Makita BTD146, LXDT04CW, BTD146RHE, LXDT04, BTD146RFE3 Technical Information

...

Models No.

Description

PRODUCT

P 1/ 11

BTD146 (LXDT04*1)

Cordless Impact Driver

*1 Model number for North and Central American countries

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

Model BTD146 Cordless Impact Driver is an advanced version of Model BTD141,

featuring the same ergonomically designed handle and 4-pole motor as the existing model,

plus more compact design, enhanced dust and drip-proof performance and battery fuel gauge*

2.

This product is powered by 18V/1.3Ah Li-ion battery BL1815 and 18V/3.0Ah Li-ion battery

BL1830.

See the product variation list above.

*5 torque at 3 seconds after seating, when fastening M14 high tensile bolt

*2 This gauge is available for all countries except North and Central American countries

Battery

No load speed: min.-

1=rpm

Impacts per min.: min.-

1=ipm

Max. fastening torque*

5: N.m (kgf.cm/ in.lbs)

Charging time: min.

Capacities

Electric brake

LED job light

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

Variable speed control by trigger

Capacity: Ah

Cell

Voltage: V

18V

0 - 2,300

0 - 3,200

160 (1,630/ 1,420)

Standard bolt

High tensile bolt

Machine screw

Driving shank

M5 - M14 (3/16 - 9/16")

M5 - M12 (3/16 - 1/2")

Coarse thread screw

22 - 125mm (7/8 - 4-7/8")

M4 - M8 (5/32 - 5/16")

Yes

Yes

Yes

Reverse switch Yes

1.3*

3/ 1.5*4 (2.8*3/ 3.3*4)

1.3/ 3.0 (battery BL1815/ BL1830)

Li-ion

220

approx. 15/ 22 with DC18RC or DC18RA

6.35mm (1/4") Hex

This product is available in the following variations.

Phillips bits

Socket bits

Drill chucks

Bit piece

Drill bits

with 6.35mm Hex shank

Hole saws for Impact driver

Stopper for Impact driver

Hook set (Belt clip)

Tool hanger

Battery protectors

Li-ion Battery BL1830

Li-ion Battery BL1815

Fast charger DC18RA

(for North and Central American countries only)

Fast charger DC18RC

(for all countries except North and Central American countries)

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

138 (5-7/16)

79 (3-1/8)

238 (9-3/8)*

4

220 (8-5/8)*3

*3 with Battery BL1815

*4 with Battery BL1830

W

L

H

(with Battery BL1830)

Max output (W)

T

ECHNICAL INFORMATION

BTD146RFE

BTD146Z

LXDT04Z

LXDT04ZW

BTD146RF

LXDT04

LXDT04CW

BTD146RFE3

BL1830

(Li-ion 3.0Ah)

BL1815

(Li-ion 1.3Ah)

No

DC18RC

DC18RC

DC18RA

DC18RA

No

Model No.

type quantity

Charger

Yes

Belt

clip

1

2

No

Battery

cover

Yes

No

Plastic

carrying

case

2

0

1

BTD146RHE

1

2

3

2

No

Battery

Makita-blue

Makita-blue

White

White

Housing

color

1

P 2/ 11

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICANT

Description

Vise plate removing Hammer case complete

removing Hammer case

removing Hammer case complete

removing Bit holder section

removing Hammer

Code No.

1R041

1R045 Gear extractor (large)

Torque wrench shaft 20-90N·m

Ratchet head 12.7 (for 1R223)

Pipe 30

Socket 30 -78 ass’y

Socket 32 -50 ass’y

Screwdriver Magnetizer

Retaining Ring S and R Pliers removing Ring spring 11 from Bit holder section

1R223

1R224

1R232

1R288

1R291

134847-1

134848-9

Use for

removing Steel balls

Fig. 1

16

21

25

27

28

Spur gear 22

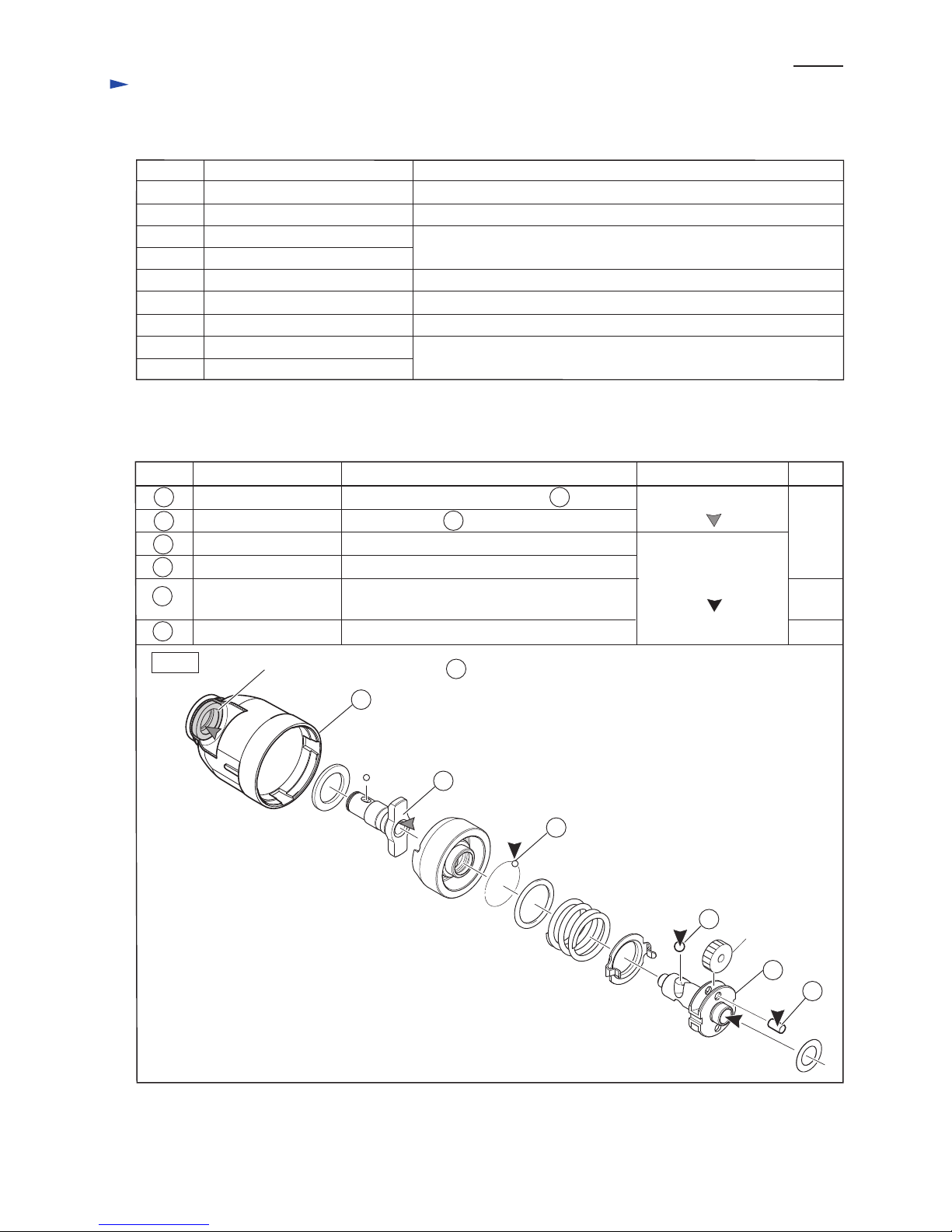

Apply the following lubricants to protect parts and product from unusual abrasion. (Fig. 1)

Item No. Description

Anvil

Steel ball 3.5 (24pcs.)

Steel ball 5.6 (2pcs.)

Hammer case complete Inside of Sleeve 14 which touches 19

Hole into which 27 Spindle top is inserted

Hole into which Armature's drive end is inserted

to engage Spur gear 22

Whole portion

Whole portion

Whole portion

Portion to lubricate

16

19

21

25

27

Spindle 2g

16

Sleeve 14 (The component of )

28 Pin 5

Lubricant Amount

a little

a little

Makita grease FA. No.2

Makita grease N. No.2

19

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Hammer case complete

DISASSEMBLING

Fig. 2 Fig. 3

Fig. 4

Fig. 6 Fig. 7

Fig. 5

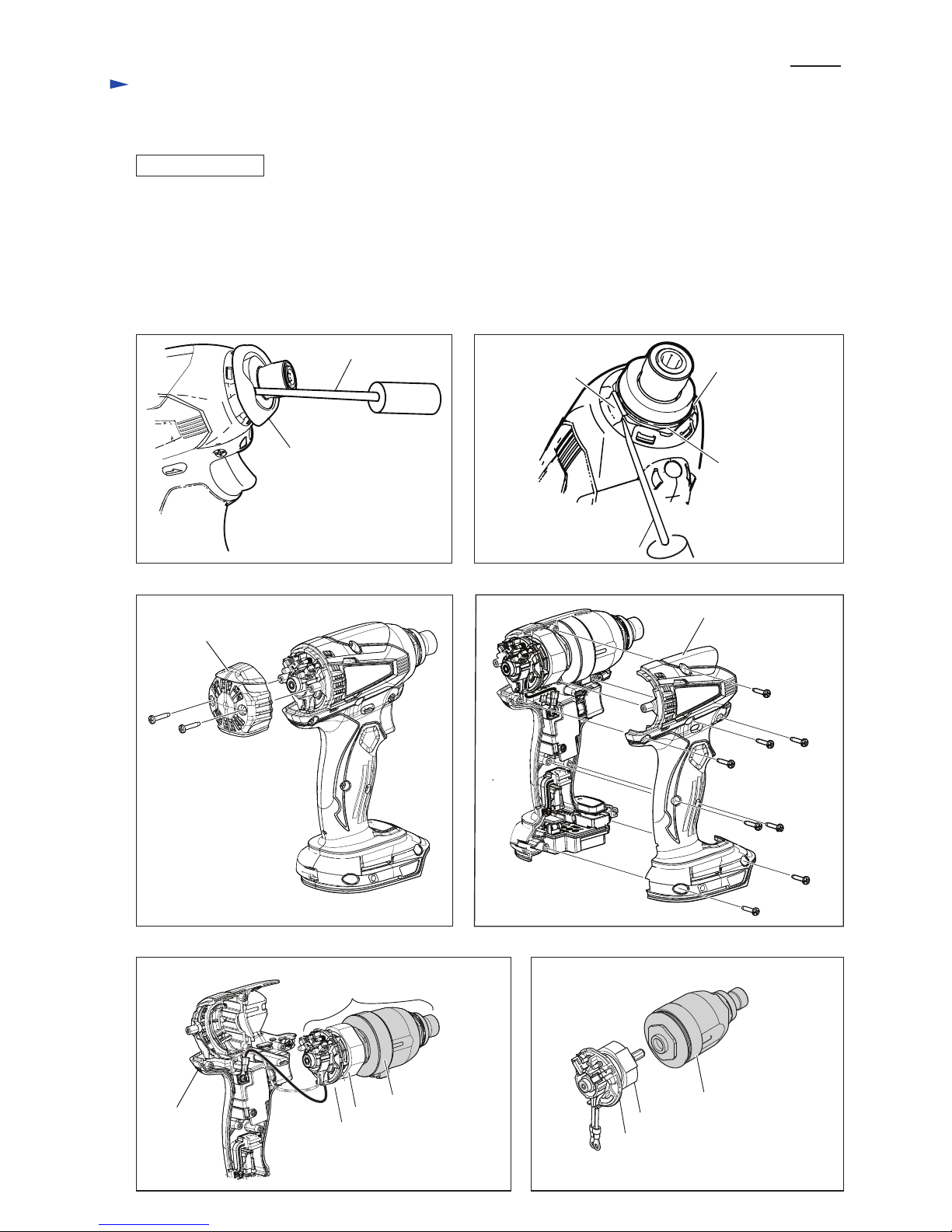

(1) Twist and remove Bumper with slotted screwdriver. (Fig. 2)

(2) While releasing the hooks of Hammer case cover from Hammer case complete carefully, remove Hammer case

cover. (Fig. 3)

(3) Unscrew two 3x16 Tapping screws on Rear cover and remove Rear cover. (Fig. 4)

(4) Unscrew eight 3x16 Tapping screws on Housing set (R) and then remove Housing set (R). (Fig. 5)

(5) Remove an assembled part consists of three sections from Housing set (L). (Fig. 6)

(6) Pull out Hammer section from the other sections. (Fig. 7)

Rear cover

Bumper

hook of Hammer

case cover

hook of Hammer

case cover

Hammer

case complete

Slotted screwdriver

Slotted screwdriver

3x16 Tapping

screw (2pcs.)

3x16 Tapping

screw (8pcs.)

Housing set (R)

Housing

set (L)

Hammer section

An assembled part consists

of three sections.

Motor section

Brush holder section

Motor section

Brush holder section

Hammer section

P 3/ 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Hammer case complete (cont.)

DISASSEMBLING

ASSEMBLING

Fig. 8

Fig. 9

Fig. 10 Fig. 11

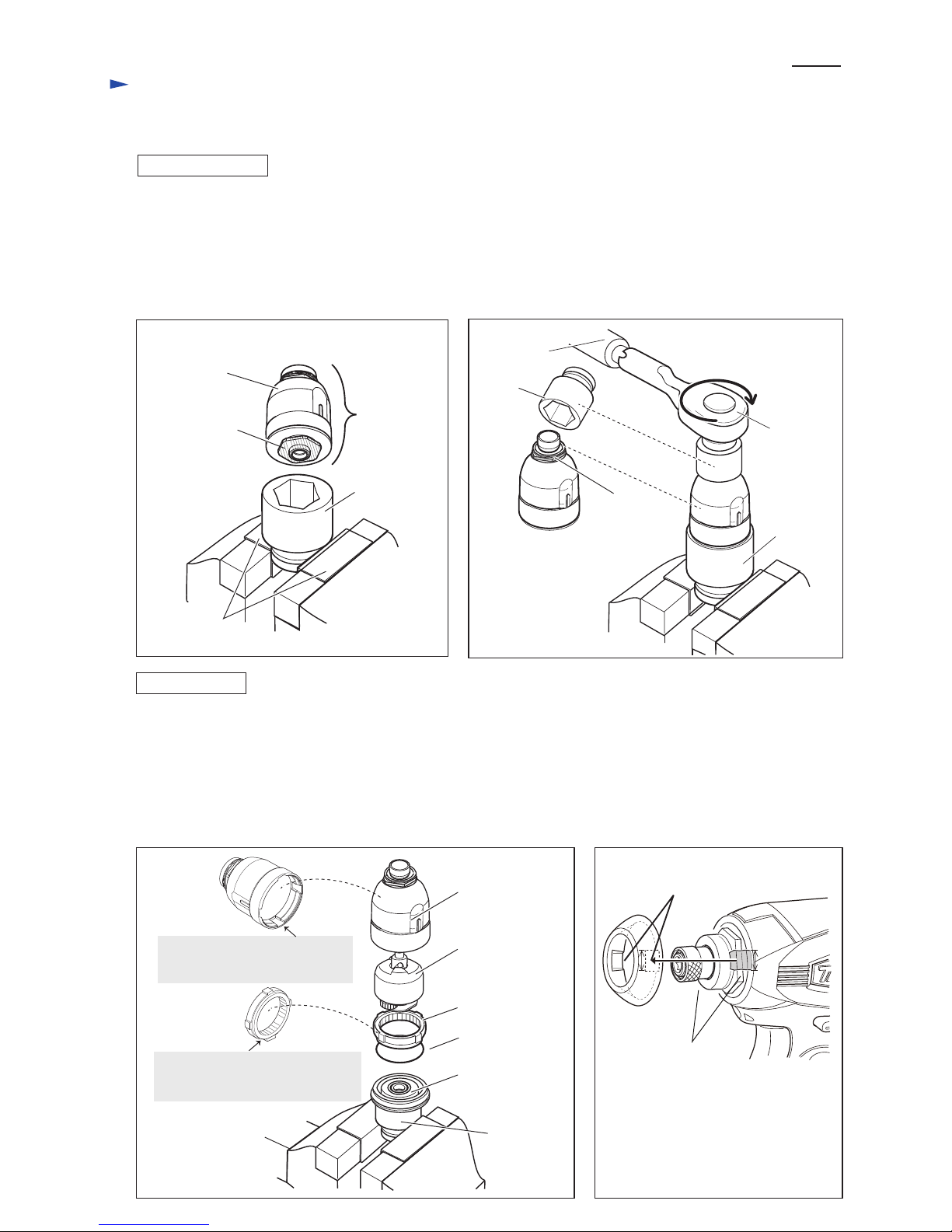

(7) Hold 134848-9 with 1R041 in Vise, and then fit the hexagonal portion of Bearing box complete into 134848-9.

(Fig. 8)

(8) Set 1R224 and 134847-1 to 1R223, and then fit the hexagonal portion on Hammer case complete into 134847-1 and

turn 1R223 clockwise. (Fig. 9)

Note: Hammer case complete has a left hand thread.

(9) Hammer section can be disassembled as drawn Fig. 10.

(1) Reverse the disassembling steps of Hammer case complete, Hammering mechanism, Internal gear 51, O ring 40 and

Bearing box complete as drawn in Figs 10 and 9.

(2) Set 1R224 and 134847-1 to 1R223, and then fit the hexagonal portion on Hammer case complete into 134847-1 and

turn 1R223 counterclockwise.

Note: The fastening torque has to be 30N.m to 40N.m.

(3) Hook Hammer case cover to the hexagonal portion of Hammer case complete, and then fit its hooks to

the depressions on the reverse of Bumper.

P 4/ 11

Repair

Hexagonal

portion of

Bearing box

complete

Hexagonal

portion of

Hammer case

complete

134848-9

134848-9

134848-9

1R041

Hammer case

complete

Hammer

section

Bearing box

complete

Hammer case

complete

Hammering

mechanism

Internal gear 51

hooks of Hammer case

cover

depressions of Bumper

Fit the four projections of

Internal gear 51 into the grooves

of Hammer case complete.

Fit the stepped end of Internal

gear 51 into the groove of Bearing

box complete.

O ring 40

134847-1

1R223

1R224

Loading...

Loading...