Page 1

T

ECHNICAL INFORMATION

Models No.

Description

HP1630, HP1631

Hammer Drill 16 mm (5/8")

CONCEPT AND MAIN APPLICATIONS

Models HP1630 and HP1631 have been developed to surpass the competitors in

wattage, no load speed and impacts per minute.

Cylinder-shaped motor housing and aluminum gear housing cover provide

high performance.

Specification

PRODUCT

P 1/ 6

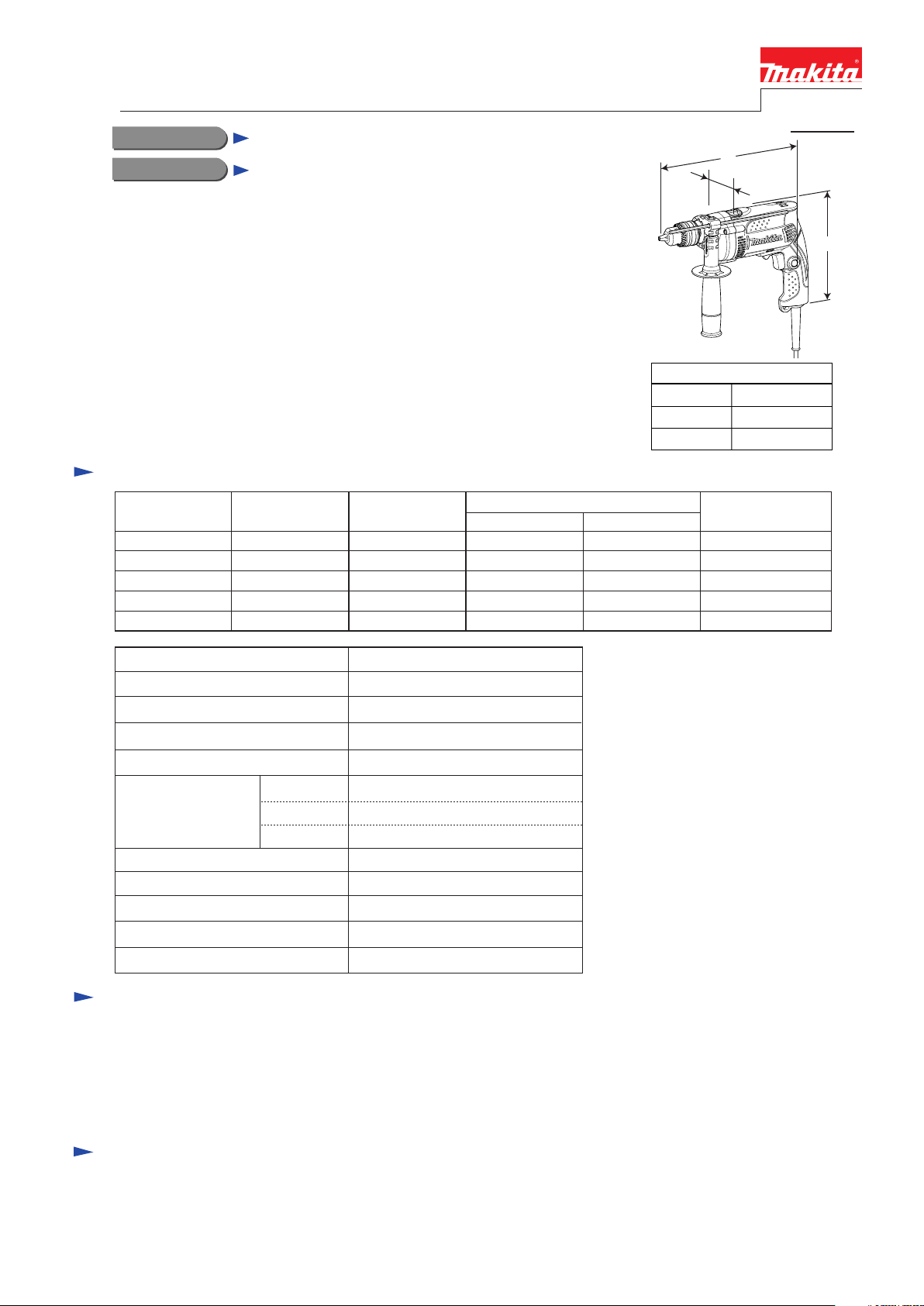

L

W

Dimensions: mm (")

Length (L) 296 (11-5/8)

Width (W)

Height (H)

75 (2-15/16)

204 (8)

H

Voltage (V) Cycle (Hz)

110

120

220

230

240

No load speed: min -1= rpm

Impacts per min: min -1= ipm

Drill chuck type

Chuck capacity: mm (")

Capacities: mm (")

Reversing switch

Protection against electric shock

Variable speed control by trigger

Power supply cord: m (ft)

Net weight: kg (lbs)

Current (A)

6.8

6.2

3.4

3.3

3.1

Concrete

Steel

Wood

50/60

50/60

50/60

50/60

50/60

Keyed chuck / Keyless Chuck

Continuous Rating (W)

Input Output

710

710

710

710

HP1630 / HP1631

0 - 3,200

0 - 48,000

1.5 - 13 (1/16 - 1/2)

16 (5/8)

13 (1/2)

30 (1-3/16)

Yes

Double insulation

Yes

2.0 (6.6)

1.9 (4.2)

---

420

420

420

420

420

Max. Output (W)

630

630

630

630

630

Standard equipment

Chuck key S-13 ........................ 1 (HP1630 only)

Key holder ................................. 1 (HP1630 only)

Depth gauge .............................. 1

Side grip .................................... 1

Plastic carrying case ................. 1 (K model only)

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

TCT drill bits

HSS metal drill bits

Wool bonnet 100

Rubber pad ass'y

Foam polishing pad 125

Page 2

Repair

CAUTION: Unplug the tool and remove the bit from the machine for safety before

repair/ maintenance in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

1R005 Retaining ring pliers RT-2N

1R026

Bearing Setting Pipe 16-8.2

Removing Retaining ring R-35

Removing Helical gear 37

P 2 / 6

1R028

1R035

1R037

1R045

1R139

1R223

1R224

1R269

1R283 Round bar for arbor 9-50

1R346

781024-2

781007-2 Wrench 14 Removing / Installing keyless Drill chuck

Bearing setting pipe 20-12.2

Bearing setting plate 15.2

Bearing setting plate 20.2

Gear extractor (large)

Drill chuck extractor

Torque wrench shaft 20-90N.m

Ratchet head 12.7

Bearing extractor

Center Attachment for 1R045

Wrench 43 Removing / Installing keyed Drill chuck

Installing Helical gear 37

Removing Helical gear 37

Removing/ Installing Armature

Removing / Installing Drill chuck

Removing Ball Bearings 607LLB and 608LLB

Removing Helical gear 37

Removing / Installing Drill chuck1R298 Hex. bar 10 with square socket

Removing/ Installing Armature

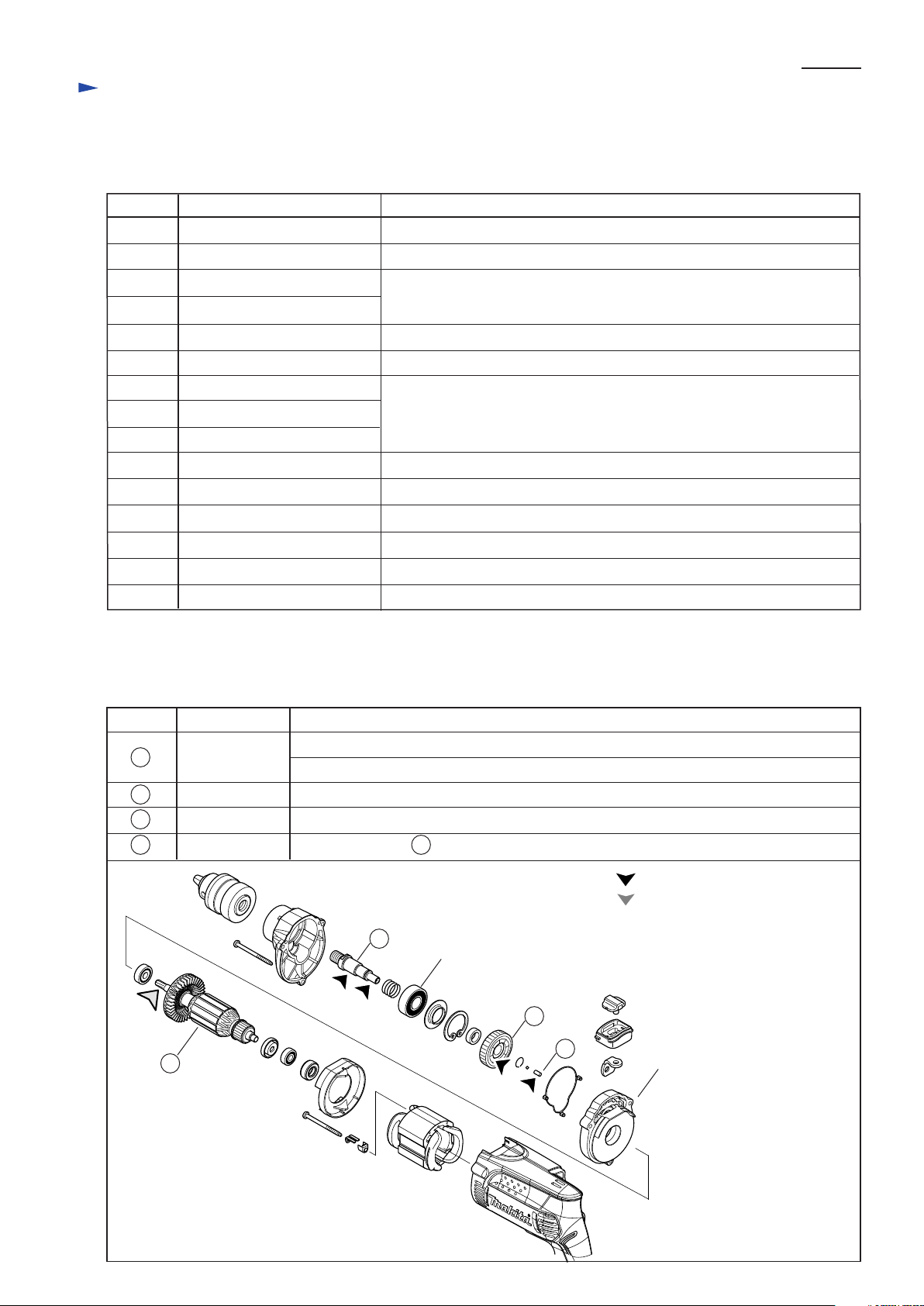

[2] LUBRICATION

Apply a little amount of molybdenum disulfide lubricant to the portions designated with the black triangle, and apply

Makita grease N. No.1 to the portion designated with the gray triangle to protect parts and product from unusual abrasion.

Fig. 1

Item No.

8

14

17

25

Description

Spindle

Helical gear 37 Cam portions

Pin 4 Drum portion

Armature

Drum portion where Ball bearing 6202DDW contacts

Drum portion where Gear housing cover contacts

Gear teeth where 12 Helical gear 37 contacts: 3g in total

Portion to lubricate

25

:Molybdenum disulfide lubricant

:Makita grease N No.1

8

Ball bearing 6202DDW

14

17

Gear housing cover

Page 3

Repair

[3] DISASSEMBLY/ASSEMBLY (cont.)

[3] -1. Armature

P 3 / 6

DISASSEMBLY

1) Remove Handle cover by loosening 4x18 Tapping screws, and then remove

Carbon brushes with Brush holders.

2) Remove Armature, Gear housing cover and Gear housing by loosening

4x30 Tapping screws and striking Motor housing with plastic hammer.

3) Drive the thread of 1R045 into 1R346 tightly, and set them to Gear housing

cover. (Fig. 2)

4) Remove Armature from Gear housing cover by turning the handle of 1R045.

5) Remove Ball bearings 607LLB and 608LLB of Armature with 1R269.

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Drill Chuck

DISASSEMBLY

1) Hold 1R139 in vise.

2) Hold 1R298 with Drill chuck.

3) Fit the flat portions of Spindle to 1R139. (Fig. 3)

4) Turn Drill chuck counterclockwise with 1R298, 1R224 and 1R223. (Fig. 4)

Note: If Keyed drill chuck does not work, use 781024-2 to remove it.

If Keyless drill chuck does not work, hold the flat portions in vise and

fit 781007-2 into the flat portions of Spindle (Fig. 5), and then turn

Spindle clockwise.

Fig. 2

Thread of 1R045

1R346

Fig. 3

Flat portions of Spindle

1R139

Vise

Fig. 4

Fig. 5

Sleeve of Drill chuck

1R298

1R224

1R223

Flat portions of

Keyless drill chuck

DISASSEMBLY

Turn 1R223 clockwise to tighten Drill chuck to fastening torque 34.3 to 44.1 N.m.

Page 4

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Helical Gear 37 and Ball Bearing 6202DDW

P 4 / 6

Fig. 6 Fig. 7

DISASSEMBLY

1) Remove Gear housing. Refer to page 3.

2) Remove Pin 4 and Steel ball 3.5 from Spindle to prevent

missing and breaking. (Fig. 6)

3) Hook awl to inner periphery of Ring spring 12 and remove

Ring spring 12. (Fig. 7)

4) Put Gear housing section on 1R037 and fit 1R026 to Spindle.

And then press Spindle slightly with arbor press. (Fig. 8)

5) Put 1R283 on Spindle and push out Spindle from Helical

gear 37 with arbor press. (Fig. 9)

Note: When Helical Gear 37 is removed from Spindle,

a heavy load arises in Ball bearing 6202DDW in Gear

housing section. Therefore, be sure to replace Ball bearing

6202DDW.

6) Remove Retaining ring R-35 in Bearing room, and remove

Ring 12 and Ring 19.

7) Remove Compression spring 16 from Spindle and insert

Compression spring in Ball bearing 6202DDW.

Strike Spindle top with plastic hammer, and Ball bearing

6202DDW can be removed from Gear housing.

Spindle

Fig. 8

1R026

Gear

housing

section

1R037

Fig. 9

1R283

Steel ball

3.5

Pin 4

Spindle

Awl

Helical gear 37

Ring spring 12

Spindle end

is put in

1R283.

Helical gear 37

ASSEMBLY

1) Complete assembling work to installation of Retaining ring

R-35 in the reverse order of the disassembling steps.

2) Mount Compression spring 16 on Spindle and put a little

amount of Molybdenum disulfide lubricant to Compression

spring 16, and then install them to Ball bearing 6202DDW.

3) Put Spindle on 1R035 and set 1R028 on Helical gear 37, and

then Press-fit Helical gear 37. (Fig. 10)

Fig. 10

1R028

1R035

Page 5

Circuit diagram

Fig. 11

Color index of lead wires' sheath

Black

White

Red

Orange

Purple

P 5 / 6

Brush holder

(far side from Switch)

6 4

1b

2a

2b

2 1

Brush holder

(near side from Switch)

3

5

1a

Noise suppressor

(if used)

Field

Switch

Page 6

Wiring diagram

Fig. 12

P 6 / 6

Route them between

Ribs A and B.

Field lead wire (white)

Field lead wire (red)

Fig. 13

Field lead wire (black )

Insulated terminal

1

Rib A

Rib B

Field lead wire

(black )

Rib C

2

Route them between

Ribs B and C.

When lead wires rise,

use Lead wire holder A

not to rise them.

Lead wire holder A

Lead wire holder B

1

Field lead wires (black, )

have to fixed with Lead wire

holder B.

2

Brush holder

Insulated terminal

Noise suppressor (if used)

Loading...

Loading...