Makita LXDG01 1 Series, BGD800, LXDG01Z 1 Series, BGD801, BGD800Z Technical Information

...

T

ECHNICAL INFORMATION

Model No.

Description

BGD800 (LXDG01)*1, BGD801

Cordless Die Grinder

*1 Model number for North and Central American countries

CONCEPT AND MAIN APPLICATIONS

Models BGD800 (LXDG01)*1 and BGD801 are Cordless die grinders

powered by 18V/3.0A Li-ion battery BL1830, featuring the same

easy-to-grip slim motor housing as used for Model BGA402 Cordless

angle grinder.

BGD800 is a long-nose die grinder using the mechanical section of

Model GD601 while BGD801 is a short-nose type using that of

Model GD602.

Note: These models are not compatible with 1.3Ah Li-ion battery BL1815.

These new products are available in the following variations.

BGD800 (LXDG01)*1

Model No.

BGD800Z

(LXDG01Z)*1

BGD800RFE

(LXDG01)*1

BGD801

Model No.

BGD801Z

BGD801RFE

All models also include the accessories listed below in "Standard equipment".

Battery

Type Quantity

--- --- ------ ---

BL1830 DC18RA Yes

Battery

Type Quantity

---

BL1830

Battery

cover

2 1

Battery

cover

2 1

Charger

Charger

--- ------ ---

DC18RA Yes

Plastic

carrying case

Plastic

carrying case

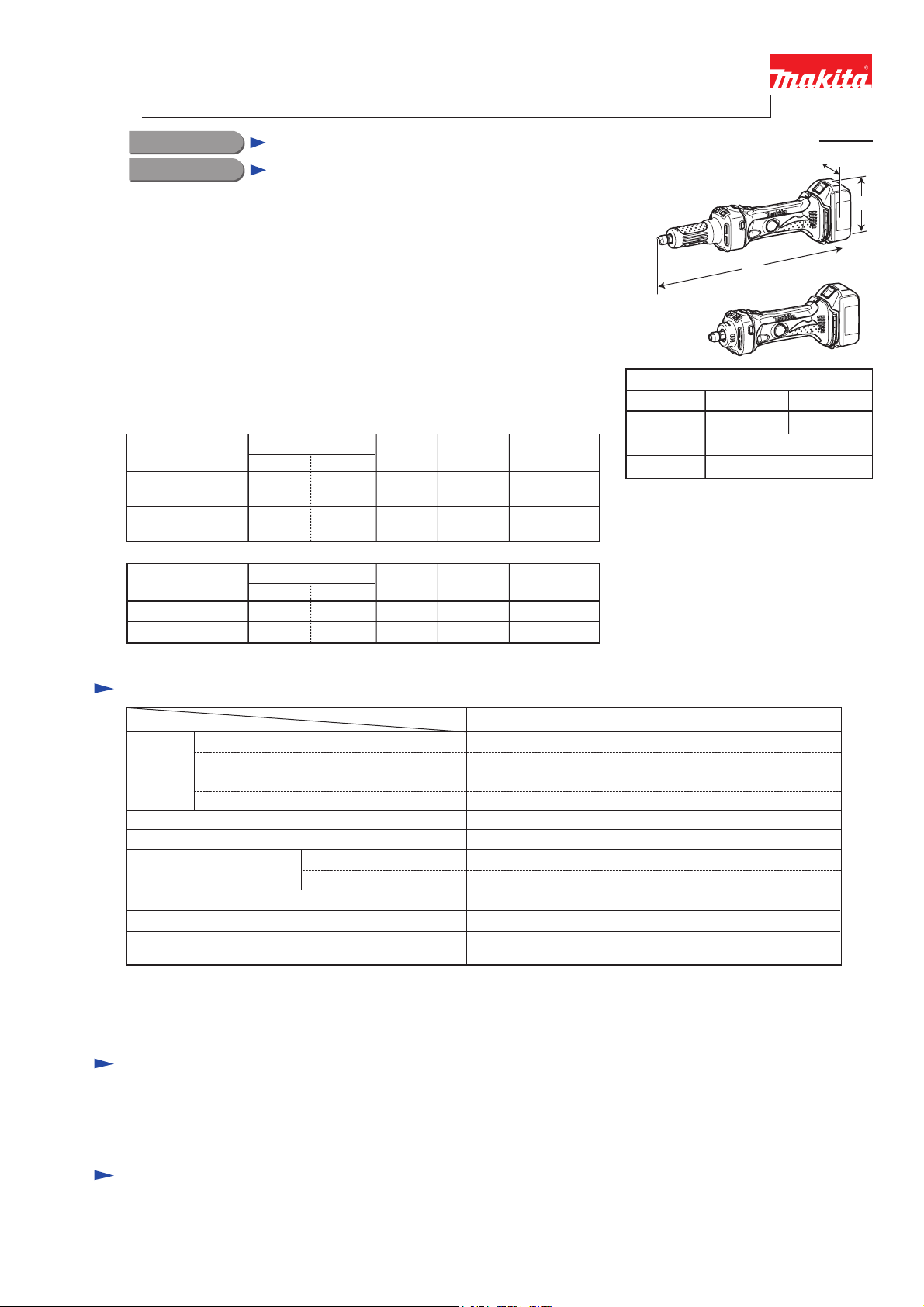

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

PRODUCT

P 1/10

W

BGD800

H

L

BGD801

BGD800 BGD801

402 (15-3/4) 307 (12-1/8)

82 (3-1/4)

118 (4-5/8)

Specification

Specification

Cell

Battery

Max output: W 350

No load speed: min-1=rpm 25,000

Collet size: mm (")

Max collet capacity: mm (")

Max wheel diameter: mm (")

Weight according to

EPTA-Procedure 01/2003*4: kg (lbs)

*2: The tools for India additionally includes 8mm collet cone.

*3: 1/4" is the Max. collet capacity in inch for North American countries.

(Collet cone of inch size corresponding to 8mm is not available for these models.)

*4: with battery, collet cone and collet nut

Voltage: V

Capacity: Ah

Supplied with the tool

Option

Model

BGD800 BGD801

22 with DC18RACharging time (approx.): min.

6*2 (1/4)

3, 6, 8 (1/8, 1/4)

8 (1/4)*3

38 (1-1/2)

2.0 (4.4) 1.7 (3.8)

Standard equipment

Wrench 13 ............................................... 2

Collect cone 6mm or 1/4" ....................... 1

Collect cone 8mm ................................... 1 (for India)

Note: The standard equipment shown above may vary by country.

Li-ion

18

3.0

Optional accessories

Collet cones (3mm, 6mm, 8mm, 1/8", 1/4")

Side grip

Wheel points

Battery BL1830

Fast charger DC18RA

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

BGD0800 (LXDG01)

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R279 Round bar for arbor 5-50 removing Armature

1R291 Retaining ring S and R pliers removing Retaining rings S-9 and S-12

1R350 Ring 60 holding Bearing box complete when removing Armature

1R382 Armature positioning jig

Hex socket bit 17 fixing Coupling when removing it from Spindle

Wrench 13 removing Spindle from Coupling

[2] LUBRICATION

Apply lubricant as instructed in the table below.

positioning Armature at the precise position when mounting it to

Bearing box complete

P 2/ 10

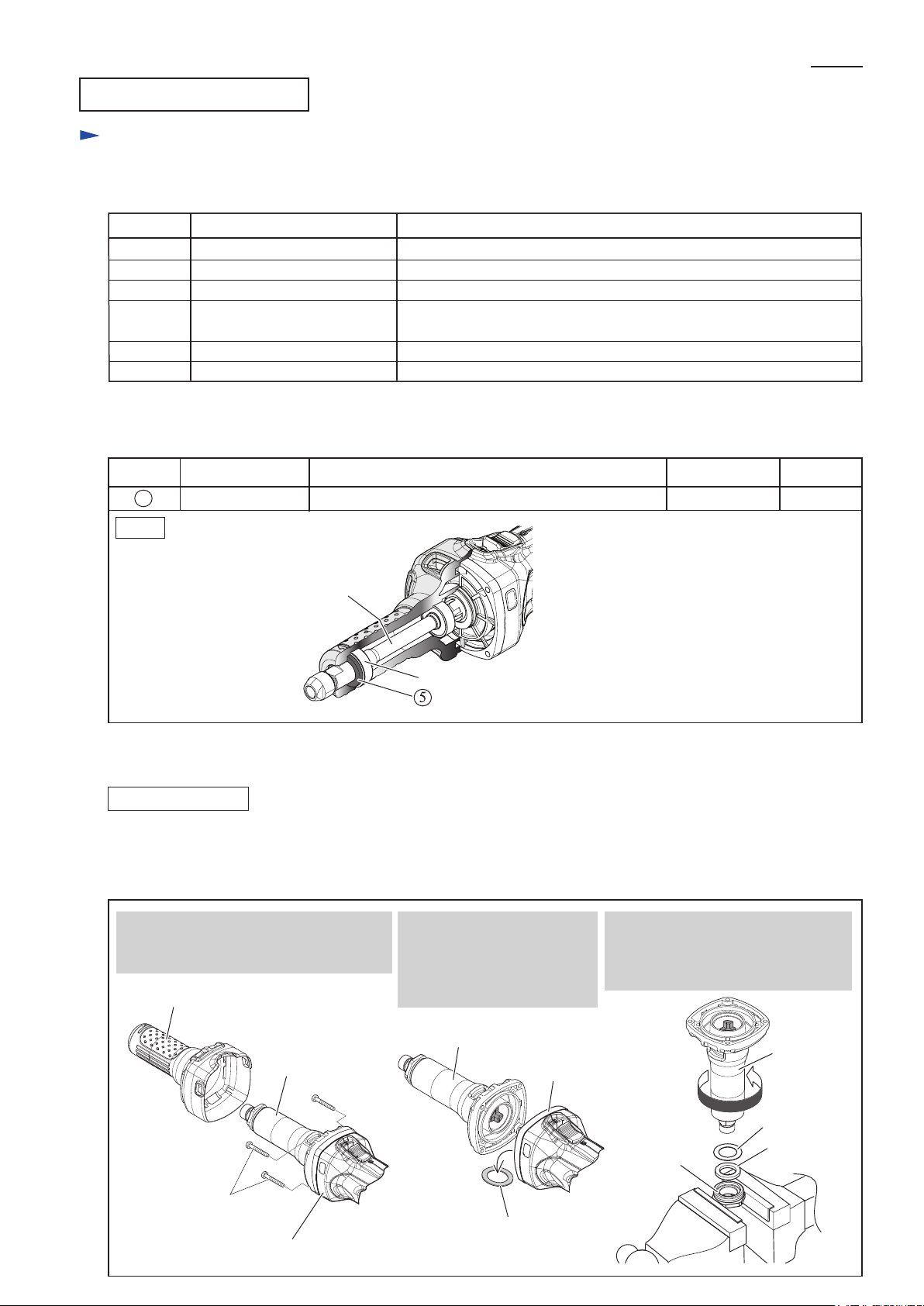

Item No.

5 Felt Ring 17 Apply sufficient lubricant to protect from dust.

Fig. 1

Description Lubricant Amount (g)Portion to lubricate

Spindle

Ball bearing 6001LLB

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Coupling, Spindle

DISASSEMBLING

(1) Remove Collet cone and Collet sleeve from Spindle.

(2) Remove Insulation cover from Barrel section. Separate Barrel section from Housing,

then disassemble Barrel section using vise. (Fig.2)

Fig. 2

“VG100”

1. Remove Insulation cover from Barrel,

then remove four 4x30 Tapping screws

that fasten Barrel section to Housing.

Insulation cover

Barrel section

4x30 Tapping screw

(4 pcs)

Housing

2. Separate Barrel section

from Housing.

Note:

Be careful not to lose

Flat washer 22 in this step.

Barrel section

Housing

Flat washer 22

3. Fix Barrel section in vise securely,

then remove Bearing retainer from

Barrel complete by turning Barrel

complete counterclockwise.

Barrel

complete

Flat washer 18

Bearing

retainer

Felt ring

BGD0800 (LXDG01)

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Coupling, Spindle

DISASSEMBLING

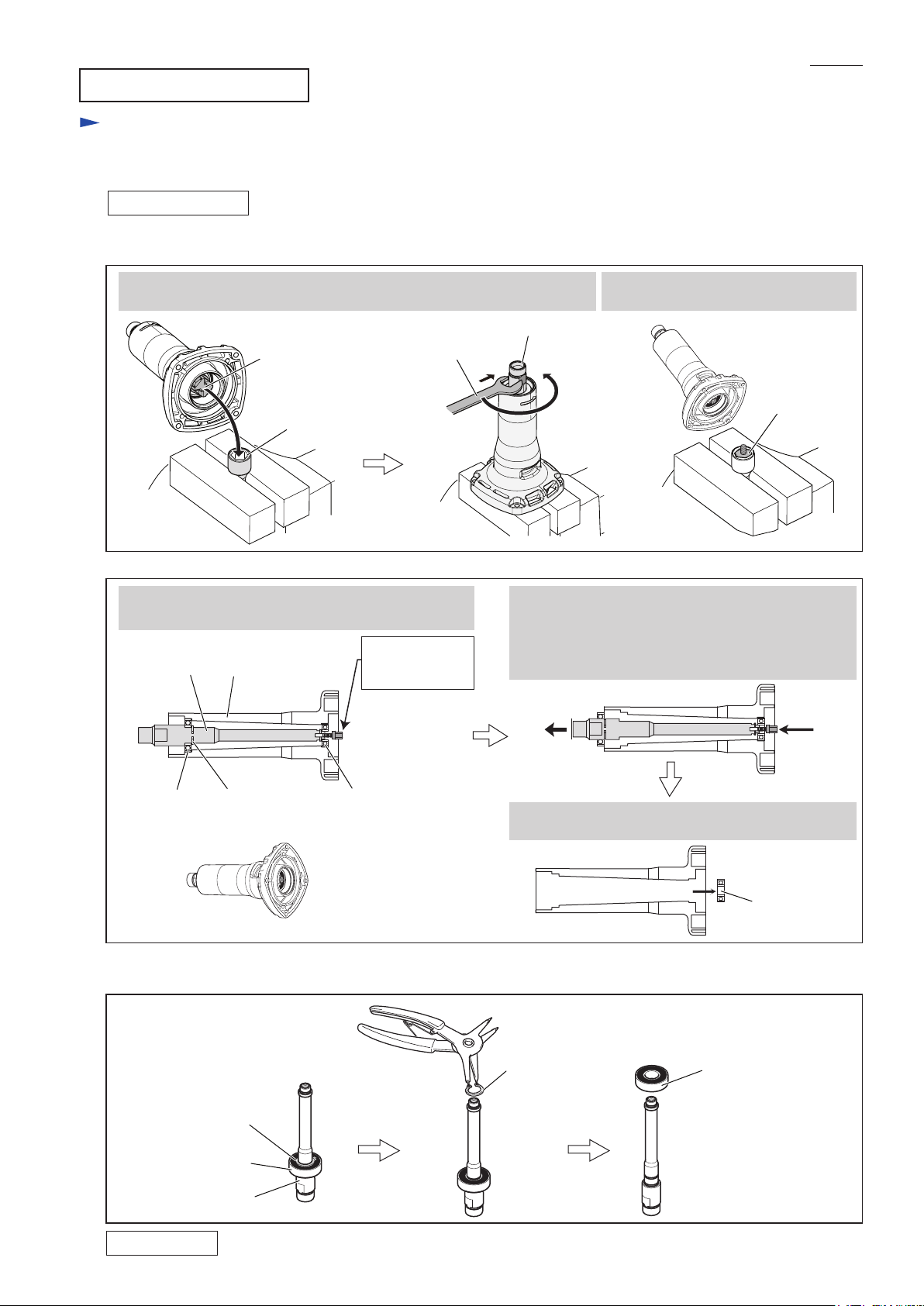

(2) Remove Coupling from Spindle, then separate Spindle from Barrel complete. (Figs. 3, 4)

Fig. 3

P 3/ 10

4. Turn Spindle counterclockwise with Wrench 13 while holding Coupling

with Hex box bit 17.

Spindle

Coupling

Hex socket

bit 17

Fig. 4

6. Drive the removed Coupling in Spindle again

about 2 pitches for utilizing it as a removing tool.

Spindle

Barrel complete

Wrench 13

Drive Coupling

about 2 pitches

in Spindle again.

7. Push Coupling by hand towards the front end of

Barrel complete, and remove Spindle together with

Ball bearing 6001LLB and Retaining ring S-12;

in this step, Ball bearing 629LLB remains in

Barrel complete.

5. The Coupling disconnected from

Spindle remains in Hex box bit 17.

Coupling

[front end]

Ball bearing

6001LLB

(3) Remove Retaining ring S-12 and Ball bearing 6001LLB from Spindle. (Fig. 5)

Fig. 5

Ball bearing

6001LLB

Retaining ring

S-12

[front end]

Retaining

ring S-12

Spindle

[rear end]

[rear end]

Ball bearing

629LLB

8. Remove Ball bearing 629LLB from the rear end of

Barrel complete.

Retaining

ring S-12

Ball bearing

6291LLB

Ball bearing

6001LLB

ASSEMBLING

Do the reverse of the disassembling steps.

Loading...

Loading...