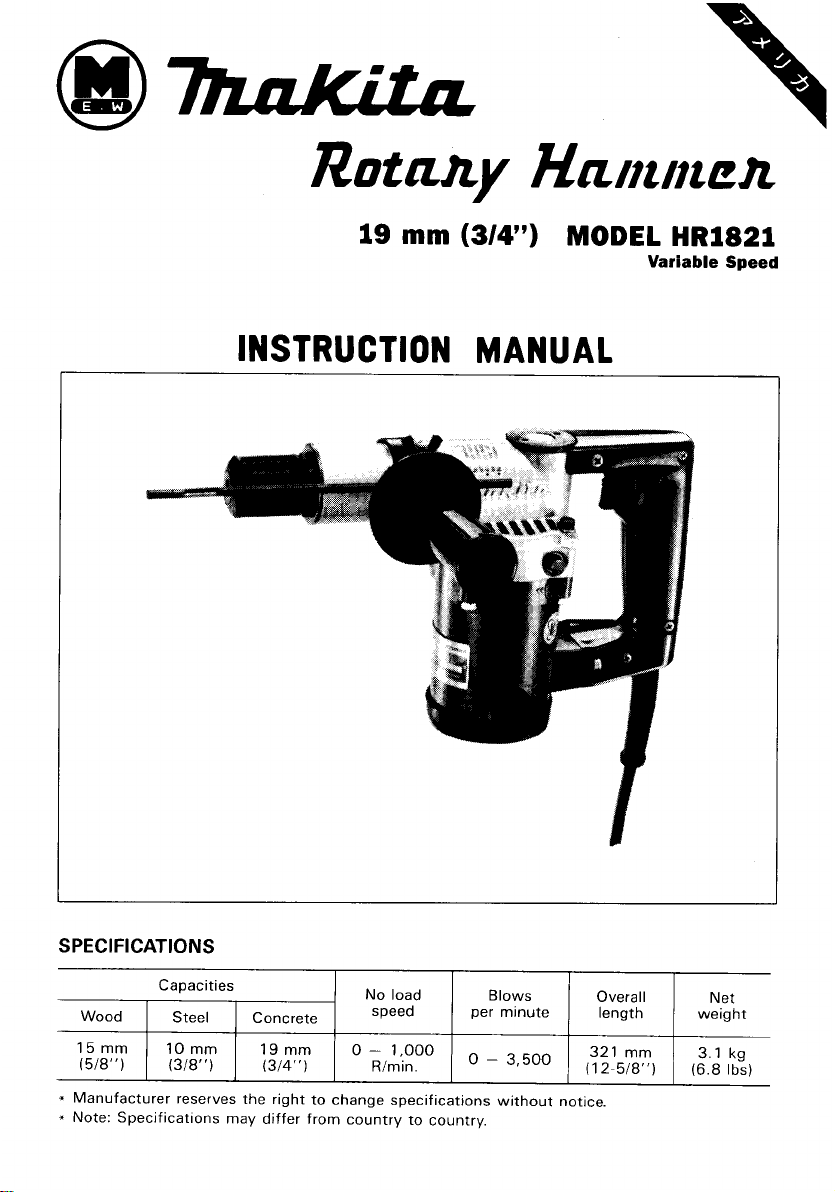

Page 1

19

mm

(3/4")

MODEL

INSTRUCTION MANUAL

HR1821

Variable

Speed

Capacities

Wood Steel Concrete

15"

(518") (3/8") (314"

10" 19"

No load Blows Overall Net

0

speed

;/A,i:OO

per minute

0

-

3,500

length weight

321

mm

(12-518") (6.8

3.1 kg

Ibs)

Page 2

IMPORTANT

SAFETY INSTRUCTIONS

(For

All

Tools)

WARNING:

WHEN USING ELECTRIC TOOLS, BASIC SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO

REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, AND PERSONAL INJURY, INCLUDING THE FOLLOWING:

READ

1.

2.

3.

4.

5.

6.

7.

8.

9.

IO.

11.

12.

13.

ALL INSTRUCTIONS.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp

lit.

or wet locations. Keep work area well

Don‘t use tool in presence of flammable liquids or gases.

KEEP CHILDREN AWAY. All visitors should be kept away from work area.

Don’t let visitors contact tool or extension cord.

STORE IDLE TOOLS. When not

high or locked-up place

DON’T FORCE TOOL.

it

was intended.

USE RIGHT TOOL. Don’t force small tool or attachment to do the job of

a

heavy-duty tool. Don’t use tool for purpose not intended.

DRESS PROPERLY. Don’t wear loose clothing or jewelry. They can be caught

in moving parts. Rubber gloves and non-skid footwear are recommended

when working outdoors. Wear protective hair covering to contain long hair.

USE SAFETY GLASSES. Also use face or dust mask if cutting operation

is dusty.

DON’T ABUSE CORD. Never carry tool by cord or yank

receptacle. Keep cord from heat, oil, and sharp edges.

SECURE WORK. Use clamps or a vise to hold work. It’s safer than using

your hand and

DON’T OVERREACH. Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have repaired by

authorized service facility. Inspect extension cords periodically and replace

if damaged. Keep handles dry, clean, and free from oil and grease.

DISCONNECT TOOLS. When not

ing accessories, such as blades, bits, cutters.

it

frees both hands to operate tool.

-

It

will

in

out of reach of children.

do the job better and safer at the rate for which

in

Don‘t expose power tools to rain.

use, tools should be stored in dry, and

it

to disconnect from

use, before servicing, and when chang-

Page 3

REMOVE ADJUSTING

14.

see that keys and adjusting wrenches are removed from tool before turn-

ing

it

on.

AVOID UNINTENTIONAL STARTING. Don't carry plugged-in tool with finger

15.

on switch. Be sure switch is

16.

OUTDOOR USE EXTENSION CORDS. When tool

extension cords intended for use outdoors and

17.

STAY ALERT. Watch what you are doing, use common sense. Don't oper-

ate tool when you are tired.

CHECK DAMAGED PARTS. Before further use of the tool,

18.

part that is damaged should be carefully checked to determine that

operate properly and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere

al. Have defective switches replaced by authorized service center. Don't

use tool if switch does not turn

GUARD AGAINST ELECTRIC

19.

surfaces. For example; pipes, radiators, ranges, refrigerator enclosures.

PROPER GROUNDING. This tool should be grounded while in use to pro-

20.

tect the operator from electric shock.

EXTENSION CORDS: Use only three-wire extension cords which have three-

21.

prong grounding-type plugs and three-pole receptacles which accept the

tool's plug. Replace or repair damaged or worn cord immediately.

KEYS

AND WRENCHES. Form habit of checking to

OFF

when plugging

it

on and off.

SHOCK.

Prevent body contact with grounded

in.

is

used outdoors, use only

so

marked.

a

guard or other

in

this instruction manu-

it

will

VOLTAGE WARNING: Before connecting the tool to a power source (receptacle,

outlet, etc.) be sure the voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage greater than that specified

for the tool can result

in

the tool. If

voltage less than the nameplate rating is harmful to the motor.

doubt, DO NOT PLUG

in

SERIOUS INJURY to the user - as well as damage to

IN

THE TOOL. Using a power source with

3

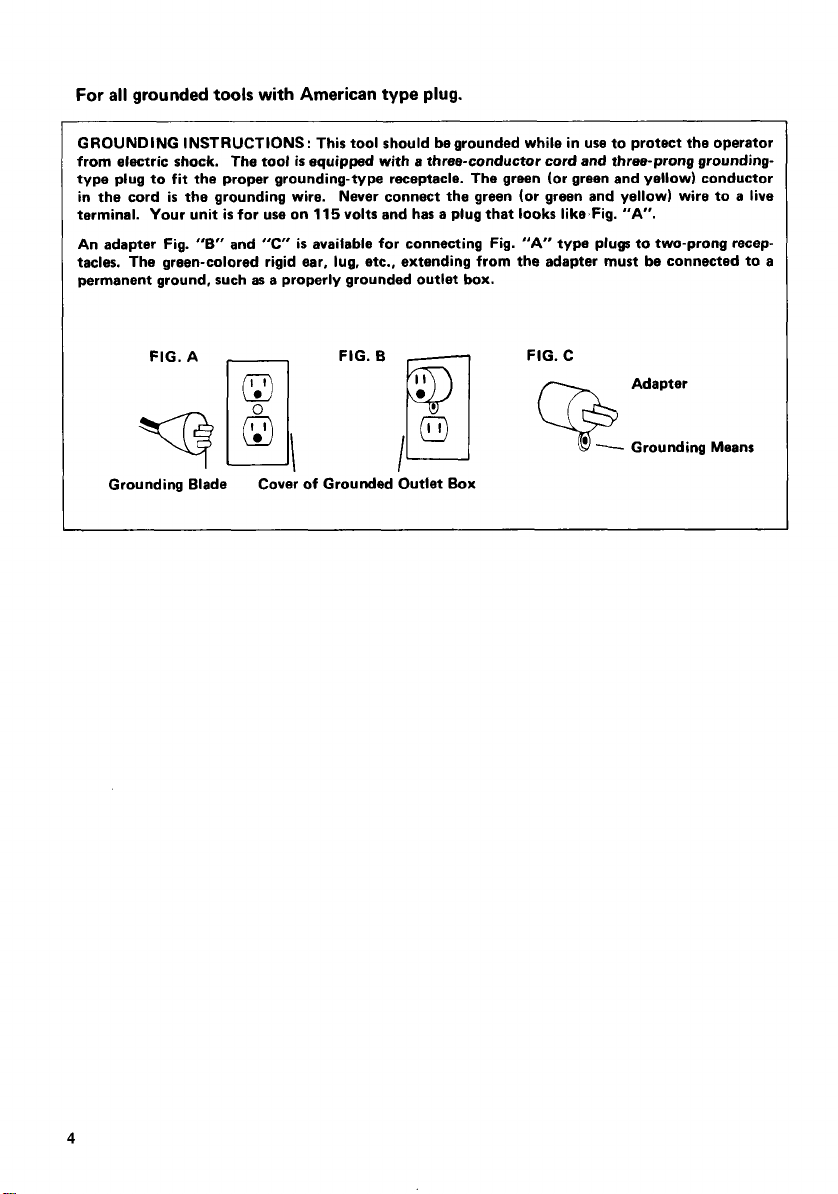

Page 4

For all grounded tools with American type plug.

GROUNDING INSTRUCTIONS: This tool should begrounded while in use to protect

from electric shock. The

type plug to fit the proper grounding-type receptacle. The green (or green and yellow) conductor

in

the cord

terminal. Your unit

An adapter Fig. "B" and

tacles. The green-colored rigid ear, lug, etc., extending from the adapter must be connected to

permanent ground, such

is

the

FIG. A FIG.

Grounding Blade

tool

is

equipped with a three-conductor cord and three-prong grounding-

grounding wire. Never connect the green (or green and yellow) wire to a live

is

for use on

as

115

volts and has a plug that

"C"

is

available for connecting Fig. "A"

a properly grounded outlet box.

0

Cover of Grounded Outlet Box

looks

FIG. C

like,Fig. "A".

type

plugs to two-prong recap

Adapter

the

operator

a

4

Page 5

ADDITIONAL SAFETY RULES

1.

Wear a hard hat (safety helmet) and an ear protector

2.

Be sure the drill bit is secured in place before operation.

Under normal operation, the

3.

screws can come loose easily, causing a breakdown or accident. Check

of

tightness

In cold weather or when the tool has not been used for a long time, let

4.

tool

warm

loosen

is difficult.

Always be sure you have a firm footing.

5.

Be sure no one is below when using the tool in high locations.

6.

Hold the tool firmly with both hands. Always use the side grip.

7.

Keep hands away from rotating parts.

Do

8.

9.

IO.

11.

not leave the tool running. Operate the tool only when hand-held.

Do

not point the tool at any one in the area when operating. The drill bit

could fly out and injure someone seriously.

When drilling into walls, floors

encountered,

Hold the tool only by the plastic handle or the side grip to prevent electric

shock

Do

not touch the drill

ation; they may be extremely hot and could burn your skin.

screws carefully before operation.

up

for several minutes by operating

up

the lubrication. Without proper warm-up hammering operation

DO

NOT

TOUCH ANY METAL PARTS

if

you drill into a “live” wire.

bit

tool

is designed to produce vibration. The

it

or

wherever ”live” electrical wires may be

or parts close to the drill bit immediately after oper-

if

necessary.

under no load. This will

OF

THE TOOL!

the

SAVE THESE

INSTRUCTIONS.

5

Page 6

HOW

Bit grease

0

Installing and removing the drill bit

TO

USE

Coat the drill bit shank head beforehand with a small amount (about

0.04

02.)

of bit grease. This chuck lubrication assures smooth action and longer service

life.

To install the drill bit, align protrusion

(A)

with the red dot, then align the key

groove on the drill bit shank with the red

dot and insert the drill bit. Now turn the

chuck cover

90

degrees.

0.5

-

1

g;

0.02

-

*To remove the drill bit, turn the chuck

cover until protrusion

the red dot. Then slip out the drill bit.

Side grip

0The side grip can be swivelled

degrees. To

unscrew the grip counterclockwise and

swivel to the desired position.

Then tighten

base in the barrel groove before tightening in place.)

set

it

(A)

is

aligned with

a

full

360

it

at

any desired angle,

securely. (Keep the grip

I

Key-groove

I

Fig.

Fig.

1

2

I

I

I

Fig.

3

6

Page 7

Depth rod

.The depth rod

is

used to drill holes of

uniform depth. Loosen the thumb screw

set

the depth rod

to

desired position,

then tighten the thumb screw.

Handling dust collector

0

Use the dust collector for safe, sanitary

overhead operations. Install the drill bit,

then fix the dust collector on the end

by turning and applying pressure. Then

it

secure

by turning the metal retainer

clockwise.

CAUTION:

Empty the dust collector of

2

after drilling every

How

to

work switchover mechanism

0

For Rotation + Hammering:

or 3 holes.

its

contents

Press the push rod indCDodirection.

Dust

collector

Fig.

Fig.

4

!

For Rotation only:

Press the Dush rod in &+direction.

Lb-

CAUTION:

Press the push rod

Failure to do

as

far

as

so

can cause rapid wear

the switchover mechanism.

it

will go.

of

Push

rod

Fig.

7

Page 8

Switch action

Tool speed

sure on the trigger. To

simply pull the trigger.

is

increased by increasing pres-

start

the tool,

Release

the

trigger to stop.

.A speed control screw

is

provided

so

that tool speed (RPM) can be changed

pulled trigger position. Turn the speed control screw clockwise

(-)

counterclockwise

for lower speed.

CAUTION:

see

Before plugging in the tool, always check to

and returns to the

"OFF"

position when released.

that the trigger switch actuates properly

Hammer drilling operation

at

.Position the drill bit

the location for

the hole, then pull the trigger.

Do

not force the tool. Light pressure

gives

best results. Keep the tool in posi-

tion and prevent

it

from slipping away

from the hole.

,

Speed

control

screw

(+)

for higher speed and

at

the fully-

Fig.

t

When holes become clogged

.Do

not apply more pressure when the

hole becomes clogged with chips or par-

ticles.

Instead, run the tool

at

idle, then

remove from the hole. By repeating this

several times, the hole will

be

cleaned out

completely.

Fig.

CAUTION:

it

is

When drilling in concrete,

or some other object that could cause

quite possible that the drill bit could hit a reinforcing rod

a

kickback. Although this tool

is

equipped with

the torque limiter, protect yourself by holding the tool firmly with both hands. (Be sure

the side grip

8

is

secured tightly before operation.)

9

Page 9

Blow-out bulb

0

Use the blow-out bulb to clean out the

hole.

Fig.

Anchor setting procedure

0

The drill bit has a red marking which can be used to indicate the anchor length. Use the

a

depth rod when drilling for setting

ed

marking chor setting tool

number of anchors

at

the same depth.

10

a

Put

an anchor and hammer

it

into concrete.

Drilling in wood or metal

Set

the push rod for “rotation only.”

Then use the drill chuck and chuck

adapter (optional equipment), installing

it

as

described in “Installing and removing

(P.

the drill bit

6).”

CAUTION:

DO

not perform “rotation + hammering“

action with the drill chuck, or the chuck

will probably be damaged.

plug in the tip of

I

d

a

Drill

chuck

bolt for

Fig.

Fig.

fi

12

Screw in

fastening equipment.

\

9

Page 10

MAINTENANCE

CAUTION:

be

Always

inspection and maintenance.

sure that the tool

is

switched off and unplugged before attempting to perform

Replacing

0

Both carbon brushes should be replaced

after about

resin insulating tip inside the carbon

brush

mutator,

the motor. If carbon brushes wear out

too quickly, ask Makita Authorized or

Factory Service Centers to determine

the cause before replacing them. Use

only Makita carbon brushes.

*Use the screwdriver to remove the brush

holder cap

Take out the worn brush, insert the new

one and secure the brush holder cap.

carbon

brushes

150

hours of use. When the

is

exposed to contact the com-

it

will automatically shut off

as

shown in the figure.

77

Insulating tip

Fig.

Fig.

1

14

10

I

Fig.

15

I

Page 11

Lubrication

0

Lubricate

the

tool every time after replacing carbon brushes.

Run the tool for several minutes to warm

it

up, then rest the tool on the table with

the chuck cover (bit) end pointing toward

the ceiling. This will allow the old grease

to collect inside the crank housing. After

five minutes, take off the crank cap and

remove the old grease. Wipe out

all

grease

inside and replace with the fresh supply

(30

9).

CAUTION:

Filling with more than the specified

30

g;

amount of grease (approx.

1

can cause faulty hammering action or

a

failure. Fill only with the specified

amount of grease.

CAUTION:

Do

not tighten the crank cap too much,

when installing.

It

is

made of resin and

subject to breakage.

Never use the bit grease for lubrication of

hammer mechanism.

02.)

is

Fig.

16

To maintain product SAFETY and RELIABILITY, repairs, any other maintenance and

adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

11

Page 12

ACC

ESSO

R

I

ES

CAUTION:

These accessories or attachments are recommended for use with your Makita tool specified in this

manual. The use

The accessories or attachments should be used only in the proper and intended manner.

0

Taper shank adapter

Part

No.

0

Taper shank adapter

Part

No.

0

Dust collector

Part

No.

0

Depth rod

Part

No.

of

798131-4

798176-2

122290-6

321 144-6

any other accessories or attachments might present a risk of injury to persons.

No.

1

A

0

Blowout bulb

Part

No.

7650096

Hex

wrench

Part

No.

7832038

0

Lock nut wrench

Part

No.

782402-9

0

Hammer grease

Part

No.

181490-7

5

28

30

g;

1

02.

0

Drill chuck

Part

No.

0

Chuck adapter

Part

No.

0

Chuck key

Part

No.

12

S10

763056-1

321832-5

S10

7634038

1

t

*Bit grease

Part

0

Steel carrying case

Part

0

Cotter

Part

No.

No.

No.

100

181573-3

155826-6

765010-1

g;

3.5

oz.

Page 13

0

Tungsten-carbide tip bits

Anchor setting

rod

(Manual setting)

Part

0

Anchors

No

Blt

diameter depth lenath

(30

sets per pkg)

Max

drilling

Overall

No

Makita anchor

1

0

Anchor setting rod

(Set

I

765014 3

25

765015

by

tool)

Plug for interior applications

1

only

Anchor settinq rod

for

interior applications

Anchor setting rod

Anchor

outer

N~

1

dyzer

No.2

11

17/16")

NO

2

5

12 Ill2") 35 11-318") W 5/16" 13 1112") 798056-2

NO

3 14.3 19/16")

N0.4

17.5l11/16"~50

0

Anchor setting tool

No.

Part

Overall

I

leegmf:

30

(1

40

I1

12")

765012-7

1

Thread

3/16")

W

114''

518") W 318''

W

112"

1

10 1318") 798054-6

15

20

Thread

k3;g_f;

I

Part

NO.

1518")

798058-8

(13/16") 798060-1

(Manual setting)

Plug for interior aoolications

Anchor setting rod

13

Page 14

@ma

-

19

mm

(3/4")

ROTARY HAMMER

Model

HR1821

Seo.--19-'84

US

14

Note: The switch and other part configurations

may differ from country to country.

Page 15

MODEL HR1821

'ikM

,,!!D

MACHINE

~

3

1

1

2

1

3

4

1

1

5

1

6

1

7

1

8

1

9

1

10

1

11

12

1

1

13

4

14

4

15

1

16

17

1

1

18

1

19

1

20

1

21

1

22

2

23

1

24

1

25

1

26

1

27

1

28

1

29

1

30

1

31

1

32

1

33

1

34

1

35

1

36

1

37

1

38

1

39

1

40

1

41

1

42

1

43

1

44

1

45

Note

The

switch and

DESCRIPTION

Steel

Ball 6 4

Key 4

Liner

Cylinder

Ball Bearing 3007

Nut M30 3-36

Barrel

0

Flat

Spiral

Striker

0

0

Piston

Spring

Hex

Pl"

Makita Label

Crank Cap

0

Rod

Needle Bearing 810

Crank Shaft

Steel

Compression Spring

Change

Crank

0

Ball Bearing 6002

Helical

Flat

Torque

Flat

0

ea,

Ball

0

011

Fan

ARMATURE ASSEMBLY

iAssembled

Insulatnm

Rubber

Ball

011

Felt

0

20

Ring 40

Washer 30

Bevel

Gear

26

Ring 16

Ring 16

Washer

6

Socket

Head Bolt M6x50

5

Ring

35

Ball

5

6

Pin

8

Housing

Ring 32

Gear

29

Washer 15

Limiter

Washer

6

Ring

65

tiouslng

Bearing 6200

Ring 30

Seal

13

67

Items 38 - 40

Washer

Pin

4

Bearing

608LB

Sea1

21

Ring 20

Ring 40

other

part specifications may differ

Sep-19-'84

,!:,

DESCRIPTION

46

1

Seal

3

Steel

1

Impact

1

0

1

0

1

Drill

2

Key

1

0

1

0

1

0

1

Change Ring

1

Steel

1

Leaf sprrng

1

0

Flat

1

1

Spiro Lock Washer

1

Chuck

1

Fan

2

Hex

2

Rivet

1

Name

4

Hex Nut M6

Label

1

2

Brush

2

Carbon

1

Motor Housing

2

Pan

3

Pan

1

Handle

2

Pan

2

Pan

1

Strain

CORD ASSEMBLY

1

IWith

Cord

1

Dust

1

1

Switch

1

Handle

1

Grip

1

Cap

1

Belt

1

Grip

1

Rubber Washer

1

Thumb

1

FIELD ASSEMBLY

1

Pan

Holder

Ball 6 4

Bolt

Ring 10

Ring

10

Holder

4

Ring 10

Ring 10

Ring 19

Ball

4

Ring 19

Washer

Cover

Gwde

Bolt

M5x40

0-5

Plate

Holder

Brush

Head

Head

Set

Head

Head

Relief

Cord

Guard

Cover

Set

37

Square Neck

Base

Screw

Head

fl

20

Cap

Screw

Screw

lWith

Screw

Screw

Plug

IWith

Screw

20

lWith Washer)

M6x16

M5x22

Item

M6x25

M4x18

E

Item

Item 741

Bolt MBx35

4 5

M5x15

M4x8

IWith Washer)

IWith Washer)

851

lWith Washer)

(With Washer1

791

IWith Washer)

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

country

68

69

70

71

72

73

74

75

76

77

78

79

82

83

85

86

87

88

89

90

91

92

93

-

to

-

country

6

&

Item

42)

from

US

15

Page 16

MAKITA LIMITED ONE YEAR WARRANTY

Warranty

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to

be free of defects from workmanship and materials for the period of ONE YEAR from the date of

original purchase. Should any trouble develop during this one-year period, return the COMPLETE

tool, freight prepaid, to one of Makita’s Factory or Authorized Service Centers. If inspection shows

the trouble is caused by defective workmanship or material, Makita will repair (or at

replace) without charge.

This Warranty dses not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and tear:

The tool has been abused, misused or improperly maintained;

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER

APPLIES BOTH DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

WARRANTIES OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,”

AFTER THE ONE-YEAR TERM

This Warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Some states do not allow the exclusion or limitation of incidental or consequential

so

damages,

limitation on how long an implied warranty lasts,

the above limitation or exclusion may not apply to you. Some states do not allow

OF

THIS WARRANTY.

Policy

our

so

the above limitation may not apply to you.

option,

11-8,J-chome.

~~.Ltd.

Sumiyorhi-cho, Anjo, Aichi 446, Japan

8834808065 PRINTED IN

JAPAN

1986-2-N

Loading...

Loading...