Makita HP2051 User Manual [ru]

2-Gang Schlagbohrmaschine

Dwubiegowa wiertarka udarowa

2-скоростная отбойная дрель

HP2050

HP2050F

HP2051

HP2051F

2-Speed Hammer Drill

Instruction Manual

Betriebsanleitung

Instrukcja obsługi

Инструкция по эксплуатации

1

3

7

6

2

5

4

6

8

12

7

65

9

10

11

34

15

16

13

14

12

A

B

17

18

56

20

19

21

78

2

23

22

910

Symbols

The following show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt

mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich

znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Betriebsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

3

ENGLISH

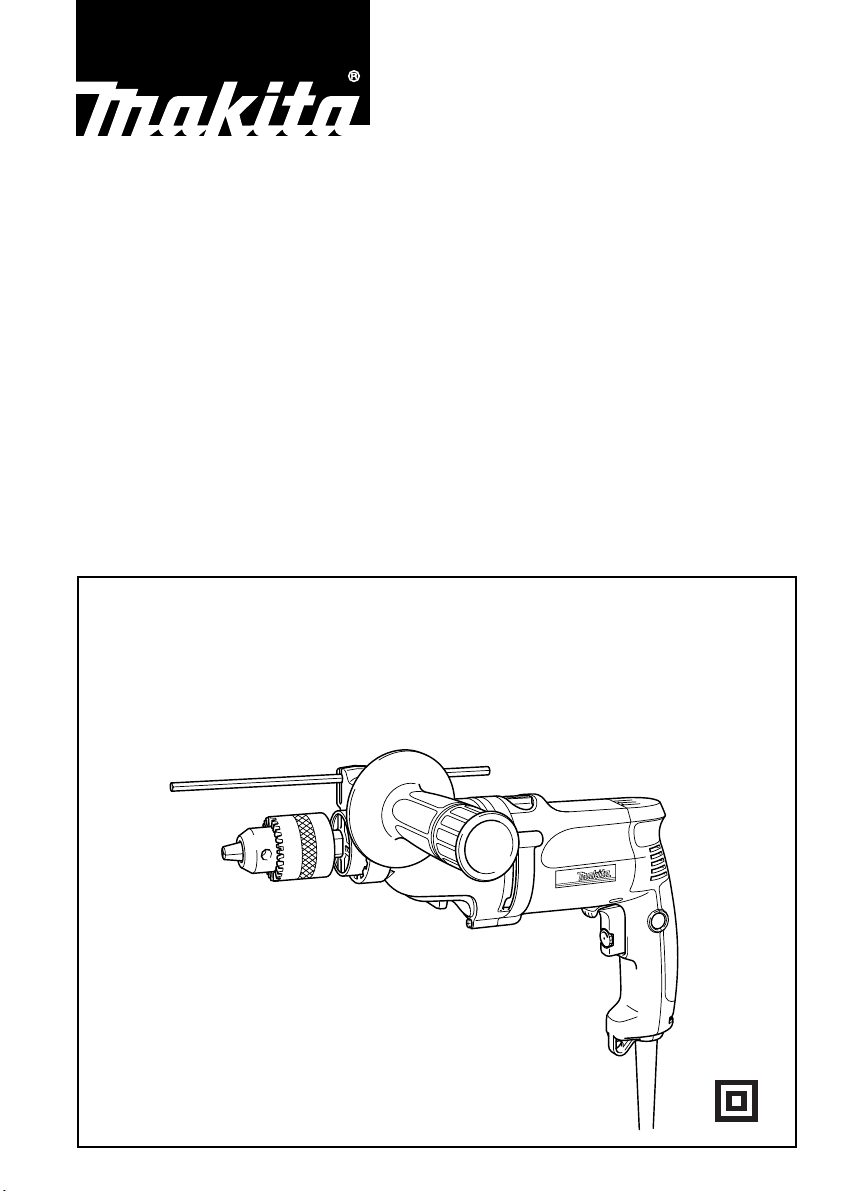

Explanation of general view

1Grip base

2 Side grip (auxiliary handle)

3 Teeth

4 Protrusions

5 Loosen

6Tighten

7Bit

8 Chuck key

Model HP2050/HP2050F HP2051/HP2051F

Max. capacities

Concrete

Tungsten-carbide tipped bit ........................... High: 20 mm 20 mm

Steel ................................................................. High: 8 mm 8 mm

Wood ................................................................ High: 5 mm 25 mm

-1

No load speed (min

) ...................................... High: 0 – 2,900 0 – 2,900

Blows per minute .............................................. High: 0 – 58,000 0 – 58,000

Overall length ................................................................. 362 mm 360 mm

Net weight ...................................................................... 2.3 kg 2.3 kg

9Sleeve

10 Ring

11 Depth gauge

12 Lower

13 Higher

14 Speed control screw

15 Switch trigger

16 Lock button

Low: 13 mm 13 mm

Low: 40 mm 40 mm

Low: 0 – 1,200 0 – 1,200

Low: 0 – 24,000 0 – 24,000

17 Reversing switch lever

18 Lamp

19 Speed change knob

20 Arrow

21 Action mode changing lever

22 Blow-out bulb

23 Vent holes

• Due to our continuing programme of research and

development, the specifications herein are subject to

change without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for impact drilling in brick, concrete

and stone as well as for drilling without impact in wood,

metal, ceramic and plastic.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety

precautions should always be followed to reduce

the risk of fire, electric shock and personal injury,

including the following. Read all these instructions before attempting to operate this product

and save these instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work

area well lit. Don’t use power tools in presence of

flammable liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry,

high, or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for

which it was intended.

7. Use right tool

Don’t force small tools or attachments to do the

job of a heavy duty tool. Don’t use tools for purposes not intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non-skid footwear are recommendemd when

working outdoors. Wear protective hair covering

to contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

4

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and

sharp edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when

changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch.

Be sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other

part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended function. Check for alignment of

moving par ts, binding of moving par ts, breakage

of parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by

and authorized service center. Do not use tool if

switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment

other than recommended in this operating

instruction or the catalog may present a risk of

personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the relevant safety rules. Repairing of electric appliances

may be carried out only by experts otherwise it may

cause considerable danger for the user.

ADDITIONAL SAFETY RULES

1. Hold tools by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

2. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

3. Hold the tool firmly with both hands. Always use

the side grip.

4. Keep hands away from moving parts.

5. Do not leave the tool running. Operate the tool

only when hand-held.

6. Do not touch the bit or the workpiece immediately after operation; they may be extremely hot

and could burn your skin.

ENB002-1

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

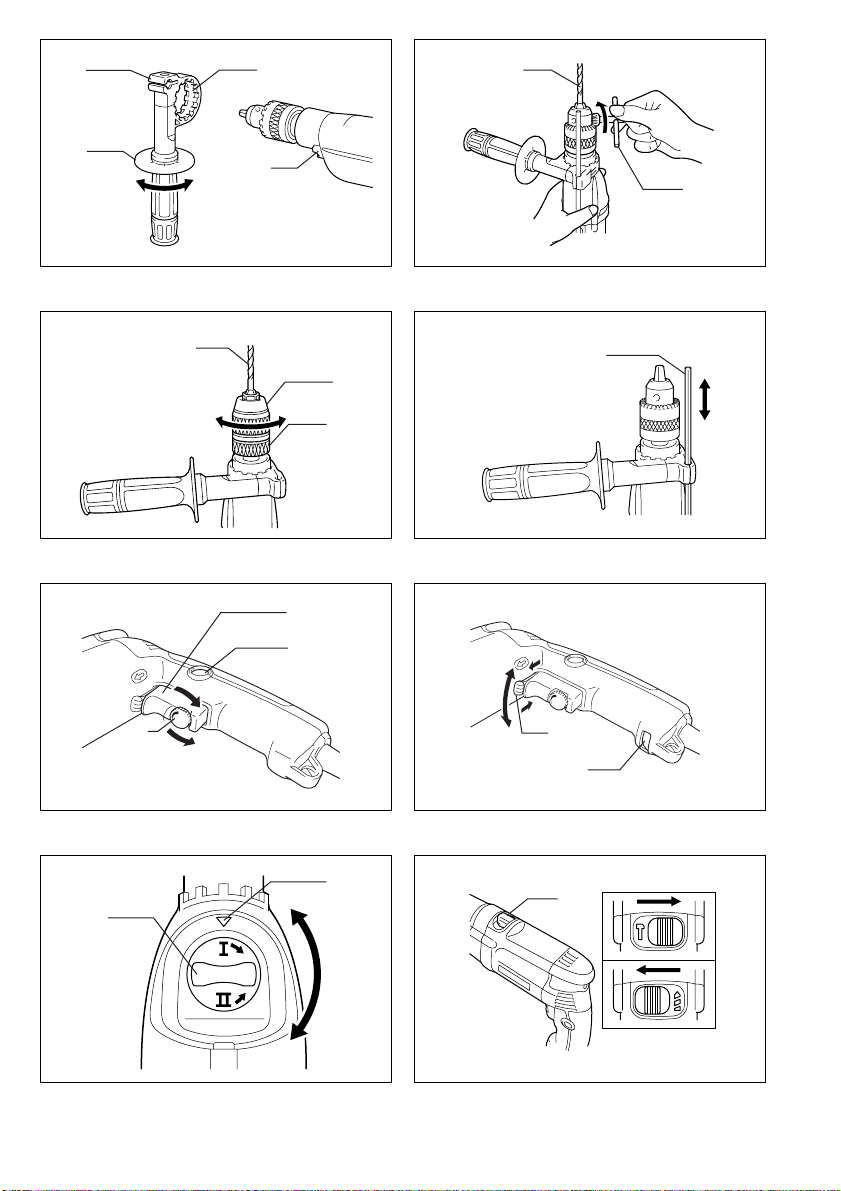

Installing side grip (auxiliary handle) (Fig. 1)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the side grip.

Always use the side grip to ensure operating safety.

Install the side grip so that the teeth on the grip fit in

between the protrusions on the tool barrel. Then tighten

the grip by turning clockwise at the desired position. It

may be swung 360° so as to be secured at any position.

Installing or removing drill bit (Fig. 2 & 3)

CAUTION:

Always be sure that the tool is switched off and

unplugged before installing or removing the bit.

For HP2050, HP2050F

To install the bit, place it in the chuck as far as it will go.

Tighten the chuck by hand. Place the chuck key in each

of the three holes and tighten clockwise. Be sure to

tighten all three chuck holes evenly. To remove the bit,

turn the chuck key counterclockwise in just one hole,

then loosen the chuck by hand. After using the chuck key,

be sure to return it to the original position.

For HP2051, HP2051F

Hold the ring and tur n the sleeve counterclockwise to

open the chuck jaws. Place the bit in the chuck as far as it

will go. Hold the ring firmly and turn the sleeve clockwise

to tighten the chuck. To remove the bit, hold the ring and

turn the sleeve counterclockwise.

Depth gauge (Fig. 4)

The depth gauge is convenient for drilling holes of uniform depth. Loosen the side grip and insert the depth

gauge into the hole in the grip base. Adjust the depth

gauge to the desired depth and tighten the side grip.

NOTE:

The depth gauge cannot be used at the position where

the depth gauge strikes against the gear housing.

5

Switch action (Fig. 5)

CAUTION:

Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the "OFF"

position when released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop. For continuous operation, pull the switch trigger and then push in the lock button. To stop the tool from the locked position, pull the

switch trigger fully, then release it.

A speed control screw is provided so that maximum tool

speed can be limited (variable). Turn the speed control

screw clockwise for higher speed, and counterclockwise

for lower speed.

Lighting up the lamps (HP2050F, HP2051F)

CAUTION:

Do not look in the light or see the source of light directly.

To turn on the lamp, pull the trigger. Release the trigger

to turn it off.

NOTE:

Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of lamp, or it may lower the

illumination.

Reversing switch action (Fig. 6)

This tool has a reversing switch to change the direction of

rotation. Move the reversing switch lever to the

tion (A side) for clockwise rotation or to the

(B side) for counterclockwise rotation.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

Speed change knob (Fig. 7)

Two speed ranges can be preselected with the speed

change knob. Turn the speed change knob so that the

arrow on the tool body points toward the " I " position on

the knob for low speed or " II " position for high speed.

If it is hard to turn the knob, first turn the chuck slightly in

either direction and then turn the knob again.

CAUTION:

• Use the speed change knob only after the tool comes

to a complete stop. Changing the tool speed before the

tool stops may damage the tool.

• Always set the speed change knob to the correct position. If you operate the tool with the speed change knob

positioned halfway between the " I " and " II " position,

the tool may be damaged.

Selecting the action mode (Fig. 8)

This tool has an action mode change lever. For rotation

with hammering, slide the action mode change lever to

the right (

mode change lever to the left (

CAUTION:

Always slide the action mode change lever all the way to

your desired mode position. If you operate the tool with

the lever positioned halfway between the mode symbols,

the tool may be damaged.

g symbol). For rotation only, slide the action

m symbol).

E

posi-

D

position

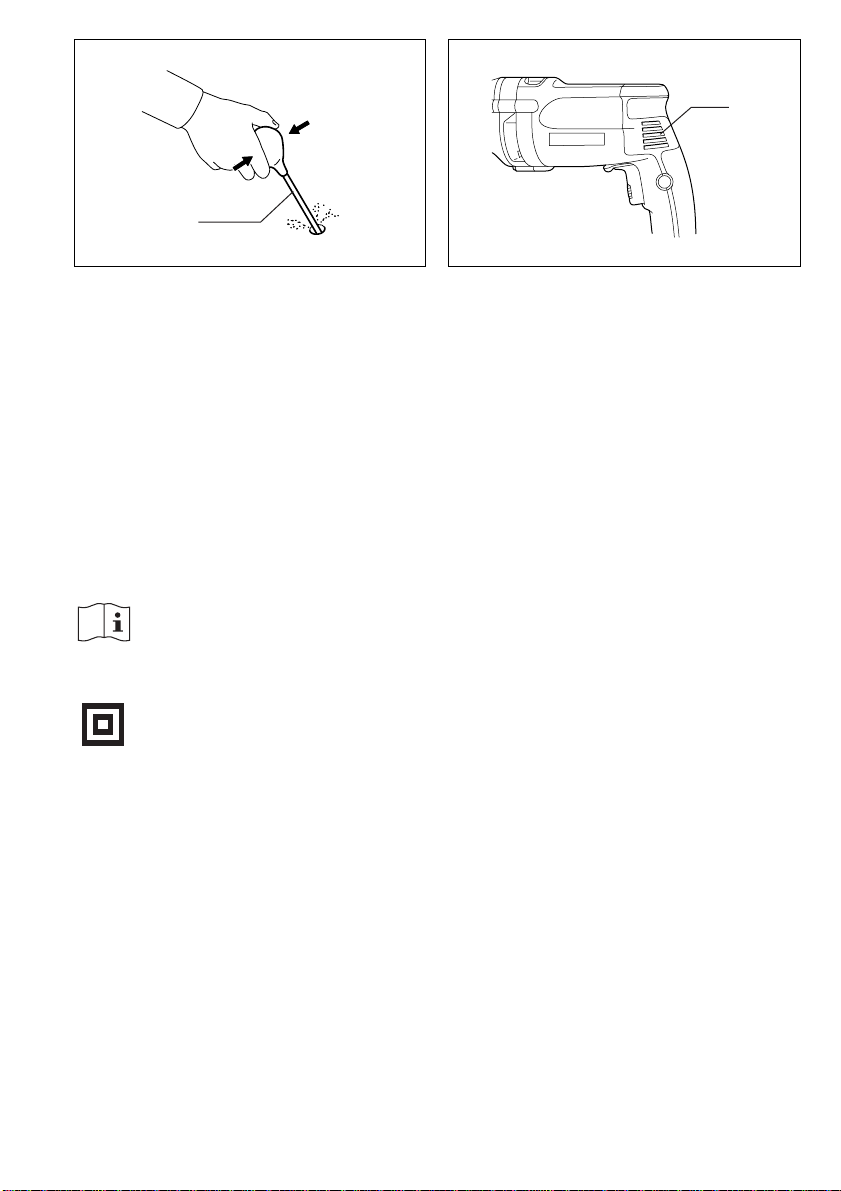

OPERATION

Hammer drilling operation

When drilling in concrete, granite, tile, etc., move the

action mode change lever to the position of

use "rotation with hammering" action. Be sure to use a

tungsten-carbide tipped bit. Do not apply more pressure

when the hole becomes clogged with chips or particles.

Instead, run the tool at an idle, then remove the bit partially from the hole. By repeating this several times, the

hole will be cleaned out. After drilling the hole, use the

blow-out bulb to clean the dust out of the hole. (Fig. 9)

Drilling operation

When drilling in wood, metal or plastic materials, move

the action mode change lever to the position of

to use "rotation only" action.

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide

screw makes drilling easier by pulling the bit into the

workpiece.

Drilling in metal

To prevent the bit from slipping when starting a hole,

make an indentation with a center-punch and hammer at

the point to be drilled. Place the point of the bit in the

indentation and start drilling. Use a cutting lubricant

when drilling metals. The exceptions are iron and brass

which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole break through. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

g symbol to

symbol

m

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Cleaning vent holes (Fig. 10)

Periodically clean the vent holes to prevent them from

being clogged with dust, dirt or the like.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

6

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is 6 m/s

sound pressure level: 97 dB (A)

sound power level: 110 dB (A)

– Wear ear protection. –

2

.

EC-DECLARATION OF CONFORMITY

We declares that our sole responsibility that this

product is in compliance with the following standards

or standardized documents,

HD400, EN50144, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

Noise and Vibration

Yasuhiko Kanzaki

Director

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE 2001

.

7

DEUTSCH

Übersicht

1 Griffbasis

2 Zusatzhandgriff (Seitengriff)

3 Innenverzahnung

4 Außenverzahnung

5 Lösen

6 Festziehen

7 SDS-Plus-Bohrer

8 Bohrfutterschlüssel

TECHNISCHE DATEN

Modell

Max. Bohrleistungen

Beton

HM-bestückter Bohrer ..................................... 1.Gang

Stahl ................................................................... 1.Gang

Holz .................................................................... 1.Gang

-1

(min

Leerlaufdrehzahl

Schlagzahl........................................................... 1.Gang

Gesamtlänge

Nettogewicht

................................................................... 362 mm 360 mm

.................................................................... 2,3 kg 2,3 kg

)

.................................... 1.Gang

9 Werkzeugverriegelung

10 Klemmring

11 Tiefenanschlag

12 Niedriger

13 Höher

14 Drehzahl-Einstellrad

15 Elektronikschalter

16 Schalterarretierung

2.Gang

2.Gang

2.Gang

2.Gang

17 Drehrichtungsumschalter

18 Lampe

19 Drehzahl-Umschaltknopf

20 Pfeil

21 Betriebsart-Umschalthebel

22 Ausbläser

23 Ventilationsöffnungen

HP2050/HP2050F HP2051/HP2051F

: 20 mm 20 mm

: 8 mm 8 mm

: 13 mm 13 mm

: 25 mm 25 mm

: 40 mm 40 mm

: 0 – 2 900 0 – 2 900

: 0 – 12 00 0 – 1 200

: 0 – 58 000 0 – 58 000

: 0 – 24 000 0 – 24 000

• Wir behalten uns vor, Änderungen im Zuge der Entwicklung und des technischen Fortschritts ohne vorherige Ankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land zu

Land abweichen.

Vorgesehene Verwendung

Die Maschine ist für Schlagbohren in Ziegel, Beton und

Stein sowie für Bohren in Holz, Metall, Keramik und

Kunststoff vorgesehen.

Stromversorgung

Die Maschine darf nur an die auf dem Typenschild angegebene Spannung angeschlossen werden und arbeitet

nur mit Einphasen-Wechselspannung. Sie ist entsprechend den Europäischen Richtlinien doppelt schutzisoliert und kann daher auch an Steckdosen ohne

Erdungskabel angeschlossen werden.

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen

aus. Benützen Sie Elektrowerkzeuge nicht in

feuchter oder nasser Umgebung. Sorgen Sie für

gute Beleuchtung. Benützen Sie Elektrowerkzeuge nicht in Nähe von brennbaren Flüssigkeiten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten

Teilen, zum Beispiel Rohren, Heizkörpern, Herden, kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug oder Kabel berühren, halten Sie sie von

Ihrem Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

Unbenutzte Werkzeuge sollten in trockenem,

verschlossenem Raum und für Kinder nicht

erreichbar aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum

Beispiel benützen Sie keine Handkreissäge, um

Bäume zu flällen oder Äste zu schneiden.

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck.

Sie können von beweglichen Teilen erfaßt werden. Bei Arbeiten im Freien sind Gummihandschuhe und rutschfestes Schuhwerk

empfehlenswert. Tragen Sie bei langen Haaren

ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

8

Loading...

Loading...