Page 1

Optional accessories

Nylon cutting head, Charger DC36WA/DC36RA, Battery BL3622A/BL3626, Battery converter BCV02

Standard equipment

Note: The standard equipment for the tool shown above may vary by country.

Nylon cutting head (Bump & Feed 4)..... 1

Hex wrench (for M4) .............................. 1

Socket wrench ........................................ 1

Pin 4 (Lock key) ..................................... 1

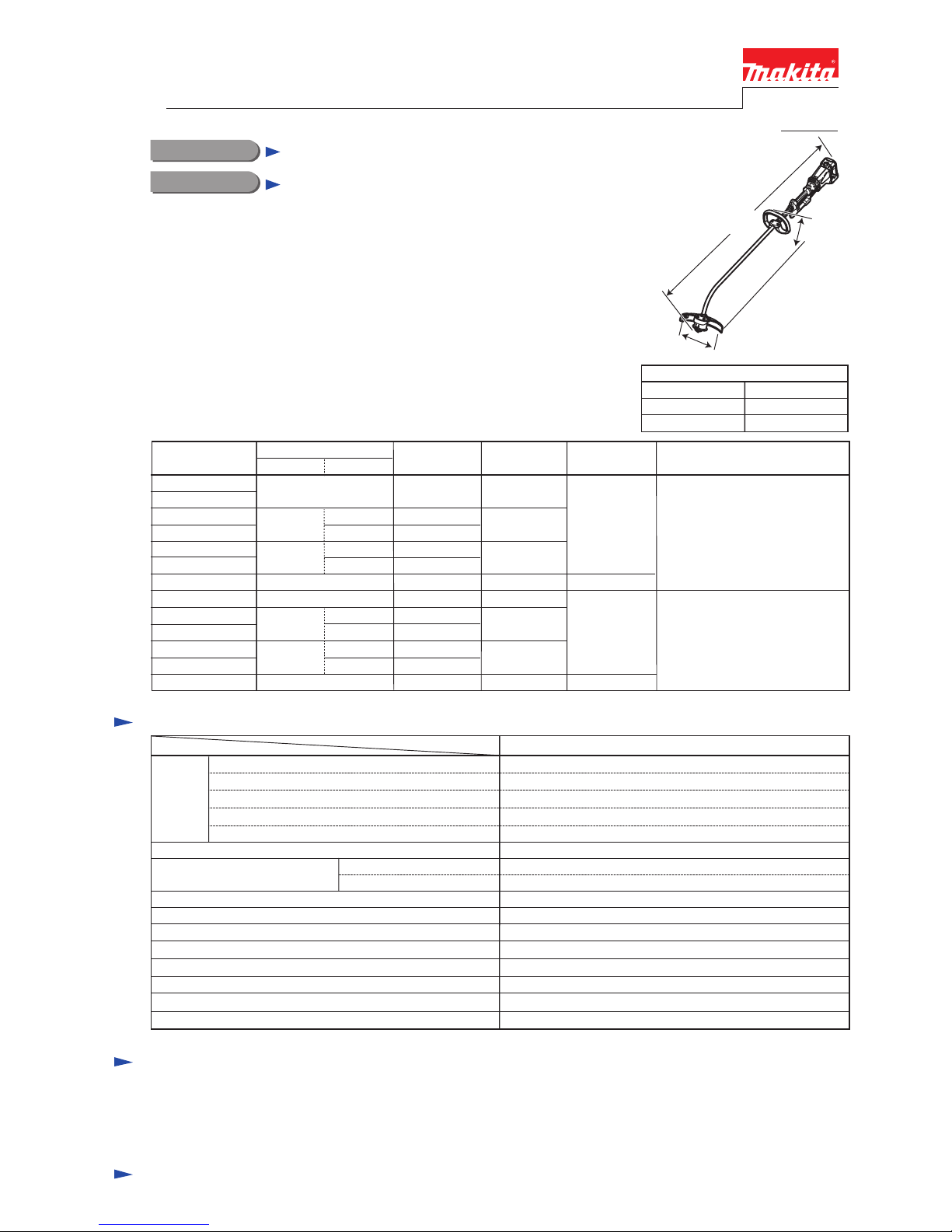

Models No.

Description

CONCEPT AND MAIN APPLICATIONS

BUR360 (HRU01*1), UR360D

Cordless String Trimmer 300mm (11-3/4

")

Models BUR360 is a cordless string trimmer 300mm(11-3/4") with a bent shaft,

powered by 36V/2.6Ah Li-ion battery BL3626, and charged by DC36RA.

The main advantages are "Environment-friendly" and "Light weight and

compact size" obtained by using Zero exhaust emission Li-ion battery and

Brushless DC motor as the power unit instead of gasoline and engine.

Other advantages are:

• Grass clipping removal function

• High/Low 2-speed selection with variable speed in each range

Model BUR360 is available in the following variations, like UR360D.

Specification

80/ 94

300

36

Standard cutting tool/ Spindle thread size

Battery

Max output: W

Voltage: V

2.2/ 2.6Capacity: Ah

Li-ion

Specifications

Model

Cell

Electric brake Yes

Overload protection Current limiter

*

1 No load speed of the cutting tool *2 with Nylon cutting head

Nylon cutting head/ M8 Right-handed

BUR360

5.1 (11.2)

No load speed*

1: min.-1 = rpm

60(with DC36WA) / 22(with DC36RA)Charging time (approx.): min.

Energy capacity: Wh

High

Low

0 - 7,000

0 - 5,100

Model No. Offered to

type quantity

Charger

Battery

converter

Battery

Battery

cover

BUR360Z

UR360DZ

BUR360RD

BUR360RDE

UR360DWB

UR360DWBE

BUR360ZX2C

HRU01Z

HRU011

HRU01

HRU01C1

HRU01C

HRU01ZX2

No

1

BL3626

BL3622A

BL3622A

2

1

2

No

No

No

No

No

No

No

No

No

No NoNo

1

1

DC36RA

DC36WA

1

2

No

1

DC36WA

No

No

No

BCV02

BCV02

All countries except North and

Central American countries

The models also includes the accessories listed below in "Standard equipment".

1

BL3626

2

No

1

DC36RA

Variable speed control Yes

Soft start Yes

Reversing switch Yes

L

295 (11-5/8)Width (W)

Height (H)

Dimensions: mm (")

Length (L)

420 (16-1/2)

1,720 (67-3/4)

W

H

*

1 Model number for North and Central American countries

North and Central

American countries

Weight according to EPTA-Procedure 01/2003: kg (lbs)*2

Cutting width: mm (") 300 (11-3/4)

PRODUCT

T

ECHNICAL INFORMATION

Accessory bag ........................... 1

Hex wrench (for M5) ................ 1

BCV02 (Battery converter) ....... 1 (for model BUR360ZX2C and

HRU01ZX2 only)

P 1/ 13

Page 2

Repair

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No. Description Use for

1R036 Bearing setting plate 17.2

1R232 Pipe 30

1R285 Round bar for arbor 11-50

holding Ball bearing 6001ZZ when removing Spindle hub

1R130 Nose 10-30

1R089 Bearing extractor

removing Ball bearing 6901ZZ left in Gear box

holding Helical gear 33, when removing Spindle hub

removing Spindle hub

1R286 Round bar for arbor 12-50 removing Ball bearing 608DDW from Head case

1R350 Ring 60 supporting Motor housing set when assembling Motor section

1R308 Spring pin extractor 4.0 locking Cutter holder when loosening Cutter holder

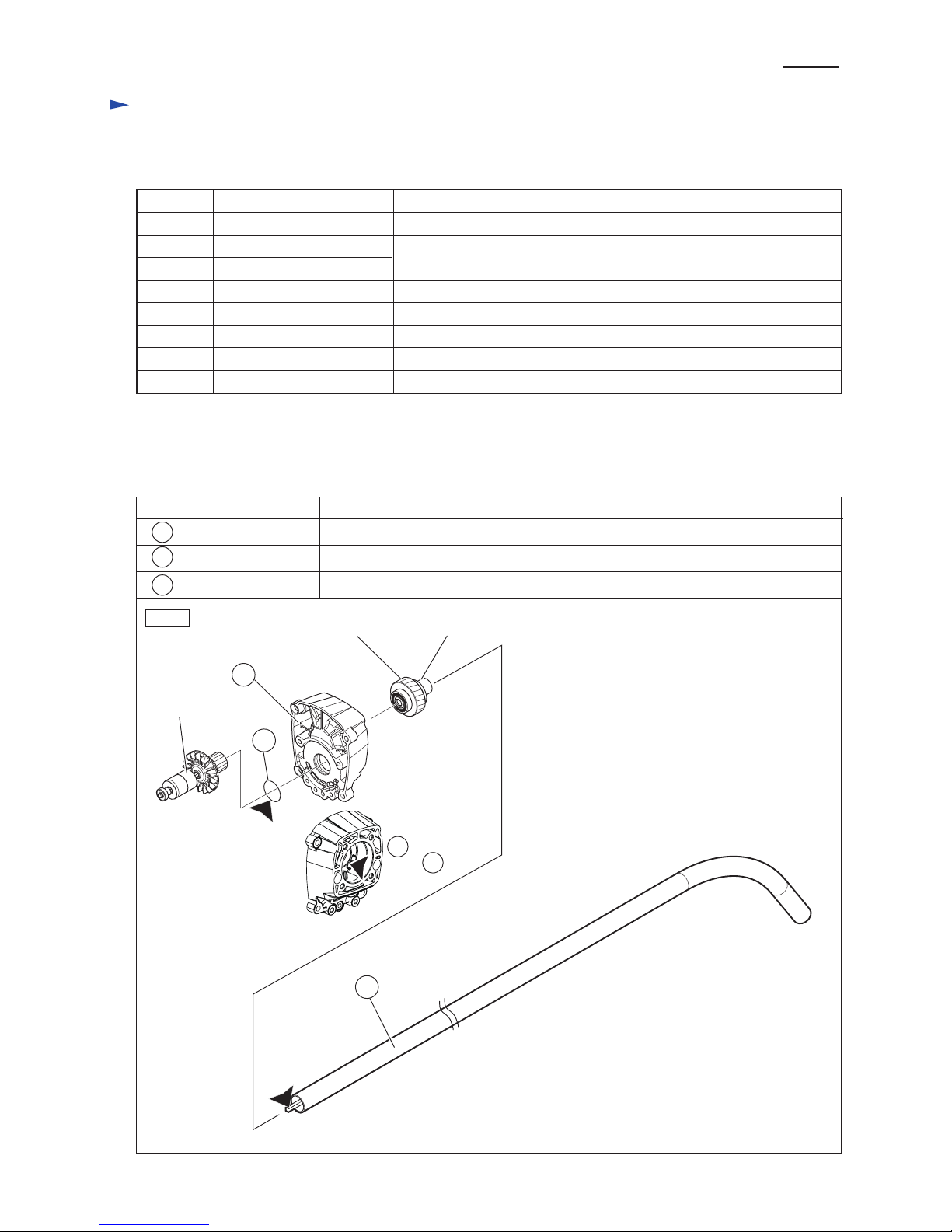

[2] LUBRICATION

Apply Makita grease N. No.2 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion.

Fig. 1

Item No. Description

Bent pipe complete a little

Gear box 3 g.

Square portion of Flexible shaft

O ring 22

a little

Whole portion

Gear room where Helical gear 33 engages with Armature’s gear

AmountPortion to lubricate

Armature

74

Helical gear 33 Spindle hub

31

31

74

87

87

74 viewed

from 31 side

P 2/ 13

Page 3

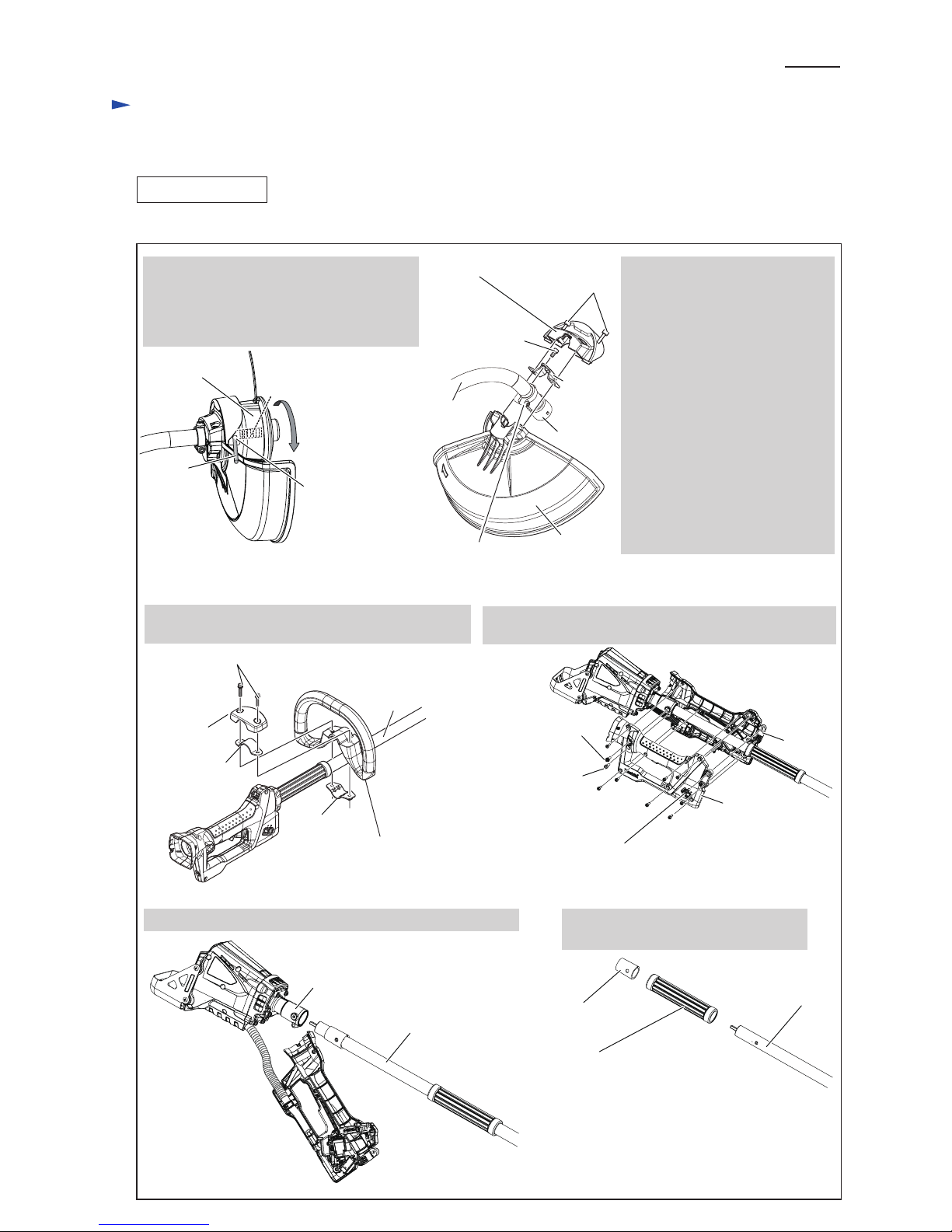

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Bent pipe complete

DISASSEMBLING

Disassemble Bent pipe complete as drawn in Fig. 2.

Fig. 2

1. While inserting 1R308 into the hole of

Cutter holder to stop Cutter shaft revolving,

turn Cutter assembly counterclockwise by

hand. Cutter assembly is removed from

Cutter shaft.

2. Loosen two M6x30 Hex socket

head bolts and remove Protector

cover and Protector.

Note: The M6x30 Hex socket

head bolts have Spring

washer 6 on each thread

to prevent losing.

It is not necessary to

separate them from

Protector.

Remove M5x10 Hex socket

head bolt and Protector clamp

from Head case complete, and

then Remove Head case complete

from Bent pipe complete by

loosening M5x25 Hex socket

head bolt.

M6x30 Hex socket

head bolt (2 pcs.)

M5x10 Hex

socket head bolt

Protector

clamp

Protector

Protector

cover

Cutter

assembly

male thread of Cutter shaft

(connected with Cutter

assembly at its inside)

1R308

M5x25 Hex

socket head bolt

Head case

3. Remove two M5x25 Hex socket head bolts and

separate Loop handle set* from Bent pipe complete.

4. Unscrew the following screws and bolts (11 pcs. in total),

and separate Grip R from Grip L.

*M5x25 Hex socket head bolt (2 pcs.)

*mark: The components of Loop handle set

*Clamp

cover B

*Clamp 33

M5x20 Pan

head screw

Grip R

M5x20 Hex

socket head bolt

M5x18 Hex

socket head bolt

4x18 Tapping

screws (8 pcs.)

Grip L

5. Pull off Bent shaft pipe complete from Pipe bracket by hand.

6. Pull off Pipe rubber and Spacer from

Bent pipe complete.

Pipe bracket

Bent pipe

complete

Spacer

Note: Some specifications

have no Spacer.

Pipe rubber

Bent pipe

complete

Repair

P 3/ 13

hole of Cutter

holder for 1R308

Bent pipe

complete

Bent pipe

complete

*Clamp 24

*Loop handle

Page 4

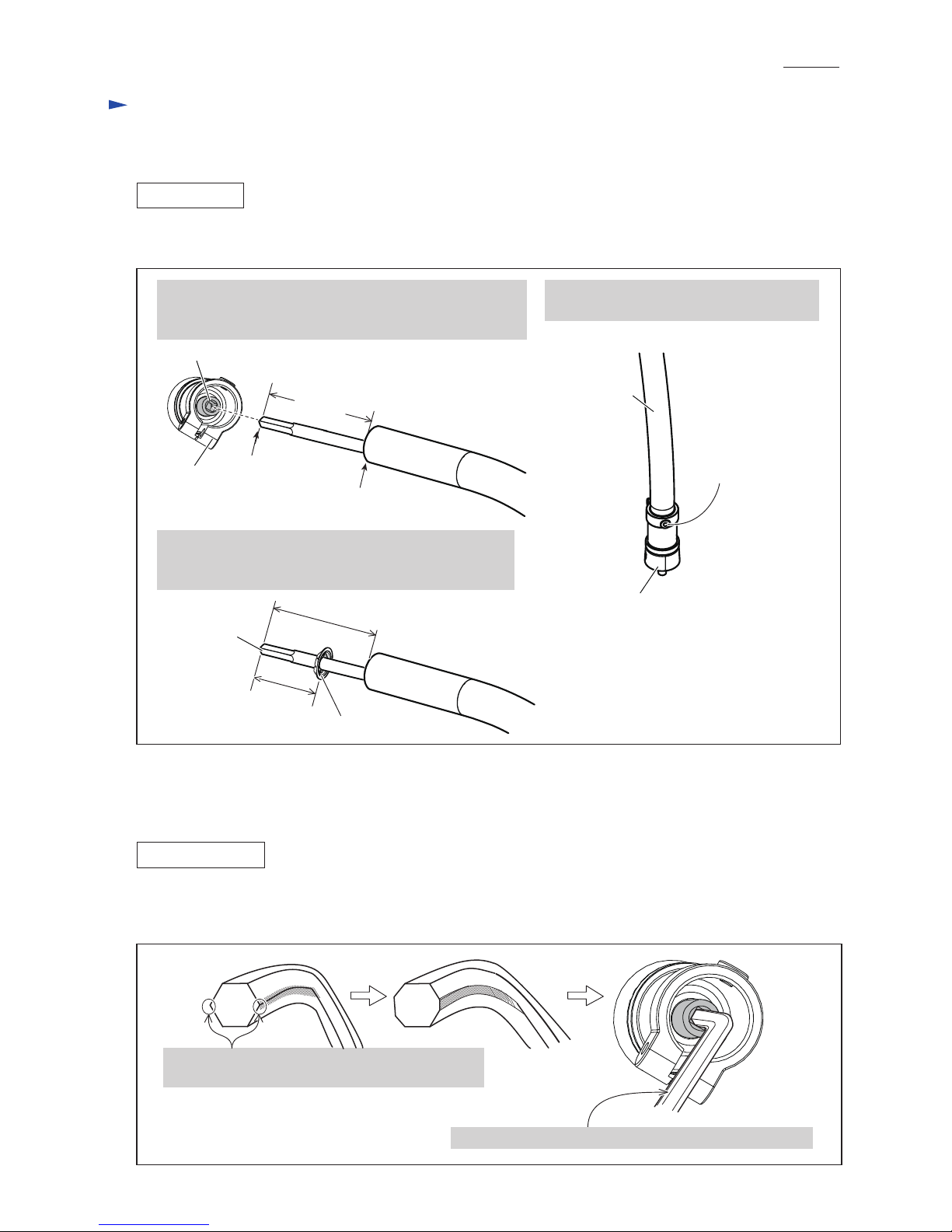

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Bent pipe complete (cont.)

[3] -2. Head case complete

ASSEMBLING

(1) Assemble Head case complete to Bent shaft pipe complete as drawn in Fig. 3.

(2) Assemble Loop hand set, Protector section, and Cutter assembly to Bent pipe complete in the reverse order of

Disassembly. Refer to Fig. 2.

Fig. 3

1. Pull out Flexible shaft to 100mm long from Bent shaft end.

Insert the square tip of Flexible shaft into the square hole

of Cutter shaft while turning.

1A. When replacing Flexible shaft with the new one,

place Bearing washer to the position that is 43 mm far

from the tip of Flexible shaft after step 1 shown above.

2. Align the hole of Head case complete with

the hole of Bend pipe complete.

The holes of Head case

complete and Bend pipe

complete for M5x10

Hex socket head bolt.

(1) Remove Head case complete from Bent pipe complete as Fig. 2.

(2) Remodel Hex wrench 5 as drawn in Fig. 4 to fit to the square hole of Cutter shaft.

DISASSEMBLING

1. File off the two edges in order to fit Hex wrench 5

to the square hole of Cutter shaft.

Fig. 4

Head case

complete

Square hole of Cutter shaft

Bearing washer

100 mm

Bent shaft end

Head case

complete

Bend pipe

complete

100 mm

43 mm

Flexible shaft

(new)

Repair

P 4/ 13

Square tip of

Flexible shaft

2. Hex wrench 5 can be fit to the square hole of Cutter shaft.

Page 5

Cutter holder

Modified Hex wrench 5 (See previous page.)

1R308

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Head case complete (cont.)

(3) Disassemble Head case complete as drawn in Fig. 5.

Assemble Head case complete in the reverse order of Disassembly. Refer to Fig. 5.

Be careful to the directions of Washer and Bearing washer. (Fig. 6)

Fig. 5

1. Lock Cutter holder with 1R308 inserted into its hole.

Hold Head case complete with vise.

Insert the modified end of Hex wrench 5 to the square

hole of Cutter shaft.

Cutter holder is removed from Head case complete by

turning Hex wrench 5 counterclockwise.

2. Put Head case complete on Turn table of

Arbor press. Press Cutter shaft with 1R286.

Cutter shaft section is separated from

Head case complete.

3. Disassemble Cutter shaft section as drawn below.

DISASSEMBLING

ASSEMBLING

Cutter holder

Cutter shaft

section

1R286

Cutter shaft

Cutter shaft

Bearing washer

Head case

complete

Head case

complete

Head case complete

Head case

Ball bearing 608ZZ Ball bearing 608DDW

Collar Washer Spring washer M8

Bearing washer

Washer

Spring washer 8

Ball bearing 608ZZ

Ball bearing 608DDW

Cutter shaft

Collar

Cutter holder

Fig. 6

Repair

P 5/ 13

Face the projection of Washer and Bearing washer to the opposite direction of Cutter holder.

Page 6

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Helical gear 33, Spindle hub

(1) Disassemble Bent pipe complete from Pipe bracket as drawn in Fig. 2.

And then, remove Helical gear section as drawn in Fig. 7.

Fig. 7

DISASSEMBLING

ASSEMBLING

1. Remove Gear box cover, and

then remove four M5x20 Pan

head screws and Pipe bracket.

2. Remove Helical gear section

from Gear box.

Fig. 8

(2) Disassemble Helical gear section as drawn in Fig. 8.

1R285

1R285

1R036

1. Put Helical gear 33 on 1R232, and press Spindle hub with 1R285.

Ball bearing 6901ZZ, Flat washer 12 and Helical gear 33 are separated from Spindle hub.

2. Put Ball bearing 6901ZZ on 1R036,

and press Spindle hub with 1R285.

Ball bearing 6901ZZ is separated

from Spindle hub.

Spindle hub

Spindle hub with

Ball bearing 6001ZZ

Spindle hub

1R232

Ball bearing

6901ZZ

Ball bearing

6001ZZ

Ball bearing

6001ZZ

Ball bearing

6901ZZ

Helical gear 33

Helical gear 33

Flat washer 12

Flat washer 12

Gear box

cover

Pipe bracket

M5x20

Pan head

screw

(4 pcs.)

Helical

gear section

2A. If Ball bearing 6901ZZ is left in Gear box,

remove it using 1R089 and 1R130 as

drawn below.

1R089

1R130

Ball bearing 6901ZZ

Ball bearing 6901ZZ

Repair

P 6/ 13

Helical

gear

section

Assemble Helical gear section in the reverse order of Disassembly.

Note: Be sure to set two Flat washers 12 in place as drawn in Fig. 8.

Page 7

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Rotor, Stator

DISASSEMBLING

(1) Separate Housing R from Housing L as drawn in Fig. 10.

Fig. 10

1. Unscrew the following screws and bolts, and separate Grip R from Grip L.

* M5x20 Hex socket head bolt * M5x16 Hex socket head bolt

* 4x18 Tapping screw (8 pcs.) * M5x20 Pan head screw

And then, pull off Shaft pipe B complete from Pipe bracket.

M5x20 Hex socket

head bolt

M5x20 Pan head screw

M5x16 Hex socket

head bolt

4x18 Tapping screw

( 8 pcs.)

Grip R

Grip L

Shaft pipe B complete

Pipe bracket

2. Remove Gear box cover from Gear box. 3. Remove four 5x25 Tapping screws.

Gear case cover

Gear box

4. Remove four M4x12 + screw and

Battery guard from Housing set.

5. Remove five 4x18 Tapping screws

and Housing R from Housing L.

Housing R

Battery guard

Repair

P 7/ 13

4x18 Tapping

screw (5 pcs.)

5x25 Tapping

screw (4 pcs.)

M4x12 + screw

(4 pcs.)

Page 8

P 8/ 13

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Rotor, Stator (cont.)

DISASSEMBLING

(2) Remove Motor section as drawn in Fig. 11.

(3) Remove Rotor from Stator as drawn in Fig. 12.

Fig. 11

2. Unscrew four 4x18 Tapping

screws, and separate Gear

box from DC motor section.

3. Unscrew three 4x18 Tapping screws,

and separate Motor housing R from

Motor housing L.

And then, remove Rotor together

with Stator from Motor housing L.

1. Disconnect the connectors of DC

motor section from those of

Controller, and then remove DC

motor section together with

Gear box from Housing L.

Motor housing R

DC motor

section

Workbench

Gear box

4x18 Tapping screw

(4 pcs.)

4x18 Tapping

screw (3 pcs.)

Motor housing L

RotorStator

4. Put Motor section on a workbench so that reverse side of the drive end of Rotor touches workbench.

Then, separate Rotor from Stator by pressing Stator down towards workbench while pulling up Rotor.

Fig. 12

Caution for Handling of Rotor

When handling or storing multiple Rotors, be sure to provide enough

distance so that they do not draw each other.

Rotor is a strongly magnetic body.

Therefore, failure to follow this instruction could result in:

* Finger injury caused by pinching between Rotors pulling each other

* Magnetic loss of Rotors

enough

distance

Repair

DC motor

section

Gear box

Housing L

Page 9

P 9/ 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Rotor, Stator (cont.)

Fig. 13

Fig. 14

ASSEMBLING

Assemble Rotor and Stator in the reverse order of disassembly. Refer to Figs. 12, 11, and 10.

Note 1: Rotor dragged by strong magnet force may bump on Circuit plate of Stator and give damage on that plate.

Therefore, assemble Rotor as drawn in Fig. 13.

Note 2: The mating face of Motor housing L tends to deviate from that of Motor housing R when assembling.

Therefore, assemble Motor housing L and Motor housing R as drawn in Fig. 14 after setting Rotor and

Stator to Motor housing L.

Circuit plate

Worktable

1. Hold Rotor perpendicularly.

3. When Rotor’s ball bearing reaches

the surface of Worktable through

the shaft hole, move Stator slowly

toward Rotor fan.

2. Pass Rotor held in perpendicular

slowly through Stator, aiming

precisely at the shaft hole of

Circuit plate.

1. After mounting Rotor and

Stator to Motor housing L,

set Motor housing R to

Motor housing L.

2. Closely applying the drive end

(Gear side) to 1R350, stand

Motor housing set on 1R350.

3. The mating face of Motor housing R is

automatically aligned to that of Motor

housing L on 1R350.

And tighten three 4x18 Tapping screws.

1R350

Motor

housing set

4x18 Tapping screw

(3 pcs.)

Motor

housing L

Motor

housing R

Page 10

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Indicator

[3] -6. Link plate

DISASSEMBLING

ASSEMBLING

ASSEMBLING

Fig. 15

Fig. 16

(1) Separate Grip R from Grip L, as per the center two illustrations in Fig. 2.

(2) Remove Indicator as drawn in Fig. 15.

(1) Assemble Indicator to Grip L.

(2) Set Steel ball 5.0 to Grip L.

(3) Mount Compression spring 2.

While holding both Steel ball 5.0 and Compression spring 2,

remove Indicator from Grip L.

Lock off button

Link plate

Link plate

holder

Fit this projection to Link plate

holder on Grip L.

Fit this prong portion to

the projection of Switch.

Fit this prong portion to the

projection of Lock off button.

Assemble Link plate as drawn in Fig. 16

Switch

Repair

P 10/ 13

Indicator

Steel ball 5.0

Compression

spring 2

Grip L

Page 11

P 11/ 13

Circuit diagram

White

Orange

Blue

Brown

Yellow

Main switch

Reverse

switch

Controller

Stator

Fig. D-1

3-pin

Connector

5-pin

Connector

6-pin

Connector

6-pin

Connector

For North American countries

Color index of lead wires' sheath

Black

Red

Terminal

AS

Terminal

Fuse

AS

Fuse is connected between Controller

and (+) pole of Terminal.

Power supply

cord unit

Page 12

P 12/ 13

Wiring diagram

Putting Power supply cord unit

Putting Connectors

Fig. D-3

Fig. D-2

Tube

Cord clamp

Cord clamp

Power supply cord unit

Face the tube of Power supply cord unit to Housing L, and set Power supply cord unit

in place as drawn below.

Housing L

Grip

Do not put any Lead wires

between Terminal and Rib B.

Rib B

Terminal

Cord clamp

5-pin connector

6-pin connector

Tube

Power supply

cord unit

Rib A

Power supply cord has to be fastened with

Cord clamp so that the cord end aligns to Rib A.

Do not clamp Tube with Cord clamp.

Power

supply

cord

Controller

Stator

Boss

Flag connectors have

to be connected so that

their wire connecting

portion is located to

the opposite side of

+ - pole marks.

Route Stator’s Lead wires

between Controller and Boss.

3-pin connector

Room for

5-pin connector

Fit 3-pin connector into the room on

Housing L as drawn below, and then

put 6-pin connector on 3-pin connector

as drawn in right.

Put Fuse in this place.

(for North American countries.)

Page 13

P 13/ 13

Wiring diagram

Wiring in Grip

Fig. D-4

See Fig. D-5 in details about the setting of

Reverse switch and its Receptacles.

Reverse switch

6-pin connector

Setting Reverse switch and Receptacles

Fig. D-5

Terminal (1)

Grip L

Receptacle covered with Sleeve

Terminal (P)

Reverse switch

Receptacle covered with Sleeve has to be

connected to Terminal (1) of Reverse switch.

Lead wires connected to Terminals

has to be faced to the direction drawn

in left so that they can be easily routed

between Boss and the wall of Grip L.

Receptacle

Boss

Put the slack portion of

lead wires in this place.

Put 6-pin connector into the room of

Grip L as drawn left.

Be careful to the direction.

Reverse switch has to be put to Grip L so

as to face its Terminal (1) to Grip L side.

Loading...

Loading...