Makita HR004GZ User Manual

EN

Cordless Combination

Hammer

INSTRUCTION MANUAL 11

FR

DE

IT

NL

ES

PT

DA

EL

TR

Marteau Combiné sans Fil MANUEL D’INSTRUCTIONS 25

Akku-Kombi-Bohrhammer BETRIEBSANLEITUNG 40

Tassellatore combinato a

batteria

Accucombihamer GEBRUIKSAANWIJZING 74

Martillo Rotativo Combinado

Inalámbrico

Martelete Combinado A

Bateria

Akku-kombinationshammer BRUGSANVISNING 123

Φορητό δράπανο

συνδυασμού

Kablosuz Kombine Darbeli

Matkap

HR001G

HR002G

ISTRUZIONI PER L’USO 57

MANUAL DE

INSTRUCCIONES

MANUAL DE INSTRUÇÕES 107

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ 137

KULLANMA KILAVUZU 154

90

HR003G

HR004G

1

AB

1

2

3

Fig.1

Fig.2

Fig.3

Fig.5

1

1

2

Fig.6

1

Fig.7

1 2

3

1 2

1

3 4

Fig.4

Fig.8

2

1

2

Fig.9

1

Fig.10

1

Fig.11

Fig.13

1

2

3

Fig.14

Fig.12

1

Fig.15

3

1 2

1

Fig.16

2

1

Fig.20

1

A

Fig.17

Fig.18

Fig.19

1

Fig.21

1

2

1

Fig.22

1

1

Fig.23

4

4

1 2

Fig.24

3

Fig.27

1

1

2

Fig.28

Fig.25

Fig.26

1

Fig.29

1

2

1

Fig.30

5

1 2

Fig.31

Fig.32

Fig.33

Fig.35

1

2

Fig.36

1

2

Fig.37

Fig.34

1

Fig.38

6

1

Fig.39

Fig.40

Fig.41

Fig.43

Fig.44

Fig.45

1

2

3

4

1

Fig.42

7

1

12

2

12

3

Fig.46

Fig.47

Fig.48

1

Fig.49

1

Fig.50

8

Fig.51

12

Fig.52

12

12

1

Fig.54

1

Fig.53

Fig.55

1

2

1

Fig.56

9

1

2

Fig.57

Fig.58

1

2

10

ENGLISH (Original instructions)

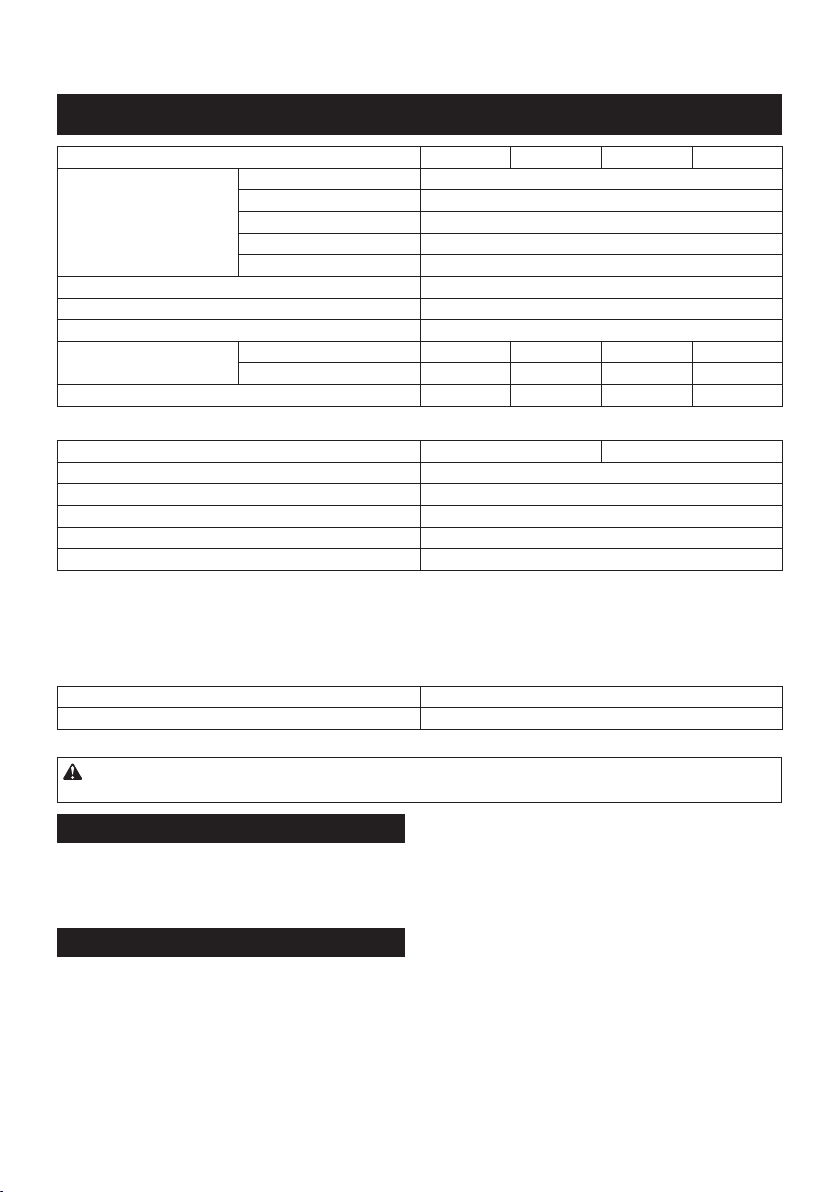

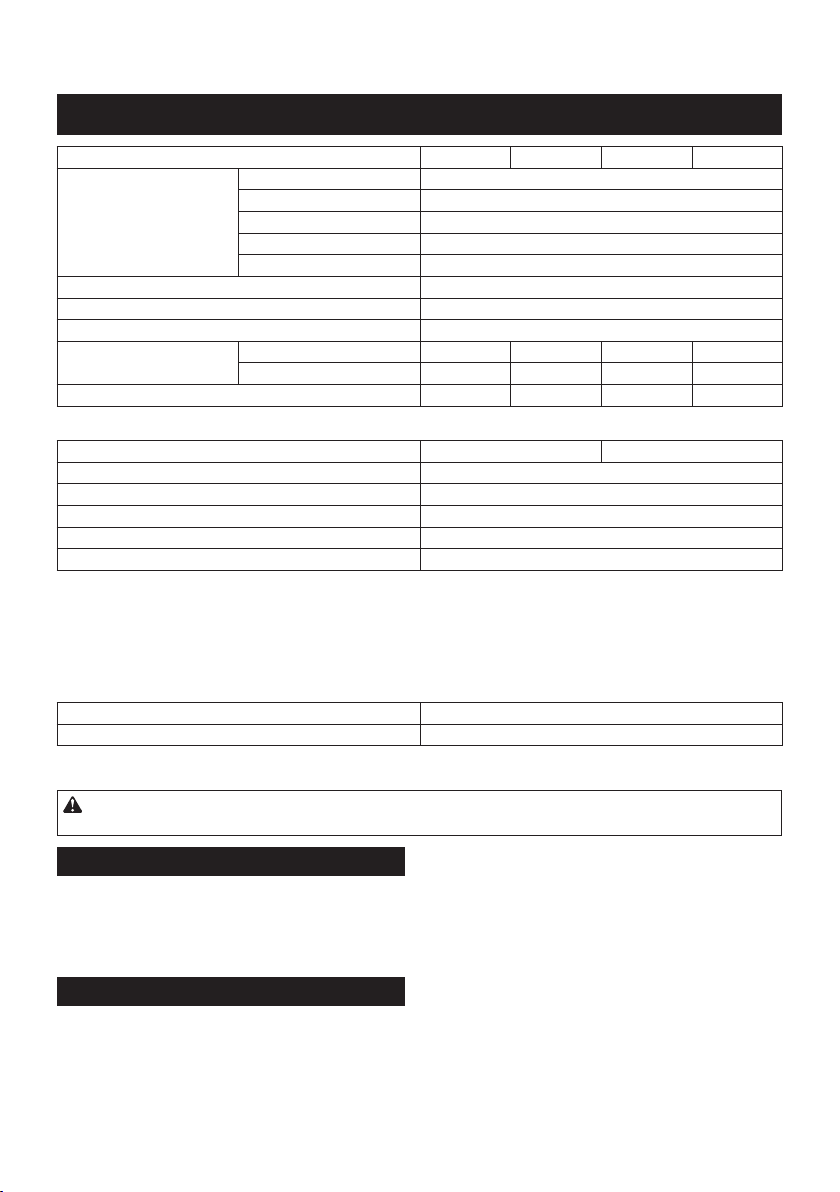

SPECIFICATIONS

Model: HR001G HR002G HR003G HR004G

Capacities Concrete 28 mm

Core bit 54 mm

Diamond core bit (dry type) 65 mm

Steel 13 mm

Wood 32 mm

No load speed 0 - 980 min

Blows per minute 0 - 5,000 min

Rated voltage D.C. 36 V - 40 V max

Overall length with BL4025 358 mm 389 mm 358 mm 389 mm

with BL4040 373 mm 404 mm 373 mm 404 mm

Net weight 3.9 - 4.6 kg 4.1 - 4.6 kg 3.9 - 4.6 kg 4.0 - 4.5 kg

Optional accessory

Model: DX12 (For HR001G/HR003G) DX14 (For HR002G/HR004G)

Suction performance 350 l/min

Operating stroke Up to 190 mm

Suitable drill bit Up to 260 mm

Rated voltage D.C. 36 V - 40 V max

Net weight 1.6 kg

•

Due to our continuing program of research and development, the specications herein are subject to change without notice.

• Specications may differ from country to country.

• The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heaviest combination, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge and charger

Battery cartridge BL4025 / BL4040

Charger DC40RA

•

Some of the battery cartridges and chargers listed above may not be available depending on your region of residence.

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

and chargers may cause injury and/or re.

Intended use

The tool is intended for hammer drilling and drilling in

brick, concrete and stone as well as for chiselling work.

It is also suitable for drilling without impact in wood,

metal, ceramic and plastic.

Noise

The typical A-weighted noise level determined according to EN60745-2-6:

Model HR001G

Sound pressure level (L

Sound power level (LWA) : 106 dB (A)

Uncertainty (K) : 3 dB(A)

Model HR002G

Sound pressure level (L

Sound power level (LWA) : 104 dB (A)

Uncertainty (K) : 3 dB(A)

) : 95 dB(A)

pA

) : 93 dB(A)

pA

Model HR003G

Sound pressure level (L

Sound power level (LWA) : 106 dB (A)

Uncertainty (K) : 3 dB(A)

Model HR004G

Sound pressure level (L

Sound power level (LWA) : 104 dB (A)

Uncertainty (K) : 3 dB(A)

Model HR001G with DX12

Sound pressure level (L

Sound power level (LWA) : 104 dB (A)

Uncertainty (K) : 3 dB(A)

Model HR002G with DX14

Sound pressure level (L

Sound power level (L

Uncertainty (K) : 3 dB(A)

WA

11 ENGLISH

-1

-1

) : 95 dB(A)

pA

) : 93 dB(A)

pA

) : 93 dB(A)

pA

) : 93 dB(A)

pA

) : 104 dB (A)

Model HR003G with DX12

Sound pressure level (L

Sound power level (LWA) : 104 dB (A)

) : 93 dB(A)

pA

Uncertainty (K) : 3 dB(A)

Model HR004G with DX14

Sound pressure level (L

Sound power level (LWA) : 104 dB (A)

) : 93 dB(A)

pA

Uncertainty (K) : 3 dB(A)

NOTE:

The declared noise emission value(s) has been

measured in accordance with a standard test method

and may be used for comparing one tool with another.

NOTE:

The declared noise emission value(s) may

also be used in a preliminary assessment of exposure.

WARNING: Wear ear protection.

WARNING:

use of the power tool can differ from the declared

value(s) depending on the ways in which the tool is

used especially what kind of workpiece is processed.

WARNING:

to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such

as the times when the tool is switched off and when

it is running idle in addition to the trigger time).

The noise emission during actual

Be sure to identify safety measures

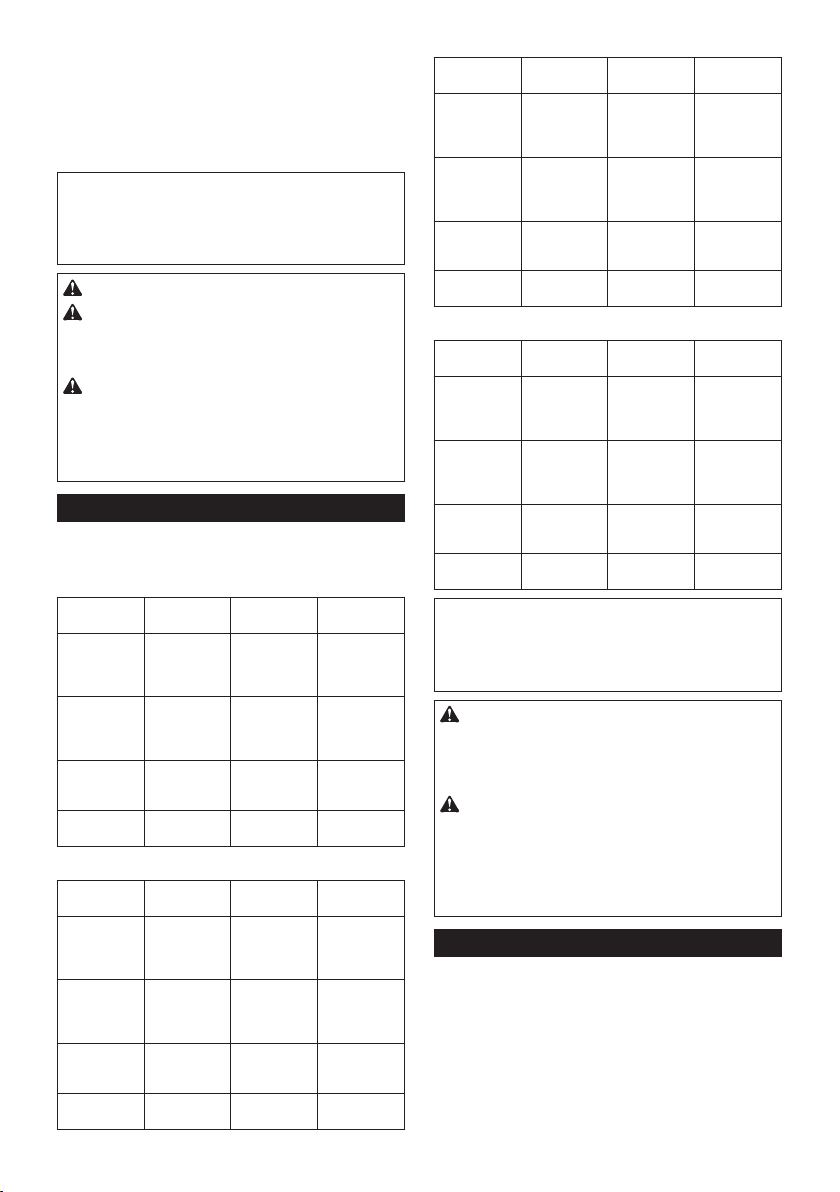

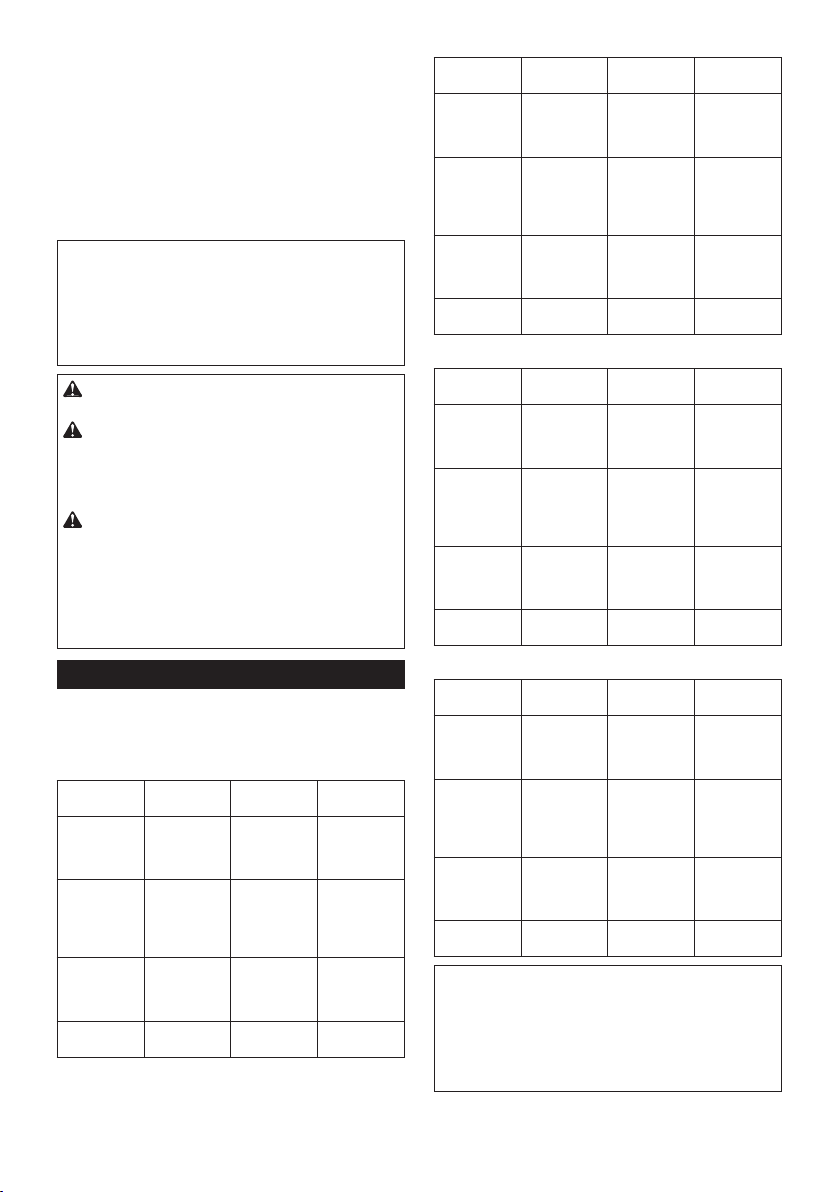

Vibration

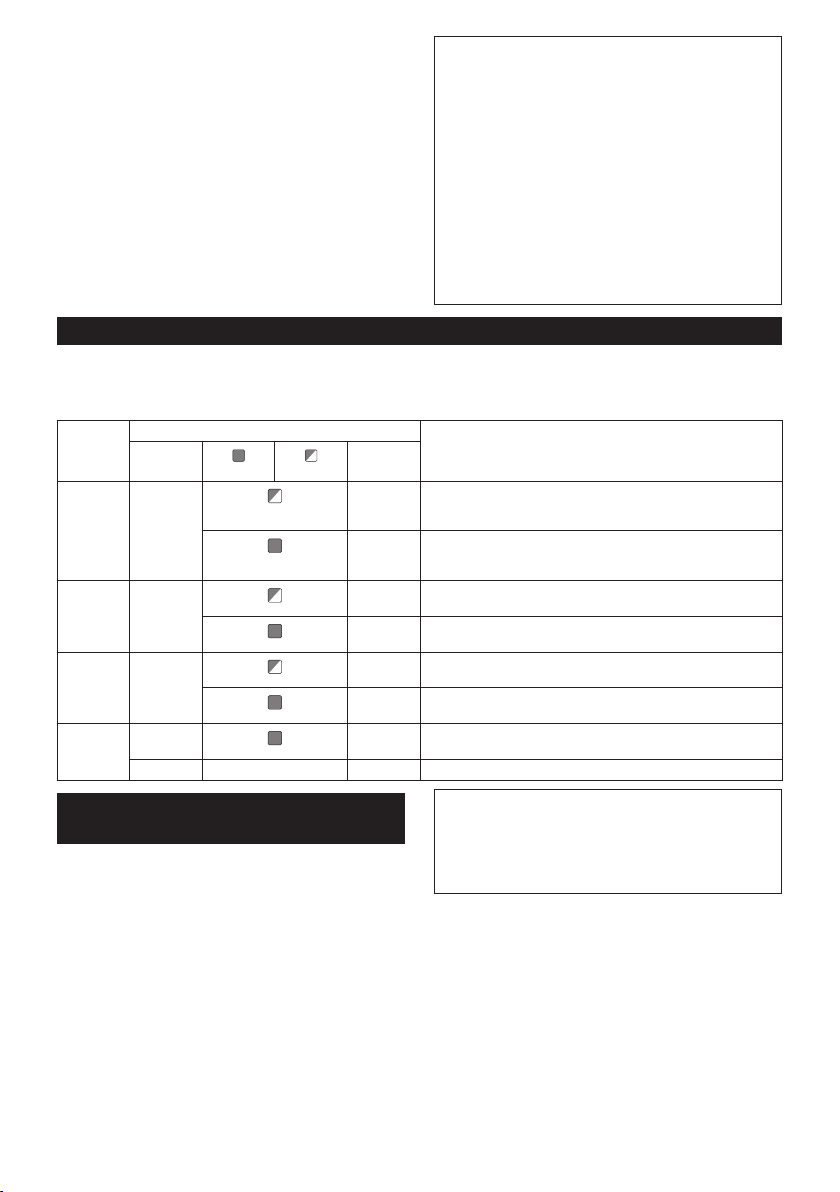

The following table shows the vibration total value (tri-axial

vector sum) determined according to applicable standard.

Model HR001G

Work mode Vibration

Hammer

drilling into

concrete

(a

h, HD

Hammer

drilling into

concrete with

DX12 (a

Chiselling function with side

grip (a

Drilling into

metal (a

)

h, Cheq

h, HD

h, D

)

)

)

emission

7.0 m/s

7.0 m/s

6.5 m/s

2.5 m/s2 or

less

Model HR002G

Work mode Vibration

Hammer

drilling into

concrete

(a

h, HD

Hammer

drilling into

concrete with

DX14 (a

Chiselling function with side

grip (a

Drilling into

metal (a

)

h, Cheq

h, HD

h, D

)

)

emission

6.5 m/s

6.0 m/s

)

7.5 m/s

2.5 m/s

2

2

2

2

2

2

2

Uncertainty (K)

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

Uncertainty (K)

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

Applicable

standard

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

Applicable

standard

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

Model HR003G

Work mode Vibration

Hammer

drilling into

concrete

(a

h, HD

Hammer

drilling into

concrete with

DX12 (a

Chiselling function with side

grip (a

Drilling into

metal (a

)

h, Cheq

h, HD

h, D

)

)

)

emission

7.0 m/s

7.0 m/s

7.0 m/s

2.5 m/s2 or

less

2

2

2

Uncertainty (K)

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

Applicable

standard

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

Model HR004G

Work mode Vibration

Hammer

drilling into

concrete

(a

h, HD

Hammer

drilling into

concrete with

DX14 (a

Chiselling function with side

grip (a

Drilling into

metal (a

)

h, Cheq

h, HD

h, D

)

)

emission

6.5 m/s

6.0 m/s

)

7.5 m/s

2.5 m/s

2

2

2

2

Uncertainty (K)

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

2

1.5 m/s

Applicable

standard

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

NOTE: The declared vibration total value(s) has been

measured in accordance with a standard test method

and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also

be used in a preliminary assessment of exposure.

WARNING: The vibration emission during

actual use of the power tool can differ from the

declared value(s) depending on the ways in which

the tool is used especially what kind of workpiece

is processed.

WARNING: Be sure to identify safety mea-

sures to protect the operator that are based on an

estimation of exposure in the actual conditions of

use (taking account of all parts of the operating

cycle such as the times when the tool is switched

off and when it is running idle in addition to the

trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

12 ENGLISH

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listed below may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

CORDLESS ROTARY HAMMER

SAFETY WARNINGS

1. Wear ear protectors. Exposure to noise can

cause hearing loss.

2. Use auxiliary handle(s), if supplied with the

tool. Loss of control can cause personal injury.

3.

Hold power tool by insulated gripping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring.

Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live"

and could give the operator an electric shock.

4. Wear a hard hat (safety helmet), safety glasses

and/or face shield. Ordinary eye or sun glasses

are NOT safety glasses. It is also highly recommended that you wear a dust mask and thickly

padded gloves.

5. Be sure the bit is secured in place before

operation.

6.

Under normal operation, the tool is designed to

produce vibration. The screws can come loose

easily, causing a breakdown or accident. Check

tightness of screws carefully before operation.

7. In cold weather or when the tool has not been

used for a long time, let the tool warm up for

a while by operating it under no load. This

will loosen up the lubrication. Without proper

warm-up, hammering operation is difcult.

8. Always be sure you have a rm footing. Be

sure no one is below when using the tool in

high locations.

9. Hold the tool rmly with both hands.

10. Keep hands away from moving parts.

11. Do not leave the tool running. Operate the tool

only when hand-held.

12. Do not point the tool at any one in the area

when operating. The bit could y out and

injure someone seriously.

13.

Do not touch the bit, parts close to the bit, or

workpiece immediately after operation; they

may be extremely hot and could burn your skin.

14. Some material contains chemicals which may

be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier

safety data.

15.

Always be sure that the tool is switched off and

the battery cartridge and the bit are removed

before handing the tool to other person.

16. Before operation, make sure that there is no

buried object such as electric pipe, water pipe

or gas pipe in the working area. Otherwise, the

drill bit/chisel may touch them, resulting an electric

shock, electrical leakage or gas leak.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2.

Do not disassemble or tamper the battery cartridge.

It may result in a re, excessive heat, or explosion.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4.

If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current ow,

overheating, possible burns and even a breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Do not nail, cut, crush, throw, drop the battery

cartridge, or hit against a hard object to the

battery cartridge. Such conduct may result in a

re, excessive heat, or explosion.

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consulting an

expert for hazardous material is required. Please also

observe possibly more detailed national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

13 ENGLISH

11. When disposing the battery cartridge, remove

it from the tool and dispose of it in a safe

place. Follow your local regulations relating to

disposal of battery.

12. Use the batteries only with the products

specied by Makita. Installing the batteries to

non-compliant products may result in a re, excessive heat, explosion, or leak of electrolyte.

13. If the tool is not used for a long period of time,

the battery must be removed from the tool.

14. During and after use, the battery cartridge may

take on heat which can cause burns or low

temperature burns. Pay attention to the handling of hot battery cartridges.

15. Do not touch the terminal of the tool immediately after use as it may get hot enough to

cause burns.

16. Do not allow chips, dust, or soil stuck into the

terminals, holes, and grooves of the battery

cartridge. It may result in poor performance or

breakdown of the tool or battery cartridge.

17. Unless the tool supports the use near a

high-voltage electrical power lines, do not use

the battery cartridge near a high-voltage electrical power lines. It may result in a malfunction

or breakdown of the tool or battery cartridge.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1.

Charge the battery cartridge before completely discharged. Always stop tool operation and charge the

battery cartridge when you notice less tool power.

2.

Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3.

Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let a hot

battery cartridge cool down before charging it.

4. When not using the battery cartridge, remove

it from the tool or the charger.

5. Charge the battery cartridge if you do not use

it for a long period (more than six months).

Important safety instructions for

wireless unit

1. Do not disassemble or tamper with the wireless unit.

2. Keep the wireless unit away from young children. If accidentally swallowed, seek medical

attention immediately.

3. Use the wireless unit only with Makita tools.

4. Do not expose the wireless unit to rain or wet

conditions.

5. Do not use the wireless unit in places where

the temperature exceeds 50°C (122°F).

6. Do not operate the wireless unit in places

where medical instruments, such as heart

pace makers are nearby.

7.

Do not operate the wireless unit in places where

automated devices are nearby. If operated, auto-

mated devices may develop malfunction or error.

8. Do not operate the wireless unit in places

under high temperature or places where

static electricity or electrical noise could be

generated.

9. The wireless unit can produce electromagnetic

elds (EMF) but they are not harmful to the

user.

10. The wireless unit is an accurate instrument. Be

careful not to drop or strike the wireless unit.

11. Avoid touching the terminal of the wireless

unit with bare hands or metallic materials.

12. Always remove the battery on the product

when installing the wireless unit into it.

13. When opening the lid of the slot, avoid the

place where dust and water may come into the

slot. Always keep the inlet of the slot clean.

14. Always insert the wireless unit in the correct

direction.

15. Do not press the wireless activation button

on the wireless unit too hard and/or press the

button with an object with a sharp edge.

16. Always close the lid of the slot when

operating.

17. Do not remove the wireless unit from the slot

while the power is being supplied to the tool.

Doing so may cause a malfunction of the wireless

unit.

18. Do not remove the sticker on the wireless unit.

19. Do not put any sticker on the wireless unit.

20. Do not leave the wireless unit in a place where

static electricity or electrical noise could be

generated.

21. Do not leave the wireless unit in a place subject to high heat, such as a car sitting in the

sun.

22. Do not leave the wireless unit in a dusty or

powdery place or in a place corrosive gas

could be generated.

23. Sudden change of the temperature may bedew

the wireless unit. Do not use the wireless unit

until the dew is completely dried.

24. When cleaning the wireless unit, gently wipe

with a dry soft cloth. Do not use benzine, thinner, conductive grease or the like.

25. When storing the wireless unit, keep it in the

supplied case or a static-free container.

26. Do not insert any devices other than Makita

wireless unit into the slot on the tool.

27. Do not use the tool with the lid of the slot damaged. Water, dust, and dirt come into the slot may

cause malfunction.

28. Do not pull and/or twist the lid of the slot more

than necessary. Restore the lid if it comes off

from the tool.

29. Replace the lid of the slot if it is lost or

damaged.

SAVE THESE INSTRUCTIONS.

14 ENGLISH

FUNCTIONAL DESCRIPTION

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery cartridge

CAUTION: Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip off your hands

and result in damage to the tool and battery cartridge

and a personal injury.

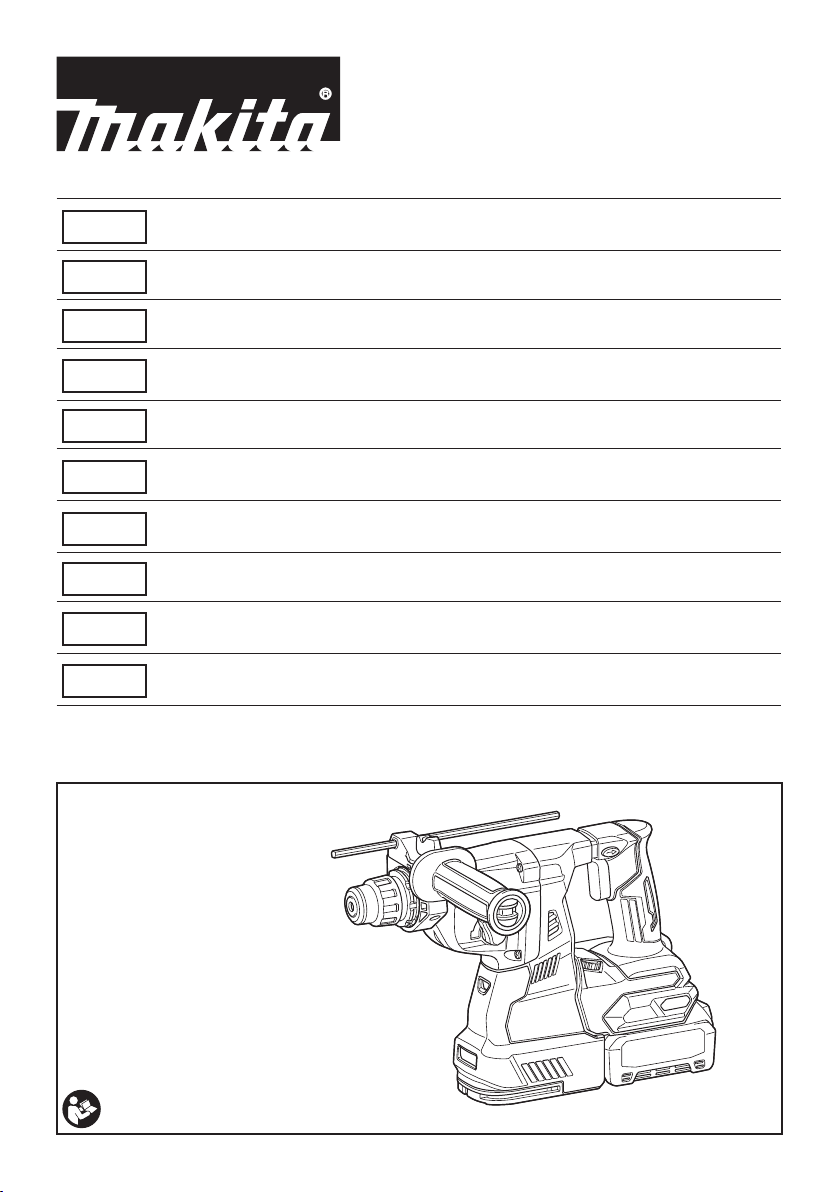

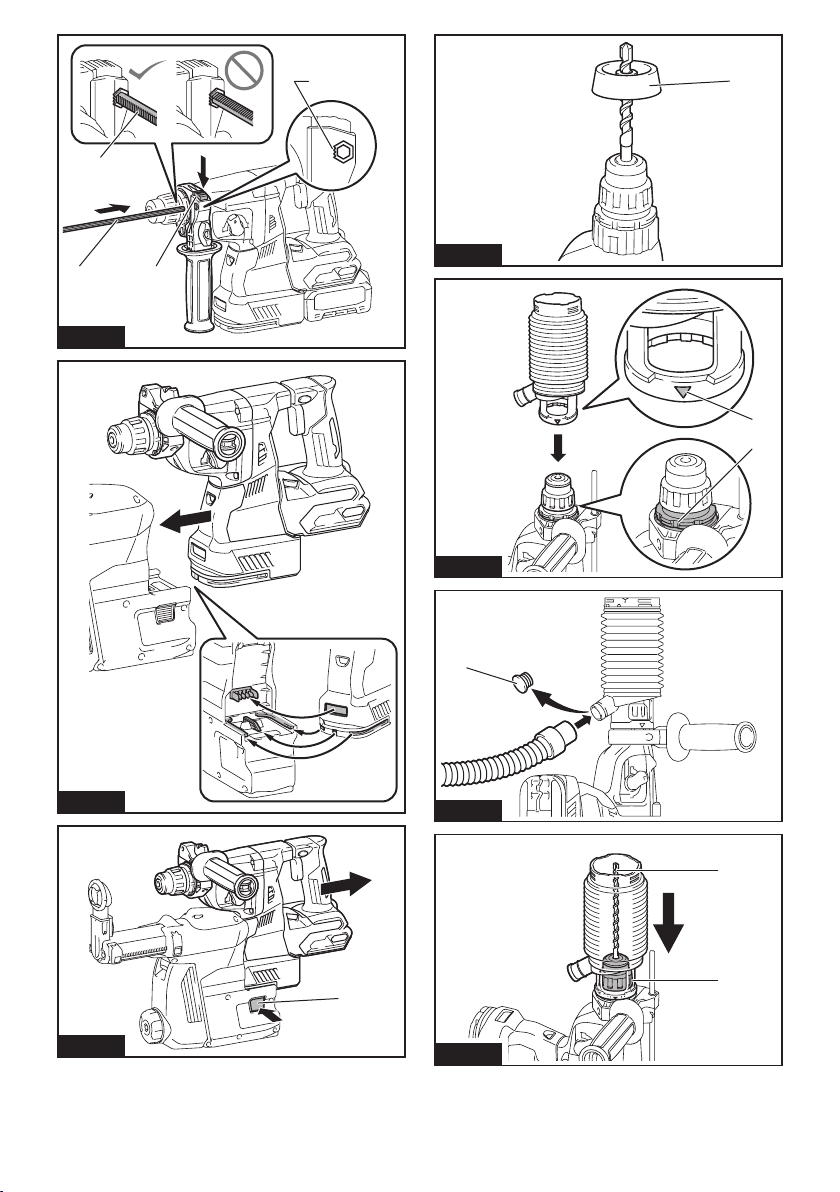

► Fig.1: 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

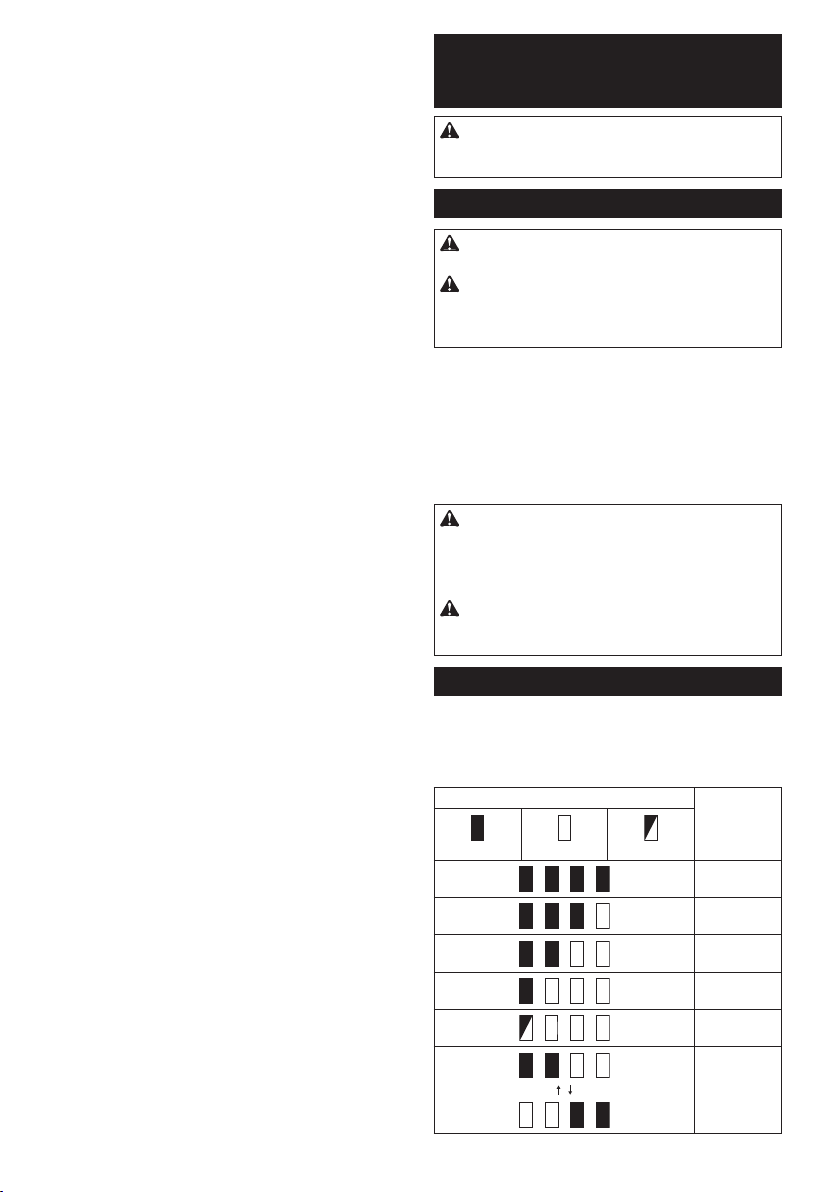

Indicating the remaining battery capacity

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for a few seconds.

► Fig.2: 1. Indicator lamps 2. Check button

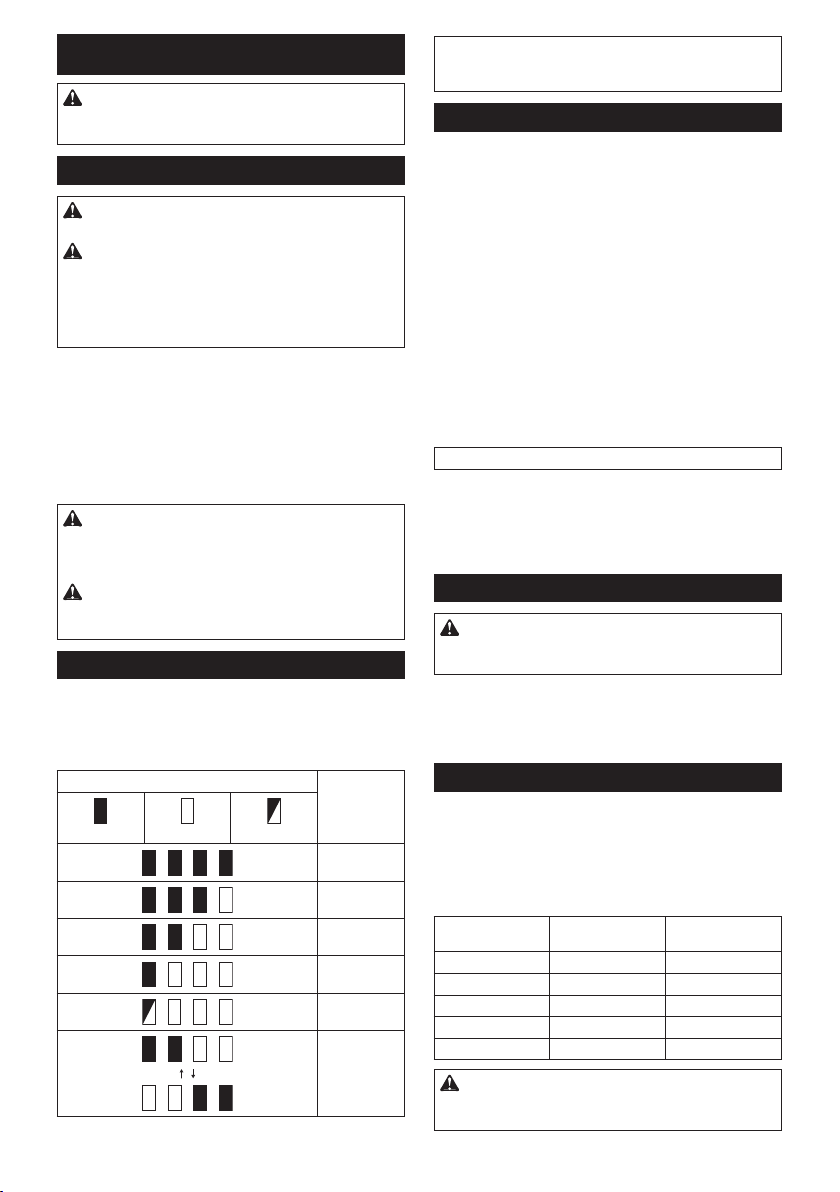

Indicator lamps Remaining

Lighted Off Blinking

capacity

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

Tool / battery protection system

The tool is equipped with a tool/battery protection system. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will automatically stop during operation if the tool or battery is

placed under one of the following conditions:

Overload protection

When the battery is operated in a manner that causes

it to draw an abnormally high current, the tool automatically stops without any indication. In this situation, turn

the tool off and stop the application that caused the tool

to become overloaded. Then turn the tool on to restart.

Overheat protection

When the tool or battery is overheated, the tool stops

automatically. In this case, let the tool and battery cool

before turning the tool on again.

NOTE: When the tool is overheated, the lamp blinks.

Overdischarge protection

When the battery capacity is not enough, the tool stops

automatically. In this case, remove the battery from the

tool and charge the battery.

Switch action

WARNING:

the tool, always check to see that the switch trigger actuates

properly and returns to the "OFF" position when released.

► Fig.3: 1. Switch trigger

To start the tool, simply pull the switch trigger. Tool

speed is increased by increasing pressure on the switch

trigger. Release the switch trigger to stop.

Before installing the battery cartridge into

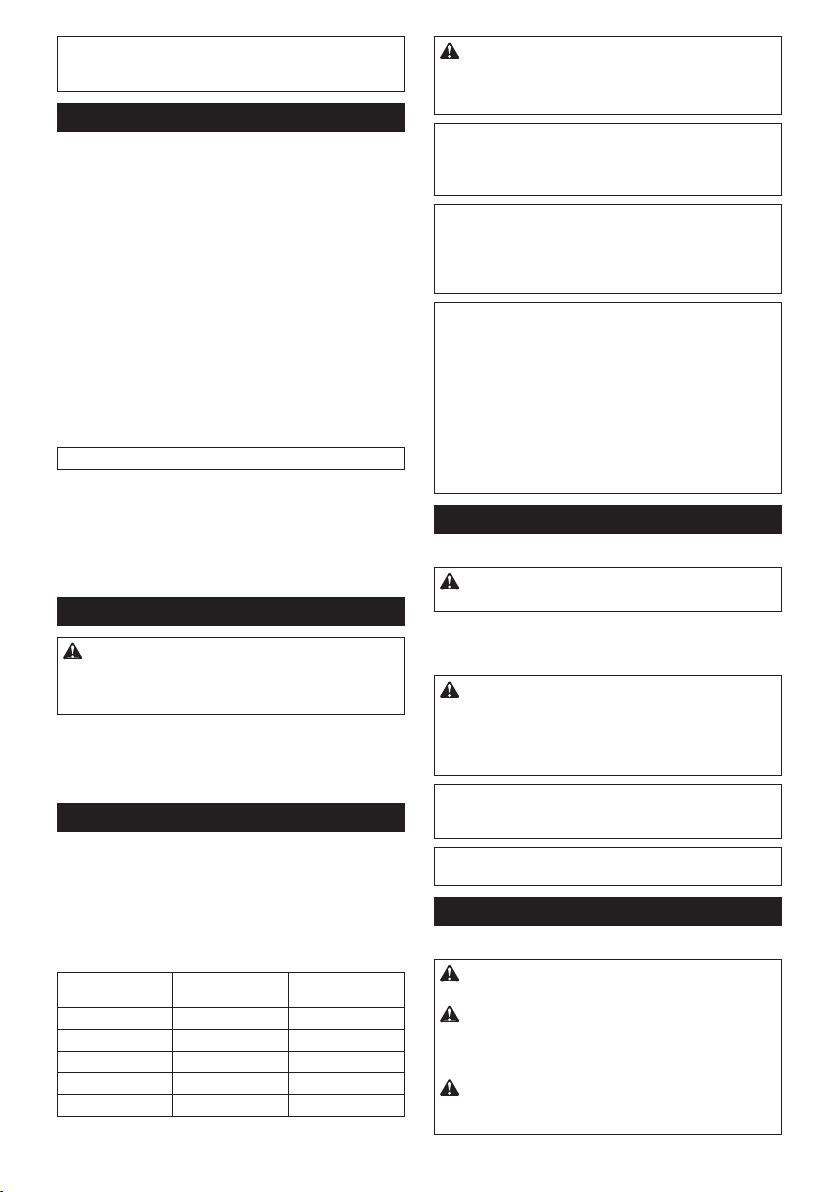

Speed change

The revolutions and blows per minute can be adjusted

by turning the adjusting dial. The dial is marked 1 (low-

est speed) to 5 (full speed).

► Fig.4: 1. Adjusting dial

Refer to the table below for the relationship between the number

on the adjusting dial and the revolutions and blows per minute.

Number Revolutions per

5 980 5,000

4 870 4,440

3 630 3,210

2 380 1,940

1 300 1,530

minute

CAUTION: Do not turn the adjusting dial when

the tool is running. Failure to do so may result in

the loss of control of the tool and cause an injury.

Blows per minute

15 ENGLISH

NOTICE: If the tool is operated continuously at

low speed for a long time, the motor will get overloaded, resulting in tool malfunction.

NOTICE: The speed adjusting dial can be turned

only as far as 5 and back to 1. Do not force it past

5 or 1, or the speed adjusting function may no

longer work.

NOTE: Soft no-load rotation function (For

HR001G/HR002G)

When the speed adjusting dial is set to "4" or higher,

the tool automatically reduces the speed at no-load to

reduce the vibration under no-load. Once operation

starts with a bit against concrete, blows per minute

increase and reach the numbers as shown in the

table. When temperature is low and there is less

uidity in grease, the tool may not have this function

even with the motor rotating.

Lighting up the front lamp

► Fig.5: 1. Lamp

CAUTION: Do not look in the light or see the

source of light directly.

Pull the switch trigger to light up the lamp. The lamp

keeps on lighting while the switch trigger is being pulled.

The lamp goes out approximately 10 seconds after

releasing the switch trigger.

CAUTION: For HR001G/HR002G

If the lamp goes off after blinking for a few seconds, the active feedback sensing technology

is not working properly. Ask your local Makita

Service Center for repair.

NOTE: Use a dry cloth to wipe the dirt off the lens of

the lamp. Be careful not to scratch the lens of lamp, or

it may lower the illumination.

NOTE: If the dust collection system is installed on the

tool, the lamp of the dust collection system lights up

instead of the lamp of the tool.

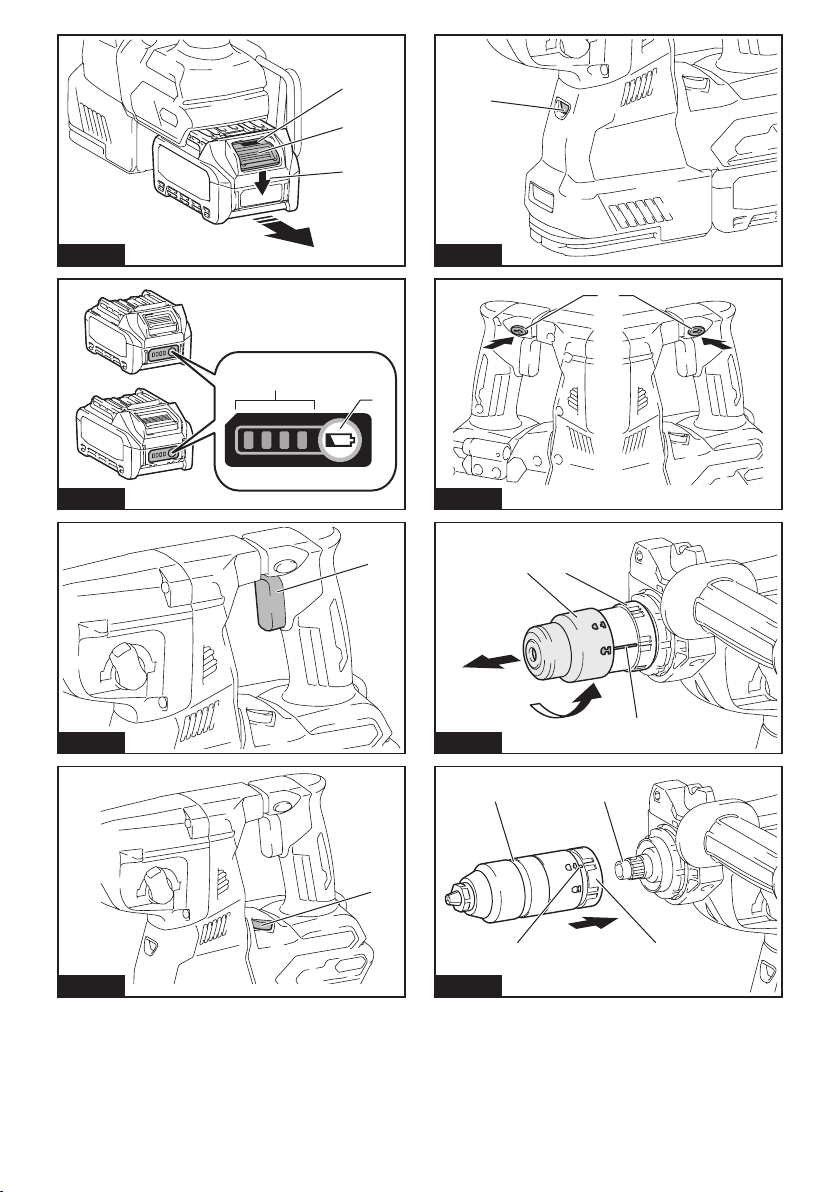

Reversing switch action

► Fig.6: 1. Reversing switch lever

CAUTION: Always check the direction of

rotation before operation.

CAUTION: Use the reversing switch only after

the tool comes to a complete stop. Changing the

direction of rotation before the tool stops may damage the tool.

CAUTION: When not operating the tool,

always set the reversing switch lever to the neutral position.

This tool has a reversing switch to change the direction

of rotation. Depress the reversing switch lever from the

A side for clockwise rotation or from the B side for counterclockwise rotation.

When the reversing switch lever is in the neutral position, the switch trigger cannot be pulled.

Changing the quick change chuck

for SDS-plus

For HR002G/HR004G

The quick change chuck for SDS-plus can be easily

exchanged for the quick change drill chuck.

Removing the quick change chuck

for SDS-plus

CAUTION: Before removing the quick change

chuck for SDS-plus, be sure to remove the bit.

Grasp the change cover of the quick change chuck for

SDS-plus and turn in the direction of the arrow until

the change cover line moves from the symbol to

the symbol. Pull forcefully in the direction of the arrow.

► Fig.7: 1. Quick change chuck for SDS-plus

2. Change cover 3. Change cover line

Installing the quick change drill chuck

Check the line of the quick change drill chuck shows

the symbol. Grasp the change cover of the quick

change drill chuck and set the line to the

Place the quick change drill chuck on the spindle of the

tool. Grasp the change cover of the quick change drill

chuck and turn the change cover line to the symbol

until a click can clearly be heard.

► Fig.8: 1. Quick change drill chuck 2. Spindle

3. Change cover line 4. Change cover

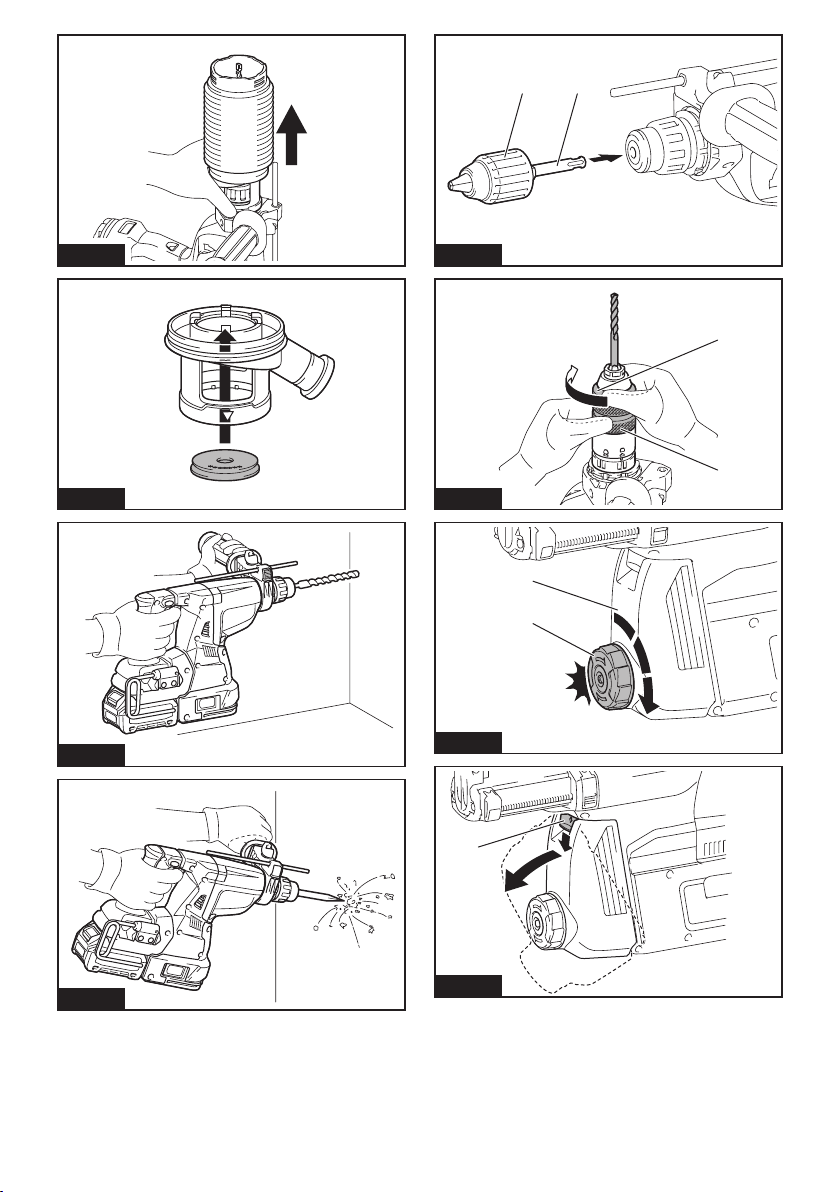

Selecting the action mode

NOTICE:

knob when the tool is running. The tool will be damaged.

NOTICE: To avoid rapid wear on the mode

change mechanism, be sure that the action mode

changing knob is always positively located in one

of the three action mode positions.

Do not rotate the action mode changing

Rotation with hammering

For drilling in concrete, masonry, etc., rotate the action

mode changing knob to the symbol. Use a tungsten-

carbide tipped bit (optional accessory).

► Fig.9: 1. Rotation with hammering 2. Action mode

changing knob

Rotation only

For drilling in wood, metal or plastic materials, rotate

the action mode changing knob to the

twist drill bit or wood drill bit.

► Fig.10: 1. Rotation only

symbol. Use a

Hammering only

For chipping, scaling or demolition operations, rotate

the action mode changing knob to the symbol. Use a

bull point, cold chisel, scaling chisel, etc.

► Fig.11: 1. Hammering only

16 ENGLISH

symbol.

Hook

CAUTION: Always remove the battery when

hanging the tool with the hook.

CAUTION: Never hook the tool at high loca-

tion or on potentially unstable surface.

The hook is convenient for temporarily hanging the tool.

To use the hook, simply lift up hook until it snaps into

the open position. When not in use, always lower hook

until it snaps into the closed position.

► Fig.12: 1. Hook

► Fig.13

Connecting lanyard (tether strap) to

the hook

CAUTION: Do not use damaged hook and

screws. Before use, always check for damages,

cracks or deformations, and make sure that the

screws are tightened.

CAUTION: Make sure that the hook is

securely installed with the screws.

CAUTION: Do not remove the battery car-

tridge while hanging the tool. The tool may fall if the

screws are not tightened.

CAUTION: Always use a locking carabiner

(multi-action and screw gate type) and be sure

to attach the lanyard (tether strap) to the double

looped portion of the hook. Improper attachment

may cause tool drop from the hook and result in

personal injury.

The hook is also used for connecting the lanyard (tether

strap). Be sure to connect the lanyard (tether strap) to

the double looped portion of the hook.

► Fig.14: 1. Double looped portion of the hook

2. Lanyard (tether strap) 3. Locking cara-

biner (multi-action and screw gate type)

Adjusting the nozzle position of the

dust collection system

Optional accessory

Push in the guide while pushing up the guide adjustment button, and then release the button at the desired

position.

► Fig.15: 1. Guide 2. Guide adjustment button

NOTE: Before adjusting the nozzle position, release

the nozzle forward completely by pushing up the

guide adjustment button.

If a long drill bit is installed, extend the guide by pushing

up the extension button.

► Fig.16: 1. Extension button

Adjusting the drilling depth of the

dust collection system

Optional accessory

Slide the depth adjustment button to the desired position while pushing it up. The distance (A) is the drilling

depth.

► Fig.17: 1. Depth adjustment button

Torque limiter

NOTICE: As soon as the torque limiter actuates,

switch off the tool immediately. This will help pre-

vent premature wear of the tool.

NOTICE: Drill bits such as hole saw, which tend

to pinch or catch easily in the hole, are not appropriate for this tool. This is because they will cause

the torque limiter to actuate too frequently.

The torque limiter will actuate when a certain torque

level is reached. The motor will disengage from the

output shaft. When this happens, the drill bit will stop

turning.

Electronic function

The tool is equipped with the electronic functions for

easy operation.

• Constant speed control

The speed control function provides the constant

rotation speed regardless of load conditions.

• Active Feedback sensing Technology (For

HR001G/HR002G)

If the tool is swung at the predetermined acceleration during operation, the motor is forcibly stopped

to reduce the burden on the wrist.

NOTE: This function does not work if the acceleration

does not reach the predetermined one when the tool

is swung.

NOTE: If the bit is swung at the predetermined

acceleration during chipping, scaling, or demolishing,

the motor is forcibly stopped. In this case, release

the switch trigger, and then pull the switch trigger to

restart the tool.

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Side grip (auxiliary handle)

CAUTION: Always use the side grip to ensure

safe operation.

CAUTION: After installing or adjusting the

side grip, make sure that the side grip is rmly

secured.

17 ENGLISH

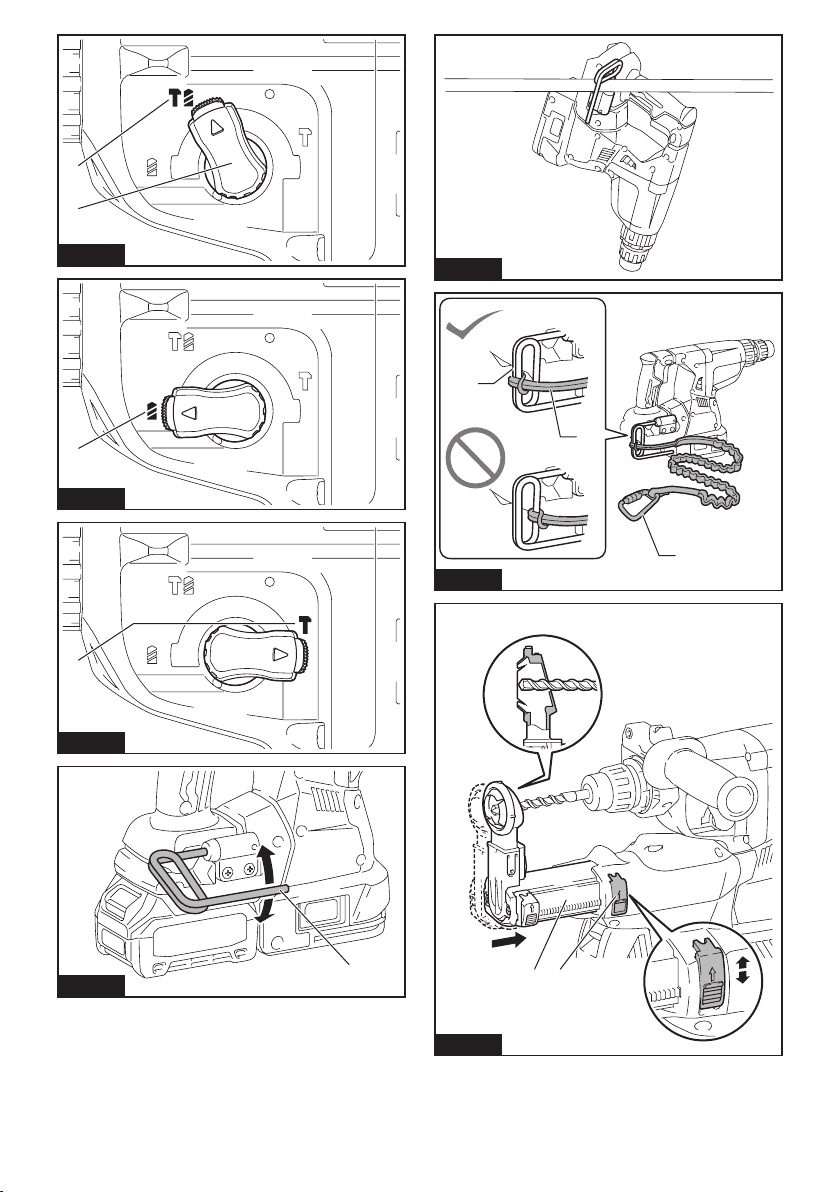

To install the side grip, follow the steps below.

1. Loosen the thumb screw on the side grip.

► Fig.18: 1. Thumb screw

2. Attach the side grip while pressing the thumb

screw so that the grooves on the grip t in the protrusions on the tool barrel.

► Fig.19: 1. Thumb screw

3. Tighten the thumb screw to secure the grip. The

grip can be xed at desired angle.

Grease

Coat the shank end of the drill bit beforehand with a

small amount of grease (about 0.5 - 1 g).

This chuck lubrication assures smooth action and longer service life.

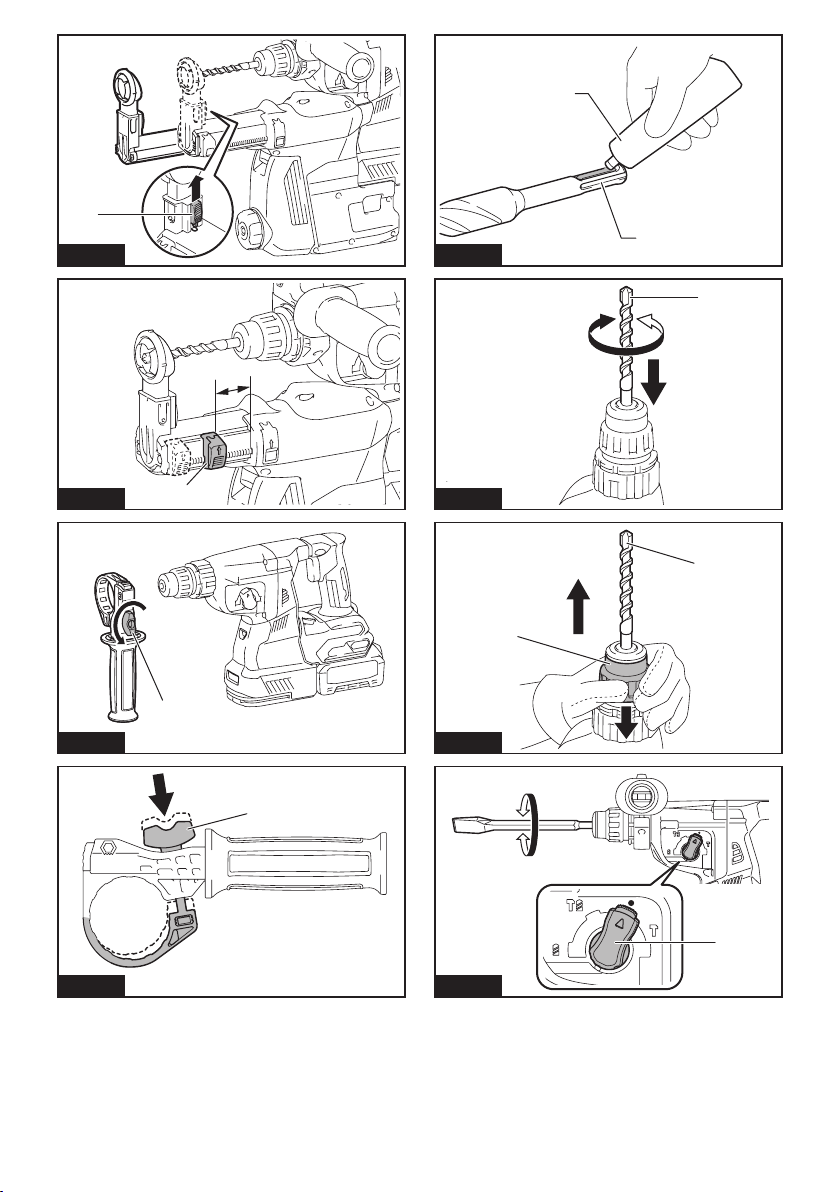

Installing or removing drill bit

Clean the shank end of the drill bit and apply grease

before installing the drill bit.

► Fig.20: 1. Shank end 2. Grease

Insert the drill bit into the tool. Turn the drill bit and push

it in until it engages.

After installing the drill bit, always make sure that the

drill bit is securely held in place by trying to pull it out.

► Fig.21: 1. Drill bit

To remove the drill bit, pull the chuck cover down all the

way and pull the drill bit out.

► Fig.22: 1. Drill bit 2. Chuck cover

Chisel angle (when chipping,

scaling or demolishing)

The chisel can be secured at the desired angle. To

change the chisel angle, rotate the action mode changing knob to the O symbol. Turn the chisel to the desired

angle.

► Fig.23: 1. Action mode changing knob

Rotate the action mode changing knob to the

bol. Then make sure that the chisel is securely held in

place by turning it slightly.

sym-

Depth gauge

The depth gauge is convenient for drilling holes of

uniform depth.

Press and hold the lock button, and then insert the

depth gauge into the hex hole. Make sure that the

toothed side of the depth gauge faces the marking.

► Fig.24: 1. Depth gauge 2. Lock button 3. Marking

Adjust the depth gauge by moving it back and forth

while pressing the lock button. After the adjustment,

release the lock button to lock the depth gauge.

NOTE: Make sure that the depth gauge does not

touch the main body of the tool when attaching it.

4. Toothed side

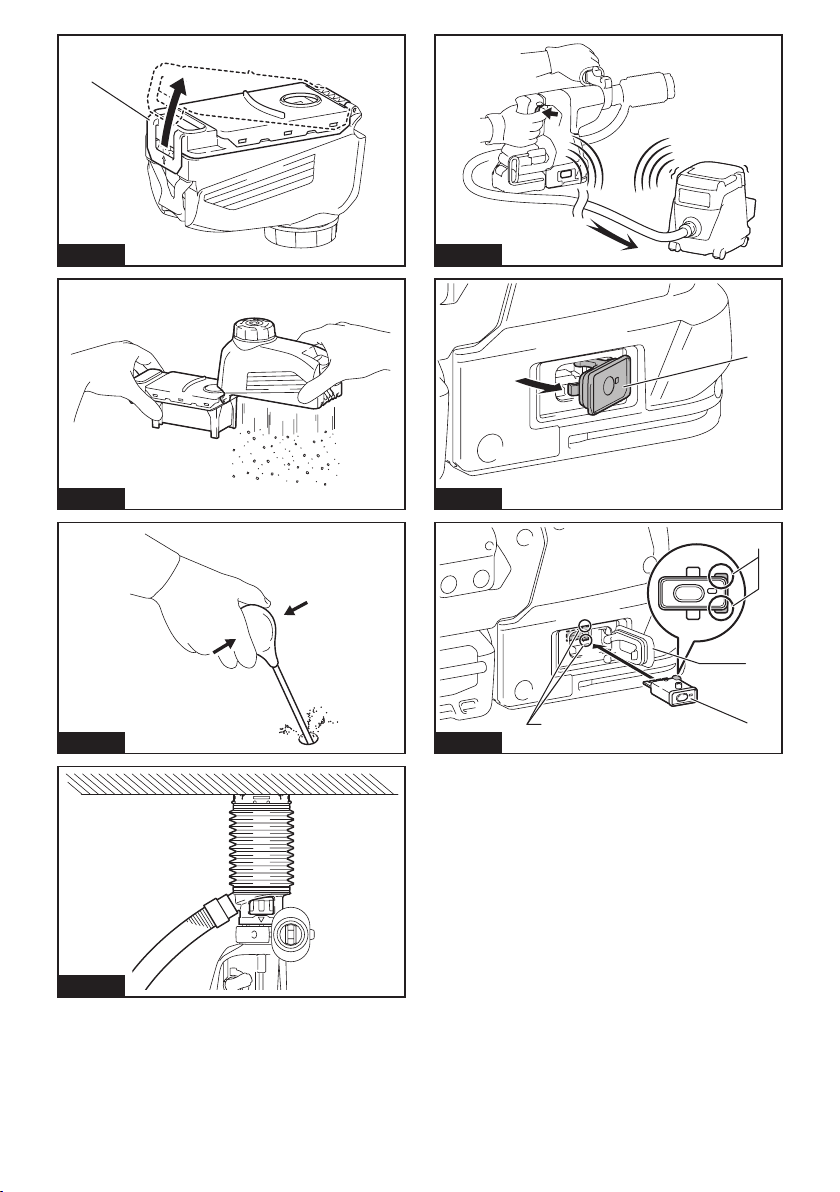

Installing or removing the dust

collection system

Optional accessory

To install the dust collection system, insert the tool into

the dust collection system all the way until it locks in

place with a little double click.

► Fig.25

To remove the dust collection system, pull the tool while

pressing the lock-off button.

► Fig.26: 1. Lock-off button

Dust cup

Optional accessory

Use the dust cup to prevent dust from falling over the tool and

on yourself when performing overhead drilling operations.

Attach the dust cup to the bit as shown in the gure. The size

of bits which the dust cup can be attached to is as follows.

Model Bit diameter

Dust cup 5 6 mm - 14.5 mm

Dust cup 9 12 mm - 16 mm

► Fig.27: 1. Dust cup

Dust cup set

Optional accessory

Before installing the dust cup set, remove the bit from

the tool if installed.

Install the dust cup set on the tool so that the

bol on the dust cup is aligned with the groove in the tool.

► Fig.28: 1. symbol 2. Groove

NOTE: If you connect a vacuum cleaner to the dust

cup set, remove the dust cap before connecting it.

► Fig.29: 1. Dust cap

To remove the dust cup set, remove the bit while pulling

the chuck cover in the direction of the arrow.

► Fig.30: 1. Bit 2. Chuck cover

Hold the root of dust cup and pull it out.

► Fig.31

NOTE: If the cap comes off from the dust cup, attach

it with its printed side facing up so that groove on the

cap ts in the inside periphery of the attachment.

► Fig.32

sym-

OPERATION

CAUTION: Always use the side grip (auxiliary

handle) and rmly hold the tool by both side grip

and switch handle during operations.

CAUTION: Always make sure that the work-

piece is secured before operation.

CAUTION:

the bit gets stuck. Loss of control may cause injury.

Do not pull the tool out forcibly even

18 ENGLISH

CAUTION: The dust collection system is

intended for drilling in concrete only. Do not use

the dust collection system for drilling in metal or

wood.

CAUTION: When using the tool with the dust

collection system, be sure to attach the lter

to the dust collection system to prevent dust

inhalation.

CAUTION: Before using the dust collection

system, check that the lter is not damaged.

Failure to do so may cause dust inhalation.

CAUTION: The dust collection system col-

lects the generated dust at a considerable rate,

but not all dust can be collected.

NOTICE: Do not use the dust collection system

for core drilling or chiseling.

NOTICE: Do not use the dust collection system

for drilling in wet concrete or use this system

in wet environment. Failure to do so may cause

malfunction.

NOTE: If the battery cartridge is in low temperature,

the tool’s capability may not be fully obtained. In this

case, warm up the battery cartridge by using the

tool with no load for a while to fully obtain the tool’s

capability.

► Fig.33

Hammer drilling operation

CAUTION: There is tremendous and sudden

twisting force exerted on the tool/drill bit at the time of

hole break-through, when the hole becomes clogged

with chips and particles, or when striking reinforcing

rods embedded in the concrete. Always use the side

grip (auxiliary handle) and rmly hold the tool by

both side grip and switch handle during operations. Failure to do so may result in the loss of control

of the tool and potentially severe injury.

Set the action mode changing knob to the symbol.

Position the drill bit at the desired location for the hole,

then pull the switch trigger. Do not force the tool. Light

pressure gives best results. Keep the tool in position

and prevent it from slipping away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at

an idle, then remove the drill bit partially from the hole.

By repeating this several times, the hole will be cleaned

out and normal drilling may be resumed.

NOTE: Eccentricity in the drill bit rotation may occur

while operating the tool with no load. The tool automatically centers itself during operation. This does not

affect the drilling precision.

Chipping/Scaling/Demolition

Set the action mode changing knob to the symbol.

Hold the tool rmly with both hands. Turn the tool on

and apply slight pressure on the tool so that the tool will

not bounce around, uncontrolled.

Pressing very hard on the tool will not increase the efciency.

► Fig.34

Drilling in wood or metal

CAUTION: Hold the tool rmly and exert care

when the drill bit begins to break through the

workpiece. There is a tremendous force exerted on

the tool/drill bit at the time of hole break through.

CAUTION: A stuck drill bit can be removed

simply by setting the reversing switch to reverse

rotation in order to back out. However, the tool

may back out abruptly if you do not hold it rmly.

CAUTION: Always secure workpieces in a

vise or similar hold-down device.

NOTICE: Never use “rotation with hammering”

when the drill chuck is installed on the tool. The

drill chuck may be damaged.

Also, the drill chuck will come off when reversing the tool.

NOTICE:

speed up the drilling. In fact, this excessive pressure will

only serve to damage the tip of your drill bit, decrease the

tool performance and shorten the service life of the tool.

Set the action mode changing knob to the symbol.

Pressing excessively on the tool will not

For HR001G/HR003G

Optional accessory

Attach the chuck adapter to a keyless drill chuck to

which 1/2"-20 size screw can be installed, and then

install them to the tool. When installing it, refer to the

section “Installing or removing drill bit”.

► Fig.35: 1. Keyless drill chuck 2. Chuck adapter

For HR002G/HR004G

Use the quick change drill chuck as standard equipment. When installing it, refer to "changing the quick

change chuck for SDS-plus".

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws. Place the bit in the chuck as far as

it will go. Hold the ring rmly and turn the sleeve clock-

wise to tighten the chuck.

► Fig.36: 1. Sleeve 2. Ring

To remove the bit, hold the ring and turn the sleeve

counterclockwise.

Diamond core drilling

NOTICE: If performing diamond core drilling

operations using “rotation with hammering”

action, the diamond core bit may be damaged.

When performing diamond core drilling operations, always set the action mode changing knob to

the position to use "rotation only" action.

19 ENGLISH

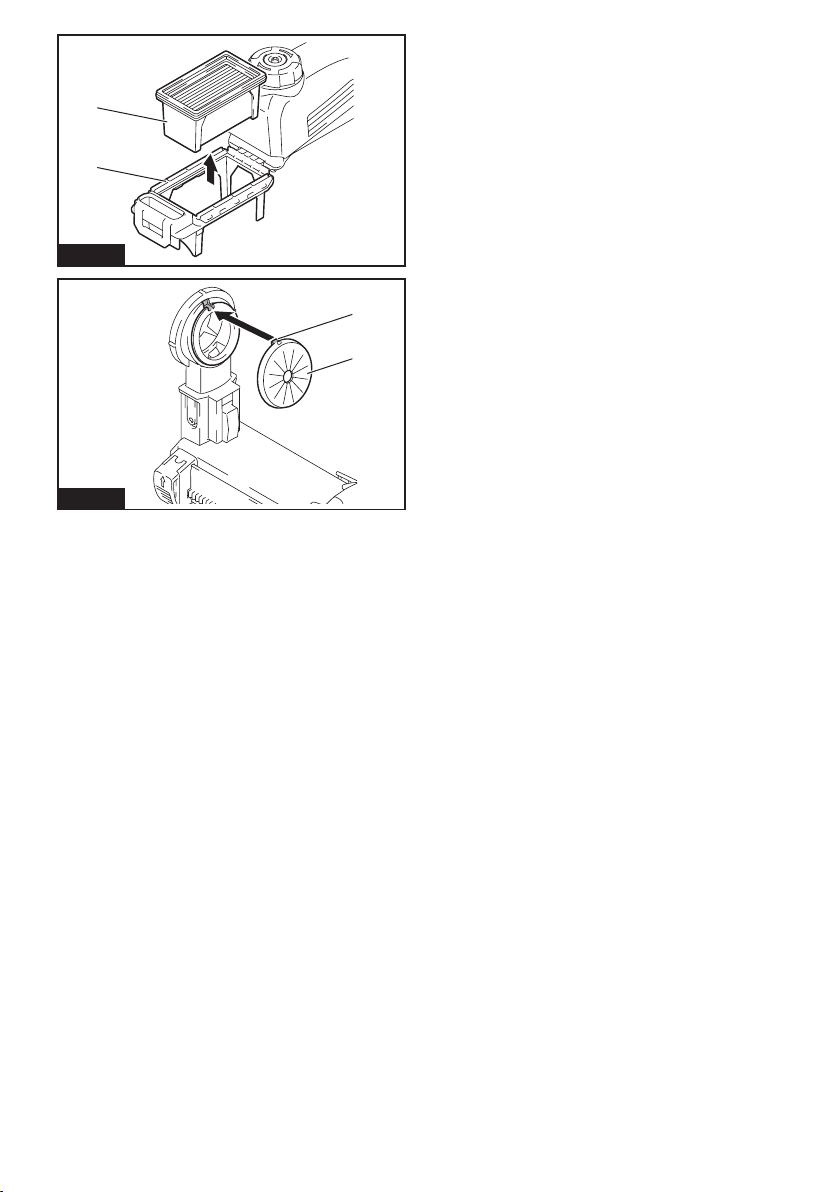

Beating dust on the lter

Optional accessory

CAUTION:

while the dust case is removed from the dust collection system. Doing so may cause dust inhalation.

Do not turn the dial on the dust case

CAUTION: Always switch off the tool when

turning the dial on the dust case. Turning the dial

while the tool is running may result in the loss of

control of the tool.

By beating the dust on the lter inside the dust case,

you can keep the vacuum efciency and also reduce

the number of times to dispose of the dust.

Turn the dial on the dust case three times after collecting every 50,000 mm3 of dust or when you feel the

vacuum performance declined.

NOTE: 50,000 mm3 of dust equivalents to drilling 10

holes of ø10 mm and 65 mm depth (14 holes of ø3/8″

and 2″ depth).

► Fig.37: 1. Dust case 2. Dial

Disposing of dust

Optional accessory

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

CAUTION: Be sure to wear dust mask when

disposing of dust.

CAUTION: Empty the dust case regularly

before the dust case becomes full. Failure to do so

may decrease the dust collection performance and

cause dust inhalation.

CAUTION: The performance of dust collection

decreases if the lter in the dust case become

clogged. Replace the lter with new one after

approximately 200 times of dust fulllment as a

guide. Failure to do so may cause dust inhalation.

1. Remove the dust case while pressing down the

lever of the dust case.

► Fig.38: 1. Lever

2. Open the cover of the dust case.

► Fig.39: 1. Cover

3. Dispose of the dust, and then clean the lter.

► Fig.40

NOTICE: When cleaning the lter, tap the case

of the lter gently by hand to remove dust. Do not

tap the lter directly; touch the lter with brush

or similar; or blow compressed air on the lter.

Doing so may damage the lter.

Blow-out bulb

Optional accessory

After drilling the hole, use the blow-out bulb to clean the

dust out of the hole.

► Fig.41

Using dust cup set

Optional accessory

Fit the dust cup set against the ceiling when operating the tool.

► Fig.42

NOTICE: Do not use the dust cup set when drill-

ing in metal or similar. It may damage the dust

cup set due to the heat produced by small metal

dust or similar.

NOTICE: Do not install or remove the dust cup

set with the drill bit installed in the tool. It may

damage the dust cup set and cause dust leak.

Connecting lanyard (tether strap) to

the hook

Safety warnings specic for use at height

Read all safety warnings and instructions. Failure to follow

the warnings and instructions may result in serious injury.

1. Always keep the tool tethered when working

"at height". Maximum lanyard length is 2 m.

The maximum permissible fall height for lanyard (tether strap) must not exceed 2 m.

2. Use only with lanyards appropriate for this tool

type and rated for at least 8.0 kg.

3. Do not anchor the tool lanyard to anything on

your body or on movable components. Anchor

the tool lanyard to a rigid structure that can

withstand the forces of a dropped tool.

4. Make sure the lanyard is properly secured at

each end prior to use.

5. Inspect the tool and lanyard before each use

for damage and proper function (including

fabric and stitching). Do not use if damaged or

not functioning properly.

6. Do not wrap lanyards around or allow them to

come in contact with sharp or rough edges.

7.

Fasten the other end of the lanyard outside the

working area so that a falling tool is held securely.

8.

Attach the lanyard so that the tool will move away

from the operator if it falls. Dropped tools will swing on

the lanyard, which could cause injury or loss of balance.

9. Do not use near moving parts or running

machinery. Failure to do so may result in a crush

or entanglement hazard.

10. Do not carry the tool by the attachment device

or the lanyard.

11. Only transfer the tool between your hands

while you are properly balanced.

12. Do not attach lanyards to the tool in a way that

keeps switches or trigger-lock (if supplied)

from operating properly.

13. Avoid getting tangled in the lanyard.

14.

Keep lanyard away from the drilling area of the tool.

15. Use a locking carabiner (multi-action and

screw gate type). Do not use single action

spring clip carabiners.

16. In the event the tool is dropped, it must be

tagged and removed from service, and should

be inspected by a Makita Factory or Authorized

Service Center.

20 ENGLISH

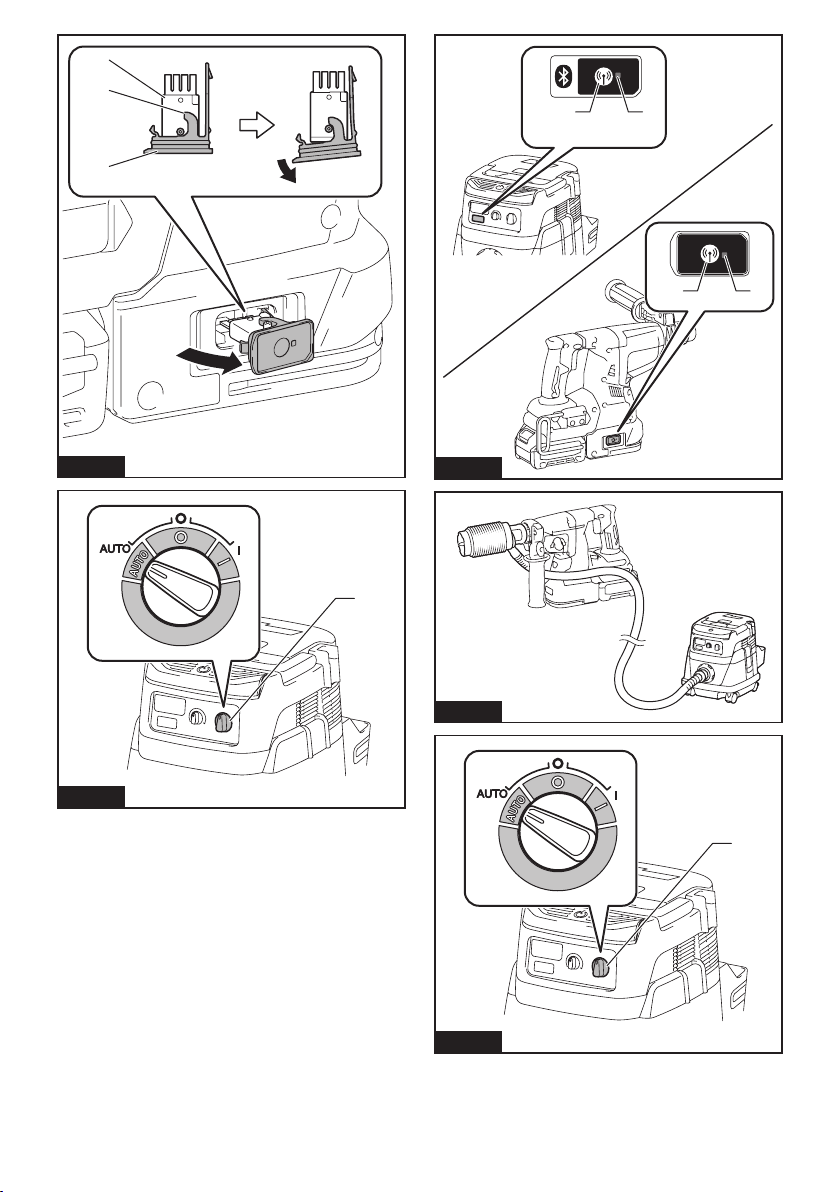

WIRELESS ACTIVATION

FUNCTION

Optional accessory for HR001G/HR002G

What you can do with the wireless

activation function

The wireless activation function enables clean and comfortable operation. By connecting a supported vacuum

cleaner to the tool, you can run the vacuum cleaner

automatically along with the switch operation of the tool.

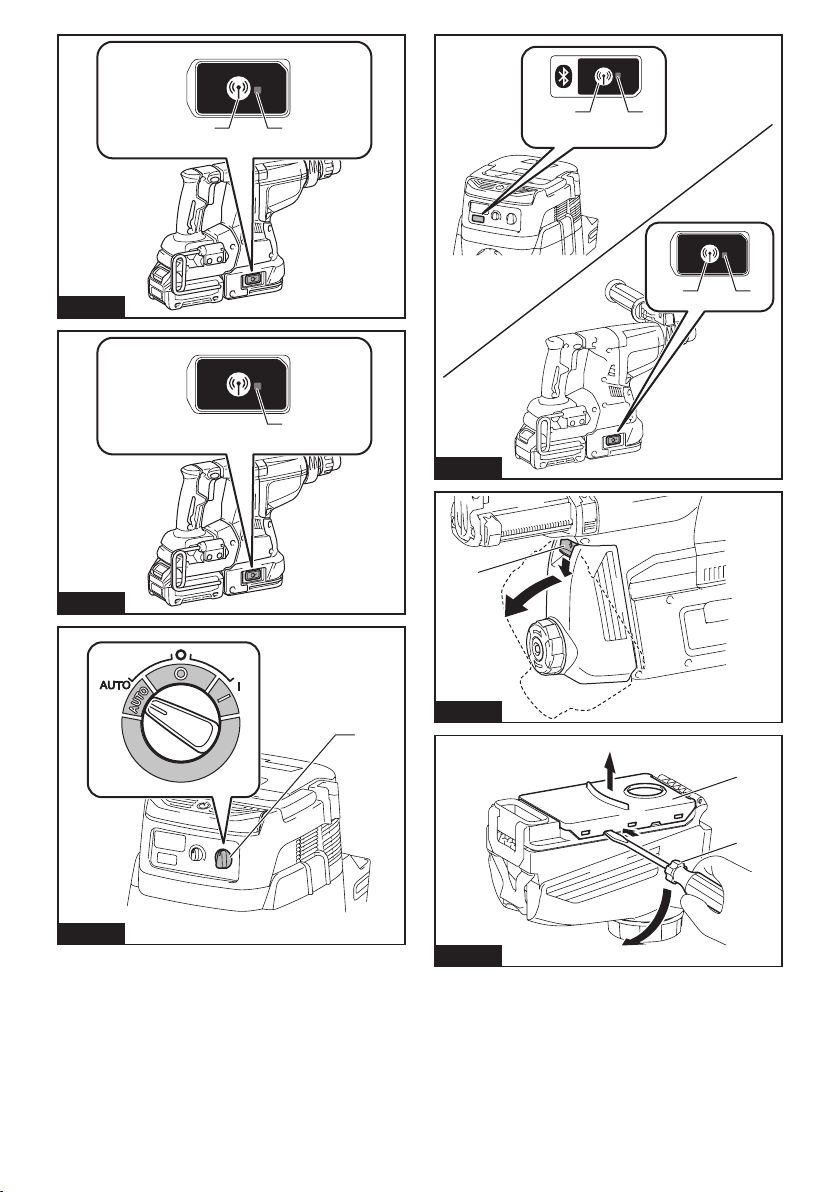

► Fig.43

To use the wireless activation function, prepare following items:

• A wireless unit (optional accessory)

• A vacuum cleaner which supports the wireless

activation function

The overview of the wireless activation function

setting is as follows. Refer to each section for detail

procedures.

1. Installing the wireless unit

2. Tool registration for the vacuum cleaner

3. Starting the wireless activation function

Installing the wireless unit

Optional accessory

CAUTION: Place the tool on a at and stable

surface when installing the wireless unit.

NOTICE:

installing the wireless unit. Dust or dirt may cause

malfunction if it comes into the slot of the wireless unit.

NOTICE:

touch a static discharging material, such as a metal part

of the tool, before picking up the wireless unit.

NOTICE:

be sure that the wireless unit is inserted in the correct direction and the lid is completely closed.

1. Open the lid on the tool as shown in the gure.

► Fig.44: 1. Lid

2. Insert the wireless unit to the slot and then close

the lid.

When inserting the wireless unit, align the projections

with the recessed portions on the slot.

► Fig.45: 1. Wireless unit 2. Projection 3. Lid

When removing the wireless unit, open the lid slowly.

The hooks on the back of the lid will lift the wireless unit

as you pull up the lid.

► Fig.46: 1. Wireless unit 2. Hook 3. Lid

After removing the wireless unit, keep it in the supplied

case or a static-free container.

NOTICE: Always use the hooks on the back of

the lid when removing the wireless unit. If the

hooks do not catch the wireless unit, close the lid

completely and open it slowly again.

Clean the dust and dirt on the tool before

To prevent the malfunction caused by static,

When installing the wireless unit, always

4. Recessed portion

Tool registration for the vacuum

cleaner

NOTE: A Makita vacuum cleaner supporting the

wireless activation function is required for the tool

registration.

NOTE: Finish installing the wireless unit to the tool

before starting the tool registration.

NOTE: During the tool registration, do not pull the

switch trigger or turn on the power switch on the

vacuum cleaner.

NOTE: Refer to the instruction manual of the vacuum

cleaner, too.

If you wish to activate the vacuum cleaner along with

the switch operation of the tool, nish the tool registration beforehand.

1. Install the batteries to the vacuum cleaner and the

tool.

2. Set the stand-by switch on the vacuum cleaner to

"AUTO".

► Fig.47: 1. Stand-by switch

3. Press the wireless activation button on the vac-

uum cleaner for 3 seconds until the wireless activation

lamp blinks in green. And then press the wireless activation button on the tool in the same way.

► Fig.48: 1. Wireless activation button 2. Wireless

activation lamp

If the vacuum cleaner and the tool are linked successfully, the wireless activation lamps will light up in green

for 2 seconds and start blinking in blue.

NOTE: The wireless activation lamps nish blinking

in green after 20 seconds elapsed. Press the wireless

activation button on the tool while the wireless activation lamp on the cleaner is blinking. If the wireless

activation lamp does not blink in green, push the wire-

less activation button briey and hold it down again.

NOTE: When performing two or more tool registra-

tions for one vacuum cleaner, nish the tool registration one by one.

Starting the wireless activation

function

NOTE: Finish the tool registration for the vacuum

cleaner prior to the wireless activation.

NOTE: Refer to the instruction manual of the vacuum

cleaner, too.

After registering a tool to the vacuum cleaner, the

vacuum cleaner will automatically runs along with the

switch operation of the tool.

1. Install the wireless unit to the tool.

2. Connect the hose of the vacuum cleaner with the

tool.

► Fig.49

3. Set the stand-by switch on the vacuum cleaner to

"AUTO".

► Fig.50: 1. Stand-by switch

21 ENGLISH

4. Push the wireless activation button on the tool

briey. The wireless activation lamp will blink in blue.

► Fig.51: 1. Wireless activation button 2. Wireless

activation lamp

5. Pull the switch trigger of the tool. Check if the

vacuum cleaner runs while the switch trigger is being

pulled.

To stop the wireless activation of the vacuum cleaner,

push the wireless activation button on the tool.

NOTE: The wireless activation lamp on the tool will

stop blinking in blue when there is no operation for

2 hours. In this case, set the stand-by switch on the

vacuum cleaner to "AUTO" and push the wireless

activation button on the tool again.

NOTE: The vacuum cleaner starts/stops with a delay.

There is a time lag when the vacuum cleaner detects

a switch operation of the tool.

NOTE: The transmission distance of the wireless unit

may vary depending on the location and surrounding

circumstances.

NOTE: When two or more tools are registered to one

vacuum cleaner, the vacuum cleaner may start running even if you don't pull the switch trigger because

another user is using the wireless activation function.

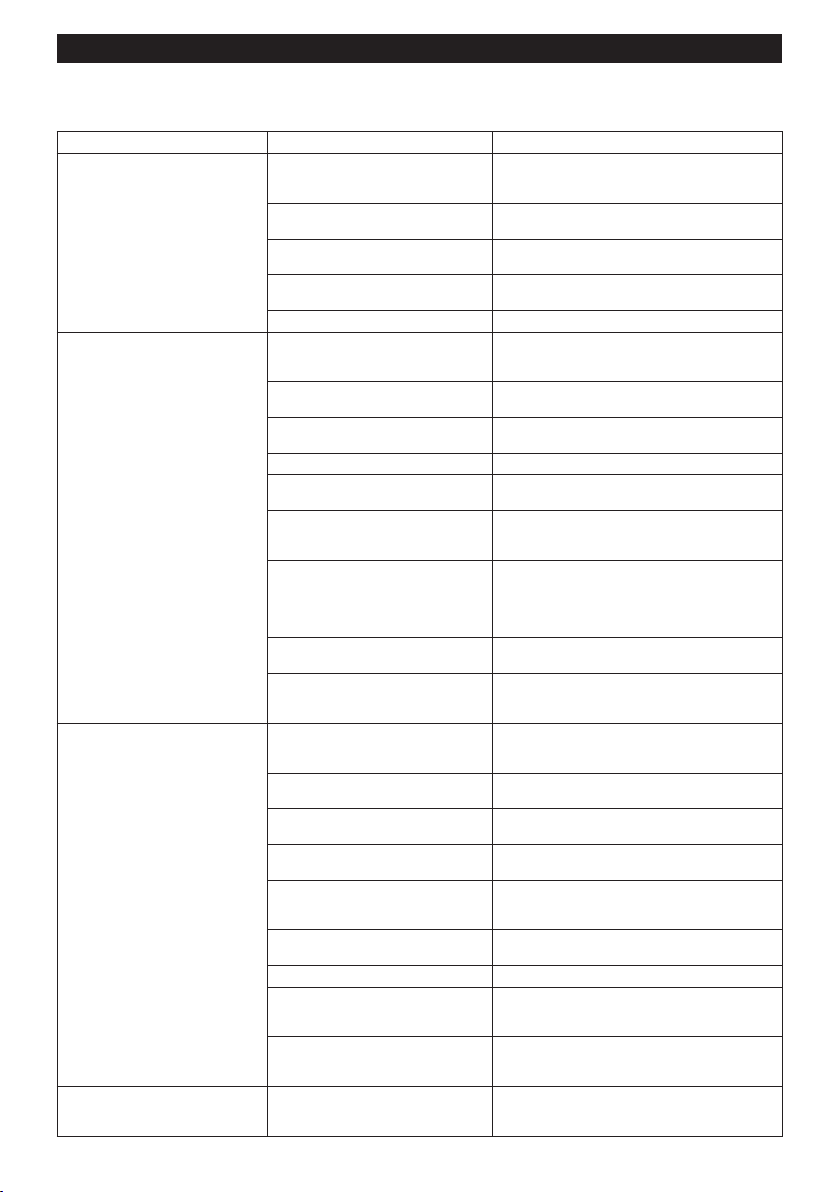

Description of the wireless activation lamp status

► Fig.52: 1. Wireless activation lamp

The wireless activation lamp shows the status of the wireless activation function. Refer to the table below for the

meaning of the lamp status.

Status Wireless activation lamp Description

Duration

2 hours The wireless activation of the vacuum cleaner is available. The

the tool is

running.

20 seconds Ready for the tool registration. Waiting for the registration by the

2 seconds The tool registration has been nished. The wireless activation

20 seconds Ready for the cancellation of the tool registration. Waiting for the

2 seconds The cancellation of the tool registration has been nished. The

3 seconds The power is supplied to the wireless unit and the wireless activa-

lamp will automatically turn off when no operation is performed

for 2 hours.

When

The wireless activation of the vacuum cleaner is available and the

tool is running.

vacuum cleaner.

lamp will start blinking in blue.

cancellation by the vacuum cleaner.

wireless activation lamp will start blinking in blue.

tion function is starting up.

NOTE: The wireless activation lamps nish blinking in

red after 20 seconds elapsed. Press the wireless activation button on the tool while the wireless activation

lamp on the cleaner is blinking. If the wireless activation lamp does not blink in red, push the wireless

activation button briey and hold it down again.

22 ENGLISH

Standby Blue

Tool

registration

Cancelling

tool

registration

Others Red

Color

Green

Red

Off - - The wireless activation of the vacuum cleaner is stopped.

On

Blinking

Cancelling tool registration for the

vacuum cleaner

Perform the following procedure when cancelling the

tool registration for the vacuum cleaner.

Install the batteries to the vacuum cleaner and the tool.

1.

2. Set the stand-by switch on the vacuum cleaner to

"AUTO".

► Fig.53: 1. Stand-by switch

Press the wireless activation button on the vacuum

3.

cleaner for 6 seconds. The wireless activation lamp blinks

in green and then become red. After that, press the wireless activation button on the tool in the same way.

► Fig.54: 1. Wireless activation button 2. Wireless

If the cancellation is performed successfully, the wireless activation lamps will light up in red for 2 seconds

and start blinking in blue.

activation lamp

Troubleshooting for wireless activation function

Before asking for repairs, conduct your own inspection rst. If you nd a problem that is not explained in the manual,

do not attempt to dismantle the tool. Instead, ask Makita Authorized Service Centers, always using Makita replacement parts for repairs.

State of abnormality Probable cause (malfunction) Remedy

The wireless activation lamp does

not light/blink.

Cannot nish tool registration / cancelling tool registration successfully.

The vacuum cleaner does not run

along with the switch operation of

the tool.

The vacuum cleaner runs while the

tool's switch trigger is not pulled.

The wireless unit is not installed into the tool.

The wireless unit is improperly installed

into the tool.

The terminal of the wireless unit and/or

the slot is dirty.

The wireless activation button on the

tool has not been pushed.

The stand-by switch on the vacuum

cleaner is not set to "AUTO".

No power supply

The wireless unit is not installed into the tool.

The wireless unit is improperly installed

into the tool.

The terminal of the wireless unit and/or

the slot is dirty.

The stand-by switch on the vacuum

cleaner is not set to "AUTO".

No power supply

Incorrect operation

The tool and vacuum cleaner are away

from each other (out of the transmission

range).

Before nishing the tool registration/

cancellation;

- the switch trigger on the tool is pulled or;

- the power button on the vacuum

cleaner is turned on.

The tool registration procedures for the

tool or vacuum cleaner have not nished.

Radio disturbance by other appliances

which generate high-intensity radio

waves.

The wireless unit is not installed into the tool.

The wireless unit is improperly installed

into the tool.

The terminal of the wireless unit and/or

the slot is dirty.

The wireless activation button on the

tool has not been pushed.

The stand-by switch on the vacuum

cleaner is not set to "AUTO".

More than 10 tools are registered to the

vacuum cleaner.

The vacuum cleaner erased all tool

registrations.

No power supply

The tool and vacuum cleaner are away

from each other (out of the transmission

range).

Radio disturbance by other appliances

which generate high-intensity radio

waves.

Other users are using the wireless

activation of the vacuum cleaner with

their tools.

23 ENGLISH

Install the wireless unit correctly.

Gently wipe off dust and dirt on the terminal of the

wireless unit and clean the slot.

Push the wireless activation button on the tool

briey.

Set the stand-by switch on the vacuum cleaner to

"AUTO".

Supply the power to the tool and the vacuum cleaner.

Install the wireless unit correctly.

Gently wipe off dust and dirt on the terminal of the

wireless unit and clean the slot.

Set the stand-by switch on the vacuum cleaner to

"AUTO".

Supply the power to the tool and the vacuum cleaner.

Push the wireless activation button briey and perform

the tool registration/cancellation procedures again.

Get the tool and vacuum cleaner closer to each other.

The maximum transmission distance is approximately 10

m however it may vary according to the circumstances.

Push the wireless activation button briey and

perform the tool registration/cancellation procedures

again.

Perform the tool registration procedures for both the

tool and the vacuum cleaner at the same timing.

Keep the tool and vacuum cleaner away from the

appliances such as Wi-Fi devices and microwave

ovens.

Install the wireless unit correctly.

Gently wipe off dust and dirt on the terminal of the

wireless unit and clean the slot.

Push the wireless activation button briey and make

sure that the wireless activation lamp is blinking in blue.

Set the stand-by switch on the vacuum cleaner to

"AUTO".

Perform the tool registration again.

If more than 10 tools are registered to the vacuum cleaner,

the tool registered earliest will be cancelled automatically.

Perform the tool registration again.

Supply the power to the tool and the vacuum cleaner.

Get the tool and vacuum cleaner closer each other. The

maximum transmission distance is approximately 10 m

however it may vary according to the circumstances.

Keep the tool and vacuum cleaner away from the

appliances such as Wi-Fi devices and microwave

ovens.

Turn off the wireless activation button of the other

tools or cancel the tool registration of the other

tools.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

Replacing lter of dust case

Optional accessory

1. Remove the dust case while pressing down the

lever of the dust case.

► Fig.55: 1. Lever

2. Insert the at-blade screwdriver into the slots of

the lter cover to remove the lter cover.

► Fig.56: 1. Flat-blade screwdriver 2. Filter cover

3. Remove the lter from the lter case.

► Fig.57: 1. Filter 2. Filter case

4. Attach a new lter to the lter case, and then

attach the lter cover.

5. Close the cover of the dust case, and then attach

the dust case to the dust collection system.

Replacing sealing cap

Optional accessory

If the sealing cap is worn out, the performance of the

dust collection decreases. Replace it if it's worn out.

Remove the sealing cap, and then attach a new one

with its protrusion facing upward.

► Fig.58: 1. Protrusion 2. Sealing cap

• Chuck adapter

• Keyless drill chuck

• Bit grease

• Depth gauge

• Blow-out bulb

• Dust cup

• Dust cup set

• Hook set

• Dust case set

• Drill chuck set

• Filter set

• Tool holder set

• Joint set

• Dust collection system

• Wireless unit

• Makita genuine battery and charger

• Safety goggles

• Plastic carrying case

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.

OPTIONAL ACCESSORIES

CAUTION: These accessories or attachments

are recommended for use with your Makita tool

specied in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

•

Carbide-tipped drill bits (SDS-Plus carbide-tipped bits)

• Core bit

• Bull point

• Diamond core bit

• Cold chisel

• Scaling chisel

• Grooving chisel

24 ENGLISH

FRANÇAIS (Instructions originales)

SPÉCIFICATIONS

Modèle : HR001G HR002G HR003G HR004G

Capacités Béton 28 mm

Trépan 54 mm

Trépan diamant (type sec) 65 mm

Acier 13 mm

Bois 32 mm

Vitesse à vide 0 - 980 min

Frappes par minute 0 - 5 000 min

Tension nominale 36 V - 40 V c.c. max.

Longueur totale avec BL4025 358 mm 389 mm 358 mm 389 mm

avec BL4040 373 mm 404 mm 373 mm 404 mm

Poids net 3,9 - 4,6 kg 4,1 - 4,6 kg 3,9 - 4,6 kg 4,0 - 4,5 kg

Accessoire en option

Modèle : DX12 (pour HR001G/HR003G) DX14 (pour HR002G/HR004G)

Performance d’aspiration 350 l/min

Course de travail Jusqu’à 190 mm

Foret adéquat Jusqu’à 260 mm

Tension nominale 36 V - 40 V c.c. max.

Poids net 1,6 kg

• Étant donné l’évolution constante de notre programme de recherche et de développement, les spécications

contenues dans ce manuel sont sujettes à modication sans préavis.

• Les spécications peuvent varier suivant les pays.

• Le poids peut être différent selon les accessoires, notamment la batterie. Les associations la plus légère et la

plus lourde, conformément à la procédure EPTA 01/2014, sont indiquées dans le tableau.

Batterie et chargeur applicables

Batterie BL4025 / BL4040

Chargeur DC40RA

• Certains chargeurs et batteries répertoriés ci-dessus peuvent ne pas être disponibles selon la région où vous

résidez.

AVERTISSEMENT : N’utilisez que les batteries et les chargeurs répertoriés ci-dessus. L’utilisation

d’autres batteries et chargeurs peut provoquer des blessures et/ou un incendie.

Utilisation prévue

L’outil est conçu pour le perçage avec martelage et le

perçage dans la brique, le béton et la pierre, ainsi que

pour les tâches de ciselage.

Il convient également au perçage sans impact dans le

bois, le métal, la céramique et le plastique.

Bruit

Niveau de bruit pondéré A typique, déterminé selon

EN60745-2-6 :

Modèle HR001G

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

) : 95 dB (A)

pA

) : 106 dB (A)

WA

Modèle HR002G

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

Modèle HR003G

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

Modèle HR004G

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

Modèle HR001G avec DX12

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

-1

-1

) : 93 dB (A)

pA

) : 104 dB (A)

WA

) : 95 dB (A)

pA

) : 106 dB (A)

WA

) : 93 dB (A)

pA

) : 104 dB (A)

WA

) : 93 dB (A)

pA

) : 104 dB (A)

WA

25 FRANÇAIS

Modèle HR002G avec DX14

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

) : 93 dB (A)

pA

) : 104 dB (A)

WA

Modèle HR003G avec DX12

Niveau de pression sonore (L

Niveau de puissance sonore (LWA) : 104 dB (A)

) : 93 dB (A)

pA

Incertitude (K) : 3 dB (A)

Modèle HR004G avec DX14

Niveau de pression sonore (L

Niveau de puissance sonore (LWA) : 104 dB (A)

) : 93 dB (A)

pA

Incertitude (K) : 3 dB (A)

NOTE : La ou les valeurs d’émission de bruit déclarées ont été mesurées conformément à la méthode

de test standard et peuvent être utilisées pour comparer les outils entre eux.

NOTE : La ou les valeurs d’émission de bruit déclarées peuvent aussi être utilisées pour l’évaluation

préliminaire de l’exposition.

AVERTISSEMENT : Portez un serre-tête

antibruit.

AVERTISSEMENT : L’émission de bruit

lors de l’usage réel de l’outil électrique peut être

différente de la ou des valeurs déclarées, suivant

la façon dont l’outil est utilisé, particulièrement

selon le type de pièce usinée.

AVERTISSEMENT : Les mesures de sécurité

à prendre pour protéger l’utilisateur doivent être

basées sur une estimation de l’exposition dans

des conditions réelles d’utilisation (en tenant

compte de toutes les composantes du cycle

d’utilisation, comme par exemple le moment de

sa mise hors tension, lorsqu’il tourne à vide et le

moment de son déclenchement).

Vibrations

Le tableau suivant indique la valeur totale de vibrations

(somme de vecteur triaxial) déterminée selon la norme

applicable.

Modèle HR001G

Mode de

travail

Perçage avec

martelage

dans le béton

(a

h, HD

Perçage avec

martelage

dans le béton

avec le DX12

(a

h, HD

Fonction de

ciselage avec

poignée latérale (a

Perçage dans

le métal (a

)

)

h, Cheq

)

)

h, D

Émission de

vibrations

2

7,0 m/s

2

7,0 m/s

2

6,5 m/s

2,5 m/s2 ou

moins

Incertitude (K)

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

Norme

applicable

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

Modèle HR002G

Mode de

travail

Perçage avec

martelage

dans le béton

(a

h, HD

Perçage avec

martelage

dans le béton

avec le DX14

(a

h, HD

Fonction de

ciselage avec

poignée latérale (a

Perçage dans

le métal (a

)

)

h, Cheq

)

)

h, D

Émission de

vibrations

2

6,5 m/s

2

6,0 m/s

2

7,5 m/s

2

2,5 m/s

Incertitude (K)

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

Norme

applicable

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

Modèle HR003G

Mode de

travail

Perçage avec

martelage

dans le béton

(a

h, HD

Perçage avec

martelage

dans le béton

avec le DX12

(a

h, HD

Fonction de

ciselage avec

poignée latérale (a

Perçage dans

le métal (a

)

)

h, Cheq

)

)

h, D

Émission de

vibrations

2

7,0 m/s

2

7,0 m/s

2

7,0 m/s

2,5 m/s2 ou

moins

Incertitude (K)

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

Norme

applicable

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

Modèle HR004G

Mode de

travail

Perçage avec

martelage

dans le béton

(a

h, HD

Perçage avec

martelage

dans le béton

avec le DX14

(a

h, HD

Fonction de

ciselage avec

poignée latérale (a

Perçage dans

le métal (a

)

)

h, Cheq

)

)

h, D

Émission de

vibrations

2

6,5 m/s

2

6,0 m/s

2

7,5 m/s

2

2,5 m/s

Incertitude (K)

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

2

1,5 m/s

Norme

applicable

EN60745-2-6

EN60745-2-6

EN60745-2-6

EN60745-2-1

NOTE : La ou les valeurs de vibration totales déclarées ont été mesurées conformément à la méthode

de test standard et peuvent être utilisées pour comparer les outils entre eux.

NOTE : La ou les valeurs de vibration totales déclarées peuvent aussi être utilisées pour l’évaluation

préliminaire de l’exposition.

26 FRANÇAIS

AVERTISSEMENT : L’émission de vibrations

lors de l’usage réel de l’outil électrique peut être

différente de la ou des valeurs déclarées, suivant

la façon dont l’outil est utilisé, particulièrement

selon le type de pièce usinée.

AVERTISSEMENT : Les mesures de sécurité

à prendre pour protéger l’utilisateur doivent être

basées sur une estimation de l’exposition dans

des conditions réelles d’utilisation (en tenant

compte de toutes les composantes du cycle

d’utilisation, comme par exemple le moment de

sa mise hors tension, lorsqu’il tourne à vide et le

moment de son déclenchement).

Déclaration de conformité CE

Pour les pays européens uniquement

La déclaration de conformité CE est fournie en Annexe

A à ce mode d’emploi.

CONSIGNES DE

SÉCURITÉ

Consignes de sécurité générales

pour outils électriques

AVERTISSEMENT : Veuillez lire les

consignes de sécurité, instructions, illustrations

et spécications qui accompagnent cet outil

électrique. Le non-respect de toutes les instructions

indiquées ci-dessous peut entraîner une électrocution, un incendie et/ou de graves blessures.

Conservez toutes les mises en

garde et instructions pour référence ultérieure.

Le terme « outil électrique » dans les avertissements

fait référence à l’outil électrique alimenté par le secteur

(avec cordon d’alimentation) ou à l’outil électrique fonctionnant sur batterie (sans cordon d’alimentation).

CONSIGNES DE SÉCURITÉ POUR

PERFORATEUR SANS FIL

1. Portez des protecteurs d’oreilles. L’exposition

au bruit peut entraîner la surdité.

2. Utilisez la ou les poignées auxiliaires, si l’outil

en possède. Toute perte de maîtrise de l’outil

comporte un risque de blessure.

3. Tenez l’outil électrique par des surfaces de

prise isolées lorsque vous effectuez une tâche

au cours de laquelle l’accessoire de coupe

peut entrer en contact avec des ls cachés.

Le contact de l’accessoire de découpe avec un l

sous tension peut transmettre du courant dans les

pièces métalliques exposées de l’outil électrique

et électrocuter l’utilisateur.

4. Portez un casque de sécurité (casque de chan-

tier), des lunettes de sécurité et/ou un écran

facial. Les lunettes de vue ou les lunettes de

soleil NE sont PAS des lunettes de sécurité.

Il est également vivement recommandé de

porter un masque anti-poussière et des gants

matelassés.

5. Avant utilisation, assurez-vous que le foret est

bien xé en place.

6. Dans des conditions normales de fonctionnement, l’outil est conçu pour émettre des vibrations. Les vis peuvent se desserrer facilement

et provoquer une panne ou un accident. Avant

utilisation, vériez soigneusement que les vis

sont bien serrées.

7. Par temps froid ou si l’outil n’a pas été utilisé

pendant longtemps, laissez-le chauffer un

instant en le faisant fonctionner à vide. Cela

ramollira le lubriant. Si vous ne chauffez pas

adéquatement l’outil, le martelage s’exécutera

difcilement.

8. Assurez-vous toujours de travailler en position

stable. Veillez à ce que personne ne se trouve

en dessous de vous quand vous utilisez l’outil

en hauteur.

9. Tenez l’outil fermement à deux mains.

10. Éloignez les mains des pièces en mouvement.

11. Ne vous éloignez pas en laissant l’outil tour-

ner. Ne le faites fonctionner que lorsque vous

l’avez bien en main.

12. Ne pointez l’outil vers personne dans la zone

d’utilisation. Le foret peut être projeté et blesser gravement quelqu’un.

13. Ne touchez pas le foret, les pièces proches du

foret ou la pièce immédiatement après l’exécution du travail ; ils peuvent être extrêmement

chauds et vous brûler la peau.

14. Certains matériaux contiennent des produits

chimiques qui peuvent être toxiques. Prenez

garde de ne pas avaler la poussière et évitez

tout contact avec la peau. Suivez les données

de sécurité du fournisseur du matériau.

15. Assurez-vous toujours que l’outil est hors

tension et que la batterie et le foret sont retirés

avant de passer l’outil à une autre personne.

16. Avant utilisation, assurez-vous qu’aucun objet

tel que des conduites électriques, de tuyaux

d’eau ou de tuyaux de gaz n’est pas enterré

sous la zone de travail. Sinon, le foret/burin

risque d’entrer en contact avec eux, ce qui peut

entraîner une électrocution, une dispersion électrique ou une fuite de gaz.

CONSERVEZ CES

INSTRUCTIONS.

AVERTISSEMENT : NE vous laissez PAS

tromper (au l d’une utilisation répétée) par un

sentiment d’aisance et de familiarité avec le

produit, en négligeant le respect rigoureux des