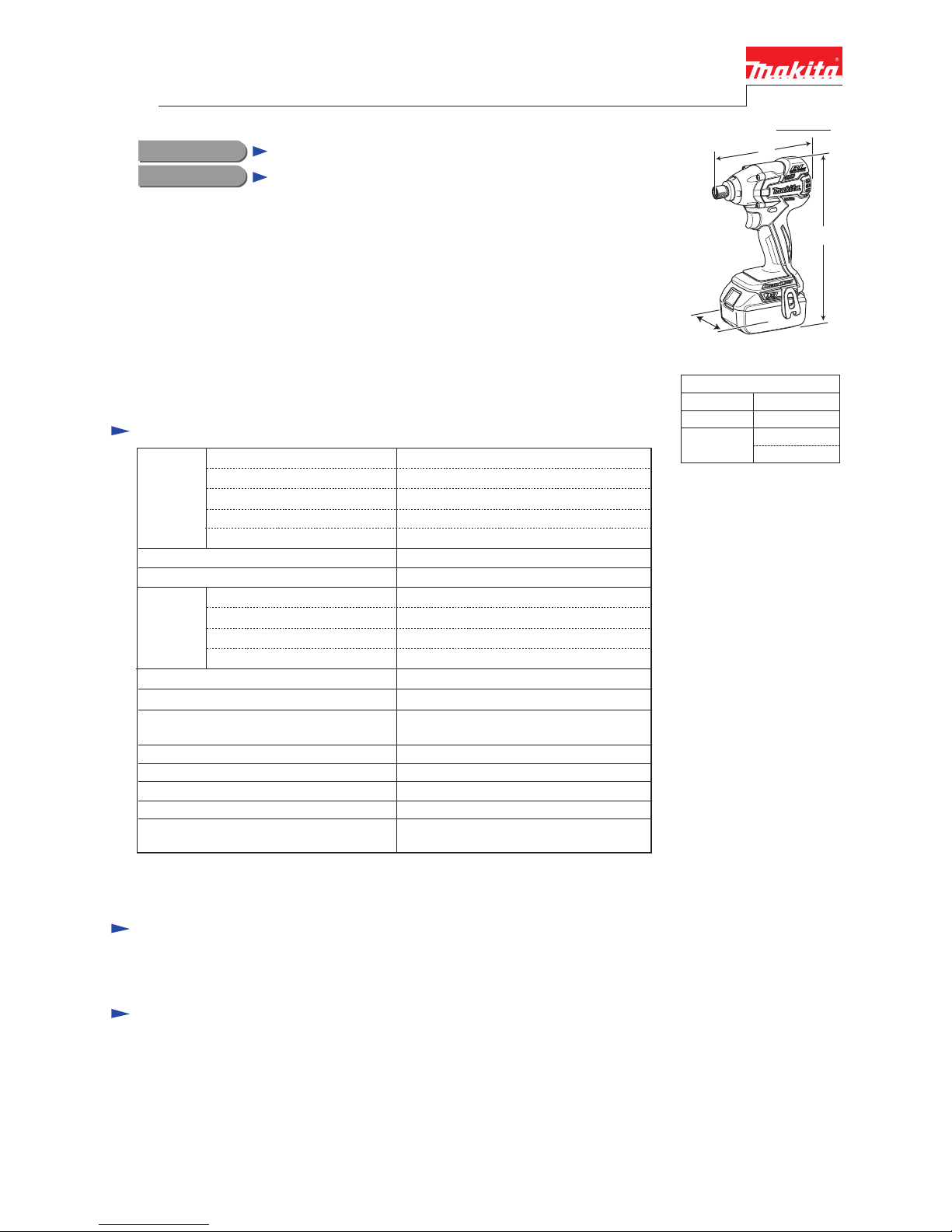

H

W

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

147 (5-7/8)

79 (3-1/8)

226 (8-7/8)*

2

244 (9-5/8)*3

*2: with Battery BL1815

*3: with Battery BL1830

Phillips bits

Socket bits

Drill chucks

Bit piece

Hole saws for Impact driver

Stopper for Impact driver

Hook set (Belt clip)

Drill bits with 6.35mm Hex shank

Battery protectors

Li-ion Battery BL1830

Li-ion Battery BL1815

Fast charger DC18RA

(for USA, Canada, Guam, Panama, Colombia, Mexico)

Fast charger DC18RC

(for all countries except the countries above)

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

L

[Drawn above is the image

with BL1830.]

T

ECHNICAL INFORMATION

P 2/ 12

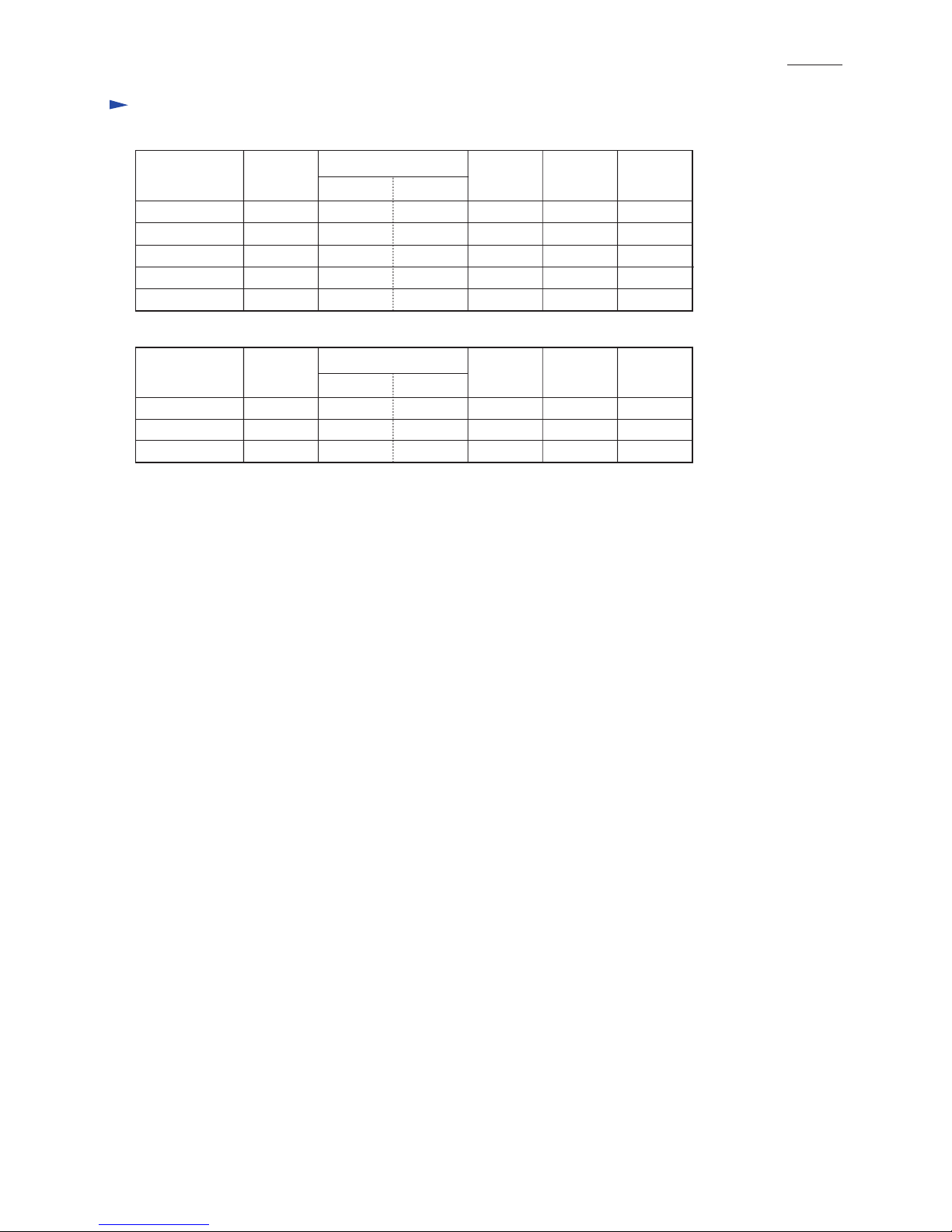

Variation list

BTD129RFE

BTD129RHE

Model No.

Type Quantity

Plastic

carrying

case

Battery

cover

Battery

No NoBTD129Z No

2 1

No

Yes

Yes

Yes

DC18RC

Charger

No

No YesNo NoNo

YesBL1830 Yes

Yes

Yes

2 1DC18RC

BTD129ZK

BL1815

BTD129SHE 2 1 YesDC18SD BL1815

BTD129

Model No.

Quantity

Battery

LXDT08Z NoNoNo No Yes

LXDT08 Yes2BL1830 1 Yes

Yes

No

DC18RA

LXDT08C1 Yes2BL1815 1DC18SD

*1 Model number for North and Central American countries

LXDT08*

1

Belt

clip

Type

Plastic

carrying

case

Battery

cover

Charger

Belt

clip

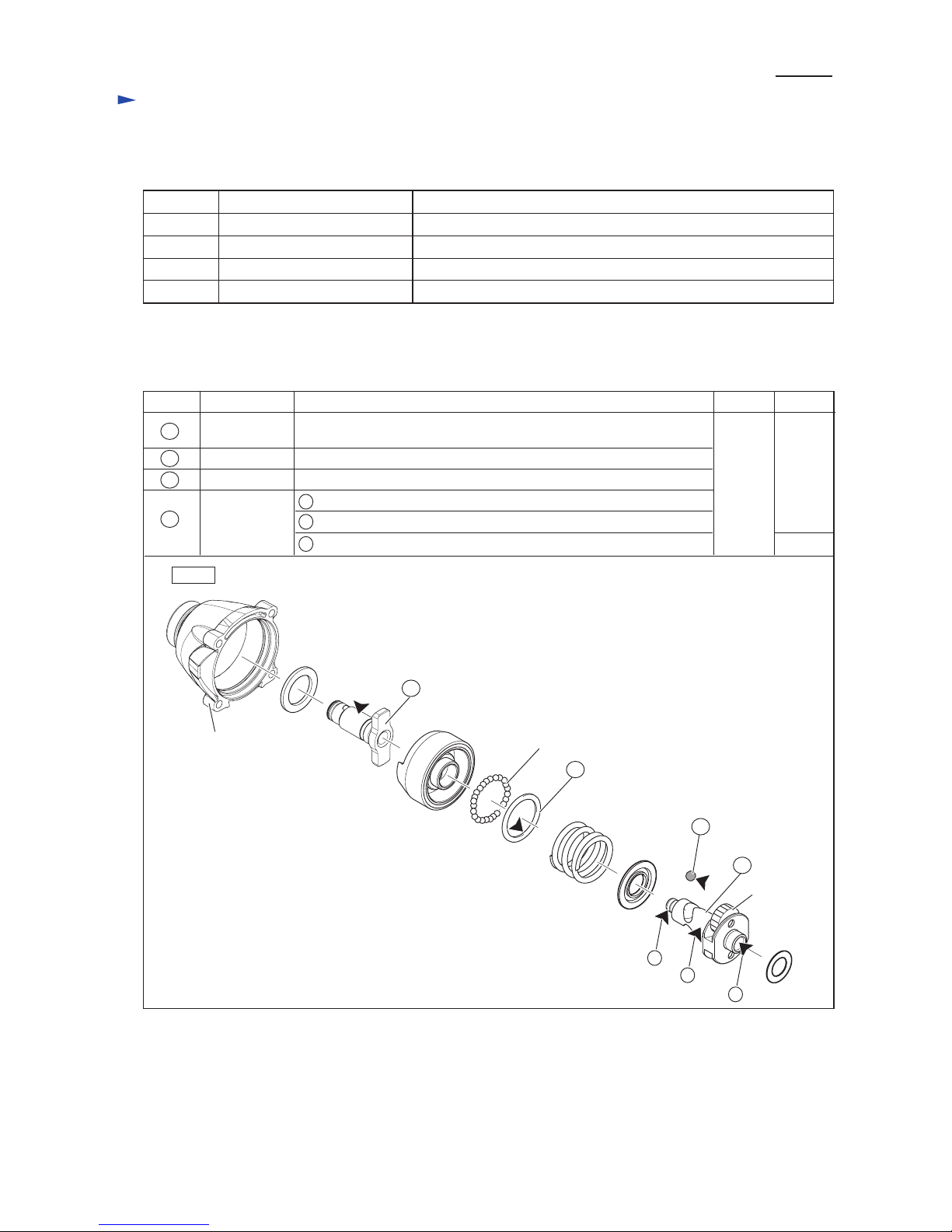

Repair

Apply Makita grease FA No.2 to the following portions indicated by the black triangle to protect

parts and product from unusual abrasion.

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No. Description Use for

1R045 Gear extractor (large) Disassembling/ assembling Hammer section

1R232 Pipe 30 Holding hammer case when removing/ assembling Bit holder section

1R288 Screwdriver magnetizer Magnetizing a screwdriver for easy removal of Steel ball 5.6

1R291 Retaining ring S and R pliers Removing/ mounting Ring spring 11 of Bit holder section

[2] LUBRICATION

Fig. 1

DescriptionItem No.

Grease

Makita

FA No.2

AmountPortion to lubricate

2 g

19

Hammer case

Anvil

Flat washer 24

Steel ball 5.6 a little

Drum portion that contacts Sleeve and O ring 14 of Hammer case

complete

Surface that contacts 24 pcs. of Steel ball 3.5

Whole portion

Spur gear 22

Steel ball 3.5

(24 pcs.)

a

c

Insertion hole for Armature for smooth engaging with Spur gear 22

b

Spindle

Tip portion to be inserted into the hole of Anvil

Surface that contacts Hammer

22

19

22

25

25

27

27

a

c

b

P 3/ 12

Repair

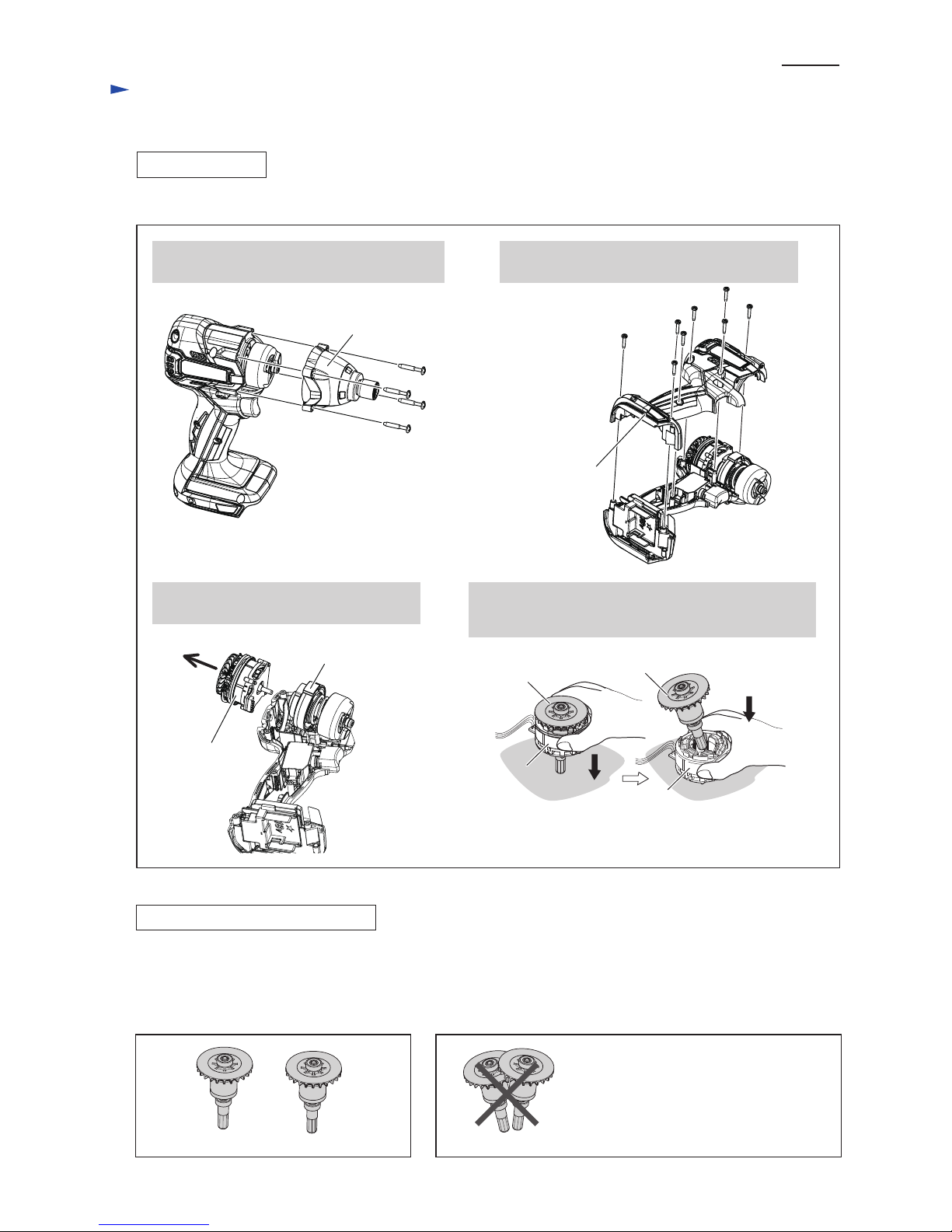

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Rotor

DISASSEMBLING

Fig. 2

Hammer case

complete

1. By unscrewing four 4x25 Tapping screws,

remove Hammer case complete.

2. By unscrewing 8 pcs. of 3x16 Tapping screws,

remove Housing (R).

3. Separate Rotor section (Rotor and Stator)

from Internal gear case complete.

Housing (R)

Disassemble Rotor. (Fig. 2)

4x25 Tapping screw

(4 pcs.)

3x16 Tapping screw

(8 pcs.)

4. Put Rotor section on a workbench so that the drive end

of Rotor touches the workbench.

Press Stator down to separate it from Rotor.

Rotor

Stator

Stator

Rotor

Internal gear case

complete

Rotor section

Caution for Handling of Rotor

Fig. 3R Fig. 3F

* Magnetic loss of Rotors

* Damage on the magnet portion of Rotors

When handling or storing multiple Rotors, be sure to keep a proper distance between Rotors as shown in Fig. 3R because

Rotor has a strong magnet, failure to follow this instruction could result in:

• Finger injury caused by pinching between Rotors pulling each other.

• Magnetic loss of Rotors or damage on the magnet portion of Rotors. (Fig. 3F)

P 4/ 12

Loading...

Loading...