Makita HR2400 User Manual

GB

Rotary Hammer Instruction Manual

F

Marteau perforateur Manuel d’instructions

D

Bohrhammer Betriebsanleitung

I

Martello rotativo Istruzioni d’uso

NL

Boorhamer Gebruiksaanwijzing

E

Martillo rotativo Manual de instrucciones

P

Martelo perfurador Manual de instruções

DK

Borehammer Brugsanvisning

S

Borrhammare Bruksanvisning

N

Borhammer Bruksanvisning

SF

Poravasara Käyttöohje

GR Περιστροφικ σφυρί Οδηγίες χρήσεως

HR2400

3

2

4

1

12

4

5

67

34

8

9

10

11

56

12 14 13

16

15

78

2

ENGLISH

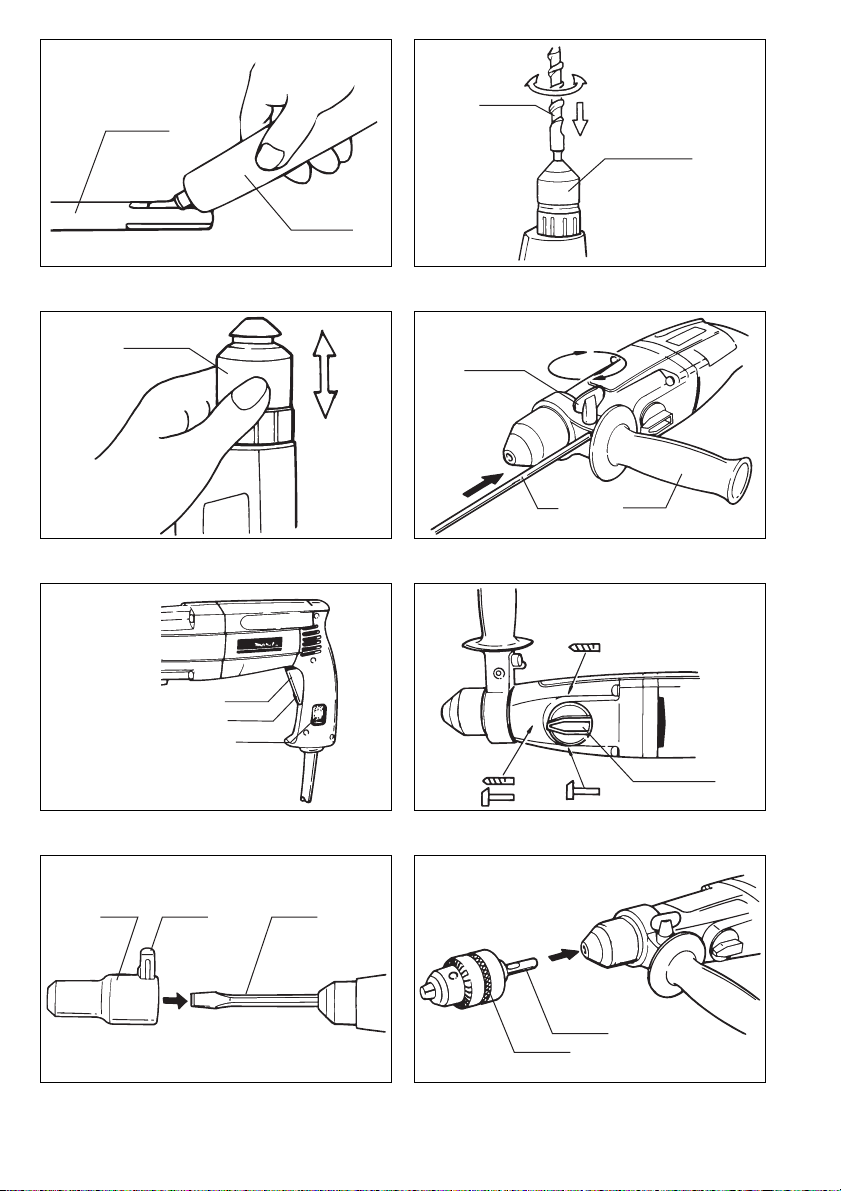

1 Bit grease

2 Bit shank

3Bit

4Chuck cover

5 Wing bolt

6 Depth gauge

Explanation of general view

7 Side grip

8 Switch trigger

9Lock lever

10 Reversing switch

11 Action mode changing knob

12 Chisel adapter

13 Chisel

14 Clamp screw

15 Drill chuck

16 Chuck adapter

SPECIFICATIONS

Model HR2400

Capacities

Concrete ............................................................ 24 mm

Wood ...............................................................* 38 mm

Steel .................................................................. 13 mm

No load speed (min

Blows per minute .............................................. 0 – 4,200

Overall length ..................................................... 333 mm

Net weight .............................................................. 2.3 kg

* When using a flat boring bit.

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

–1

) ...................................... 0 – 1,200

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to rotary hammer safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious personal injury.

1. Wear ear protectors. Exposure to noise can cause

hearing loss.

2. Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

4. Wear a hard hat (safety helmet), safety glasses

and/or face shield. Ordinary eye or sun glasses

are NOT safety glasses. It is also highly recommended that you wear a dust mask and thickly

padded gloves.

5. Be sure the bit is secured in place before opera-

tion.

6. Under normal operation, the tool is designed to

produce vibration. The screws can come loose

easily, causing a breakdown or accident. Check

tightness of screws carefully before operation.

GEB007-2

7. In cold weather or when the tool has not been

used for a long time, let the tool warm up for a

while by operating it under no load. This will

loosen up the lubrication. Without proper warmup, hammering operation is difficult.

8. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

9. Hold the tool firmly with both hands.

10. Keep hands away from moving parts.

11. Do not leave the tool running. Operate the tool

only when hand-held.

12. Do not point the tool at any one in the area when

operating. The bit could fly out and injure someone seriously.

13. Do not touch the bit or parts close to the bit

immediately after operation; they may be

extremely hot and could burn your skin.

14. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

OPERATING INSTRUCTIONS

Installing or removing drill bit (Fig. 1, 2 & 3)

Important:

Always be sure that the tool is switched off and

unplugged before installing or removing the bit.

Clean the bit shank and apply bit grease before installing

the bit. (Fig. 1)

Insert the bit into the tool. Turn the bit and push it in until

it engages. (Fig. 2)

If the bit cannot be pushed in, remove the bit. Pull the

chuck cover down a couple of times. Then insert the bit

again. Turn the bit and push it in until it engages. (Fig. 3)

After installing, always make sure that the bit is securely

held in place by trying to pull it out.

To remove the bit, pull the chuck cover down all the way

and pull the bit out. (Fig. 4)

3

Adjusting depth of drilling (Fig. 4)

Loosen the wing bolt and adjust the depth gauge to the

desired depth. After adjusting, tighten the wing bolt.

NOTE:

The depth gauge cannot be used at the position where

the depth gauge strikes against the gear housing.

Side grip (Auxiliary handle) (Fig. 4)

The side grip swings around to either side, allowing easy

handling of the tool in any position. Loosen the wing bolt

on the side grip and swing the side grip to the desired

position. Then tighten the wing bolt to secure the side

grip.

Operating instruction (Fig. 5)

Important:

Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the “OFF”

position when released.

Switching ON and OFF (Fig. 5)

To switch on, press the trigger.

To switch off, release the trigger.

Continuous running (Fig. 5)

Press the trigger and at the same time slide the lock lever

upward. To stop from this lock position, press the trigger

and release it.

Variable trigger speed control (Fig. 5)

The speed varies from 0 to maximum, depending on the

pressure applied to the trigger. The more the trigger is

pressed, the faster the tool runs.

Reversing switch (Fig. 5)

Important:

Only reverse the direction of rotation when the motor

stops completely.

To change the direction of rotation:

Position FWD: right hand rotation

Position REV: left hand rotation

Three selecting action modes (Fig. 6)

For hammer drilling:

Turn the knob so that the arrow points toward the

symbol.

For drilling only:

Turn the knob so that the arrow points toward the

symbol.

For hammering only:

Turn the knob so that the arrow points toward the

symbol.

NOTE:

When it is hard to turn the knob, pull the switch trigger

half-way for running at low speed and turn the knob.

Torque limiter

The torque limiter will actuate when a certain torque level

is reached. The motor will disengage from the output

shaft. When this happens, the bit will stop turning.

CAUTION:

As soon as the torque limiter actuates, switch off the tool

immediately. This will help prevent premature wear of the

tool. Hole saws, core bit, diamond core bit, etc. cannot be

used with this tool. They tend to pinch or catch easily in

the hole. This will cause the torque limiter to actuate too

frequently.

Using cold chisel or bull point (Fig. 7)

1. Disconnect plug.

2. Remove the side grip from the tool.

3. Turn the knob to hammer drilling symbol .

4. Install the cold chisel or bull point and then the chisel

adapter (optional accessory) on the tool.

5. Rotate the cold chisel toward the direction suitable

for your work. Then secure the cold chisel and chisel

adapter by using the clamp screw on the chisel

adapter.

6. Turn the knob to hammering only symbol . Now

you can use the cold chisel or bull point.

NOTE:

Always set “hammering only” action when using the cold

chisel or bull point. If you use “hammer drilling” or “drilling

only” action, the hammering mechanism may be damaged on the tool.

Drilling in wood or metal (Fig. 8)

Use the optional drill chuck assembly (consisting of drill

chuck and chuck adapter assembly). When installing it,

refer to “installing or removing drill bit” described on the

previous page. Set the knob to “drilling only”. You can drill

up to 13 mm diameter in metal and up to 38 mm diameter in wood. (Note: When using a flat boring bit.)

NOTE:

Never set “hammer drilling” action when using the drill

chuck assembly because it may be damaged and come

off when reversing the tool.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

4

Loading...

Loading...