Makita HP1620 User Manual

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Hammer Drill

Marteau perforateur

Taladro de percusión

HP1620

HP1620F

HP1621

HP1621F

004358

DOUBLE INSULATION

DOUBLE ISOLATION

DOBLE AISLAMIENTO

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

ENGLISH

SPECIFICATIONS

Model HP1620/HP1620F/HP1621/HP1621F

Concrete 16 mm (5/8”)

Capacities

No load speed (RPM) 0 - 2,800/min.

Blows per minute 0 - 44,800

Overall length 303 mm (11-7/8”)

Net weight 1.7 kg (3.7 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Steel 13 mm (1/2”)

Wood 30 mm (1-3/16”)

GENERAL SAFETY RULES

USA002-2

(For All Tools)

WARNING:

Read and understand all instructions.

Failure to follow all instructions listed below,

may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

4. Double insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only

one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet.

Do not change the plug in any way. Double insula-

tion eliminates the need for the three wire

grounded power cord and grounded power supply

system.

5. Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

7. Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric

shock.

8. When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce

the risk of electric shock.

Personal Safety

9. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in

serious personal injury.

10. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

11. Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger

on the switch or plugging in tools that have the

switch on invites accidents.

12. Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

2

13. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the tool in unexpected situations.

14. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions. Ordinary eye or sun glasses are NOT eye

protection.

Tool Use and Care

15. Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable and may lead to loss of control.

16. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

17. Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

18. Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such preventive

safety measures reduce the risk of starting the tool

accidentally.

19. Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

20. Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are

easier to control.

21. Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tools operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

22. Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

23. Tool service must be performed only by qualified

repair personnel. Service or maintenance per-

formed by unqualified personnel could result in a risk

of injury.

24. When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unau-

thorized parts or failure to follow Maintenance

instructions may create a risk of electric shock or

injury.

USE PROPER EXTENSION CORD: Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating. Table 1 shows the correct size to

use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

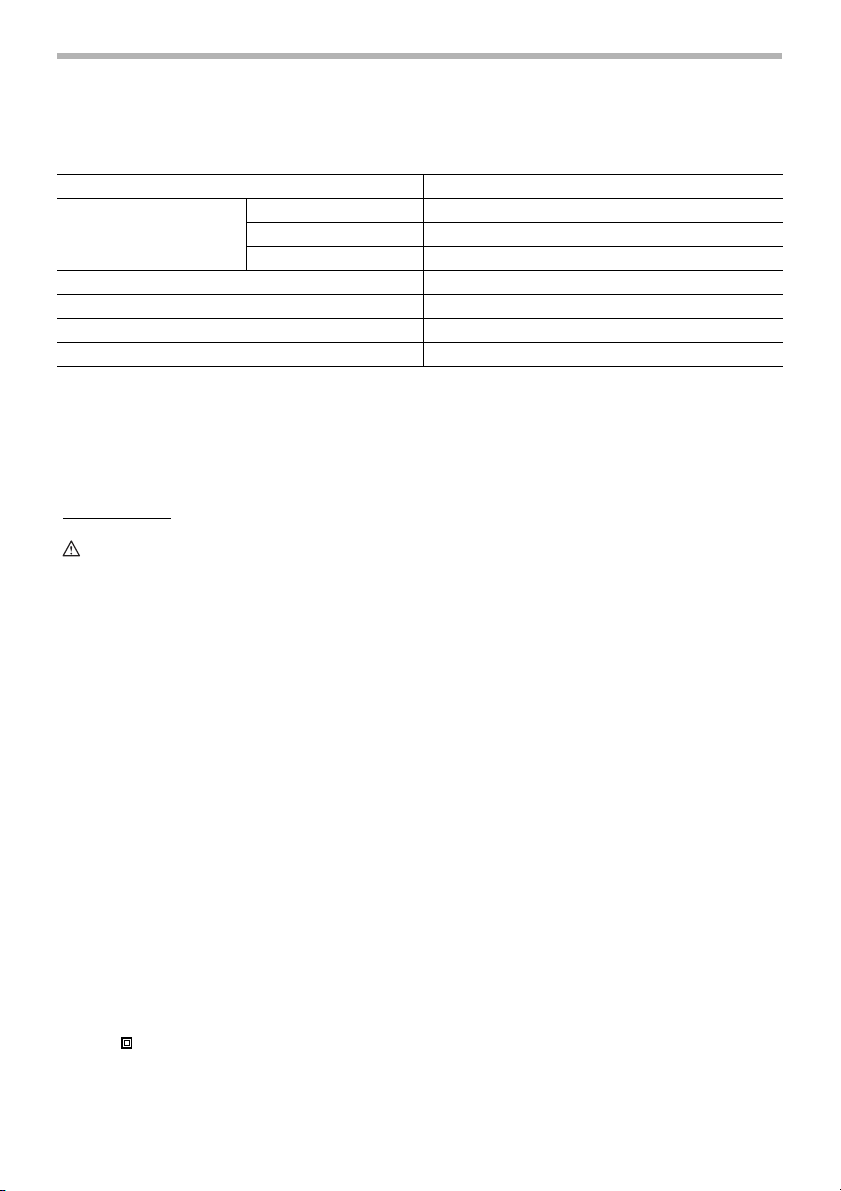

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

SPECIFIC SAFETY RULES

USB002-2

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to hammer drill

safety rules. If you use this tool unsafely

or incorrectly, you can suffer serious personal injury.

1. Hold tools by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring or its own cord. Con-

tact with a “live” wire will make exposed metal parts

of the tool “live” and shock the operator.

2. Always be sure you have a firm footing. Be sure

no one is below when using the tool in high locations.

3. Hold the tool firmly with both hands. Always use

the side grip.

4. Keep hands away from rotating parts.

5. Do not leave the tool running.

Operate the tool only when hand-held.

3

6. Do not touch the bit or the workpiece immediately after operation; they may be extremely hot

and could burn your skin.

7. Some material contains chemicals which may be

toxic. Take caution to prevent working dust inhalation and skin contact. Follow material supplier

safety data.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

SYMBOLS

The followings show the symbols used for tool.

V............................volts

A ...........................amperes

Hz..........................hertz

..................alternating current

.......................no load speed

n

˚

.......................Class II Construction

.../min....................revolutions or reciprocation per

..................number of blow

minute

USD202-2

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

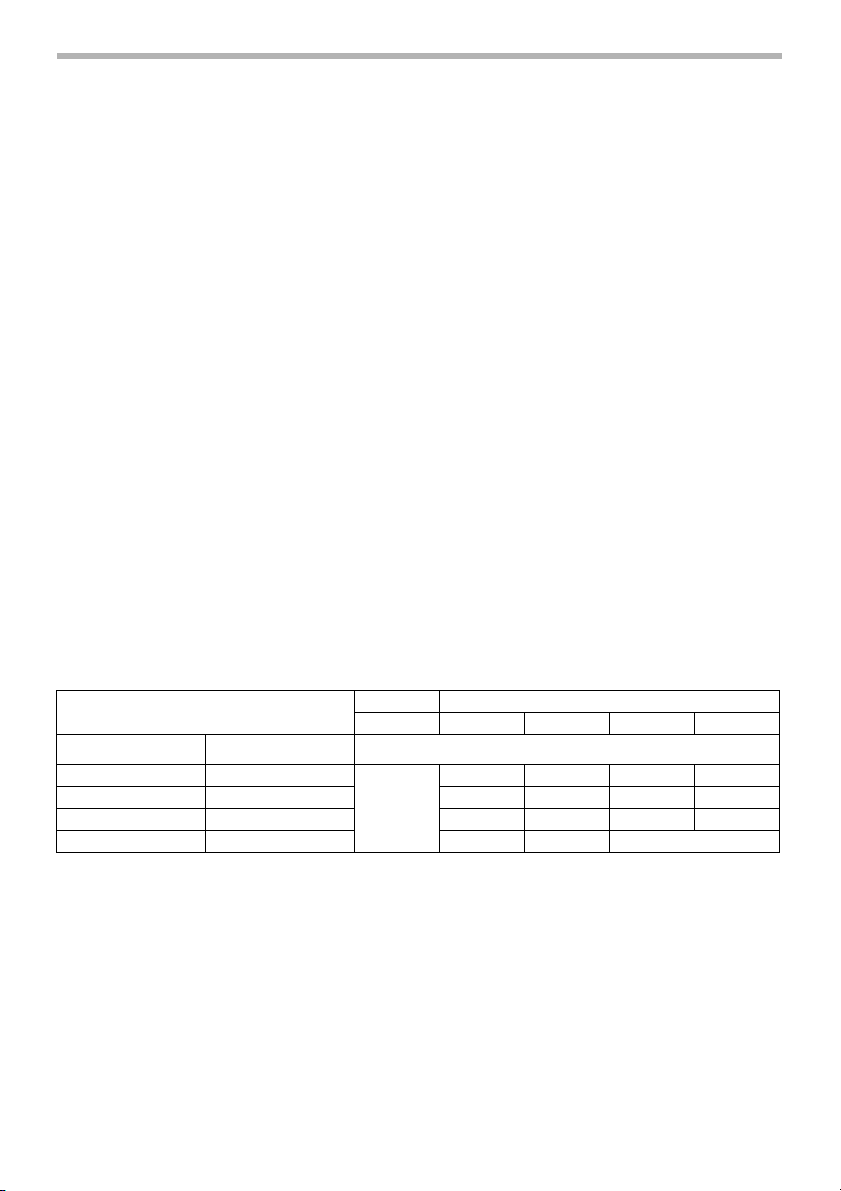

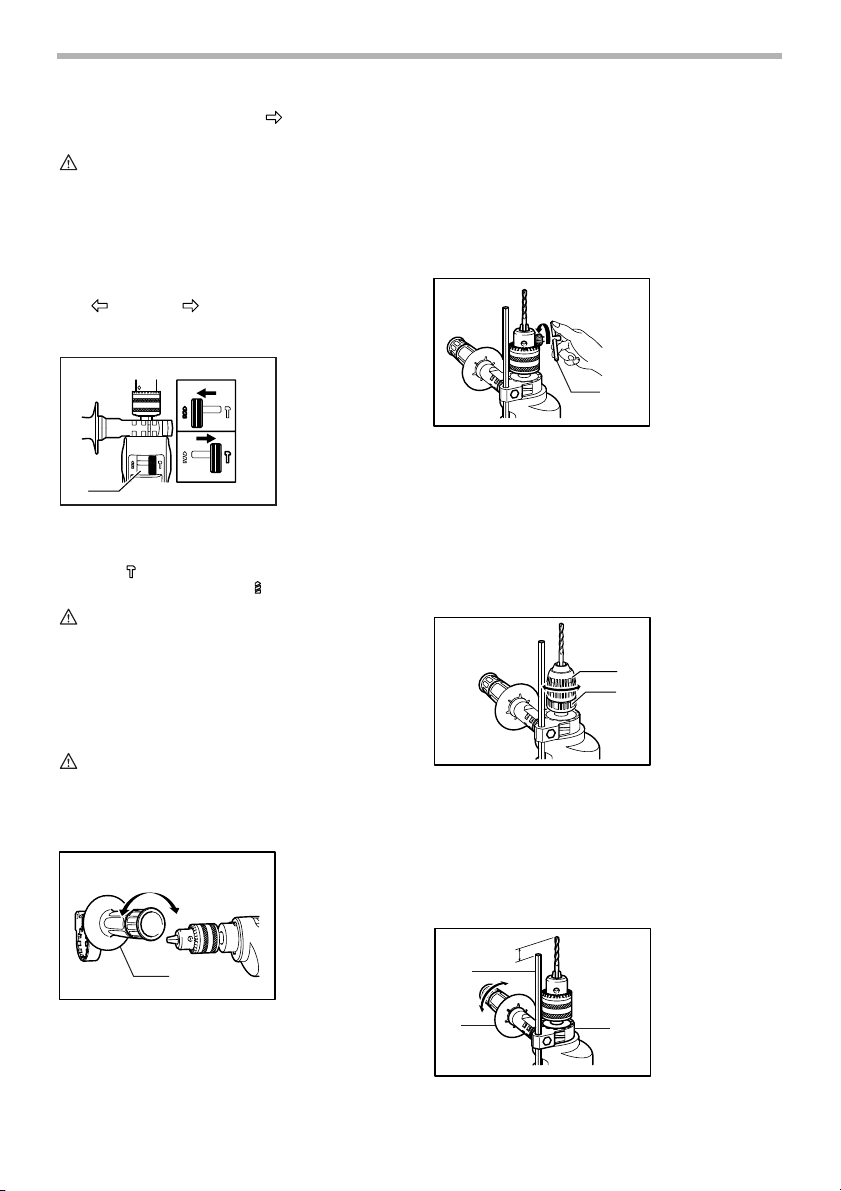

Switch action

1

2

004359

1. Switch trigger

2. Lock button

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and returns

to the “OFF” position when released.

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply

caution when locking tool in “ON” position and

maintain firm grasp on tool.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

For continuous operation, pull the switch trigger and then

push in the lock button.

To stop the tool from the locked position, pull the switch

trigger fully, then release it.

Lighting up the lamps

For Model HP1620F, HP1621F

1

CAUTION:

• Do not look in the light or see the source of light

directly.

To turn on the lamp, pull the trigger. Release the trigger

to turn it off.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp.

Be careful not to scratch the lens of lamp, or it may

lower the illumination.

• Never use gasoline or thinner to clean the lens of

the lamp, or it will be damaged.

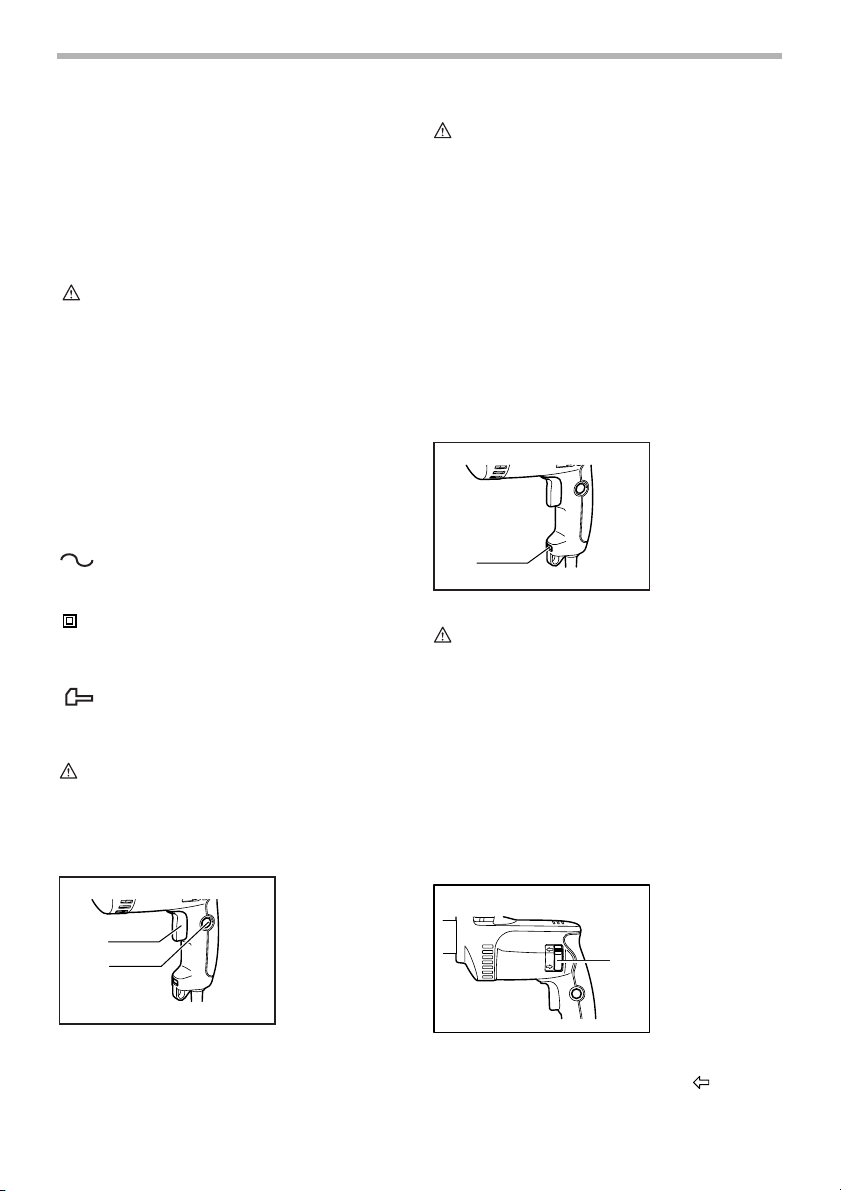

Reversing switch action

A

B

004360

1. Lamp

004361

1. Reversing

switch

1

This tool has a reversing switch to change the direction of

rotation. Move the reversing switch to the position (A

4

side) for clockwise rotation or the position (B side) for

counterclockwise rotation.

CAUTION:

• Always check the direction of rotation before

operation.

• Use the reversing switch only after the tool comes

to a complete stop. Changing the direction of

rotation before the tool stops may damage the tool.

• If the switch trigger can not be depressed, check to

see that the reversing switch is fully set to position

(A side) or (B side).

Selecting the action mode

004362

1. Action mode

changing lever

1

This tool has an action mode change lever. For rotation

with hammering, slide the action mode change lever to

the right ( symbol). For rotation only, slide the action

mode change lever to the left ( symbol).

CAUTION:

• Always slide the action mode change lever all the

way to your desired mode position. If you operate

the tool with the lever positioned halfway between

the mode symbols, the tool may be damaged.

desired position. It may be swung 360° so as to be

secured at any position.

NOTE:

• The side grip cannot swing 360° when the depth

gauge is installed.

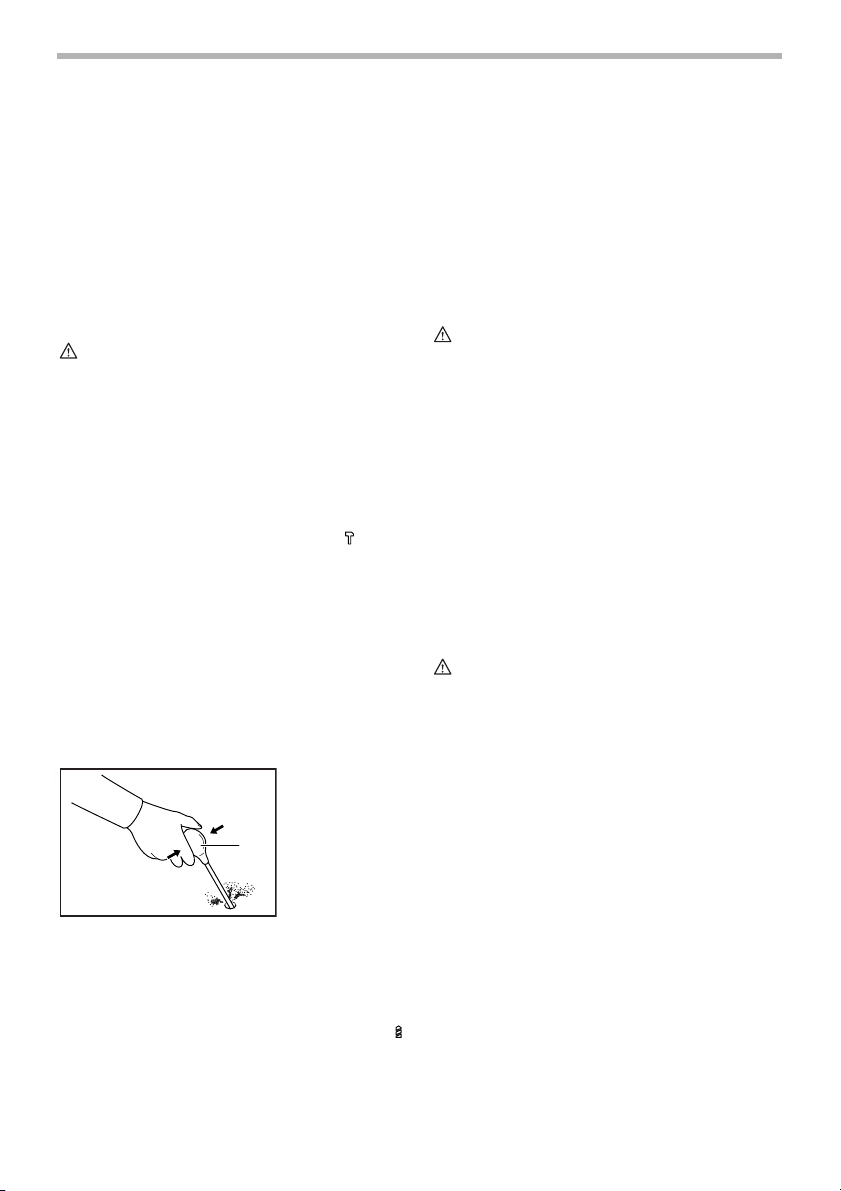

Installing or removing drill bit

For Model HP1620, HP1620F

To install the bit, place it in the chuck as far as it will go.

Tighten the chuck by hand. Place the chuck key in each

of the three holes and tighten clockwise. Be sure to

tighten all three chuck holes evenly.

To remove the bit, turn the chuck key counterclockwise in

just one hole, then loosen the chuck by hand.

After using the chuck key, be sure to return to the original

position.

For Model HP1621, HP1621F

004364

1. Chuck key

1

005963

1. Sleeve

2. Ring

1

2

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing side grip (auxiliary handle)

1

Always use the side grip to ensure operating safety.

Install the side grip on tool barrel.

Then tighten the grip by turning clockwise securely at the

004363

1. Side grip

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws. Place the bit in the chuck as far as

it will go. Hold the ring firmly and turn the sleeve clockwise to tighten the chuck.

To remove the bit, hold the ring and turn the sleeve counterclockwise.

Depth gauge

004366

1. Depth gauge

1

2

2. Side grip

3. Grip base

3

5

The depth gauge is convenient for drilling holes of uniform depth. Loosen the side grip and insert the depth

gauge into the hole in the side grip. Adjust the depth

gauge to the desired depth and tighten the side grip.

NOTE:

• The depth gauge cannot be used at the position

where the depth gauge strikes against the tool

body.

OPERATION

Hammer drilling operation

CAUTION:

• There is a tremendous and sudden twisting force

exerted on the tool/bit at the time of hole breakthrough, when the hole becomes clogged with

chips and particles, or when striking reinforcing

rods embedded in the concrete. Always use the

side grip (auxiliary handle) and firmly hold the tool

by both side grip and switch handle during

operations. Failure to do so may result in the loss of

control of the tool and potentially severe injury.

When drilling in concrete, granite, tile, etc., move the

action mode changing lever to the position of symbol

to use “rotation with hammering” action.

Be sure to use a tungsten-carbide tipped bit.

Position the bit at the desired location for the hole, then

pull the switch trigger. Do not force the tool. Light pressure gives best results. Keep the tool in position and prevent it from slipping away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at an

idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out

and normal drilling may be resumed.

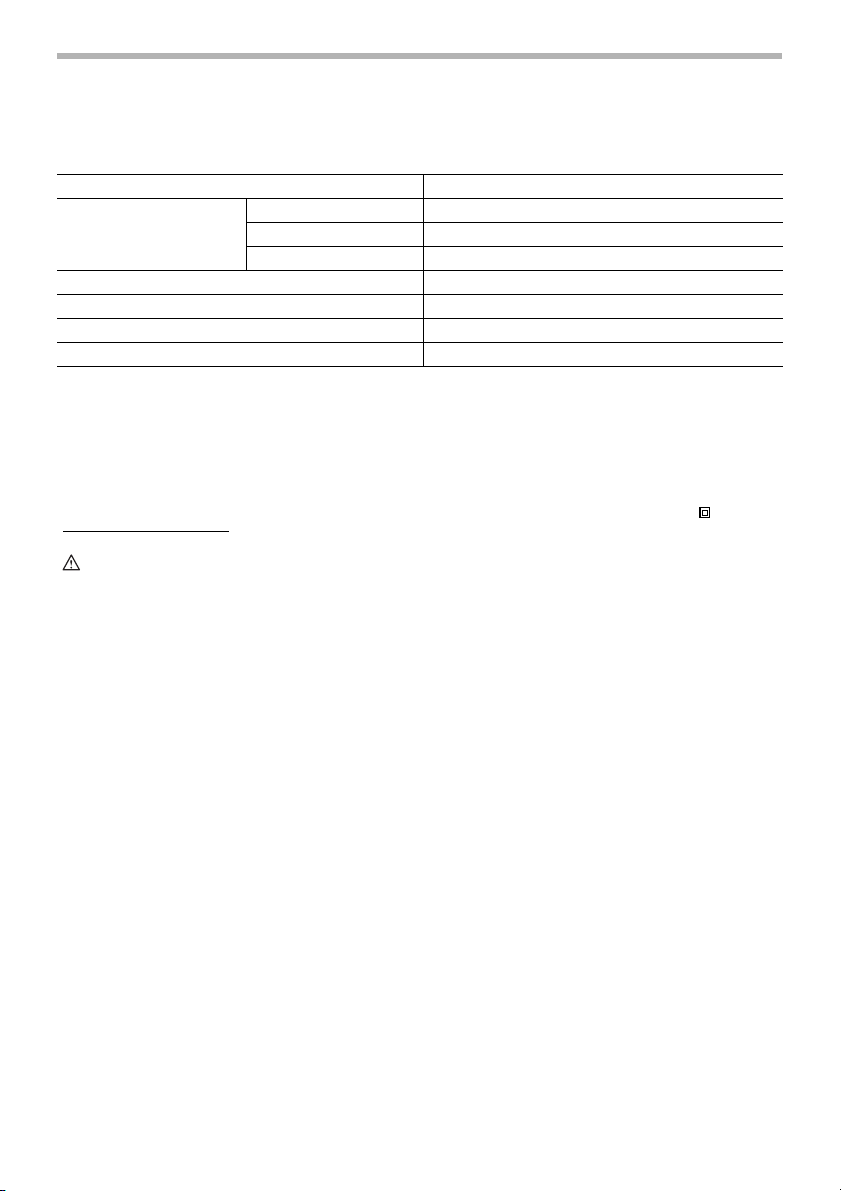

Blow-out bulb (optional accessory)

001302

1. Blow-out bulb

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide

screw makes drilling easier by pulling the bit into the

workpiece.

Drilling in metal

To prevent the bit from slipping when starting a hole,

make an indentation with a center-punch and hammer at

the point to be drilled. Place the point of the bit in the

indentation and start drilling.

Use a cutting lubricant when drilling metals. The exceptions are iron and brass which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up

the drilling. In fact, this excessive pressure will only

serve to damage the tip of your bit, decrease the

tool performance and shorten the service life of the

tool.

• There is a tremendous force exerted on the tool/bit

at the time of hole break through. Hold the tool

firmly and exert care when the bit begins to break

through the workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back

out. However, the tool may back out abruptly if you

do not hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

To maintain product SAFETY and RELIABILITY, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using

Makita replacement parts.

1

After drilling the hole, use the blow-out bulb to clean the

dust out of the hole.

Drilling operation

When drilling in wood, metal or plastic materials, move

the action mode changing lever to the position of

symbol to use “rotation only” action.

6

ACCESSORIES

CAUTION:

• These accessories or attachments are

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Drill bits

• Hammer drill bits

• Hole saws

• Blow-out bulb

• Safety goggles

• Chuck key

• Grip assembly

• Depth gauge

• Plastic carrying case

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

EN0006-1

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

7

FRENCH

SPÉCIFICATIONS

Modèle HP1620/HP1620F/HP1621/HP1621F

CapacitésBéton 16 mm (5/8”)

Acier 13 mm (1/2”)

Bois 30 mm (1-3/16”)

Vitesse à vide (T/MIN) 0 - 2,800/min.

Nombre de frappes par minutes 0 - 44,800

Longueur hors tout 303 mm (11-7/8”)

Poids net 1.7 kg (3.7 lbs)

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

RÈGLES DE SÉCURITÉ GÉNÉRALES

USA002-2

(Pour tous les outils)

AVERTISSEMENT:

Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel,

des instructions ci-après entraîne un risque

de choc électrique, d’incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS

Aire de travail

1. Veillez à ce que l’aire de travail soit propre et

bien éclairée. Le désordre et le manque de lumière

favorisent les accidents.

2. N’utilisez pas d’outils électriques dans une

atmosphère explosive, par exemple en présence

de liquides, de gaz ou de poussières inflammables. Les outils électriques créent des étincelles qui

pourraient enflammer les poussières ou les vapeurs.

3. Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillez avec un

outil électrique. lls pourraient vous distraire et vous

faire une fausse manoeuvre.

Sécurité électrique

4. Les outils à double isolation sont équipés d’une

fiche polarisée (une des lames est plus large que

l’autre), qui ne peut se brancher que d'une seule

façon dans une prise polarisée. Si la fiche

n’entre pas parfaitement dans la prise, inversez

sa position ; si elle n’entre toujours pas bien,

demandez à un électricien qualifié d’installer une

prise de courant polarisée. Ne modifiez pas la

fiche de l’outil. La double isolation élimine le

besoin d’un cordon d’alimentation à trois fils avec

mise à la terre ainsi que d’une prise de courant mise

à la terre.

5. Évitez tout contact corporel avec des surfaces

mises à la terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.). Le risque de choc électri-

que est plus grand si votre corps est en contact avec

la terre.

6. N’exposez pas les outils électriques à la pluie ou

à l’eau. La présence d’eau dans un outil électrique

augmente le risque de choc électrique.

7. Ne maltraitez pas le cordon. Ne transportez pas

l’outil par son cordon et ne débranchez pas la

fiche en tirant sur le cordon. N’exposez pas le

cordon à la chaleur, à des huiles, à des arêtes

vives ou à des pièces en mouvement. Remplacez immédiatement un cordon endommagé. Un

cordon endommagé augmente le risque de choc

électrique.

8. Lorsque vous utilisez un outil électrique à l’extérieur, employez un prolongateur pour l’extérieur

marqué “W-A” ou “W”. Ces cordons sont faits pour

être utilisés à l’extérieur et réduisent le risque de

choc électrique.

Sécurité des personnes

9. Restez alerte, concentrez-vous sur votre travail

et faites preuve de jugement. N’utilisez pas un

outil électrique si vous êtes fatigué ou sous

l'influence de drogues, d’alcool ou de médicaments. Un instant d’inattention suffit pour entraîner

des blessures graves.

10. Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les che-

8

Loading...

Loading...