Page 1

GB

Rotary Hammer Instruction Manual

F

Perforateur

D

Bohrhammer Betriebsanleitung

I

Martello rotativo Istruzioni per l’uso

NL

Boorhamer Gebruiksaanwijzing

E

Martillo rotativo Manual de instrucciones

P

Martelo misto Manual de instruções

DK

Borehammer Brugsanvisning

S

Borrhammare Bruksanvisning

N

Borhammer Bruksanvisning

FIN

Poravasara Käyttöohje

GR Περιστροφικ σφυρί Οδηγίες χρήσεως

Manuel d’instructions

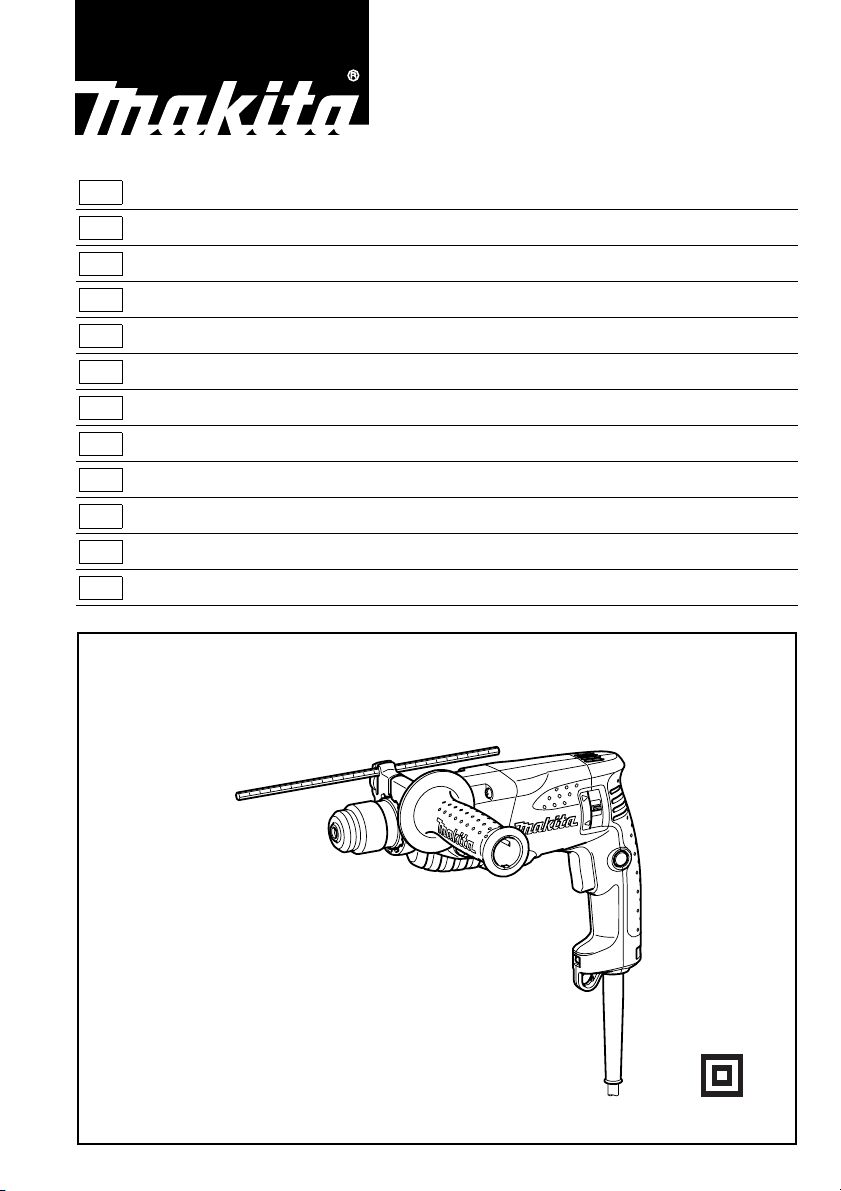

HR1830

HR1830F

Page 2

1

2

3

12

B

A

4

5

34

6

7

8

10

11

9

12

13

56

14

15

14

15

78

2

Page 3

16

17

9

18

8

910

20

19

21

11 12

22

13

23

3

Page 4

ENGLISH

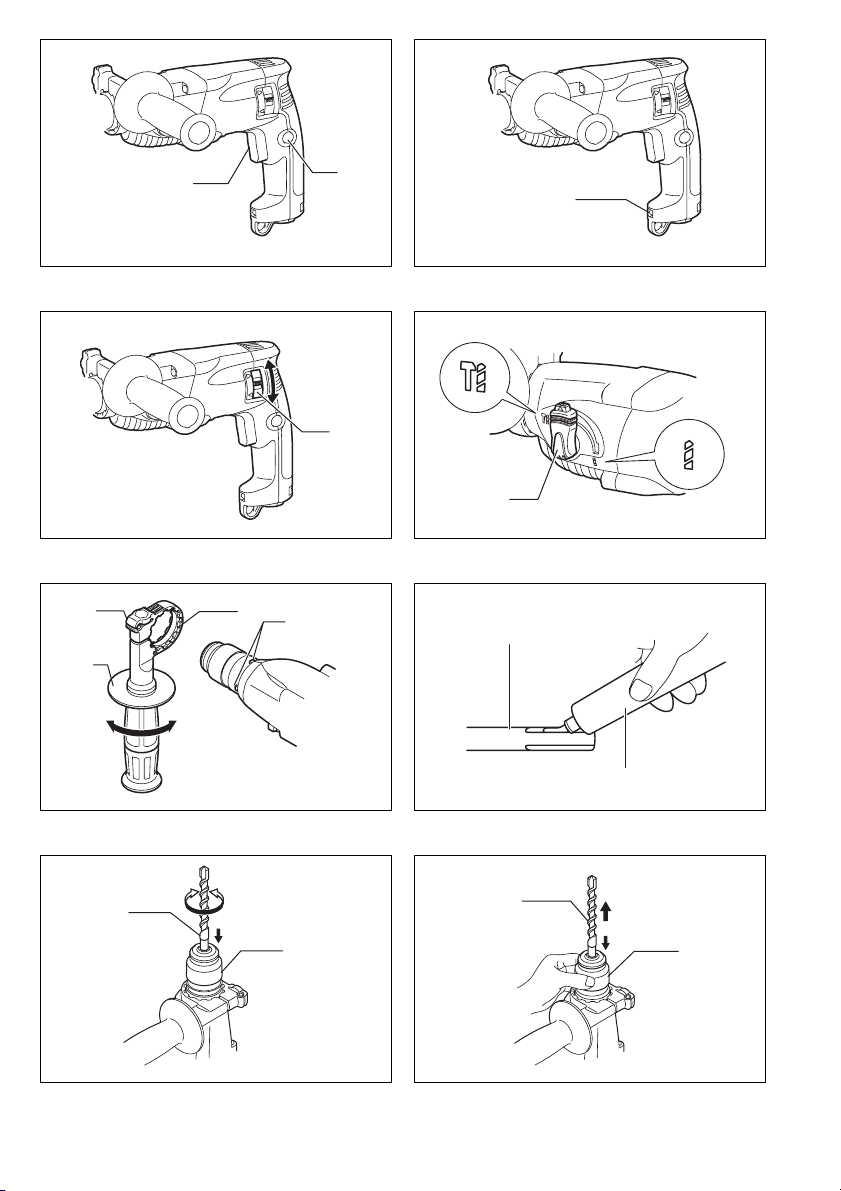

1 Switch trigger

2 Lock button

3Lamp

4 Reversing switch

5 Action mode changing knob

6Grip base

7 Side grip

8 Loosen

Explanation of general view

9 Tighten

10 Teeth

11 Protrusion

12 Bit shank

13 Bit grease

14 Bit

15 Chuck cover

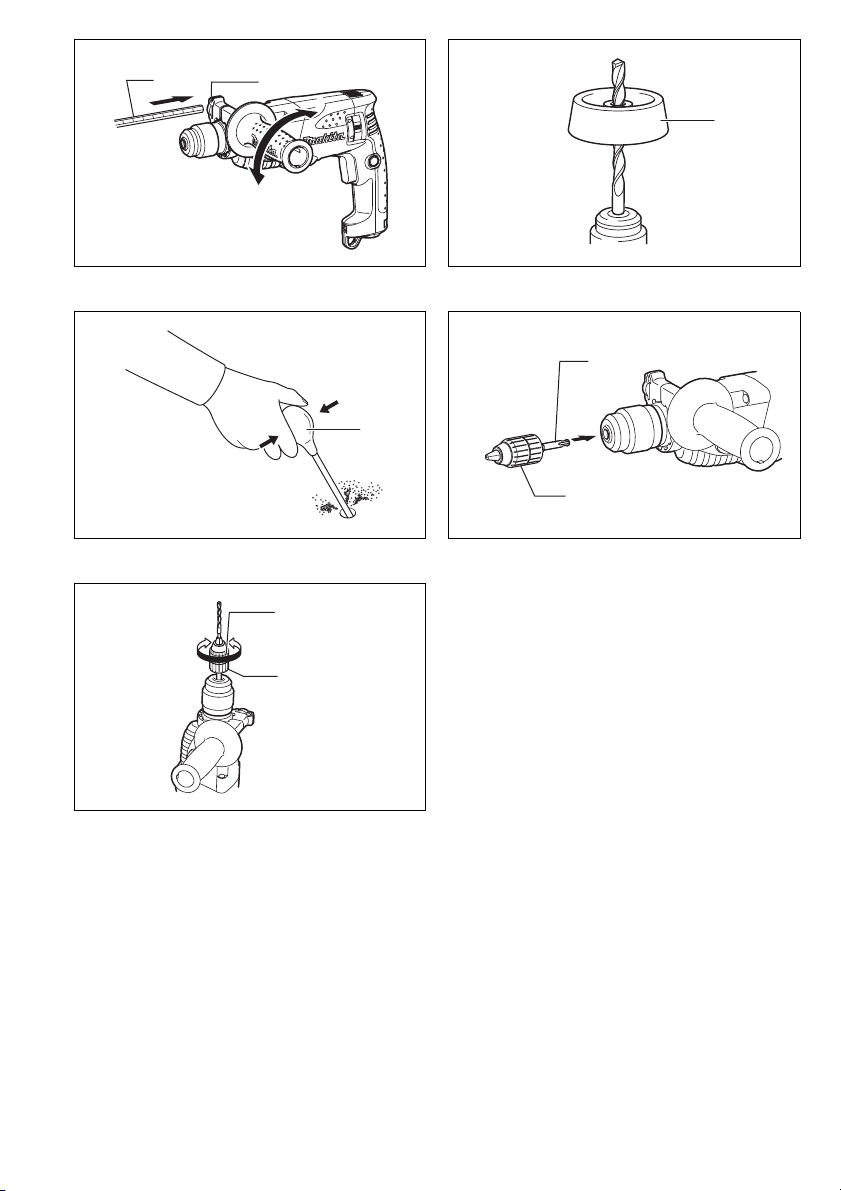

16 Depth gauge

17 Hole of grip base

18 Dust cup

19 Blow-out bulb

20 Keyless drill chuck

21 Chuck adapter

22 Sleeve

23 Ring

SPECIFICATIONS

Model HR1830/HR1830F

Capacities

Concrete............................................................. 18 mm

Core bit............................................................... 35 mm

Diamond core bit (dry type) ................................ 65 mm

Steel ................................................................... 13 mm

Wood.................................................................. 24 mm

No load speed (min

Blows per minute................................................0 –5,000

Overall length ...................................................... 279 mm

Net weight ............................................................... 1.7 kg

Safety class ........................................................... /II

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for hammer drilling and drilling in

brick, concrete and stone.

It is also suitable for drilling without impact in wood,

metal, ceramic and plastic.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

-1

) ........................................ 0– 1,500

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to rotary hammer safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious personal injury.

1. Wear ear protectors. Exposure to noise can cause

hearing loss.

2. Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

GEB007-2

4. Wear a hard hat (safety helmet), safety glasses

and/or face shield. Ordinary eye or sun glasses

are NOT safety glasses. It is also highly recommended that you wear a dust mask and thickly

padded gloves.

5. Be sure the bit is secured in place before operation.

6. Under normal operation, the tool is designed to

produce vibration. The screws can come loose

easily, causing a breakdown or accident. Check

tightness of screws carefully before operation.

7. In cold weather or when the tool has not been

used for a long time, let the tool warm up for a

while by operating it under no load. This will

loosen up the lubrication. Without proper warmup, hammering operation is difficult.

8. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

9. Hold the tool firmly with both hands.

10. Keep hands away from moving parts.

11. Do not leave the tool running. Operate the tool

only when hand-held.

12. Do not point the tool at any one in the area when

operating. The bit could fly out and injure someone seriously.

13. Do not touch the bit or parts close to the bit

immediately after operation; they may be

extremely hot and could burn your skin.

14. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

4

Page 5

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Switch action (Fig. 1)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop. For continuous operation, pull the switch trigger and then push in the lock button. To stop the tool from the locked position, pull the

switch trigger fully, then release it.

Lighting up the lamps (Fig. 2)

For Model HR1830F only

CAUTION:

• Do not look in the light or see the source of light

directly.

To turn on the lamp, pull the trigger. Release the trigger

to turn it off.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of lamp, or it may lower

the illumination.

Reversing switch action (Fig. 3)

This tool has a reversing switch to change the direction of

rotation. Move the reversing switch lever to the position (A side) for clockwise rotation or to the position

(B side) for counterclockwise rotation.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• If the switch trigger can not be depressed, check to see

that the reversing switch is fully set to position (A

side) or (B side).

Selecting action mode (Fig. 4)

This tool employs an action mode changing knob. Select

one of the two modes suitable for your work needs by

using this knob.

For rotation only, depress the lock button and turn the

knob so that the arrow on the knob points toward the

symbol on the tool body.

For rotation with hammering, depress the lock button and

turn the knob so that the arrow on the knob points toward

the symbol on the tool body.

CAUTION:

• Always set the knob fully to your desired mode symbol.

If you operate the tool with the knob positioned halfway between the mode symbols, the tool may be damaged.

• Use the knob after the tool comes to a complete stop.

Torque limiter

The torque limiter will actuate when a certain torque level

is reached. The motor will disengage from the output

shaft. When this happens, the bit will stop turning.

CAUTION:

• As soon as the torque limiter actuates, switch off the

tool immediately. This will help prevent premature wear

of the tool.

• Hole saws cannot be used with this tool. They tend to

pinch or catch easily in the hole. This will cause the

torque limiter to actuate too frequently.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Side grip (auxiliary handle) (Fig. 5)

CAUTION:

• Always use the side grip to ensure operating safety.

Install the side grip so that the teeth on the grip fit in

between the protrusions on the tool barrel. Then tighten

the grip by turning clockwise at the desired position. It

may be swung 360° so as to be secured at any position.

Bit grease

Coat the bit shank head beforehand with a small amount

of bit grease (about 0.5 – 1 g).

This chuck lubrication assures smooth action and longer

service life.

Installing or removing the bit

Clean the bit shank and apply bit grease before installing

the bit. (Fig. 6)

Insert the bit into the tool. Turn the bit and push it in until

it engages. (Fig. 7)

After installing, always make sure that the bit is securely

held in place by trying to pull it out.

To remove the bit, pull the chuck cover down all the way

and pull the bit out. (Fig. 8)

Depth gauge (Fig. 9)

The depth gauge is convenient for drilling holes of uniform depth. Loosen the side grip and insert the depth

gauge into the hole in the side grip. Adjust the depth

gauge to the desired depth and tighten the side grip.

NOTE:

• The depth gauge cannot be used at the position where

the depth gauge strikes against the gear housing.

Dust cup (Fig. 10)

Use the dust cup to prevent dust from falling over the tool

and on yourself when performing overhead drilling operations. Attach the dust cup to the bit as shown in Fig. 10.

The size of bits which the dust cup can be attached to is

as follows.

Bit diameter (mm)

Dust cup 5 6 – 14.5

Dust cup 9 12 – 16

5

Page 6

OPERATION

Hammer drilling operation

CAUTION:

• There is tremendous and sudden twisting force exerted

on the tool/bit at the time of hole break-through, when

the hole becomes clogged with chips and particles, or

when striking reinforcing rods embedded in the concrete. Always use the side grip (auxiliary handle) and

firmly hold the tool by both side grip and switch handle

during operations. Failure to do so may result in the

loss of control of the tool and potentially severe injury.

When drilling in concrete, granite, etc., move the action

mode changing knob to the position of symbol to use

“rotation with hammering” action.

Be sure to use a tungsten-carbide tipped bit.

Position the bit at the desired location for the hole, then

pull the switch trigger.

Do not force the tool. Light pressure gives best results.

Keep the tool in position and prevent it from slipping away

from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at an

idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out

and normal drilling may be resumed.

NOTE:

• Eccentricity in the bit rotation may occur while operating the tool with no load. The tool automatically centers

itself during operation. This does not affect the drilling

precision.

Blow-out bulb (optional accessory) (Fig. 11)

After drilling the hole, use the blow-out bulb to clean the

dust out of the hole.

Drilling in wood or metal (Fig. 12 & 13)

Use the optional drill chuck assembly. When installing it,

refer to “Installing or removing drill bit” described on the

previous page.

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws. Place the bit in the chuck as far as

it will go. Hold the ring firmly and turn the sleeve clockwise to tighten the chuck.

To remove the bit, hold the ring and turn the sleeve counterclockwise. Set the action mode changing knob to

“rotation only”.

You can drill up to 13 mm diameter in metal and up to

24 mm diameter in wood.

Never use “rotation with hammering” when the drill chuck

assembly is installed on the tool. The drill chuck assembly may be damaged.

Also, the drill chuck will come off when reversing the tool.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

• There is a tremendous twisting force exerted on the

tool/bit at the time of hole breakthrough. Hold the tool

firmly and exert care when the bit begins to break

through the workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

Diamond core drilling

When performing diamond core drilling operations,

always set the change lever to the position to use

“rotation only” action.

CAUTION:

• If performing diamond core drilling operations using

“rotation with hammering” action, the diamond core bit

may be damaged.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

To maintain product SAFETY and RELIABILITY, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using

Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• SDS Plus Carbide-tipped bits

• Core bit

• Diamond core bit

• Drill chuck assembly

• Drill chuck S13

• Chuck adapter

• Chuck key S13

•Bit grease

• Side grip

• Depth gauge

• Blow-out bulb

•Dust cup

• Dust extractor attachment

• Safety goggles

• Plastic carrying case

• Keyless drill chuck

6

Page 7

NEDERLANDS

1 Trekschakelaar

2 Vastzetknop

3 Lamp

4 Omkeerschakelaar

5 Omschakelknop

6 Handgreepvoet

7 Zijhandgreep

8 Losdraaien

Verklaring van algemene gegevens

9 Vastzetten

10 Tanden

11 Nokken

12 Boorschacht

13 Boorvet

14 Boor

15 Boorkopdeksel

16 Diepteaanslag

17 Gat in handgreepvoet

18 Stofvanger

19 Blaasbalgje

20 Sleutelloze boorkop

21 Boorkop-adapter

22 Bus

23 Ring

TECHNISCHE GEGEVENS

Model HR1830/HR1830F

Vermogen

Beton ..................................................................18 mm

Kroonboor ...........................................................35 mm

Diamant kroonboor (droog type) .........................65 mm

Staal....................................................................13 mm

Hout ....................................................................24 mm

Nullasttoerental (min

Aantal slagen/minuut .........................................0 – 5 000

Totale lengte ........................................................279 mm

Netto gewicht .......................................................... 1,7 kg

Veiligheidsklasse ................................................... /II

• In verband met ononderbroken research en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

-1

) ...................................... 0 – 1 500

Doeleinden van gebruik

Het gereedschap is bedoeld voor hamerboren en boren

in baksteen, beton en steen.

Het is ook geschikt voor boren zonder slag in hout,

metaal, keramisch materiaal en kunststof.

Stroomvoorziening

Het gereedschap mag alleen worden aangesloten op

een stroombron van hetzelfde voltage als aangegeven op

de naamplaat, en kan alleen op enkel-fase wisselstroom

worden gebruikt. Het gereedschap is dubbel-geïsoleerd

volgens de Europese standaard en kan derhalve ook op

een niet-geaard stopcontact worden aangesloten.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

Laat u NIET misleiden door een vals gevoel van comfort en bekendheid met het gereedschap (na veelvuldig gebruik) en neem alle veiligheidsvoorschriften

van de boorhamer altijd strikt in acht. Bij onveilig of

verkeerd gebruik van het gereedschap, bestaat de

kans op ernstig persoonlijk letsel.

1. Draag gehoorbescherming. Blootstelling aan

harde geluiden kan leiden tot gehoorbeschadiging.

2. Gebruik de hulphandgrepen die bij het gereed-

schap werden geleverd. Als u de controle over het

gereedschap verliest, kan dit leiden tot ernstig persoonlijk letsel.

3. Houd elektrisch gereedschap vast aan het geïsoleerde oppervlak van de handgrepen wanneer u

werkt op plaatsen waar het zaaggereedschap

met verborgen bedrading of zijn eigen snoer in

aanraking kan komen. Door contact met onder

spanning staande draden, zullen de niet-geïsoleerde metalen delen van het gereedschap onder

spanning komen te staan zodat de gebruiker een

elektrische schok kan krijgen.

4. Draag een veiligheidshelm, veiligheidsbril en/of

gezichtsbescherming. Een gewone bril of een

zonnebril is GEEN veiligheidsbril. Het wordt

tevens sterk aanbevolen een stofmasker en dik

gevoerde handschoenen te dragen.

5. Controleer dat het bit stevig op zijn plaats is

vastgezet voordat u het gereedschap gebruikt.

6. Bij normale bediening behoort het gereedschap

te trillen. De schroeven kunnen gemakkelijk losraken, waardoor een defect of ongeluk kan ontstaan. Controleer of de schroeven goed zijn

aangedraaid, alvorens het gereedschap te

gebruiken.

7. In koude weersomstandigheden of wanneer het

gereedschap gedurende een lange tijd niet is

gebruikt, laat u het gereedschap eerst opwarmen

door het onbelast te laten werken. Hierdoor zal

de smering worden verbeterd. Zonder degelijk

opwarmen, zal de hamerwerking moeilijk zijn.

8. Zorg er altijd voor dat u stevig staat.

Zorg ervoor dat er niemand zich onder u bevindt

wanneer u het gereedschap op een hoge plaats

gebruikt.

9. Houd het gereedschap met beide handen stevig

vast.

10. Houd uw handen uit de buurt van bewegende

delen.

11. Laat het gereedschap niet ingeschakeld liggen.

Bedien het gereedschap alleen wanneer u het

vasthoudt.

12. Richt het gereedschap niet op iemand in de

buurt terwijl het is ingeschakeld. Het bit zou eruit

kunnen vliegen en iemand ernstig verwonden.

13. Raak het bit en onderdelen in de buurt van het

bit niet onmiddellijk na gebruik aan. Zij kunnen

bijzonder heet zijn en brandwonden op uw huid

veroorzaken.

14. Sommige materialen bevatten chemische stoffen

die giftig kunnen zijn. Neem de nodige voorzorgsmaatregelen tegen inademing van stof en

contact met de huid. Volg de veiligheidsinstructies van de leverancier van het materiaal op.

BEWAAR DEZE VOORSCHRIFTEN.

18

Page 8

WAARSCHUWING:

VERKEERD GEBRUIK of het niet naleven van de

veiligheidsvoorschriften in deze gebruiksaanwijzing

kan leiden tot ernstige verwondingen.

GEBRUIK VAN HET GEREEDSCHAP

LET OP:

• Zorg altijd dat het gereedschap is uitgeschakeld en de

stekker ervan uit het stopcontact is verwijderd vooraleer u begint met afstelling of onderhoud van het

gereedschap.

Werking van de trekschakelaar (Fig. 1)

LET OP:

• Alvorens de machine op een stopcontact aan te sluiten,

moet u altijd controleren of de trekschakelaar juist

werkt en bij het loslaten naar de “OFF” positie terugkeert.

Om de machine te starten, drukt u gewoon de trekschakelaar in. Hoe dieper de trekschakelaar wordt ingedrukt,

hoe sneller de machine draait. Om de machine uit te

schakelen, de trekschakelaar loslaten. Voor continuë

werking, drukt u de trekschakelaar in en dan drukt u de

vastzetknop in. Om de machine vanuit deze vergrendelde stand te stoppen, de trekschakelaar volledig

indrukken en deze dan loslaten.

Aanzetten van de lampen (Fig. 2)

Alleen voor Model HR1830F

LET OP:

• Kijk niet direct in het licht of de lichtbron.

Druk de trekker in om de lamp aan te zetten. Laat de

trekker los om de lamp uit te doen.

OPMERKING:

• Gebruik een droge doek om vuil op de lamplens eraf te

vegen. Let op dat u geen krassen maakt op de lamplens, aangezien de verlichtingssterkte daardoor zal verminderen.

Werking van de omkeerschakelaar (Fig. 3)

Dit gereedschap heeft een omkeerschakelaar voor het

veranderen van de draairichting. Beweeg de omkeerschakelaar naar de positie (kant A) voor rechtse

draairichting, of naar de positie (kant B) voor linkse

draairichting.

LET OP:

• Controleer altijd de draairichting alvorens de machine

te gebruiken.

• Gebruik de omkeerschakelaar alleen nadat de machine

volledig tot stilstand is gekomen. Indien u de draairichting verandert voordat de machine is gestopt, kan de

machine beschadigd raken.

• Als de trekschakelaar niet kan worden ingeknepen,

controleert u dat de omkeerschakelaar helemaal naar

de positie (kant A) of naar de positie (kant B) is

gezet.

Kiezen van de bedieningsfunctie (Fig. 4)

Dit gereedschap heeft een omschakelknop. Gebruik

deze knop voor het kiezen van een van de twee bedieningsfuncties die geschikt is voor uw werk.

Voor gewoon boren drukt u de vastzetknop in en draait u

de knop zodat de pijl op de knop in de richting van de

symbool op de behuizing van het gereedschap wijst.

Voor hamerboren drukt u de vastzetknop in en draait u

de knop zodat de pijl op de knop in de richting van de

symbool op de behuizing van het gereedschap wijst.

LET OP:

• Zet de knop altijd volledig op het gewenste symbool.

Indien u het gereedschap gebruikt met de knop halverwege tussen de twee symbolen geplaatst, kan het

gereedschap beschadigd raken.

• Bedien de knop pas nadat het gereedschap volledig tot

stilstand is gekomen.

Koppelbegrenzer

De koppelbegrenzer treedt in werking wanneer de motor

een bepaald koppel bereikt. De motor wordt dan ontkoppeld van de uitgangsas. Wanneer dit gebeur t, zal de boor

ophouden met draaien.

LET OP:

• Schakel het gereedschap onmiddellijk uit wanneer de

koppelbegrenzer in werking treedt. Hierdoor helpt u

vroegtijdige slijtage van het gereedschap voorkomen.

• Gatenzagen kunnen met dit gereedschap niet worden

gebruikt. Deze lopen of klemmen gemakkelijk vast in

het boorgat, zodat de koppelbegrenzer te vaak in werking zal worden gesteld.

INEENZETTEN

LET OP:

• Zorg altijd dat het gereedschap is uitgeschakeld en de

stekker ervan uit het stopcontact is verwijderd alvorens

enig werk aan het gereedschap uit te voeren.

Zijhandgreep (hulphandgreep) (Fig. 5)

LET OP:

• Gebruik altijd de zijhandgreep om een veilige bediening te verzekeren.

Installeer de zijhandgreep zodanig dat de tanden op de

greep tussen de nokken op het huis van de machine

komen te zitten. Zet dan de handgreep vast door deze in

de gewenste positie naar rechts te draaien. De handgreep kan 360° worden verdraaid zodat u deze in elke

gewenste positie kunt vastzetten.

Boorvet

Voordat u de boor aanbrengt, smeer een beetje vet

(ca. 0,5 tot 1,0 gram) op de kop van de boorschacht.

Met een ingevette boorkop zal het gereedschap beter

werken en langer meegaan.

Aanbrengen of verwijderen van de boor

Reinig de boorschacht en smeer er boorvet op alvorens

de boor te installeren. (Fig. 6)

Steek de boor in de machine. Draai de boor en duw deze

naar binnen tot zij vergrendelt. (Fig. 7)

Nadat de boor is geïnstalleerd, moet u altijd controleren

of de boor goed vastzit door te proberen hem eruit te

trekken.

Om de boor te verwijderen, trekt u het boorkopdeksel

helemaal omlaag en dan trekt u de boor eruit. (Fig. 8)

19

Page 9

Diepteaanslag (Fig. 9)

De diepteaanslag is handig voor het boren van gaten van

gelijke diepte. Maak de zijhandgreep los en steek de

diepteaanslag in het gat in de zijhandgreep. Stel de diepteaanslag af op de gewenste diepte en zet de zijhandgreep vast.

OPMERKING:

• De diepteaanslag kan niet worden gebruikt in de positie waarbij deze tegen het tandwielhuis aanstoot.

Stofvanger (Fig. 10)

Gebruik de stofvanger om te voorkomen dat stof op de

machine en op uzelf terechtkomt wanneer u boven uw

hoofd boort. Bevestig de stofvanger aan de boor, zoals

getoond in Fig. 10. De diameter van de boren waaraan

de stofvanger kan worden bevestigd, is als volgt.

Boordiameter (mm)

Stofvanger 5 6 – 14,5

Stofvanger 9 12 – 16

BEDIENING

Hamerend of kloppend boren

LET OP:

• Op het moment dat een gat wordt geboord, of wanneer

het boorgat verstopt raakt met schilfertjes en metaaldeeltjes, of wanneer de machine op versterkingsstaven

in gewapend beton stoot, wordt er plotseling een

enorme wringingskracht op de machine/boor uitgeoefend. Gebruik daarom altijd de zijhandgreep (hulphandgreep) en houd de machine tijdens het gebruik stevig

vast bij zowel de zijhandgreep als de hoofdhandgreep.

Indien u dit verzuimt, kunt u de controle over de

machine verliezen en mogelijk zware verwondingen

oplopen.

Bij het boren in beton, graniet, enz., zet u de omschakelknop in de positie met het symbool om te hamerboren.

Zorg ervoor dat u een bit met een hardmetalen punt

gebruikt.

Plaats de punt van de boor op de gewenste plaats waar

geboord moet worden, en druk vervolgens de schakelaar

in.

Forceer het gereedschap niet. Een lichte druk geeft de

beste resultaten. Houd het gereedschap stevig vast en

zorg dat het niet uitglijdt.

Oefen geen grotere druk uit wanneer het boorgat verstopt raakt met schilfertjes of metaaldeeltjes. Laat in zo’n

geval het gereedschap onbelast lopen en verwijder de

boor gedeeltelijk uit het boorgat. Wanneer dit verschillende keren wordt herhaald, zal het boorgat schoon worden en kunt u normaal verder boren.

OPMERKING:

• Terwijl het gereedschap onbelast wordt gebruikt, kan

de boor excentrisch draaien. Het gereedschap centreert zichzelf automatisch tijdens het gebruik. Dit heeft

geen nadelige invloed op de nauwkeurigheid van het

boren.

Blaasbalgje (los verkrijgbaar accessoire) (Fig. 11)

Gebruik na het boren het blaasbalgje om het stof uit het

boorgat te blazen.

Boren in hout of metaal (Fig. 12 en 13)

Gebruik de los verkrijgbare boorkopmontage. Om deze

te installeren, zie “Aanbrengen of verwijderen van de

boor” op de vorige pagina.

Houd de ring vast en draai de bus naar links om de klauwen van de boorkop te openen. Steek de boor zo ver

mogelijk in de boorkop. Houd de ring weer stevig vast en

draai de bus naar rechts om de boorkop vast te zetten.

Om de boor te verwijderen, houdt u de ring vast en draait

u de bus naar links. Zet de omschakelknop op “alleen

boren”.

U kunt boren tot een diameter van maximaal 13 mm in

metaal en een diameter van maximaal 24 mm in hout.

Gebruik nooit “boren plus hameren” wanneer de boorkop

op het gereedschap is gemonteerd. De boorkop kan hierdoor namelijk beschadigd raken.

Bovendien zal de boorkop loskomen wanneer de draairichting van het gereedschap wordt omgekeerd.

LET OP:

• Door teveel druk op het gereedschap uit te oefenen

verloopt het boren niet sneller. Integendeel, teveel druk

op het gereedschap zal alleen maar de boor beschadigen, de prestatie van het gereedschap verminderen en

de gebruiksduur verkorten.

• Er ontstaan enorme spanningen op het ogenblik dat de

boor uit het gat tevoorschijn komt. Houd derhalve het

gereedschap stevig vast en wees op uw hoede.

• Wanneer de boor klemraakt, keert u met de omkeerschakelaar de draairichting om, om de boor uit het gat

te krijgen. Pas echter op en houd het gereedschap stevig vast, aangezien het anders uit het gat weg kan

schieten.

• Kleine werstukken dient u altijd eerst vast te zetten met

een klemschroef of iets dergelijks.

Boren met de diamant kroonboor

Voor boren met de diamant kroonboor dient de boorwerkingskeuzehendel altijd in de positie voor “alleen

boren” te worden gezet.

LET OP:

• Indien u de diamant kroonboor gebruikt voor “hamerend boren”, kan de diamant kroonboor beschadigd

raken.

ONDERHOUD

LET OP:

• Zorg altijd dat het gereedschap is uitgeschakeld en de

stekker ervan uit het stopcontact is verwijderd vooraleer u met inspectie of onderhoud van het gereedschap

begint.

Om de VEILIGHEID en BETROUWBAARHEID van het

gereedschap te handhaven, dienen alle reparaties,

inspectie en vervanging van de koolborstels, en alle

andere onderhoudswerkzaamheden of afstellingen te

worden uitgevoerd bij een erkend Makita servicecentrum

of fabriekscentrum, en altijd met gebruik van originele

Makita vervangingsonderdelen.

20

Page 10

ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita gereedschap dat in deze

gebruiksaanwijzing is beschreven. Bij gebruik van

andere accessoires of hulpstukken bestaat er gevaar

voor persoonlijke verwonding. Gebruik de accessoires

of hulpstukken uitsluitend voor hun bestemd doel.

Wenst u meer bijzonderheden over deze accessoires,

neem dan contact op met het plaatselijke Makita servicecentrum.

• SDS Plus boor met wolfraamcarbide punt

• Kernboor

• Diamantkernboor

• Boorkopmontage

• Boorkop S13

• Boorkop-adapter

• Boorkopsleutel S13

• Boorvet

• Zijhandgreep

• Diepteaanslag

• Blaasbalgje

• Stofvanger

• Hulpstuk voor stofafscheiding

• Veiligheidsbril

• Plastic draagtas

• Sleutelloze boorkop

21

Page 11

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

EN60745, EN55014, EN61000

ENH101-5

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che

questo prodotto è conforme agli standard di documenti

standardizzati seguenti:

secondo le direttive del Consiglio 89/336/CEE e 98/37/CE.

EN60745, EN55014, EN61000

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux normes des documents standardisés suivants,

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

EN60745, EN55014, EN61000

DEUTSCH

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt gemäß den Ratsdirektiven

89/336/EWG und 98/37/EG mit den folgenden Normen

von Normendokumenten übereinstimmen:

EN60745, EN55014, EN61000.

Yasuhiko Kanzaki

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid dat dit produkt voldoet aan de volgende

normen van genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

89/336/EEC en 98/37/EC.

EN60745, EN55014, EN61000

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos normalizados,

de acuerdo con las directivas comunitarias,

89/336/EEC y 98/37/CE.

CE 2005

EN60745, EN55014, EN61000

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

:

Verantwoordelijke fabrikant:

45

Page 12

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este

produto obedece às seguintes normas de documentos

normalizados,

de acordo com as directivas 89/336/CEE e 98/37/CE do

Conselho.

EN60745, EN55014, EN61000

ENH101-5

NORSK

EUs SAMSVARS-ERKLÆRING

Vi erklærer på eget ansvar at dette produktet er i overensstemmelse med følgende standard i de standardiserte dokumenter:

i samsvar med Råds-direktivene, 89/336/EEC og

98/37/EC.

EN60745, EN55014, EN61000,

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer hermed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de normsættende dokumenter,

i overensstemmelse med Rådets Direktiver 89/336/EEC

og 98/37/EC.

EN60745, EN55014, EN61000

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna

produkt överensstämmer med följande standardiseringar

för standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

EN60745, EN55014, EN61000

Yasuhiko Kanzaki

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote

on seuraavien standardoitujen dokumenttien standardien mukainen,

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

EN60745, EN55014, EN61000

ΕΛΛΗΝΙΚΑ

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

∆ηλώνουµε υπ την µοναδική µας ευθύνη τι αυτ

το προιν βρίσκεται σε Συµφωνία µε τα ακλουθα

πρτυπα τυποποιηµένων εγγράφων,

σύµφωνα µε τις Οδηγίες του Συµβουλίου,

89/336/EEC και 98/37/ΚE.

CE 2005

EN60745, EN55014, EN61000

46

Director Direktor

Direktør Johtaja

Direktör ∆ιευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Υπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

Page 13

ENGLISH

For European countries only

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is 8 m/s

These values have been obtained according to

EN60745.

Noise and Vibration

sound pressure level: 88 dB (A)

sound power level: 99dB (A)

Uncertainty is 3 dB (A).

– Wear ear protection. –

2

.

ENG006-2-V4

ITALIANO

Modello per l’Europa soltanto

I livelli del rumore pesati secondo la curva A sono:

Il valore quadratico medio di accellerazione è di 8 m/s

Questi valori sono stati ottenuti in conformità EN60745.

Rumore e vibrazione

Livello pressione sonora: 88 dB (A)

Livello potenza sonora: 99 dB (A)

L’incertezza è di 3 dB (A).

– Indossare i paraorecchi. –

2

.

FRANÇAISE

Pour les pays d’Europe uniquement

Les niveaux de bruit ponderes types A sont:

Bruit et vibrations

niveau de pression sonore: 88 dB (A)

niveau de puissance du son: 99 dB (A)

L’incertitude de mesure est de 3 dB (A).

L’accélération pondérée est de 8 m/s

– Porter des protecteurs anti-bruit. –

Ces valeurs ont été obtenues selon EN60745.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

8m/s

Diese Werte wurden gemäß EN60745 erhalten.

Schalldruckpegel: 88 dB (A)

Schalleistungspegel: 99 dB (A)

Die Abweichung beträgt 3 dB (A).

– Gehörschutz tragen. –

2

.

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling

De typische A-gewogen geluidsniveau’s zijn

geluidsdrukniveau: 88 dB (A)

geluidsenergie-niveau: 99 dB (A)

Onzekerheid is 3 dB (A).

De typische gewogen effectieve versnellingswaarde is

8m/s

– Draag oorbeschermers. –

2

.

Deze waarden werden verkregen in overeenstemming

met EN60745.

ESPAÑOL

Para países europeos solamente

Los niveles típicos de ruido ponderados A son

El valor ponderado de la aceleración es de 8 m/s

Estos valores han sido obtenidos de acuerdo con

EN60745.

Ruido y vibración

presión sonora: 88 dB (A)

nivel de potencia sonora: 99 dB (A)

Incerteza 3 dB (A).

– Póngase protectores en los oídos. –

2

.

47

Page 14

PORTUGUÊS

Só para países Europeus

Os níveis normais de ruído A são

– Utilize protectores para os ouvidos –

O valor médio da aceleração é 8m/s

Estes valores foram obtidos de acordo com EN60745.

Ruído e vibração

nível de pressão de som: 88 dB (A)

nível do sum: 99 dB (A)

A incerteza é de 3 dB (A).

2

.

ENG006-2-V4

NORSK

Gjelder bare land i Europa

De vanlige A-belastede støynivå er

Den vanlig belastede effektiv-verdi for akselerasjon er

2

.

8m/s

Disse verdiene er beregnet eller målt i samsvar med

EN60745.

Støy og vibrasjon

lydtrykksnivå: 88 dB (A)

lydstyrkenivå: 99 dB (A)

Usikkerheten er på 3dB (A).

– Benytt hørselvern. –

DANSK

Kun for lande i Europa

De typiske A-vægtede lydniveauer er

Den vægtede effektive accelerationsværdi er 8 m/s

Disse værdier er beregnet i overensstemmelse med

EN60745.

Lyd og vibration

lydtryksniveau: 88 dB (A)

lydeffektniveau: 99 dB (A)

Der er en usikkerhed på 3 dB (A).

– Bær høreværn. –

2

.

SVENSKA

Endast för Europa

De typiska A-vägda bullernivåerna är

Det typiskt vägda effektivvärdet för acceleration är

2

.

8m/s

Dessa värden har erhållits i enlighet med EN60745.

Buller och vibration

ljudtrycksnivå: 88 dB (A)

ljudeffektnivå: 99 dB (A)

Osäkerheten är 3 dB (A).

– Använd hörselskydd –

SUOMI

Vain Euroopan maat

Tyypilliset A-painotetut melutasot ovat

Tyypillinen kiihtyvyyden painotettu tehollisarvo on

2

.

8m/s

Nämä arvot on mitattu normin EN60745 mukaisesti.

Melutaso ja tärinä

äänenpainetaso: 88 dB (A)

äänen tehotaso: 99 dB (A)

Epävarmuus on 3 dB (A).

– Käytä kuulosuojaimia. –

ΕΛΛΗΝΙΚΑ

Μνο για χώρες της Ευρώπης

Οι τυπικές A-µετρούµενες εντάσεις ήχου είναι

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης είναι 8 m/s

Αυτές οι τιµές έχουν σηµειωθεί σύµφωνα µε το

EN60745.

Θρυβος και κραδασµς

πίεση ήχου: 88 dB (A)

δύναµη του ήχου: 99 dB (A)

Η Αβεβαιτητα είναι 3dB (A).

– Φοράτε ωτοασπίδες. –

2

.

Makita Corporation

Anjo, Aichi, Japan

884667-997

Loading...

Loading...