Page 1

GB

Rotary Hammer Instruction Manual

F

Perforateur Manuel d’instructions

D

Bohrhammer Betriebsanleitung

I

Martello rotativo Istruzioni per l’uso

NL

Boorhamer Gebruiksaanwijzing

E

Martillo ligero Manual de instrucciones

P

Martelo ligeiro Manual de instruções

DK

Borehammer Brugsanvisning

S

Borrhammare Bruksanvisning

N

Borhammer Bruksanvisning

SF

Poravasara Käyttöohje

GR

Περιστροφικ σφυρί Οδηγίες χρήσεως

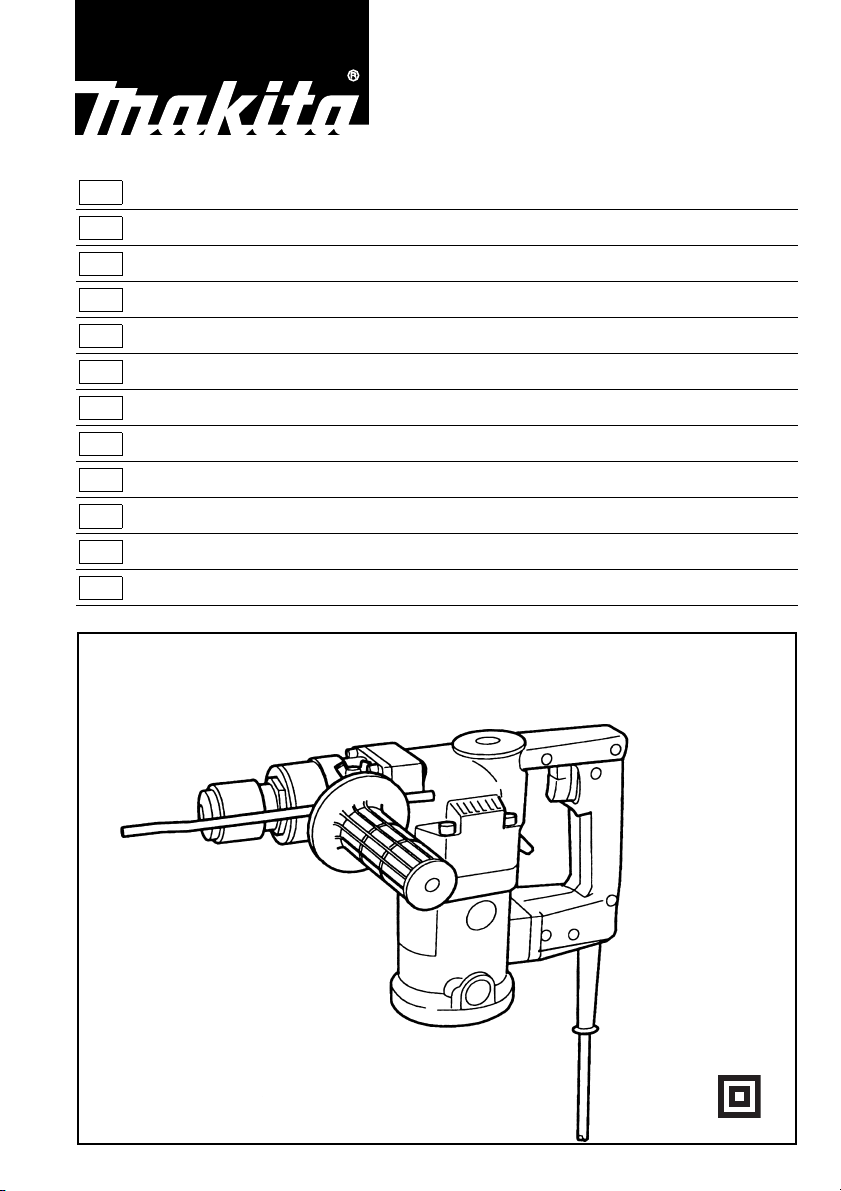

HR2510 25 mm

Page 2

12

34

56

78

2

Page 3

910

11

3

Page 4

ENGLISH

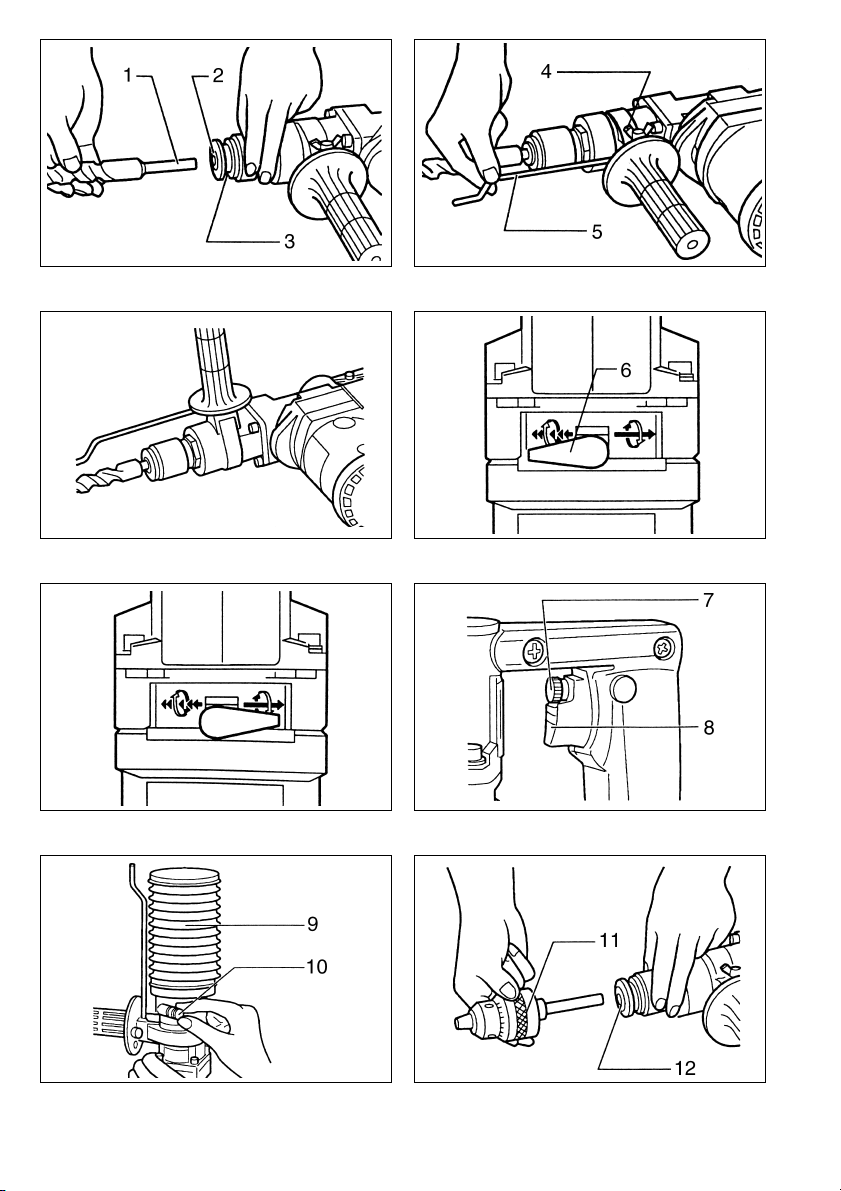

1Key groove

2 Red dot

3 Change ring

4 Wing bolt

5 Depth gauge

6 Change lever

Explanation of general view

7 Speed control screw

8 Switch trigger

9 Dust collector

10 Metal retainer

11 Drill chuck

12 Drill holder

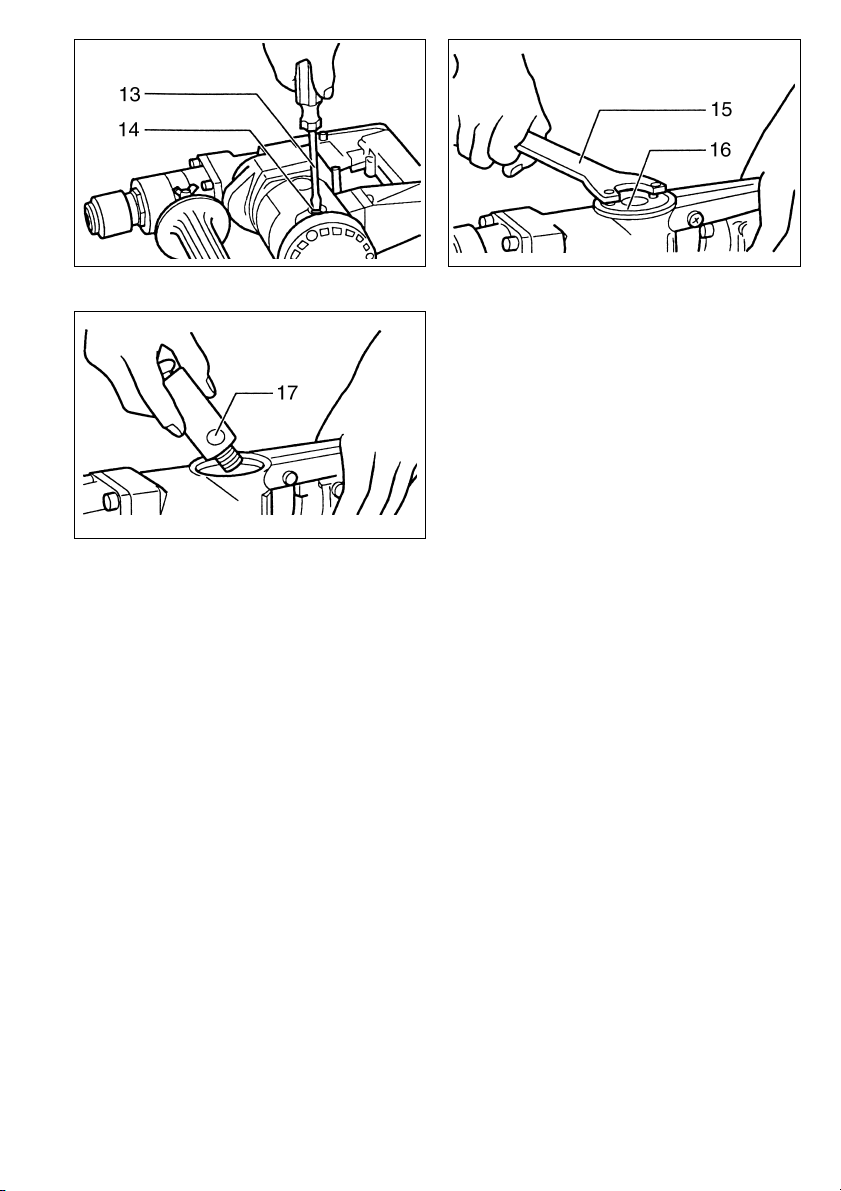

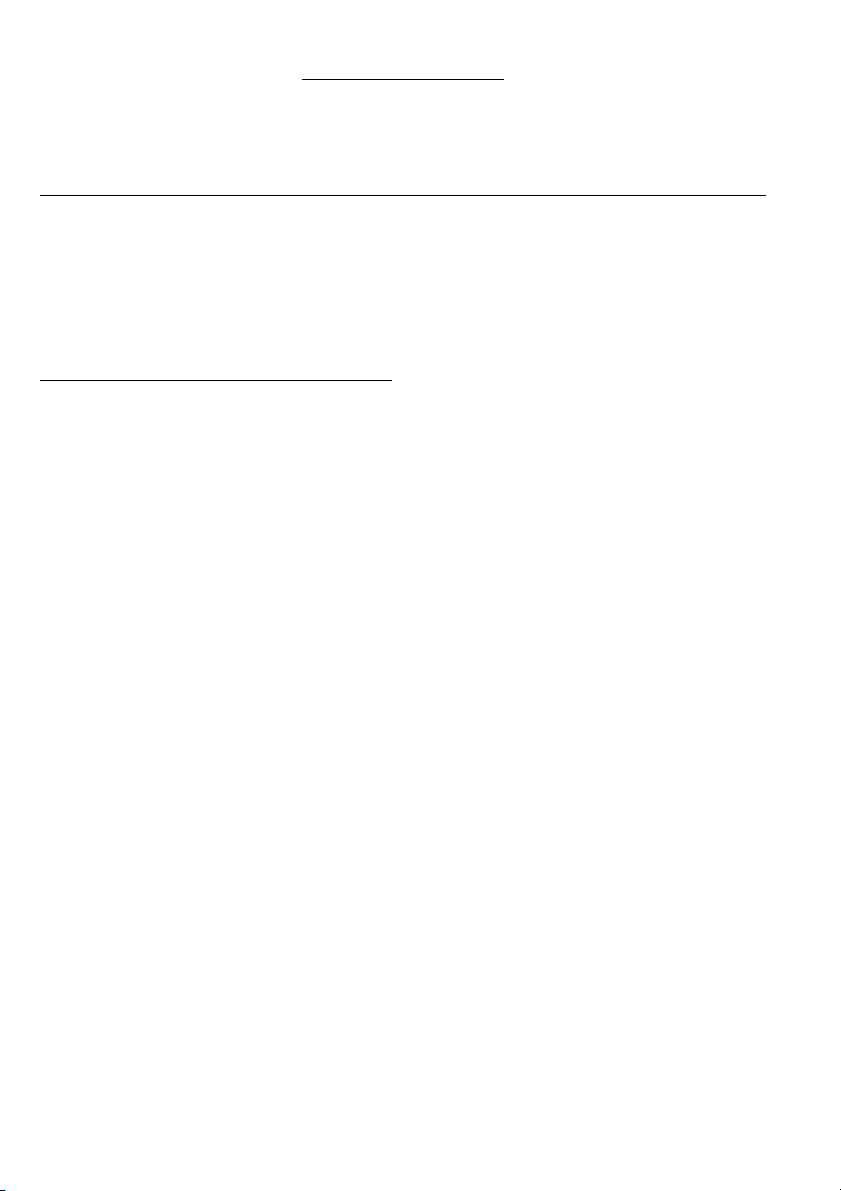

13 Screwdriver

14 Brush holder cap

15 Lock nut wrench

16 Crank cap

17 Hammer grease

SPECIFICATIONS

Model HR2510

Capacities

Wood ................................................................. 30 mm

Steel .................................................................. 13 mm

Concrete ............................................................ 25 mm

No load speed (min

Blows per minute .............................................. 0 –3,000

Overall length .................................................... 330 mm

Net weight ............................................................. 4.2kg

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed Safety

instructions.

–1

) ......................................... 0 –800

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to rotary hammer safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious personal injury.

1. Wear ear protectors. Exposure to noise can cause

hearing loss.

2. Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

4. Wear a hard hat (safety helmet), safety glasses

and/or face shield. Ordinary eye or sun glasses

are NOT safety glasses. It is also highly recommended that you wear a dust mask and thickly

padded gloves.

5. Be sure the bit is secured in place before opera-

tion.

6. Under normal operation, the tool is designed to

produce vibration. The screws can come loose

easily, causing a breakdown or accident. Check

tightness of screws carefully before operation.

GEB007-2

7. In cold weather or when the tool has not been

used for a long time, let the tool warm up for a

while by operating it under no load. This will

loosen up the lubrication. Without proper warmup, hammering operation is difficult.

8. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

9. Hold the tool firmly with both hands.

10. Keep hands away from moving parts.

11. Do not leave the tool running. Operate the tool

only when hand-held.

12. Do not point the tool at any one in the area when

operating. The bit could fly out and injure someone seriously.

13. Do not touch the bit or parts close to the bit

immediately after operation; they may be

extremely hot and could burn your skin.

14. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

Holding the tool

Hold the tool firmly with one hand on the gripping part of

the tool and the other hand on the side grip when performing the tool.

Bit grease

Coat the bit shank head beforehand with a small amount

(about 0.5–1g) of bit grease. This chuck lubrication

assures smooth action and longer service life.

Installing or removing drill bit (Fig. 1)

Important:

Always be sure that the tool is switched off and

unplugged before installing or removing the bit.

To install the bit, press the change ring in the direction of

the arrow, align the key groove in the bit shank with the

red dot and insert the bit. Now release the change ring. If

the change ring does not return to its original position

easily, turn the bit slightly in either direction.

To remove the bit, press the change ring in the direction

of the arrow and the bit will slip out.

Adjusting depth of drilling (Fig. 2)

Loosen the wing bolt and adjust the depth gauge to the

desired depth. After adjusting, tighten the wing bolt.

4

Page 5

Side grip (auxiliary handle) (Fig. 3)

The side grip swings around to either side, allowing easy

handling of the tool in any position. Loosen the side grip

by turning it counterclockwise, swing it to the desired

position and then tighten it by turning clockwise.

Selecting action mode

Rotation with hammering:

For drilling in concrete, granite, tile, etc., rotate the

change lever to the

Rotation only:

For drilling in wood or metal, rotate the change lever to

the

position. (Fig. 5)

Q

CAUTION:

To avoid rapid wear on the mode change mechanism, be

sure that the change lever is always positively located in

one of the two action mode positions.

position. (Fig. 4)

P

Switch action (Fig. 6)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

• Do not tape, tie or otherwise secure the trigger in the

“ON” position.

To start the tool simply pull the trigger. Tool speed is

increased by increasing pressure on the trigger. Release

the trigger to stop. A speed control screw is provided so

that maximum tool speed can be limited (variable). Turn

the speed control screw clockwise for higher speed, and

counterclockwise for lower speed.

Hammer drilling operation

Position the bit at the location for the hole, then pull the

trigger.

Do not force the tool. Light pressure gives best results.

Keep the tool in position and prevent it from slipping away

from the hole. Do not apply more pressure when the hole

becomes clogged with chips or particles. Instead, run the

tool at an idle, then remove from the hole. By repeating

this several times, the hole will be cleaned out.

CAUTION:

When the bit begins to break through concrete or if the

bit strikes reinforcing rods embedded in concrete, the tool

may react dangerously. Maintain good balance and safe

footing while holding the tool firmly with both hands to

prevent dangerous reaction.

Dust collector (Fig. 7)

Use the dust collector for safe, sanitary overhead operations. Install the bit, then attach the dust collector on the

end by turning and applying pressure. Then secure it by

turning the metal retainer clockwise.

CAUTION:

Empty the dust collector of its contents after drilling every

2 or 3 holes.

Drilling in wood or metal (Fig. 8)

Set the change lever for “rotation only”. Use the optional

drill chuck and chuck adapter for drilling up to 13 mm in

metal and up to 30 mm in wood. To install the drill chuck

and chuck adapter, refer to “Installing or removing drill

bit”.

CAUTION:

When the drill chuck is installed on this tool, do not use

“rotation with hammering” action. The drill chuck and

chuck adapter may be damaged.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Replacement of carbon brushes (Fig. 9)

Whenever carbon brushes must be replaced, they cut out

the tool automatically. When this occurs, replace both

carbon brushes at the same time. Use only identical carbon brushes.

Lubrication (Fig. 10 & 11)

This tool requires no hourly or daily lubrication because it

has a grease-packed lubrication system. Lubricate the

tool every time the carbon brushes are replaced.

Run the tool for several minutes to warm it up. Switch off

and unplug the tool. Remove the crank cap using a Makita lock nut wrench 35 (optional accessory). Rest the tool

on the table with the bit end pointing upwards. This will

allow the old grease to collect inside the crank housing.

Wipe out the old grease inside and replace with a fresh

grease (60 g). Use only Makita genuine grease (optional

accessory). Filling with more than the specified amount

of grease (approx. 60 g) can cause faulty hammering

action or tool failure. Fill only with the specified amount of

grease. Reinstall the crank cap and tighten with the lock

nut wrench. Do not tighten the crank cap excessively. It is

made of resin and is subject to breakage.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

5

Page 6

NEDERLANDS

1Groef

2 Rood stipje

3 Klemring

4 Vleugelbout

5 Diepte instelling

6 Keuzehendel

Verklaring van algemene gegevens

7 Snelheidschroef

8 Trekschakelaar

9 Stofvanger

10 Metalen klemring

11 Boorkop

12 Boorhouder

13 Schroevedraaier

14 Koolborsteldop

15 Nokkensleutel

16 Carterdeksel

17 Smeerolie voor

hamermechanisme

TECHNISCHE GEGEVENS

Model HR2510

Capaciteit

Hout .................................................................. 30mm

Staal .................................................................. 13 mm

Beton ................................................................ 25 mm

Toerental onbelast/min. ....................................... 0– 800

Aantal slagen/min. (min

Totale lengte ....................................................... 330mm

Netto gewicht ......................................................... 4,2 kg

• In verband met ononderbroken research en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

Stroomvoorziening

De machine mag alleen worden aangesloten op een

stroombron van hetzelfde voltage als aangegeven op de

naamplaat, en kan alleen op enkel-fase wisselstroom

worden gebruikt. De machine is dubbel-geïsoleerd volgens de Europese standaard en kan derhalve ook op

een niet-geaard stopcontact worden aangesloten.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

–1

) ............................... 0–3000

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

Laat u NIET misleiden door een vals gevoel van comfort en bekendheid met het gereedschap (na veelvuldig gebruik) en neem alle veiligheidsvoorschriften

van de boorhamer altijd strikt in acht. Bij onveilig of

verkeerd gebruik van het gereedschap, bestaat de

kans op ernstig persoonlijk letsel.

1. Draag gehoorbescherming. Blootstelling aan

harde geluiden kan leiden tot gehoorbeschadiging.

2. Gebruik de hulphandgrepen die bij het gereed-

schap werden geleverd. Als u de controle over het

gereedschap verliest, kan dit leiden tot ernstig persoonlijk letsel.

3. Houd elektrisch gereedschap vast aan het geïso-

leerde oppervlak van de handgrepen wanneer u

werkt op plaatsen waar het zaaggereedschap

met verborgen bedrading of zijn eigen snoer in

aanraking kan komen. Door contact met onder

spanning staande draden, zullen de niet-geïsoleerde metalen delen van het gereedschap onder

spanning komen te staan zodat de gebruiker een

elektrische schok kan krijgen.

4. Draag een veiligheidshelm, veiligheidsbril en/of

gezichtsbescherming. Een gewone bril of een

zonnebril is GEEN veiligheidsbril. Het wordt

tevens sterk aanbevolen een stofmasker en dik

gevoerde handschoenen te dragen.

5. Controleer dat het bit stevig op zijn plaats is

vastgezet voordat u het gereedschap gebruikt.

6. Bij normale bediening behoort het gereedschap

te trillen. De schroeven kunnen gemakkelijk losraken, waardoor een defect of ongeluk kan ontstaan. Controleer of de schroeven goed zijn

aangedraaid, alvorens het gereedschap te

gebruiken.

7. In koude weersomstandigheden of wanneer het

gereedschap gedurende een lange tijd niet is

gebruikt, laat u het gereedschap eerst opwarmen

door het onbelast te laten werken. Hierdoor zal

de smering worden verbeterd. Zonder degelijk

opwarmen, zal de hamerwerking moeilijk zijn.

8. Zorg er altijd voor dat u stevig staat.

Zorg ervoor dat er niemand zich onder u bevindt

wanneer u het gereedschap op een hoge plaats

gebruikt.

9. Houd het gereedschap met beide handen stevig

vast.

10. Houd uw handen uit de buurt van bewegende

delen.

11. Laat het gereedschap niet ingeschakeld liggen.

Bedien het gereedschap alleen wanneer u het

vasthoudt.

12. Richt het gereedschap niet op iemand in de

buurt terwijl het is ingeschakeld. Het bit zou eruit

kunnen vliegen en iemand ernstig verwonden.

13. Raak het bit en onderdelen in de buurt van het

bit niet onmiddellijk na gebruik aan. Zij kunnen

bijzonder heet zijn en brandwonden op uw huid

veroorzaken.

14. Sommige materialen bevatten chemische stoffen

die giftig kunnen zijn. Neem de nodige voorzorgsmaatregelen tegen inademing van stof en

contact met de huid. Volg de veiligheidsinstructies van de leverancier van het materiaal op.

BEWAAR DEZE VOORSCHRIFTEN.

WAARSCHUWING:

VERKEERD GEBRUIK of het niet naleven van de

veiligheidsvoorschriften in deze gebruiksaanwijzing

kan leiden tot ernstige verwondingen.

14

Page 7

BEDIENINGSVOORSCHRIFTEN

Het gereedschap vasthouden

Houd het gereedschap tijdens het gebruik stevig vast

met de ene hand op het grijpgedeelte van het gereedschap en de andere hand op de zijhandgreep.

Boorvet

Smeer alvorens het gereedschap te gebruiken, de boorkop met ongeveer 0,5–1gram boorvet in. Hierdoor wordt

een soepele werking en een langere gebruiksduur van

de boorkop verzekerd.

Installeren of verwijderen van de boor en

andere hulpstukken (Fig. 1)

Belangrijk:

Zorg er altijd voor dat het gereedschap is uitgeschakeld

en de stekker uit het stopkontakt is getrokken, alvorens

de boor te installeren of te verwijderen.

Om de boor of een ander hulpstuk te installeren, dient u

de klemring in de richting van de pijl te drukken, de groef

op de boorschacht op het rode stipje te richten en de

boor in te steken. Laat hierna de kelmring los. Indien de

klemring niet onmiddelijk terugspringt, draai dan het

boorijzer een beetje naar links of rechts om.

Om de boor te verwijderen, drukt u de klemring in de

richting van de pijl, waarna u het gemakkelijk uit kunt

nemen.

Instellen van de boordiepte (Fig. 2)

Draai de vleugelbout los en stel de diepteaanslag in op

de gewenste diepte. Draai vervolgens de vleugelbout

weer stevig vast.

Zijhandgreep (Fig. 3)

De zijhandgreep is verstelbaar dat wil zeggen u kunt hem

links of rechts plaatsen. Kies derhalve de positie die voor

u het prettigste is. Draai de zijhandgreep los naar links,

plaats hem in de gewenste positie en draai hem weer

stevig naar rechts vast.

Kiezen van de gereedschapswerking

Hamerende rotatie:

Voor boren in beton, graniet, tegel, enz., wordt de keuzehendel in de

Uitsluitend roteren:

Voor boren in hout of metaal, wordt de keuzehendel in de

P positie gezet. (Fig. 4)

Q positie gezet. (Fig. 5)

LET OP:

Teneinde voortijdige slijtage van het keuzemechanisme

te voorkomen, dient u ervoor te zorgen dat de keuzehendel altijd correct in een van de twee keuzeposities wordt

gezet.

Trekschakelaar (Fig. 6)

LET OP:

• Alvorens het netsnoer op het stopkontakt aan te sluiten, dient u altijd te kontroleren of de trekschakelaar

behoorlijk werkt en bij loslaten onmiddelijk naar de

“OFF” positie terugkeert.

• Zet de schakelaar nooit met plakband, draad of iets

dergelijks in de “ON” positie vast.

Men drukt, voor het starten, simpelweg de schakelaar in.

Bij het opvoeren van de druk op de schakelaar wordt de

snelheid van het apparaat verhoogd. Laat deze los om te

stoppen. Een snelheids regelschroef is aanwezig, waarmee de snelheid van het apparaat veranderd kan worden

bij volledig ingetrokken positie van de schakelaar. Draai

de schroef naar rechts voor sneller, en naar links voor

langzamer (RPM).

Hamerend boren

Plaats de punt van de boor op de plaats waar geboord

moet worden en druk vervolgens de schakelaar in.

Forceer het gereedschap niet. Een lichte druk geeft de

beste resultaten. Houd het gereedschap stevig vast en

zorg dat het niet uitglijdt. Oefen geen grotere druk uit op

het gereedschap, wanneer het gat vol raakt met gruis.

Laat integendeel het gereedschap onbelast draaien en

verwijder het uit het gat. Door dit een paar keer te herhalen wordt het gruis verwijderd.

LET OP:

Wanneer de boor door het beton heenkomt, of wanneer

de boor op betonstaven stuit, kan het apparaat gevaarlijk

vooruit- of terugschieten. Bewaar daarom tijdens het

boren een goede balans en houdt het apparaat met

beide handen stevig vast.

Stofvanger (Fig. 7)

Wanneer u boven uw hoofd moet boren is het aan te

bevelen een stofvanger te gebruiken om te voorkomen

dat u stof in uw ogen krijgt. Installeer de boor, en bevestig vervolgens de stofvanger op de daarvoor bestemde

plaats. Daarna de stofvanger vastklemmen door de

schroef van de metalen klemring naar rechts te draaien.

LET OP:

De stofvanger telkens na 2 of 3 keer boren, ledigen.

Boren in hout of metaal (Fig. 8)

Zet de keuzehendel in de positie voor “uitsluitend roteren”. Gebruik de losverkrijgbare boorkop en boorkopadapter voor het boren van maximaal 13 mm gaten in

metaal of maximaal 30 mm gaten in hout. Voor het installeren van de boorkop en boorkopadapter, zie de paragraaf “installeren of verwijderen van de boor”.

LET OP:

Wanneer op het gereedschap een boorkop is geinstalleerd dient u het gereedschap niet te gebruiken voor

“hamerende rotatie”. De boorkop en boorkopadapter kan

hierdoor worden beschadigd.

15

Page 8

ONDERHOUD

LET OP:

Zorg er altijd voor dat het gereedschap is uitgeschakeld

en de stekker uit het stopcontact is verwijderd alvorens

onderhoud aan het gereedschap uit te voeren.

Vervangen van koolborstels (Fig. 9)

Wanneer de koolborstels aan vervanging toe zijn, wordt

het gereedschap automatisch uitgeschakeld. Beide koolborstels dienen dan tegelijkertijd te worden vervangen.

Gebruik enkel identieke koolborstels.

Smeren (Fig. 10en 11)

Dit gereedschap hoeft niet om het uur of dagelijks te worden gesmeerd, aangezien het voorzien is van een automatisch smeersysteem. Smeer het gereedschap telkens

wanneer de koolborstels worden vervangen.

Start het gereedschap en laat het enkele minuten lang

warm lopen. Schakel het gereedschap vervolgens uit en

verbreek de aansluiting op het lichtnet. Verwijder met de

los verkrijgbare Makita nokkensleutel 35 de dop van het

carter. Plaats het gereedschap op een tafel met het booreind naar boven, zodat het oude smeervet in het carter

wordt verzameld. Verwijder dit oude smeervet en vervang het door 60 g vers smeervet. Gebruik uitsluitend het

los verkrijgbare, originele smeervet van Makita. Indien u

meer dan de aangegeven hoeveelheid smeervet (ongeveer 60 g) toevoegt, kunnen storingen optreden in het

hameren, of in de werking van het gereedschap. Vul derhalve uitsluitend bij met de aangegeven hoeveelheid

smeervet. Draai daarna met de nokkensleutel de dop

weer op het carter vast. Denk eraan de dop niet te stevig

vast te draaien. De dop is gemaakt van hars en is derhalve breekbaar.

Opdat het gereedschap veilig en betrouwbaar blijft, dienen alle reparaties, onderhoud of afstellingen te worden

uitgevoerd bij een erkend Makita service centrum.

16

Page 9

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

EN60745, EN55014, EN61000

ENH101-5

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che

questo prodotto è conforme agli standard di documenti

standardizzati seguenti:

secondo le direttive del Consiglio 89/336/CEE e 98/37/CE.

EN60745, EN55014, EN61000

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux normes des documents standardisés suivants,

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

EN60745, EN55014, EN61000

DEUTSCH

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt gemäß den Ratsdirektiven

89/336/EWG und 98/37/EG mit den folgenden Normen

von Normendokumenten übereinstimmen:

EN60745, EN55014, EN61000.

Yasuhiko Kanzaki

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid dat dit produkt voldoet aan de volgende

normen van genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

89/336/EEC en 98/37/EC.

EN60745, EN55014, EN61000

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos normalizados,

de acuerdo con las directivas comunitarias,

89/336/EEC y 98/37/CE.

CE 2005

EN60745, EN55014, EN61000

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

Verantwoordelijke fabrikant:

:

33

Page 10

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este

produto obedece às seguintes normas de documentos

normalizados,

de acordo com as directivas 89/336/CEE e 98/37/CE do

Conselho.

EN60745, EN55014, EN61000

ENH101-5

NORSK

EUs SAMSVARS-ERKLÆRING

Vi erklærer på eget ansvar at dette produktet er i overensstemmelse med følgende standard i de standardiserte dokumenter:

i samsvar med Råds-direktivene, 89/336/EEC og

98/37/EC.

EN60745, EN55014, EN61000,

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer hermed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de normsættende dokumenter,

i overensstemmelse med Rådets Direktiver 89/336/EEC

og 98/37/EC.

EN60745, EN55014, EN61000

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna

produkt överensstämmer med följande standardiseringar

för standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

EN60745, EN55014, EN61000

Yasuhiko Kanzaki

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote

on seuraavien standardoitujen dokumenttien standardien mukainen,

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

EN60745, EN55014, EN61000

ΕΛΛΗΝΙΚΑ

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

∆ηλώνουµε υπ την µοναδική µας ευθύνη τι αυτ

το προιν βρίσκεται σε Συµφωνία µε τα ακλουθα

πρτυπα τυποποιηµένων εγγράφων,

σύµφωνα µε τις Οδηγίες του Συµβουλίου,

89/336/EEC και 98/37/ΚE.

CE 2005

EN60745, EN55014, EN61000

34

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής

Müdür

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Υπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

Sorumlu imalatçı:

Page 11

ENGLISH

For European countries only

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is 8 m/s

These values have been obtained according to

EN60745.

Noise and Vibration

sound pressure level: 90 dB (A)

sound power level: 101dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG006-2-V4

ITALIANO

Modello per l’Europa soltanto

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione è di 8 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Rumore e vibrazione

Livello pressione sonora: 90dB (A)

Livello potenza sonora: 101dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

2

.

FRANÇAISE

Pour les pays d’Europe uniquement

Les niveaux de bruit ponderes types A sont:

Bruit et vibrations

niveau de pression sonore: 90 dB (A)

niveau de puissance du son: 101 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée est de 8m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

8m/s

Diese Werte wurden gemäß EN60745 erhalten.

Schalldruckpegel: 90 dB (A)

Schalleistungspegel: 101 dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 90 dB (A)

geluidsenergie-niveau: 101 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

8m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración es de 8 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

Ruido y vibración

presión sonora: 90 dB (A)

nivel de potencia sonora: 101 dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

2

.

35

Page 12

PORTUGUÊS

Só para países Europeus

Os níveis normais de ruído A são

– Utilize protectores para os ouvidos –

O valor médio da aceleração é 8m/s

Estes valores foram obtidos de acordo com EN60745.

Ruído e vibração

nível de pressão de som: 90 dB (A)

nível do sum: 101 dB (A)

A incerteza é de3 dB (A).

2

.

ENG006-2-V4

NORSK

Gjelder bare land i Europa

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon er

2

.

8m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

Støy og vibrasjon

lydtrykksnivå: 90 dB (A)

lydstyrkenivå: 101dB (A)

Usikkerheten er på 3 dB (A).

– Benytt hørselvern. –

DANSK

Kun for lande i Europa

De typiske A-vægtede lydniveauer er

Den vægtede effektive accelerationsværdi er 8 m/s

Disse værdier er beregnet i overensstemmelse med

EN60745.

Lyd og vibration

lydtryksniveau: 90 dB (A)

lydeffektniveau: 101 dB (A)

Der er en usikkerhed på 3 dB (A).

– Bær høreværn. –

2

.

SVENSKA

Endast för Europa

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration är

2

.

8m/s

Dessa värden har erhållits i enlighet med EN60745.

Buller och vibration

ljudtrycksnivå: 90dB (A)

ljudeffektnivå: 101 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

SUOMI

Vain Euroopan maat

Tyypilliset A-painotetut melutasot ovat

Tyypillinen kiihtyvyyden painotettu tehollisarvo on

2

.

8m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

Melutaso ja tärinä

äänenpainetaso: 90 dB (A)

äänen tehotaso: 101 dB (A)

Epävarmuus on 3 dB (A).

– Käytä kuulosuojaimia. –

ΕΛΛΗΝΙΚΑ

Μνο για χώρες της Ευρώπης

Οι τυπικές A-µετρούµενες εντάσεις ήχου είναι

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης είναι 8 m/s

Αυτές οι τιµές έχουν σηµειωθεί σύµφωνα µε το

EN60745.

Θρυβος και κραδασµς

πίεση ήχου: 90 dB (A)

δύναµη του ήχου: 101 dB (A)

Η Αβεβαιτητα είναι 3 dB (A).

– Φοράτε ωτοασπίδες. –

2

.

Makita Corporation

Anjo, Aichi, Japan

883436F979

Loading...

Loading...