Page 1

GB Circular Saw Instruction Manual

F Scie Circulaire Manuel d’instructions

D Handkreissäge Betriebsanleitung

I Sega circolare Istruzioni per l’uso

NL Cirkelzaagmachine Gebruiksaanwijzing

E Sierra Circular Manual de instrucciones

P Serra Circular Manual de instruções

DK Rundsav Brugsanvisning

GR Δισκοπρίονο Οδηγίες χρήσεως

TR Daire testere Kullanma kılavuzu

HS6100

HS6101

HS7100

HS7101

Page 2

1

2

12

3

012459

4

34

5

6

7

8

9

56

012472

012473012476

10

012461012460

11

14

12

012471 012463

13

15

78

2

Page 3

16 17

20

16 17

20

19

18

910

011231

19

18

011230

19

21

17

20

18

11 12

12

012462012464

24

22

8

23

13 14

15

012469

012465

012470

3

Page 4

27

28

17

25

26

16 18

30

8

18

A

B

19 20

012467

29

012474012466

31

001145012475

21

4

33

32

012468

Page 5

ENGLISH (Original instructions)

Explanation of general view

1 Lever

2 Front lever

3 Rear wing nut

4 Stopper

5 0° position

6 45° position

7 Cutting line

8Screw

9 Switch trigger

10 Lock-off button

11 Light

SPECIFICATIONS

Model HS6100 HS6101 HS7100 HS7101

Blade diameter 165 mm 190 mm

at 0° 54.5 mm 67 mm

Max. cutting depth

No load speed (min

Overall length 297 mm 310 mm

Net weight 3.7 kg 3.7 kg 4.0 kg 4.0 kg

Safety class /II

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for performing lengthways and

crossways straight cuts and mitre cuts with angles in

wood while in firm contact with the workpiece. With

appropriate saw blades, aluminum can also be sawed.

For public low-voltage distribution systems of

between 220 V and 250 V

Switching operations of electric apparatus cause voltage

fluctuations. The operation of this device under unfavorable mains conditions can have adverse effects to the

operation of other equipment. With a mains impedance

equal or less than 0.32 Ohms it can be presumed that

there will be no negative effects.

The mains socket used for this device must be protected

with a fuse or protective circuit breaker having slow tripping characteristics.

General Power Tool Safety Warnings

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and instruc-

tions may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference.

at 45° 39.5 mm 48.5 mm

at 50° 35.5 mm 43.5 mm

–1

) 5,500

12 Hex wrench

13 Loosen

14 Tighten

15 Shaft lock

16 Mounting shaft

17 Inner flange

18 Saw blade

19 Outer flange

20 Hex bolt

21 Ring

22 Dust nozzle

ENE078-1

ENF100-1

GEA010-1

23 Vacuum cleaner

24 Hose

25 Clamp lever

26 Rip fence (Guide rule)

27 Adjusting screw for 0°

28 Adjusting screw for 45°

29 Triangular rule

30 Base

31 Limit mark

32 Screwdriver

33 Brush holder cap

GEB013-6

CIRCULAR SAW SAFETY WARNINGS

Cutting procedures

1. DANGER: Keep hands away from cutting

area and the blade. Keep your second hand on

auxiliary handle, or motor housing. If both hands

are holding the saw, they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below the

workpiece.

3. Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade teeth

should be visible below the workpiece.

4. Never hold piece being cut in your hands or

across your leg. Secure the workpiece to a

stable platform. It is important to support the work

properly to minimize body exposure, blade binding,

or loss of control.

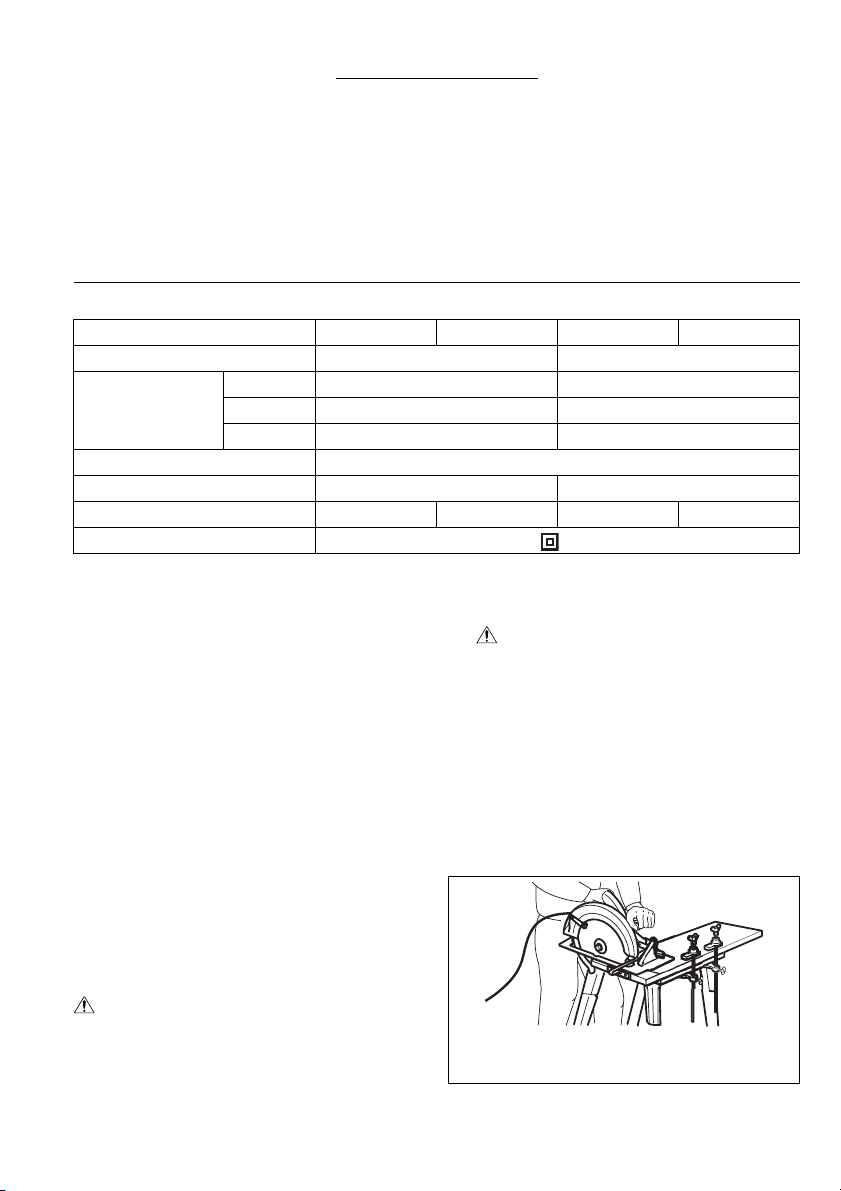

A typical illustration of proper hand support,

workpiece support, and supply cord routing (if

applicable).

000157

5

Page 6

5. Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting tool may contact hidden wiring

or its own cord. Contact with a “live” wire will also

make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

6. When ripping, always use a rip fence or straight

edge guide. This improves the accuracy of cut and

reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes. Blades

that do not match the mounting hardware of the saw

will run eccentrically, causing loss of control.

8. Never use damaged or incorrect blade washers

or bolt. The blade washers and bolt were specially

designed for your saw, for optimum performance

and safety of operation.

Kickback causes and related warnings

– kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw

to lift up and out of the workpiece toward the operator;

– when the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the operator;

– if the blade becomes twisted or misaligned in the

cut, the teeth at the back edge of the blade can dig

into the top surface of the wood causing the blade to

climb out of the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoided

by taking proper precautions as given below.

9. Maintain a firm grip with both hands on the saw

and position your arms to resist kickback forces.

Position your body to either side of the blade,

but not in line with the blade. Kickback could

cause the saw to jump backwards, but kickback

forces can be controlled by the operator, if proper

precautions are taken.

10. When blade is binding, or when interrupting a

cut for any reason, release the trigger and hold

the saw motionless in the material until the blade

comes to a complete stop. Never attempt to

remove the saw from the work or pull the saw

backward while the blade is in motion or kickback may occur. Investigate and take corrective

actions to eliminate the cause of blade binding.

11. When restarting a saw in the workpiece, centre

the saw blade in the kerf and check that saw

teeth are not engaged into the material. If saw

blade is binding, it may walk up or kickback from the

workpiece as the saw is restarted.

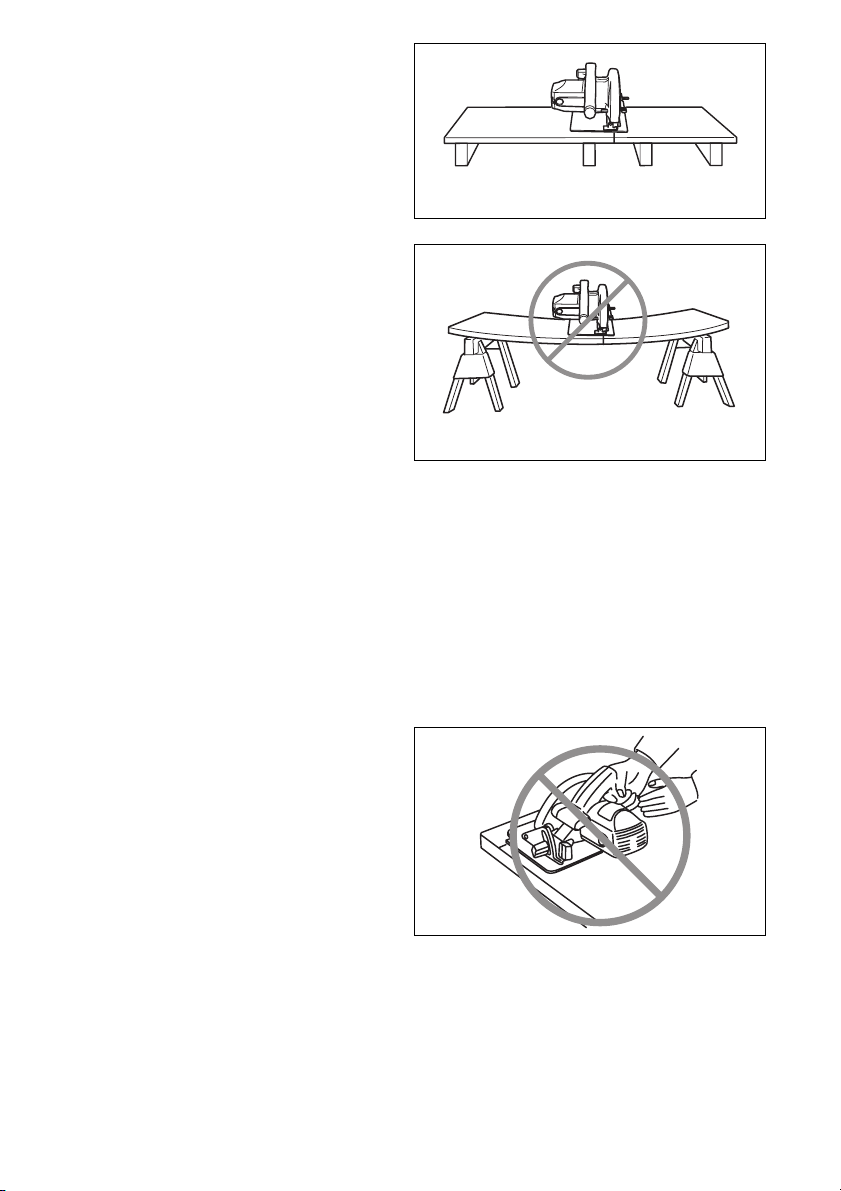

12. Support large panels to minimise the risk of

blade pinching and kickback. Large panels tend to

sag under their own weight. Supports must be

placed under the panel on both sides, near the line

of cut and near the edge of the panel.

To avoid kickback, do support board or

panel near the cut.

000154

Do not support board or panel away from the

cut.

13. Do not use dull or damaged blades. Unsharpened

or improperly set blades produce narrow kerf causing excessive friction, blade binding and kickback.

14. Blade depth and bevel adjusting locking levers

must be tight and secure before making cut. If

blade adjustment shifts while cutting, it may cause

binding and kickback.

15. Use extra caution when sawing into existing

walls or other blind areas. The protruding blade

may cut objects that can cause kickback.

16. ALWAYS hold the tool firmly with both hands.

NEVER place your hand or fingers behind the

saw. If kickback occurs, the saw could easily jump

backwards over your hand, leading to serious per-

000156

sonal injury.

17. Never force the saw. Push the saw forward at a

000194

speed so that the blade cuts without slowing.

Forcing the saw can cause uneven cuts, loss of

accuracy, and possible kickback.

6

Page 7

Lower guard function

18. Check lower guard for proper closing before

each use. Do not operate the saw if lower guard

does not move freely and close instantly. Never

clamp or tie the lower guard into the open

position. If saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with the

retracting handle and make sure it moves freely and

does not touch the blade or any other part, in all

angles and depths of cut.

19. Check the operation of the lower guard spring. If

the guard and the spring are not operating

properly, they must be serviced before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up of

debris.

20. Lower guard may be retracted manually only for

special cuts such as “plunge cuts” and

“compound cuts.” Raise lower guard by

retracting handle and as soon as blade enters

the material, the lower guard must be released.

For all other sawing, the lower guard should operate

automatically.

21. Always observe that the lower guard is covering

the blade before placing saw down on bench or

floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its

path. Be aware of the time it takes for the blade to

stop after switch is released.

22. To check lower guard, open lower guard by

hand, then release and watch guard closure.

Also check to see that retracting handle does

not touch tool housing. Leaving blade exposed is

VERY DANGEROUS and can lead to serious personal injury.

Additional safety warnings

23. Use extra caution when cutting damp wood,

pressure treated lumber, or wood containing

knots. Maintain smooth advancement of tool without

decrease in blade speed to avoid overheating the

blade tips.

24. Do not attempt to remove cut material when

blade is moving. Wait until blade stops before

grasping cut material. Blades coast after turn off.

25. Avoid cutting nails. Inspect for and remove all

nails from lumber before cutting.

26. Place the wider portion of the saw base on that

part of the workpiece which is solidly supported,

not on the section that will fall off when the cut is

made. As examples, Fig. A illustrates the RIGHT

way to cut off the end of a board, and Fig. B the

WRONG way. If the workpiece is short or small,

clamp it down. DO NOT TRY TO HOLD SHORT

PIECES BY HAND!

Fig. A

Fig. B

000147

000150

27. Before setting the tool down after completing a

cut, be sure that the lower guard has closed and

the blade has come to a complete stop.

28. Never attempt to saw with the circular saw held

upside down in a vise. This is extremely

dangerous and can lead to serious accidents.

29. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

30. Do not stop the blades by lateral pressure on the

saw blade.

31. Always use blades recommended in this manual.

Do not use any abrasive wheels.

32. Keep blade sharp and clean. Gum and wood pitch

hardened on blades slows saw and increases

potential for kickback. Keep blade clean by first

removing it from tool, then cleaning it with gum and

pitch remover, hot water or kerosene. Never use

gasoline.

000029

7

Page 8

33. Wear a dust mask and hearing protection when

use the tool.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to safety rules for the subject product. MISUSE or

failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

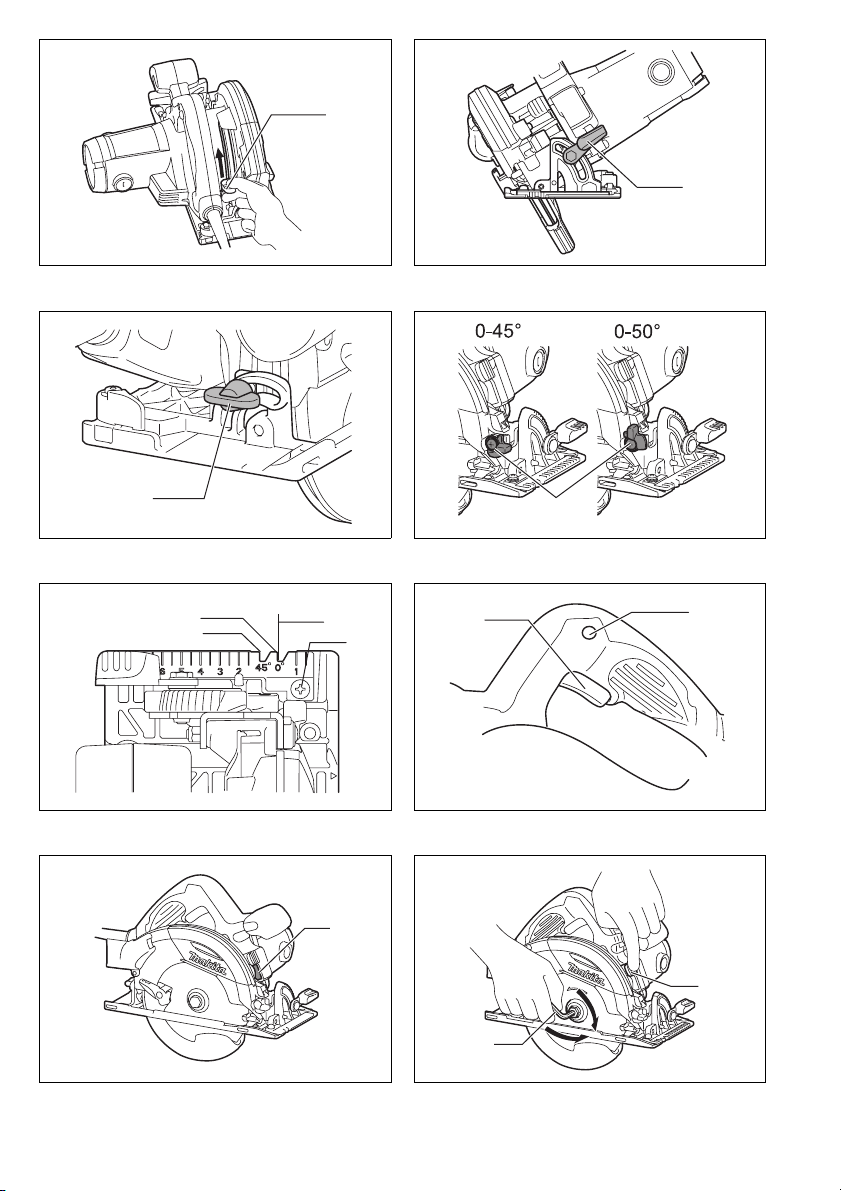

Adjusting depth of cut (Fig. 1)

CAUTION:

• After adjusting the depth of cut, always tighten the lever

securely.

Loosen the lever on the depth guide and move the base

up or down. At the desired depth of cut, secure the base

by tightening the lever.

For cleaner, safer cuts, set cut depth so that no more

than one blade tooth projects below workpiece. Using

proper cut depth helps to reduce potential for dangerous

KICKBACKS which can cause personal injury.

Bevel cutting (Fig. 2, 3 & 4)

Loosen the front lever and rear wing nut. Set for the

desired angle (0° – 50°) by tilting accordingly, then

tighten the lever and wing nut securely.

Use the 45° stopper when you do precise 45° angle cutting. Turn the stopper clockwise fully for bevel cut (0° –

45°) and turn it counterclockwise for 0° – 50° bevel cuts.

Sighting (Fig. 5)

For straight cuts, align the 0° position on the front of the

base with your cutting line. For 45° bevel cuts, align the

45° position with it. The position of the top guide is

adjustable.

Switch action (Fig. 6)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

push in the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

Do not pull the switch lever hard without pulling the lockoff lever. This can cause switch breakage.

For Model HS6101, HS7101

Lighting the lamp (Fig. 7)

CAUTION:

• Do not look in the light or see the source of light

directly.

The lamp lights up when the tool is plugged. The lamp

keeps on lighting until the tool is unplugged.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of lamp, or it may lower

the illumination.

• Do not use gasoline, thinner or the like to clean the lens

of lamp. Using such substances will damage the lens.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

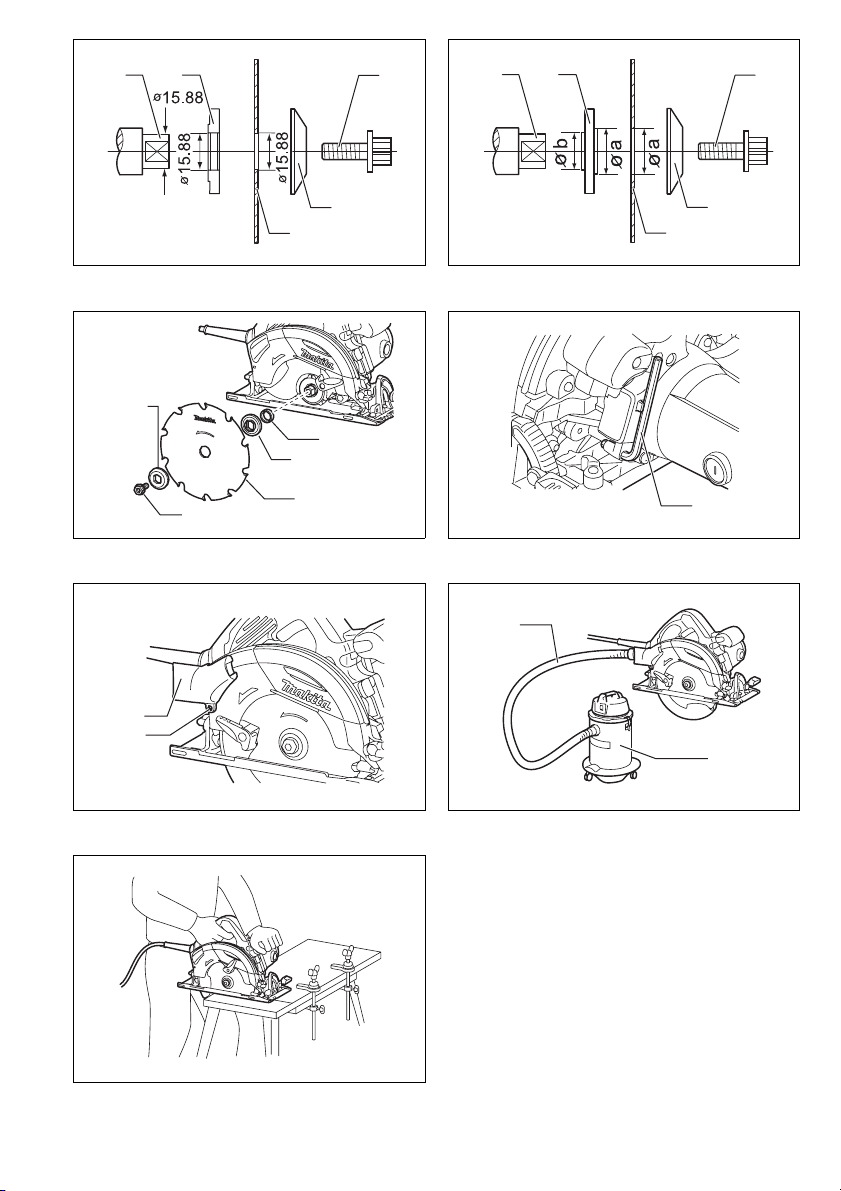

Removing or installing saw blade (Fig. 8)

CAUTION:

• Be sure the blade is installed with teeth pointing up at

the front of the tool.

• Use only the Makita wrench to install or remove the

blade.

To remove the blade, press the shaft lock so that the

blade cannot revolve and use the hex wrench to loosen

the hex bolt counterclockwise. Then remove the hex bolt,

outer flange and blade.

For tool with the inner flange for a 15.88 mm holediameter saw blade (Fig. 9)

Mount the inner flange with its recessed side facing outward onto the mounting shaft and then place saw blade,

outer flange and hex bolt.

BE SURE TO TIGHTEN THE HEX BOLT CLOCKWISE

SECURELY.

For tool with the inner flange for other than 15.88 mm

hole-diameter saw blade (Fig. 10)

The inner flange has a certain diameter protrusion on

one side of it and a different diameter protrusion on the

other side. Choose a correct side on which protrusion fits

into the saw blade hole perfectly.

Next, mount the inner flange onto the mounting shaft so

that the correct side of protrusion on the inner flange

faces outward and then place saw blade and outer

flange.

BE SURE TO TIGHTEN THE HEX BOLT CLOCKWISE

SECURELY.

CAUTION:

• Make sure that the protrusion “a” on the inner

flange that is positioned outside fits into the saw

blade hole “a” perfectly. Mounting the blade on the

wrong side can result in the dangerous vibration.

When changing blade, make sure to also clean upper

and lower blade guards of accumulated sawdust. Such

efforts do not, however, replace the need to check lower

guard operation before each use. (Fig. 11)

Hex wrench storage (Fig. 12)

When not in use, store the hex wrench as shown in the

figure to keep it from being lost.

Connecting a vacuum cleaner (Fig. 13 & 14)

When you wish to perform clean cutting operation, connect a Makita vacuum cleaner to your tool. Install the

dust nozzle on the tool using the screw. Then connect a

hose of the vacuum cleaner to the dust nozzle as shown

in the figure.

8

Page 9

OPERATION

CAUTION:

• Be sure to move the tool forward in a straight line

gently. Forcing or twisting the tool will result in

overheating the motor and dangerous kickback,

possibly causing severe injury.

• Always use a front grip and rear handle and firmly hold

the tool by both the front grip and rear handle during

operations.

Hold the tool firmly. The tool is provided with both a front

grip and rear handle. Use both to best grasp the tool. If

both hands are holding saw, they cannot be cut by the

blade. Set the base on the workpiece to be cut without

the blade making any contact. Then turn the tool on and

wait until the blade attains full speed. Now simply move

the tool forward over the workpiece surface, keeping it

flat and advancing smoothly until the sawing is

completed.

To get clean cuts, keep your sawing line straight and your

speed of advance uniform. If the cut fails to properly follow your intended cut line, do not attempt to turn or force

the tool back to the cut line. Doing so may bind the blade

and lead to dangerous kickback and possible serious

injury. Release switch, wait for blade to stop and then

withdraw tool. Realign tool on a new cut line, and start

cut again. Attempt to avoid positioning which exposes

operator to chips and wood dust being ejected from saw.

Use eye protection to help avoid injury.

Rip fence (guide rule) (Fig. 16)

The handy rip fence allows you to do extra-accurate

straight cuts. Simply slide the rip fence up snugly against

the side of the workpiece and secure it in position with

the screw on the front of the base. It also makes

repeated cuts of uniform width possible.

(Fig. 15)

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

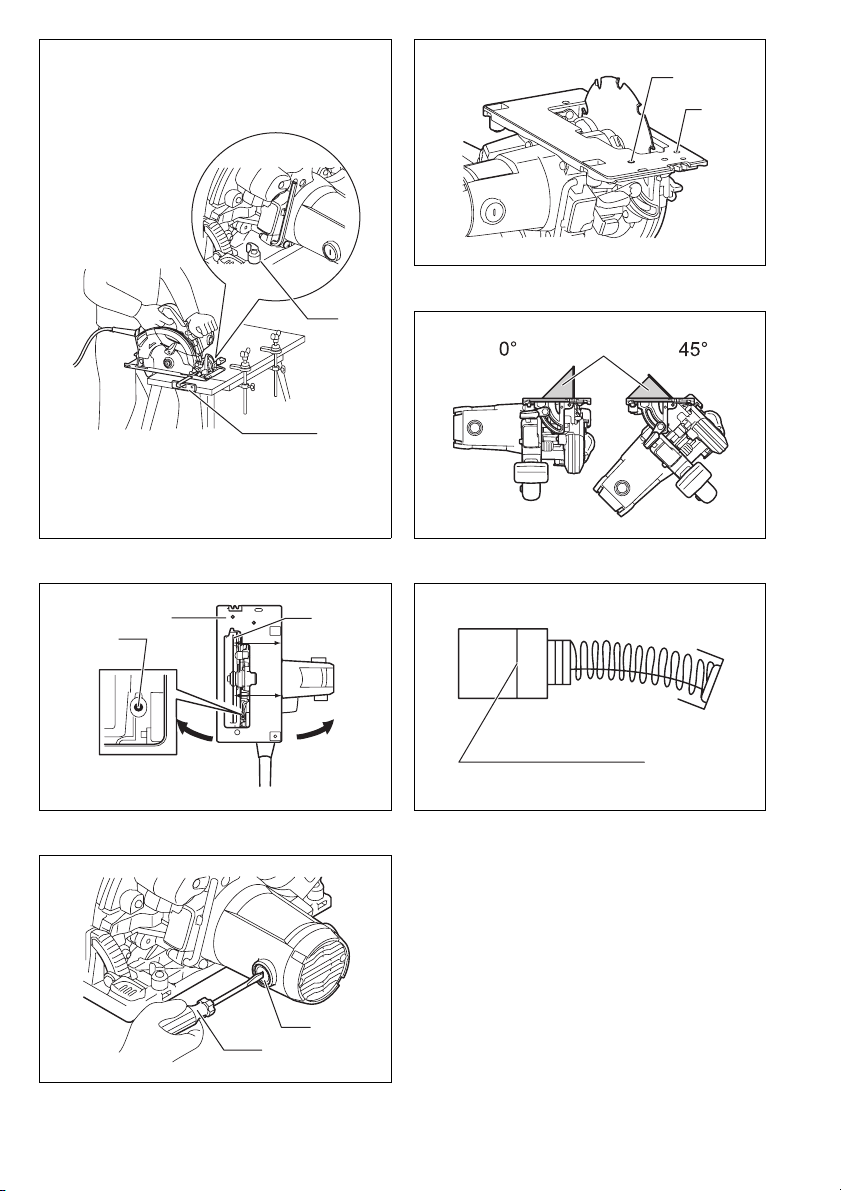

Adjusting for accuracy of 0° and 45° cut (vertical

and 45° cut) (Fig. 17 & 18)

This adjustment has been made at the factory. But if it is

off, adjust the adjusting screws with a hex wrench while

inspecting 0° or 45° the blade with the base using a triangular rule or square rule, etc.

Adjusting for parallelism (Fig. 19)

The parallelism between the blade and the base has

been factory adjusted. But if it is off, you can adjust it as

the following procedure.

Make sure all levers and screws are tightened. Slightly

loosen the screw as illustrated. While opening the lower

guard, move the rear of base so that the distance A and

B are equal. After adjusting, tighten the screw. Make a

test cut to get a correct parallelism.

Replacing carbon brushes (Fig. 20 & 21)

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10 minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If the

electric brake is not working correctly, have the tool

repaired by a Makita service center.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

OPTIONAL ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Saw blades

• Rip fence (Guide rule)

• Guide rail

• Guide rail adaptor

• Hex wrench

•Joint

NOTE:

• Some items in the list may be included in the tool package as standard accessories. They may differ from

country to country.

9

Page 10

ENG905-1

Noise

The typical A-weighted noise level determined according

to EN60745:

Model HS6100, HS6101

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

Model HS7100, HS7101

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

Vibration

The vibration total value (tri-axial vector sum) determined

according to EN60745:

Wear ear protection

): 89 dB (A)

pA

): 100 dB (A)

WA

): 90 dB (A)

pA

): 101 dB (A)

WA

ENG900-1

Model HS6100, HS6101

Work mode: cutting wood

Vibration emission (a

Uncertainty (K): 1.5 m/s

Work mode: cutting metal

Vibration emission (a

Uncertainty (K): 1.5 m/s

Model HS7100, HS7101

Work mode: cutting wood

Vibration emission (a

Uncertainty (K): 1.5 m/s

Work mode: cutting metal

Vibration emission (a

Uncertainty (K): 1.5 m/s

• The declared vibration emission value has been measured in accordance with the standard test method and

may be used for comparing one tool with another.

• The declared vibration emission value may also be

): 2.5 m/s2 or less

h, W

2

): 2.5 m/s

h, M

2

): 2.5 m/s2 or less

h, W

2

): 2.5 m/s

h, M

2

2

2

ENG901-1

used in a preliminary assessment of exposure.

WARNING:

• The vibration emission during actual use of the power

tool can differ from the declared emission value

depending on the ways in which the tool is used.

• Be sure to identify safety measures to protect the operator that are based on an estimation of exposure in the

actual conditions of use (taking account of all parts of

the operating cycle such as the times when the tool is

switched off and when it is running idle in addition to

the trigger time).

ENH101-15

For European countries only

EC Declaration of Conformity

We Makita Corporation as the responsible manufacturer declare that the following Makita machine(s):

Designation of Machine: Circular Saw

Model No./ Type: HS6100, HS6101, HS7100, HS7101

are of series production and

Conforms to the following European Directives:

2006/42/EC

And are manufactured in accordance with the following

standards or standardised documents:

EN60745

The technical documentation is kept by our authorized

representative in Europe who is:

Makita International Europe Ltd.

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, England

6.6.2011

Tomoyasu Kato

Director

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

10

Page 11

NEDERLANDS (Originele instructies)

Verklaring van algemene gegevens

1 Hendel

2 Voorste hendel

3 Achterste vleugelmoer

4 Verstekhoekknop

5 0°-markering

6 45°-markering

7 Zaagsnedelijn

8 Schroef

9 Aan/uit-schakelaar

10 Uit-vergrendelknop

11 Lamp je

TECHNISCHE GEGEVENS

Model HS6100 HS6101 HS7100 HS7101

Bladdiameter 165 mm 190 mm

Bij 0° 54,5 mm 67 mm

Max. zaagdiepte

Nullasttoerental (min

Totale lengte 297 mm 310 mm

Netto gewicht 3,7 kg 3,7 kg 4,0 kg 4,0 kg

Veiligheidsklasse /II

• In verband met ononderbroken research en ontwikkeling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• De technische gegevens kunnen van land tot land verschillen.

• Gewicht volgens de EPTA-procedure 01/2003

Doeleinden van gebruik

Het gereedschap is bedoeld voor het rechtzagen in

lengterichting en in dwarsrichting en voor het

verstekzagen van hoeken in hout terwijl het gereedschap

stevig tegen het werkstuk wordt gehouden. Met een

geschikt zaagblad is ook zagen in aluminium mogelijk.

Voor openbare laagspanningsverdeelsystemen van

tussen 220 V en 250 V

Schakelbedieningen van elektrische toestellen veroorzaken spanningsschommelingen. De bediening van dit

gereedschap onder ongunstige lichtnetomstandigheden

kan een nadelige invloed hebben op de bediening van

andere apparatuur. Het kan worden aangenomen dat er

geen negatieve effecten zullen zijn wanneer de netimpedantie gelijk is aan of minder is dan 0,32 Ohm.

Het stopcontact dat voor dit gereedschap wordt gebruikt,

moet beveiligd zijn door een zekering of een stroomonderbreker met trage afschakelkarakteristieken.

Bij 45° 39,5 mm 48,5 mm

Bij 50° 35,5 mm 43,5 mm

–1

12 Inbussleutel

13 Losmaken

14 Vastzetten

15 Asvergrendeling

16 As

17 Binnenflens

18 Zaagblad

19 Buitenflens

20 Zeskantbout

21 Ring

22 Stofzuigmondstuk

) 5 500

ENE078-1

ENF100-1

23 Stofzuiger

24 Slang

25 Klemhendel

26 Breedtegeleider (Liniaal)

27 Instelschroef voor 0°

28 Instelschroef voor 45°

29 Tekendriehoek

30 Zoolplaat

31 Limietmarkering

32 Schroevendraaier

33 Borstelhouderkap

Algemene veiligheidswaarschuwingen voor

GEA010-1

elektrisch gereedschap

WAARSCHUWING! Lees alle veiligheidswaar-

schuwingen en alle instructies. Het niet volgen van de

waarschuwingen en instructies kan leiden tot elektrische

schokken, brand en/of ernstig letsel.

Bewaar alle waarschuwingen en instructies om in de

toekomst te kunnen raadplegen.

GEB013-6

VEILIGHEIDSWAARSCHUWINGEN SPECIFIEK

VOOR EEN CIRKELZAAGMACHINE

Werkwijze bij het zagen

1. GEVAAR: Houd uw handen uit de buurt van

het zaaggebied en het zaagblad. Houd met uw

andere hand de voorhandgreep of de behuizing

van het gereedschap vast. Als u de cirkelzaag met

beide handen vasthoudt, kunt u nooit in uw handen

zagen.

2. Reik nooit met uw handen onder het werkstuk.

De beschermkap kan u niet beschermen onder het

werkstuk tegen het zaagblad.

3. Stel de zaagdiepte in overeenkomstig de dikte

van het werkstuk. Minder dan een volledige tand-

hoogte dient onder het werkstuk uit te komen.

32

Page 12

4. Houd het werkstuk waarin wordt gezaagd nooit

vast met uw handen of benen. Zorg dat het werkstuk stabiel is ten opzichte van de ondergrond.

Het is belangrijk het werkstuk goed te ondersteunen

om de kans te minimaliseren dat uw lichaam eraan

blootgesteld wordt, het zaagblad vastloopt of u de

controle over het gereedschap verliest.

Een typische afbeelding van goede handplaatsing, werkstukondersteuning en netsnoerroute (indien van toepassing).

000157

5. Houd het elektrisch gereedschap alleen vast aan

het geïsoleerde oppervlak van de handgrepen,

wanneer u werkt op plaatsen waar het zaaggereedschap met verborgen bedrading of met zijn

eigen snoer in aanraking kan komen. Bij contact

met onder spanning staande draden zullen ook de

niet-geïsoleerde metalen delen van het elektrisch

gereedschap onder spanning komen te staan, zodat

de gebruiker een elektrische schok kan krijgen.

6. Gebruik bij het schulpen altijd de breedtegeleider of de langsgeleider. Hierdoor wordt de nauw-

keurigheid van het zagen vergroot en de kans op

vastlopen van het zaagblad verkleint.

7. Gebruik altijd zaagbladen met doorngaten van

de juiste afmetingen en vorm (diamand of rond).

Zaagbladen die niet goed passen op de bevestigingsmiddelen van de cirkelzaag, zullen excentrisch

draaien waardoor u de controle over het gereedschap verliest.

8. Gebruik nooit een beschadigde of verkeerde

bouten en ringen om het zaagblad mee te bevestigen. De bouten en ringen voor de bevestiging van

het zaagblad zijn speciaal ontworpen voor gebruik

met uw cirkelzaag voor optimale prestaties en veilig

gebruik.

Oorzaken van terugslag en waarschuwingen daarvoor

– Terugslag is een plotselinge reactie op een bekneld,

vastgelopen of niet-uitgelijnd zaagblad, waardoor de

oncontroleerbare cirkelzaag omhoog, uit het werkstuk en in de richting van de gebruiker gaat.

– Wanneer het zaagblad bekneld raakt of vastloopt

doordat de zaagsnede naar beneden toe smaller

wordt, vertraagt het zaagblad en komt als reactie de

motor snel omhoog in de richting van de gebruiker.

– Als het zaagblad gebogen of niet-uitgelijnd raakt in

de zaagsnede, kunnen de tanden aan de achterrand

van het zaagblad zich in het bovenoppervlak van het

hout vreten, waardoor het zaagblad uit de zaagsnede klimt en omhoog springt in de richting van de

gebruiker.

Terugslag is het gevolg van misgebruik van de cirkelzaag

en/of onjuiste gebruiksprocedures of -omstandigheden,

en kan worden voorkomen door goede voorzorgsmaatregelen te treffen, zoals hieronder vermeld:

9. Houd de cirkelzaag stevig vast met beide handen en houd uw armen zodanig dat een terugslag wordt opgevangen. Plaats uw lichaam

zijwaarts versprongen van het zaagblad en niet

in een rechte lijn erachter. Door terugslag kan de

cirkelzaag achterwaarts springen, maar de kracht

van de terugslag kan met de juiste voorzorgsmaatregelen door de gebruiker worden opgevangen.

10. Wanneer het zaagblad vastloopt, of wanneer u

om een of andere reden het zagen onderbreekt,

laat u de aan/uit-schakelaar los en houdt u de

cirkelzaag stil in het materiaal totdat het zaagblad volledig tot stilstand is gekomen. Probeer

nooit het zaagblad uit het werkstuk te halen of

de cirkelzaag naar achteren te trekken, terwijl

het zaagblad nog draait omdat hierdoor een

terugslag kan optreden. Onderzoek waarom het

zaagblad is vastgelopen en tref afdoende maatregelen om de oorzaak ervan op te heffen.

11. Wanneer u de cirkelzaag weer inschakelt terwijl

het zaagblad in het werkstuk zit, plaatst u het

zaagblad in het midden van de zaagsnede en

controleert u dat de tanden niet in het materiaal

grijpen. Als het zaagblad is vastgelopen, kan wan-

neer de cirkelzaag wordt ingeschakeld het zaagblad

uit het werkstuk lopen of terugslaan.

12. Ondersteun grote platen om de kans te minimaliseren dat het zaagblad bekneld raakt of terugslaat. Grote platen neigen door te zakken onder hun

eigen gewicht. U moet de plaat ondersteunen aan

beide zijranden, vlakbij de zaaglijn en vlakbij het uiteinde.

Om terugslag te voorkomen, ondersteun de

plank of het paneel dichtbij de zaagsnede.

000154

Ondersteun de plank of het paneel niet van

de zaagsnede weg.

000156

33

Page 13

13. Gebruik een bot of beschadigd zaagblad niet

meer. Niet-geslepen of verkeerd gezette tanden

maken een smalle zaagsnede wat leidt tot grote wrijving, vastlopen en terugslag.

14. De vergrendelhendels voor het instellen van de

zaagbladdiepte en verstelhoek moeten vastzitten

alvorens te beginnen met zagen. Als de instellin-

gen van het zaagblad zich tijdens het zagen wijzigen, kan dit leiden tot vastlopen of terugslag.

15. Wees extra voorzichtig wanneer u een zaagsnede maakt in een bestaande wand of een

andere plaats waar u de achterkant van het zaagoppervlak niet kunt zien. Wanneer het zaagblad

door het materiaal heen breekt, kan het een voorwerp raken waardoor een terugslag optreedt.

16. Houd het gereedschap ALTIJD met beide handen

stevig vast. Plaats NOOIT uw hand of vingers

achter het zaagblad. Als een terugslag optreedt,

kan het zaagblad gemakkelijk achteruit en over uw

hand springen waardoor ernstig persoonlijk letsel

ontstaat.

000194

17. Dwing de cirkelzaag nooit. Duw de cirkelzaag

vooruit met een snelheid waarbij het zaagblad

niet vertraagt. Als u het zaagblad dwingt, kan dat

leiden tot een ongelijkmatige zaagsnede, verminderde nauwkeurigheid en mogelijke terugslag.

Functie van de onderste beschermkap

18. Controleer voor ieder gebruik of de onderste

beschermkap goed sluit. Gebruik de cirkelzaag

niet als de onderste beschermkap niet vrij kan

bewegen en onmiddellijk sluit. Zet de onderste

beschermkap nooit vast in de geopende stand.

Als u de cirkelzaag per ongeluk laat vallen, kan de

onderste beschermkap worden verbogen. Til de

onderste beschermkap op aan de terugtrekhendel

en controleer dat deze vrij kan bewegen en niet het

zaagblad of enig ander onderdeel raakt, onder alle

verstekhoeken en op alle zaagdiepten.

19. Controleer de werking van de veer van de onderste beschermkap. Als de beschermkap en de

veer niet goed werken, dienen deze te worden

gerepareerd voordat de cirkelzaag wordt

gebruikt. De onderste beschermkap kan traag wer-

ken als gevolg van beschadigde onderdelen, gomof hardafzetting, of opeenhoping van vuil.

20. De onderste beschermkap mag alleen met de

hand worden geopend voor het maken van speciale zaagsneden, zoals een “blinde” zaagsnede

en “samengestelde” zaagsnede. Til de onderste

beschermkap op aan de terugtrekhendel en laat

deze los zodra het zaagblad in het materiaal

zaagt. Bij alle andere typen zaagsneden, dient de

onderste beschermkap automatisch te werken.

21. Let er altijd op dat de onderste beschermkap het

zaagblad bedekt voordat u de cirkelzaag op een

werkbak of vloer neerlegt. Een onbeschermd

zaagblad dat nog nadraait, zal de cirkelzaag achteruit doen lopen waarbij alles op zijn weg wordt

gezaagd. Denk aan de tijd die het duurt nadat de cirkelzaag is uitgeschakeld voordat het zaagblad stilstaat.

22. U kunt de onderste beschermkap controleren,

door deze met de hand te openen, los te laten en

te kijken hoe hij sluit. Controleer tevens of de

terugtrekhendel de behuizing van het gereedschap niet raakt. Het zaagblad onbeschermd laten

is UITERST GEVAARLIJK en kan leiden tot ernstig

persoonlijk letsel.

Aanvullende veiligheidsvoorschriften

23. Wees extra voorzichtig bij het zagen in nat hout,

druk-behandeld timmerhout en hout met knoesten. Zorg dat de cirkelzaag soepel vooruit blijft gaan

zonder dat de snelheid van het zaagblad lager

wordt, om oververhitting van de zaagtanden te voorkomen.

24. Probeer niet afgezaagd materiaal te verwijderen

terwijl het zaagblad nog draait. Wacht totdat het

zaagblad volledig tot stilstand is gekomen voordat u het afgezaagde materiaal vastpakt. Het

zaagblad draait nog na nadat het gereedschap is

uitgeschakeld.

25. Voorkom dat u in spijkers zaag. Inspecteer het

hout op spijkers en verwijder deze zonodig voordat u begint te zagen.

26. Plaats het bredere deel van de zool van de cirkelzaag op het deel van het werkstuk dat goed is

ondersteund, en niet op het deel dat omlaag valt

nadat de zaagsnede gemaakt is. Als voorbeeld

laat Fig. A zien hoe u het uiteinde van een plank

GOED afzaagt, en Fig. B hoe u dit VERKEERD

doet. Als het werkstuk kort of smal is, klemt u

het vast. PROBEER NOOIT EEN KORT WERKSTUK IN UW HANDEN VAST TE HOUDEN!

34

Fig. A

000147

Page 14

Fig. B

27. Voordat u het gereedschap neerlegt na het voltooien van een zaagsnede, controleert u dat de

onderste beschermkap gesloten is en het zaagblad volledig tot stilstand is gekomen.

28. Probeer nooit te zagen waarbij de cirkelzaagmachine ondersteboven in een bankschroef is

geklemd. Dit is uiterst gevaarlijk en kan leiden

tot ernstig persoonlijk letsel.

29. Sommige materialen bevatten chemische stoffen

die giftig kunnen zijn. Neem voorzorgsmaatregelen tegen het inademen van stof en contact met

de huid. Volg de veiligheidsinstructies van de

leverancier van het materiaal op.

30. Breng het zaagblad niet tot stilstand door zijdelings op het zaagblad te drukken.

31. Gebruik altijd zaagbladen die in deze gebruiksaanwijzing aanbevolen worden. Gebruik geen

slijpschijven.

32. Houd het zaagblad scherp en schoon. Gom of

hars dat op het zaagblad is opgedroogd vertraagt

het zaagblad en verhoogt de kans op terugslag.

Houd het zaagblad schoon door dit eerst van het

gereedschap te demonteren en het vervolgens

schoon te maken met een reinigingsmiddel voor

gom en hars, heet water of kerosine. Gebruik nooit

benzine.

33. Draag een stofmasker en gehoorbescherming

tijdens gebruik van het gereedschap.

000150

000029

BEWAAR DEZE VOORSCHRIFTEN.

WAARSCHUWING:

Laat u NIET misleiden door een vals gevoel van comfort en bekendheid met het gereedschap (na veelvuldig gebruik) en neem alle veiligheidsvoorschriften

van het betreffende gereedschap altijd strikt in acht.

VERKEERD GEBRUIK of het niet naleven van de veiligheidsvoorschriften in deze gebruiksaanwijzing

kan leiden tot ernstige verwondingen.

BESCHRIJVING VAN DE FUNCTIES

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en zijn stekker uit het stopcontact is verwijderd alvorens de functies op het gereedschap te controleren of

af te stellen.

De zaagdiepte instellen (Fig. 1)

LET OP:

• Nadat u de zaagdiepte hebt ingesteld, zet u de hendel

altijd stevig vast.

Draai de hendel van de dieptegeleider los en beweeg de

zool omhoog of omlaag. Zet de zool vast op de gewenste

zaagdiepte door de hendel vast te zetten.

Voor een schonere, veiligere zaagsnede, stelt u de zaagdiepte zodanig in dat niet meer dan een tandhoogte door

het werkstuk heen steekt. Door de zaagdiepte goed in te

stellen, verkleint u de kans op een potentieel gevaarlijke

TERUGSLAG, en daarmee op persoonlijk letsel.

Verticaal verstekzagen (Fig. 2, 3 en 4)

Zet de voorste hendel en de achterste vleugelmoer los.

Stel in op de gewenste zaaghoek (0° – 50°) door de zaag

in die stand te kantelen en zet dan de voorste hendel en

de vleugelmoer weer stevig vast.

Gebruik de 45° verstekhoekknop als u in een precieze

verstekhoek van 45° wilt zagen. Draai de knop volledig

naar rechts voor verstek zagen (0° – 45°) of draai de

knop naar links voor een andere zaaghoek van 0° – 50°.

Zichtlijn (Fig. 5)

Voor recht zagen lijnt u de 0°-markering vooraan de zoolplaat precies uit met uw zaagsnedelijn. Voor 45° verstekzagen gebruikt u de 45°-markering. De stand van de

bovenste geleider is instelbaar.

Werking van de aan/uit-schakelaar (Fig. 6)

LET OP:

• Controleer altijd, voordat u de stekker in het stopcon-

tact steekt, of de aan/uit-schakelaar op de juiste manier

schakelt en weer terugkeert naar de uit-stand nadat

deze is losgelaten.

Om te voorkomen dat de aan/uit-schakelaar per ongeluk

wordt bediend, is een uit-vergrendelknop aangebracht.

Om het gereedschap te starten, drukt u de uit-vergrendelknop in en knijpt u de aan/uit-schakelaar in. Laat de

aan/uit-schakelaar los om het gereedschap te stoppen.

Trek niet hard aan de trekkerschakelaar zonder ook de

uit-vergrendelknop in te drukken. De schakelaar zou

daardoor kunnen breken.

35

Page 15

Voor model HS6101, HS7101

Het lampje laten branden (Fig. 7)

LET OP:

• Kijk niet recht in het lamplicht of de lichtbron.

Het lampje gaat branden wanneer u het gereedschap op

de stroom aansluit. Het lampje blijft branden totdat u de

stroom afsluit.

OPMERKING:

• Gebruik een zachte doek om vuil van het lensglas van

het lampje te verwijderen. Let op dat u geen krassen

maakt op het lensglas van het lampje, want dat kan het

licht belemmeren.

• Gebruik geen benzine, thinner e.d. om het lensglas

van het lampje schoon te maken. Dergelijke stoffen

kunnen het lensglas beschadigen.

INEENZETTEN

LET OP:

• Zorg altijd dat het gereedschap is uitgeschakeld en dat

zijn stekker uit het stopcontact is verwijderd alvorens

enig werk aan het gereedschap uit te voeren.

Het zaagblad aanbrengen en verwijderen

(Fig. 8)

LET OP:

• Verzeker u ervan dat het zaagblad zodanig wordt aangebracht dat de tanden aan de voorkant van het

gereedschap omhoog wijzen.

• Gebruik uitsluitend de Makita-sleutel voor het aanbrengen en verwijderen van het zaagblad.

Als u het zaagblad wilt verwijderen, drukt u eerst de

asvergrendeling in zodat het zaagblad niet meer kan

draaien, en gebruikt u vervolgens de inbussleutel om de

zeskantbout linksom los te draaien. Verwijder tenslotte

de zeskantbout, de buitenflens en het zaagblad.

Voor gereedschap met een binnenflens voor een

zaagblad met een middengatdiameter van 15,88 mm

(Fig. 9)

Plaats de binnenflens met de verzonken kant naar buiten

gericht op de as en breng daarna het zaagblad, de buitenflens en de zeskantbout aan.

ZORG ERVOOR DAT U DE ZESKANTBOUT

RECHTSOM STEVIG VASTDRAAIT.

Voor gereedschap met een binnenflens voor een

zaagblad met een andere middengatdiameter dan

15,88 mm (Fig. 10)

De binnenflens heeft een uitstulping met een zekere diameter aan één zijde en een uitstulping met een andere

diameter aan de andere zijde. Kies de juiste zijde waarvan de uitstulping perfect in het middengat van het zaagblad past.

Plaats vervolgens de binnenflens zodanig op de as dat

de zijde met de juiste uitstulping naar buiten wijst, en

breng daarna het zaagblad, de buitenflens aan.

ZORG ERVOOR DAT U DE ZESKANTBOUT

RECHTSOM STEVIG VASTDRAAIT.

LET OP:

• Zorg ervoor dat de uitstulping “a” van de binnenflens die naar buiten wijst, perfect past in het middengat “a” van het zaagblad. Als u het zaagblad op

de verkeerde kant van de binnenflens aanbrengt, kunnen gevaarlijke trillingen het gevolg zijn.

Bij het verwisselen van het zaagblad dient u vooral ook

het opgehoopt zaagsel van de bovenste en onderste

beschermkappen te verwijderen. Dit verlost u echter niet

van de plicht om vóór elk gebruik de werking van de

onderste beschermkap nog eens te controleren. (Fig. 11)

Opbergplaats voor de inbussleutel (Fig. 12)

Wanneer u de inbussleutel niet gebruikt, bergt u deze op

de plaats aangegeven in de afbeelding op, om te voorkomen dat deze wordt verloren.

Aansluiten van een stofzuiger (Fig. 13 en 14)

Wanneer u bij het zagen de omgeving schoon wilt houden, sluit u een Makita stofzuiger aan op uw gereedschap. Zet het stofzuigmondstuk op het gereedschap

vast met de schroef. Sluit vervolgens de stofzuigerslang

aan op het mondstuk, zoals in de afbeelding getoond.

BEDIENING (Fig. 15)

LET OP:

• Duw het gereedschap voorzichtig in een rechte lijn

naar voren. Als u het gereedschap dwingt of verdraait,

zal de motor oververhit raken en het gereedschap

gevaarlijk terugslaan waardoor ernstig letsel kan worden veroorzaakt.

• Gebruik altijd de voorhandgreep en achterhandgreep,

en houd het gereedschap tijdens gebruik stevig vast

aan zowel de voorhandgreep als de achterhandgreep.

Houd het gereedschap stevig vast. Het gereedschap is

voorzien van zowel een voorhandgreep als een achterhandgreep. Gebruik beide handgrepen om het gereedschap optimaal vast te houden. Als u de cirkelzaag met

beide handen vasthoudt, kunt u nooit in uw handen

zagen. Plaats eerst de zool op het werkstuk dat u wilt

zagen, zonder dat het zaagblad het werkstuk raakt.

Schakel vervolgens het gereedschap in en wacht totdat

het zaagblad op volle snelheid draait. Duw het gereedschap nu gewoon naar voren over het oppervlak van het

werkstuk, houd het daarbij vlak, en duw gelijkmatig totdat

het zagen klaar is.

Zorg voor een schone zaagsnede door een rechte zaaglijn en een constante voortgaande snelheid. Als de zaagsnede niet verloopt volgens de voorgenomen zaaglijn,

mag u niet proberen het gereedschap iets te draaien of

te dwingen terug te keren naar de zaaglijn. Als u dit doet,

kan het zaagblad vastlopen en een gevaarlijke terugslag

optreden met mogelijk ernstig persoonlijk letsel tot

gevolg. Laat de aan/uit-schakelaar los, wacht tot het

zaagblad tot stilstand is gekomen en trek vervolgens het

gereedschap terug. Lijn het gereedschap opnieuw uit

met een nieuwe zaaglijn en begin weer te zagen. Probeer te vermijden dat door de positie van het gereedschap de gebruiker wordt blootgesteld aan zaagsel en

spaanders die door het gereedschap worden uitgeworpen. Gebruik oogbescherming om verwonding te voorkomen.

Breedtegeleider (liniaal) (Fig. 16)

Met de handige breedtegeleider kunt u extra nauwkeurig

recht zagen. Schuif gewoon de breedtegeleider strak

tegen de zijkant van het werkstuk en zet deze op zijn

plaats vast met behulp van de schroef op de voorkant

van de zool van het gereedschap. Op deze manier is het

tevens mogelijk een zaagbeweging te herhalen met identieke breedte.

36

Page 16

ONDERHOUD

LET OP:

• Zorg altijd dat het gereedschap is uitgeschakeld en zijn

stekker uit het stopcontact is verwijderd alvorens te

beginnen met inspectie of onderhoud.

• Gebruik nooit benzine, wasbenzine, thinner, alcohol en

dergelijke. Hierdoor kunnen verkleuring, vervormingen

en barsten worden veroorzaakt.

Nauwkeurig de zaaghoek van 0° en 45° instellen

(verticaal en 45° verstekzagen) (Fig. 17 en 18)

Deze instelling is in de fabriek gemaakt. Maar als de

instelling niet meer juist is, draait u met een inbussleutel

de instelschroeven bij terwijl u de precieze hoek van 0° of

45° controleert met een tekendriehoek of een gradenboog, enz.

Nauwkeurig parallel instellen (Fig. 19)

De parallelstand van het zaagblad en de zoolplaat is in

de fabriek ingesteld. Maar als die instelling niet meer juist

is, kunt u deze als volgt corrigeren.

Zorg dat alle hendels en schroeven stevig vast zijn

gezet. Draai dan zoals in de afbeelding de schroef ietwat

los. Open nu de onderste beschermkap en verstel de

achterkant van de zoolplaat zo dat de afstanden A en B

precies gelijk zijn. Wanneer dit in orde is, draait u de

schroef weer vast. Maak een proefzaagsnede om te zien

of er precies parallel gezaagd wordt.

Vervangen van koolborstels (Fig. 20 en 21)

Verwijder en controleer regelmatig de koolborstels. Vervang de koolborstels wanneer ze tot aan de limietmarkering versleten zijn. Houd de koolborstels schoon, zodat

ze gemakkelijk in de houders glijden. Beide koolborstels

dienen gelijktijdig te worden vervangen. Gebruik uitsluitend gelijksoortige koolborstels.

Gebruik een schroevendraaier om de kappen van de

koolborstelhouders te verwijderen. Haal de versleten

koolborstels eruit, schuif de nieuwe erin, en zet daarna

de kappen weer goed vast.

Na het vervangen van de koolborstels sluit u de stroom

van het gereedschap aan, om dan de koolborstels in te

werken door het gereedschap onbelast zo'n 10 minuten

lang te laten draaien. Controleer dan terwijl het gereedschap draait de werking van de elektrische rem wanneer

u de trekkerschakelaar loslaat. Als de elektrische rem

niet goed werkt, laat u het gereedschap dan repareren

door een Makita servicecentrum.

Om de VEILIGHEID en BETROUWBAARHEID van het

product te handhaven, dienen alle reparaties en alle

andere onderhoudswerkzaamheden of afstellingen te

worden uitgevoerd door een erkend Makita Servicecentrum, en dat uitsluitend met gebruik van Makita vervangingsonderdelen.

OPTIONELE ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita gereedschap dat in deze

gebruiksaanwijzing wordt beschreven. Het gebruik van

andere accessoires of hulpstukken kan gevaar voor

persoonlijke verwonding opleveren. Gebruik de accessoires of hulpstukken uitsluitend voor het gespecificeerde doel.

Wenst u meer informatie over deze accessoires, neem

dan contact op met het dichtstbijzijnde Makita servicecentrum.

• Zaagbladen

• Breedtegeleider (Liniaal)

• Geleiderail

• Geleiderailadapter

• Inbussleutel

• Aansluitstuk

OPMERKING:

• Sommige van de onderdelen in deze lijst kunnen bijgeleverd zijn als standaard-accessoires. Deze accessoires kunnen per land verschillend zijn.

ENG905-1

Geluidsniveau

De typisch, A-gewogen geluidsniveaus vastgesteld volgens EN60745:

Model HS6100, HS6101

Geluidsdrukniveau (L

Geluidsvermogenniveau (L

Onnauwkeurigheid (K): 3 dB (A)

Model HS7100, HS7101

Geluidsdrukniveau (L

Geluidsvermogenniveau (L

Onnauwkeurigheid (K): 3 dB (A)

Draag oorbeschermers

Trilling

De totaalwaarde van de trillingen (triaxiale vectorsom)

vastgesteld volgens EN60745:

Model HS6100, HS6101

Gebruikstoepassing: zagen in hout

Trillingsemissie (a

Onnauwkeurigheid (K): 1,5 m/s

Gebruikstoepassing: zagen in metaal

Trillingsemissie (a

Onnauwkeurigheid (K): 1,5 m/s

Model HS7100, HS7101

Gebruikstoepassing: zagen in hout

Trillingsemissie (a

Onnauwkeurigheid (K): 1,5 m/s

Gebruikstoepassing: zagen in metaal

Trillingsemissie (a

Onnauwkeurigheid (K): 1,5 m/s

): 89 dB (A)

pA

): 100 dB (A)

WA

): 90 dB (A)

pA

): 101 dB (A)

WA

): 2,5 m/s2 of lager

h, W

2

): 2,5 m/s

h, M

): 2,5 m/s2 of lager

h, W

2

): 2,5 m/s

h, M

ENG900-1

2

2

2

2

37

Page 17

• De opgegeven trillingsemissiewaarde is gemeten volgens de standaardtestmethode en kan worden gebruikt

om dit gereedschap te vergelijken met andere gereedschappen.

• De opgegeven trillingsemissiewaarde kan ook worden

gebruikt voor een beoordeling vooraf van de blootstelling.

WAARSCHUWING:

• De trillingsemissie tijdens het gebruik van het elektrisch

gereedschap in de praktijk kan verschillen van de

opgegeven trillingsemissiewaarde afhankelijk van de

manier waarop het gereedschap wordt gebruikt.

• Zorg ervoor dat veiligheidsmaatregelen worden getroffen ter bescherming van de operator die zijn gebaseerd

op een schatting van de blootstelling onder praktijkomstandigheden (rekening houdend met alle fasen van de

bedrijfscyclus, zoals de tijdsduur gedurende welke het

gereedschap is uitgeschakeld en stationair draait,

naast de ingeschakelde tijdsduur).

ENG901-1

ENH101-15

Alleen voor Europese landen

EU-Verklaring van Conformiteit

Wij, Makita Corporation, als de verantwoordelijke

fabrikant, verklaren dat de volgende Makitamachine(s):

Aanduiding van de machine: Cirkelzaagmachine

Modelnr./Type: HS6100, HS6101, HS7100, HS7101

in serie zijn geproduceerd en

Voldoen aan de volgende Europese richtlijnen:

2006/42/EC

En zijn gefabriceerd in overeenstemming met de volgende normen of genormaliseerde documenten:

EN60745

De technische documentatie wordt bewaard door onze

erkende vertegenwoordiger in Europa, te weten:

Makita International Europe Ltd.

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, Engeland

6.6.2011

38

Tomoyasu Kato

Directeur

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

Page 18

Makita Corporation

Anjo, Aichi, Japan

885084-994

IDE

www.makita.com

Loading...

Loading...