Page 1

GENERATOR

アメリカ

INSTRUCTIONS FOR USE

ISSUE EMD-GU2000

3ZZ9020161

Page 2

WARNING :

The engine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects or other reproductive

harm.

NOTICE

FEDERAL EMISSION COMPONENT DEFECT WARRANTY and CALIFORNIA

EMISSION CONTROL WARRANTY are applicable to only those engines/

generators complied with EPA (Environmental Protection Agency) and CARB

(California Air Resources Board) emission regulations in the U.S.A.

NOTICE

To the engines/generators exported to and used in the countries other than the

U.S.A., warranty service shall be performed by the distributor in each country in

accordance with the standard engine/generator warranty policy as applicable.

AIR INDEX

To show compliance with California emission regulations, a hangtag has been

provided displaying the Air Index level and durability period of this engine.

The Air Index level defines how clean an engine’s exhaust is over a period of

time. A bar graph scaled from “0” (most clean) to “10” (least clean) is used to

show an engine’s Air Index level. A lower Air Index level represents cleaner

exhaust from an engine.

The period of time (in hours) that the Air Index level is measured is known as

the durability period. Depending on the size of the engine, a selection of time

periods can be used to measure the Air Index level (see below).

Descriptive Term Applicable to Emissions Durability Period

Moderate - 50 hours (engine from 0 to 80 cc)

125 hours (engine greater than 80 cc)

Intermediate - 125 hours (engine from 0 to 80 cc)

250 hours (engine greater than 80 cc)

Extended - 300 hours (engine from 0 to 80 cc)

500 hours (engine greater than 80 cc)

Notice : This hangtag must remain on this engine or piece of equipment, and

only be removed by the ultimate purchaser before operation.

Page 3

FEDERAL EMISSIONS COMPONENT DEFECT WARRANTY

EMISSIONS COMPONENT DEFECT WARRANTY COVERAGE - This emission warranty is

applicable in all States, except the State of California

Makita U.S.A. Inc., La Mirada, California, (herein "MAKITA") warrant(s) to the initial retail purchaser

and each subsequent owner, that this Nonroad engine (herein "engine") has been designed, built,

and equipped to conform at the time of initial sale to all applicable regulations of the U.S.

Environmental Protection Agency (EPA), and that the engine is free of defects in materials and

workmanship which would cause this engine to fail to conform with EPA regulations during its

warranty period.

For the components listed under PARTS COVERED, the Makita Factory Service Center or Service

Center authorized by MAKITA will, at no cost to you, make the necessary diagnosis, repair, or

replacement necessary to ensure that the engine complies with applicable U.S. EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the initial purchaser and continues

for a period of 2 years.

PARTS COVERED

Listed below are the parts covered by the Emission Components Defect Warranty. Some of the parts

listed below may require scheduled maintenance and are warranted up to the first scheduled

replacement point for that part.

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or

pressure regulator or fuel injection

system).

(ii) Air/fuel ratio feedback and control system,

if applicable.

(iii) Cold start enrichment system, if

applicable.

(iv) Regulator assy (gaseous fuel, if

applicable)

(2) Air Induction System

(i) Intake manifold, if applicable

(ii) Air filter.

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest Makita Factory Service Center or Service

Center authorized by MAKITA. Bring your sales receipts indicating date of purchase for this engine.

The Makita Factory Service Center or Service Center authorized by MAKITA will perform the

necessary repairs or adjustments within a reasonable amount of time and furnish you with a copy of

the repair order. All parts and accessories replaced under this warranty become the property of

MAKITA.EPA - MAKITA FEDERAL EMISSIONS COMPONENT DEFECT WARRANTY-continued

(3) Ignition System

(i) Spark plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system, if

applicable.

(4) Exhaust manifold, if applicable

(5) Miscellaneous Items Used in Above Systems

(i) Electronic controls, if applicable

(ii) Hoses, belts, connectors, and

assemblies.

(iii) Filter lock assy (gaseous fuel, if

applicable)

WHAT IS NOT COVERED

*Conditions resulting from tampering, misuse, improper adjustment (unless they were made by the

Makita Factory Service Center or Service Center authorized by MAKITA during a warranty repair),

alteration, accident, failure to use the recommended fuel and oil, or not performing required

maintenance services.

Page 4

*The replacement parts used for required maintenance services.

*Consequential damages such as loss of time, inconvenience, loss of use of the engine

orequipment, etc.

*Diagnosis and inspection charges that do not result in warranty-eligible service being performed.

*Any non-authorized replacement part, or malfunction of authorized parts due to use of non-

authorized parts.

OWNER'S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required maintenance listed in

your owner's manual. MAKITA recommends that you retain all receipts covering maintenance on

your engine, but MAKITA cannot deny warranty solely for the lack of receipts or for your failure to

ensure the performance of all scheduled maintenance.

As the engine owner, you should however be aware that MAKITA may deny warranty coverage if

your engine or a part has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your engine to the nearest Makita Factory Service Center or

Service Center authorized by MAKITA when a problem exists.

If you have any questions regarding your warranty rights and responsibilities, you should contact

the Makita Warranty Department at 1-800-4-MAKITA for the information.

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY

MAINTENANCE AND REPAIRS

You are responsible for the proper maintenance of the engine. You should keep all receipts and

maintenance records covering the performance of regular maintenance in the event questions

arise. These receipts and maintenance records should be transferred to each subsequent owner of

the engine. MAKITA reserves the right to deny warranty coverage if the engine has not been

properly maintained. Warranty claims will not be denied, however, solely because of the lack of

required maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND

SYSTEMS MAY BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL ;

HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY THE MAKITA FACTORY

SERVICE CENTER OR SERVICE CENTER AUTHORIZED BY MAKITA. THE USE OF PARTS

THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE

A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by MAKITA are used for maintenance replacements or for the

repair of components affecting emission control, you should assure yourself that such parts are

warranted by their manufacturer to be equivalent to the parts authorized by MAKITA in their

performance and durability.

HOW TO MAKE A CLAIM

All repair qualifying under this limited warranty must be performed by a Makita Factory Service

Center or Service Center authorized by MAKITA. In the event that any emission-related part is

found to be defective during the warranty period, you shall notify Makita Warranty Department at

1-800-4-MAKITA and you will be advised of the appropriate warranty service dealer or service

providers where the warranty repair can be performed.

Page 5

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

(This warranty does not apply in any other state.)

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Makita U.S.A., Inc. (herein "MAKITA") are pleased to

explain the emission control warranty on your 2005 and later small off-road engine (herein

"engine"). In California, new engine must be designed, built and equipped to meet the State's

stringent anti-smog standards. MAKITA must warrant the emission control system on your

engine for the periods of time listed below provided there has been no abuse, neglect or

improper maintenance of your engine.

Your emission control system includes parts such as the carburetor or fuel injection systems,

the ignition system and the catalytic converter. Also included are the hoses, belts, connectors

and other emission-related assemblies.

Where a warrantable condition exists, MAKITA will repair your engine at no cost to you including

diagnosis, parts and labor.

MANUFACTURER'S WARRANTY COVERAGE :

The 2005 and later engines are warranted for two years. If any emission-related part on your

engine is defective, the part will be repaired or replaced by MAKITA.

OWNER'S WARRANTY RESPONSIBILITIES :

-As the engine owner, you are responsible for the performance of the required

maintenance listed in your Owner's Manual. MAKITA recommends that you retain all

receipts covering maintenance on your engine, but MAKITA cannot deny warranty solely

for the lack of receipts or for your failure to ensure the performance of all scheduled

maintenance.

-As the engine owner, you should be aware, however, that MAKITA may deny you

warranty coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

-You are responsible for presenting your engine to a MAKITA service center as a problem

exists.

The warranty repairs should be completed in a reasonable time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

contact a Makita Factory Service Center Manager nearest you. A list of the Factory Service

Center locations and phone numbers is provided below for your convenience.

Page 6

MAKITA , a distributor of small off-road equipment in the U.S., warrants to the owner of 2005

and later engines that the engine (1) has been designed, built, and equipped at the time of

manufacture so as to conform with the applicable regulations of the California Air Resources

Board and, (2) is free from defects in materials and workmanship which may cause it to fail to

conform with those regulations as applicable according to the terms and conditions stated below.

WARRANTY PERIOD

This warranty period begins on the date which the engine is delivered to the original retail

purchaser and ends two years after that date. During this two year period MAKITA warrants to

the original retail purchaser and each subsequent purchaser that the engine is free from defect

in material and workmanship that can cause the failure of a warranted emission-related part.

WHAT IS COVERED UNDER THIS WARRANTY

Repair and/or replacement of any warranted emission-related part will be performed at no

charge provided the work is performed at an authorized warranty station. There will also be no

charge for any diagnostic labor performed at an authorized warranty station which leads to the

determination that a warranted emission-related part is defective.

Any warranted part which is not scheduled for replacement as required maintenance, or which is

scheduled only for regular inspection to the effect of "repair or replace as necessary" shall be

warranted for the warranty period. Any warranted part which is scheduled for replacement as

required maintenance shall be warranted for the period of time up to the first scheduled

replacement of that part. This warranty shall apply only towards the repair, replacement, and/or

adjustment of the component parts listed below.

EMISSION-RELATED PARTS COVERED UNDER THIS WARRANTY

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or pressure regulator or fuel injection system).

(ii) Air/fuel ratio feedback and control system, if applicable.

(iii) Cold start enrichment system, if applicable.

(iv) Regulator assy (gaseous fuel, if applicable)

(2) Air Induction System

(i)Intake manifold, if applicable

(ii)Air filter.

(3) Ignition System

(i)Spark plugs.

(ii)Magneto or electronic ignition system.

(iii)Spark advance/retard system, if applicable.

(4) Exhaust manifold, if applicable

(5) Miscellaneous Items Used in Above Systems

(i)Electronic controls, if applicable

(ii)Hoses, belts, connectors, and assemblies.

(iii) Filter lock assy (gaseous fuel, if applicable)

If it is determined by an authorized warranty station that other engine components have been

damaged due to the failure of a warranted emission-related part during the warranty period,

MAKITA will repair and/or replace the necessary components.

Page 7

WHAT IS NOT COVERED UNDER THIS WARRANTY

This warranty does not cover any emission-related part which malfunctions, fails, or is

damaged due to alterations and/or modifications such as changing, adding, or removing parts.

When an engine is being serviced under warranty, MAKITA and any of its authorized dealers,

distributors, or warranty stations shall not be liable for any loss of use of the engine, for any

damage to goods, or loss of time or inconvenience. This limited warranty also does not apply

to any emission-related part which malfunctions, fails, or is damaged due to failure to follow

the maintenance and operating instructions specified in the 2005 and later Owner's Manual

including.

(a) Improper or inadequate maintenance of any warranted emission-related part.

(b) Improper installation, adjustment, or repair of the engine or any warranted emission-

related part unless performed by a factory authorized warranty station.

(c) Failure to use recommended fuel as specified in the 2005 and later Owner's Manual.

(d) Repairs and diagnosis performed outside of an authorized warranty station.

(e) Use of parts which are not authorized by MAKITA.

MAINTENANCE SCHEDULE

The engine owner is responsible for having all scheduled inspection and maintenance services

performed at the intervals specified in the 2005 and later Owner's Manual and to retain records

of these services as having been performed. These records should be transferred to each

subsequent owner of the engine. MAKITA cannot deny a claim solely because there are no

records of scheduled maintenance, however, a warranty claim may be denied if the failure to

perform the scheduled maintenance and inspection resulted in the failure of a warranted

emission-related part.

As a minimum, the engine owner is responsible for the scheduled inspection and maintenance

described below which are based on the procedures described in the Owner's Manual.

PROCEDURE INTERVAL

1) Change engine oil : Initial 20 hours and every 100 hours afterward

2) Clean air cleaner (element) : Every 50 hours

3) Replace air cleaner element : Every 200 hours

4) Clean and adjust spark plug and electrodes : Every 200 hours

Note: More frequent maintenance may be necessary under dusty, dirty or severe conditions.

Page 8

REPAIR AND REPLACEMENT OF EMISSION-RELATED PARTS

It is recommended that only engine replacement parts which have been authorized and

approved by MAKITA should be used in the performance of any warranty maintenance or repairs

of emission-related parts. These replacement parts will be provided at no charge if the part is still

under warranty.

HOW TO FILE A WARRANTY CLAIM

AND WHERE TO GET WARRANTY SERVICES

Contact the nearest Makita Factory Service Center Manager to determine the appropriate

location where the required warranty services are to be performed. A list of the Factory Service

Center locations and phone numbers are provided below for your convenience.

41850 Christy Street

Fremont, CA 94538-5107

(510)657-9881

1421 N. Clovis Ave., Ste. 112

Fresno, CA 93727

(209)252-5166

14930 Northam Street

La Mirada, CA 90638-5753

(714)522-8088

1970 Fulton Avenue

Sacramento, CA 95825

(916)482-5197

1440 South "E" Street

San Bernardino, CA 92408

(909)885-1289

7674 Clairemont Mesa Blvd.

San Diego, CA 92111

(619)278-4471

1714 E. McFadden Ave., Unit M

Santa Ana, CA 92705

(714)667-5066

333 Littlefield Ave.

South San Francisco, CA 94080

(415)875-1002

16735 Saticoy St., Ste. 105

Van Nuys, CA 91406

(818) 782-2440

Page 9

FOREWORD

Thank you for purchasing a Makita generator.

This manual covers operation and maintenance of the Makita generators.

All information in this publication is based on the latest production

information available at the time of approval for printing.

Pay special attention to statements preceded by the following words:

WARNING

Indicates a strong possibility of severe personal injury, loss of life and

equipment damage if instructions are not followed.

[CAUTION]

Indicates a possibility of personal injury or equipment damage if instructions

are not followed.

NOTE:

Gives helpful information.

If a problem should arise, or if you have any questions about the generator,

consult an authorized dealer or factory service center.

WARNING

■

The generator is designed to give safe and dependable service if

operated according to instructions.

■

Do not operate the generator before you have read and

understood the instructions. Failure to do so could result in death,

personal injury or equipment damage.

Page 10

■

Check that following

accessories come with your

Makita Generator.

(1) Instruction for use

(2) Servicing tools

(3) Battery mounting bracket

(See page 8 and 9.)

■

Be sure to replenish with

engine oil.

(See page 6 for details.)

Page 11

CONTENTS

1. SAFETY PRECAUTIONS

2. SPECIFICATIONS

3. COMPONENTS

4. PRE-OPERATION CHECKS

5. OPERATING PROCEDURES

6. WATTAGE INFORMATION

7. SPARK ARRESTER

8. MAINTENANCE SCHEDULE

9. "HOW-TO" MAINTENANCE

10. PREPARATION FOR STORAGE

11. TROUBLESHOOTING

12. WIRING DIAGRAM

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

1

4

5

6

11

21

23

24

26

30

31

32

Page 12

1. SAFETY PRECAUTIONS

Do not operate the generator near gasoline or gaseous fuel because of the

potential danger of explosion or fire.

Do not fill the fuel tank with fuel while the engine is running. Do not smoke or

use open flame near the fuel tank. Be careful not to spill fuel during refueling.

If fuel is spilt, wipe it off and let dry before starting the engine.

Do not place inflammables near the generator.

Be careful not to place fuel, matches, gunpowder, oily cloths, straw, trash, or

any other inflammables near the generator.

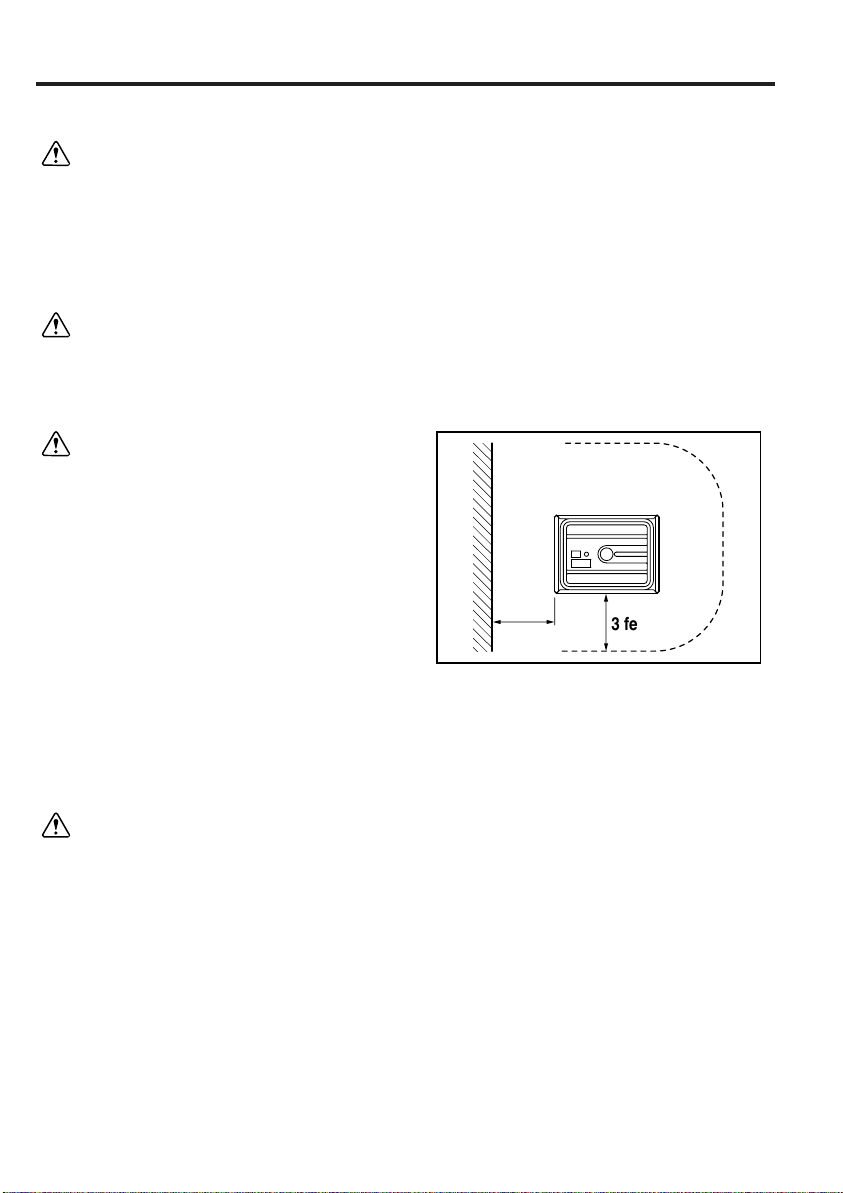

Do not operate the generator inside a

room, cave, tunnel, or other

insufficiently ventilated area. Always

operate it in a well-ventilated area,

otherwise the engine may become

overheated, and the poisonous

carbon monoxide gas contained in

the exhaust gases will endanger

human lives. Keep the generator at

least 3 feet (1 meter) away from any

structure or building during use.

If the generator must be used indoors, the area must be well-ventilated and

extreme caution must be taken regarding the discharge of exhaust gases.

3 feet

(1m

)

3 feet (1m

)

Do not enclose the generator nor cover it with a box.

The generator has a built-in forced air cooling system, and may become

overheated if it is enclosed. If generator has been covered to protect it from

the weather during non use, be sure to remove it and keep it well away from

the area during generator use.

−1−

Page 13

Operate the generator on a level surface.

It is not necessary to prepare a special foundation for the generator. However,

the generator will vibrate on an irregular surface, so choose a level place

without surface irregularities.

If the generator is tilted or moved during operation, fuel may spill and/ or the

generator may tip over, causing a hazardous situation.

Proper lubrication cannot be expected if the generator is operated on a steep

incline or slope. In such a case, piston seizure may occur even if the oil is

above the upper level.

Pay attention to the wiring or extension cords from the generator to the

connected device.

If the wire is under the generator or in contact with a vibrating part, it may

break and possibly cause a fire, generator burnout, or electric shock hazard.

Replace damaged or worn cords immediately.

Do not operate in rain, in wet or damp conditions, or with wet hands.

The operator may suffer severe electric shock if the generator is wet due to

rain or snow.

If wet, wipe and dry it well before starting. Do not pour water directly over the

generator, nor wash it with water.

Be extremely careful that all necessary electrical grounding procedures are

followed during each and every use. Failure to do so can be fatal.

Do not contact the generator to a commercial power line. Connection to a

commercial power line may short circuit the generator and ruin it or cause

electric shock hazard. Use the transfer switch for connecting to domestic

circuit.

No smoking while handling the battery. The battery emits flammable hydrogen

gas, which can explode if exposed to electric arcing or open flame.

Keep the area well-ventilated and keep open flames/sparks away when

handling the battery.

−2−

Page 14

Engine becomes extremely hot during and for some time after operation.

Keep combustible materials well away from generator area.

Be very careful not to touch any parts of the hot engine especially the muffler

area or serious burns may result.

Keep children and all bystanders at a safe distance from work areas.

It is absolutely essential that you know the safe and proper use of the power

tool or appliance that you intend to use. All operators must read, understand

and follow the tool/appliance owners manual. Tool and appliance applications

and limitations must be understood. Follow all directions given on labels and

warnings. Keep all instruction manuals and literature in a safe place for future

reference.

Notes on installation

1. Select a place which allows you to maintain and inspect the generator, which is

not exposed to contamination caused by exhaust gas.

If you are planning to install the generator without its wheels attached, consider

the work efficiency in terms of an oil change.

2. In ground connection, be sure to use the designated ground terminal.

(A grounding cable is not included in the set of accessories.)

3. During use, be sure not to disconnect the battery.

4. While the power is on, do not unplug the unit or disconnect cables from the

terminals.

−3−

Page 15

2. SPECIFICATIONS

Model G12010R

Type Brush, Self-exciting, 2-pole, Single-phase

Rated frequency

Rated voltage 120V / 240V

Maximum output

Alternator

Rated output

Power factor

Voltage regulator

Model EH65D

Type Twin cylinder, Air-cooled, 4-stroke, Overhead valve engine

Displacement 653 cm

Fuel Automotive unleaded gasoline

Engine

Oil capacity 0.41 US-gal (1.55 liters)

Starting system Electric starter

Fuel tank capacity 11.38 US-gal (44 liters)

Rated continuous

operation per a

tankful of fuel

Length

Rated

60 Hz

12000 W

9500 VA

1.0

A.V.R type

3

Approx. 8.2 hours

32.5 in. (826

mm)

Width

Dimension

High

Dry weight 310.9 lb (141 kg)

Remote controller terminal

(Auto choke)

Valve Clearance

(Intake & Exhaust)

Emissions Durability Period

(California only)

Note : Adjust the valve clearance while the engine is cold.

24.1 in. (

30.4 in. (

0.0039±0.0008 in. (0.1±0.02 mm)

611 mm)

771 mm)

Standard

500 hours

−4−

Page 16

3. COMPONENTS

FUEL TANK

CONTROL

PANEL

BATTERY

OIL FILLER CAP

TANK CAP

AIR CLEANER

COOLING AIR

INLET PORT

FUEL COCK

OIL FILTER

SPARK PLUG CAP

MUFFLER

SPARK PLUG

CAP

OIL DRAIN PLUG

CONNECTOR

FOR REMOTE

CONTROL

OIL GAUGE

ELECTRIC STARTER

−5−

Page 17

4. PRE-OPERATION CHECK

CHECK ENGINE OIL

Before checking or refilling oil, be sure

generator is located on stable and level

surface with engine stopped.

1) Remove oil level gauge and check the

engine oil level.

2) If oil level is below the lower level

refill with suitable oil (see table) to upper

"F" after removing the engine oil

level

filler cap.

3) Change oil if contaminated.

(See "How-To" Maintenance.)

Oil capacity

・・・・・

0.41 US-gal (Upper level)

1.55 liters (Upper level)

NOTE :

■

The engine is equipped with an oil sensor

unit (hydraulic pressure detection type)

that will automatically stop the engine if

oil in the crank case is reduced below the

specified level. Should the engine be

automatically stopped, be sure to check

the amounts of fuel and oil.

■

When the oil is reduced below the

specified level, add new oil to the upper

limit. Since the oil sensor will not detect

the deterioration of oil, visually check the

quality or determine it by the specified

time and then change the oil if necessary.

(Refer to page 25.)

"L"

OIL GAUGE

UPPER

LEVEL

LOWER

LEVEL

Oil gauge

Upper level

Lower level

OIL FILLER CAP

Recommended engine oil :

Use 4-stroke automotive detergent oil

of API service class

(SG, SH or SJ is recommended).

grade

SAE 10W-30 or 10W-40 is

recommended for general, alltemperature use. If single viscosity oil

is used, select the appropriate

viscosity for the average temperature

in your area.

SE or higher

Single grade

Multigrade

Ambient

temperature

−6−

5W

10W

20W

#20

10W

-

10W

30

#30

#40

-

40

Page 18

CHECK ENGINE FUEL

WARNING

Do not refuel while smoking or near open flame or other such

potential fire hazards. Otherwise fire accident may occur.

1) Check fuel level at fuel level gauge.

2) If fuel level is low, refill with automotive

unleaded gasoline only.

This engine is certified to operate on

automotive unleaded gasoline.

3) Be sure to use the fuel filter screen on

the fuel filter neck.

Recommended fuel :

Unleaded automotive gasoline of

octane rating RON87 or higher.

Fuel tank capacity :

11.38 US-gal (44 liters)

Fuel gauge

Tank cap

EMPTY FULL

Fuel filter screen

NOTE :

■

The full level of fuel is the upper

surface of the fuel filter.

EF

"LEVEL" Mark

Fuel level line

−7−

Page 19

Continuous operation time in normal use (rated load)

G12010R Approx. 8.2 hours

WARNING

Make sure you review each warning in order to prevent fire hazard.

■

Do not refill tank while engine is running or hot.

■

Close fuel cock before refueling with fuel.

■

Be careful not to admit dust, dirt, water or other foreign objects into

fuel.

■

Do not fill above the top of the fuel filter (marked "LEVEL") or the fuel

may overflow when it heats up later and expands.

■

Wipe off spilt fuel thoroughly before starting engine.

■

Keep open flames away.

BATTERY INSTALLATION

Recommended Battery

Lead-acid battery : A capacity of 12V-32A・h or larger.

For the generators used in low temperature (below -5

12V-40A

・h or larger battery is recommended.

℃),

1) Attach terminals to a lead-acid battery already charged. Mount the battery onto

the position as specified below, with its terminals facing inward.

2) Insert each long bolt through the specified hole, its tip pointing outward.

3) Put the supporting arm on the long bolts and tighten with the butterfly nuts.

(Push the lead-acid battery all the way inward.)

4) Arrange the wiring so that it won't be damaged by possible vibration caused by

the engine.

5) Only after checking that the engine's starter key is in the "OFF" position,

securely connect the red cable, to the positive (+) terminal. And then connect

the other cable to the negative (-) terminal.

Red cable : to the (+) terminal

Black cable : to the (-) terminal

−8−

Page 20

[CAUTION]

Should the connection be made in incorrect manner, the engine will be broken.

①

Butterfly nut

②Long bolt

③

Supporting arm

④Terminals and nut

┓

┣

Accessory

┛

parts

①

LESS THAN

6.7 in. (170 mm)

③

②

RED CABEL

RED CABEL

④

LESS THAN

8.1 in.

(205 mm)

LESS THAN

10.2 in. (260 mm)

WARNING

Death, personal injury and/ or property damage may occur unless

instructions are followed carefully.

■

Disconnect battery cables when charging battery.

■

Use battery of specified capacity listed in the owner's manual.

■

Turn the starter switch to the "STOP" position when mounting or

dismounting battery. Connect positive (+) terminal first when mounting

battery, and disconnect negative (-) terminal first when dismounting.

RED CABLE : To positive (+) terminal

BLACK CABLE : To negative (-) terminal

−9−

Page 21

CHECK COMPONENT PARTS

Check following items before starting engine:

■

Fuel leakage from fuel hose, etc.

■

Bolts and nuts for looseness.

■

Components for damage or breakage.

■

Generator not resting on or against any adjacent wiring.

CHECK GENERATOR SURROUNDINGS

WARNING

Make sure you review each warning in order to prevent fire hazard.

■

Keep area clear of inflammables or other hazardous materials.

■

Keep generator at least 3 feet (1 meter) away from buildings or other

structures.

■

Only operate generator in a dry, well ventilated area.

■

Keep exhaust pipe clear of foreign objects.

■

Keep generator away from open flame. No smoking!

■

Keep generator on a stable and level surface.

■

Do not block generator air vents with paper or other material.

−10−

Page 22

5. OPERATING PROCEDURES

STARTING THE ENGINE

[CAUTION]

■

Check the oil level before each operations. (See page 6)

■

Perform the specified Daily Inspection to see if it is in normal condition.

(1) Make sure that the no-fuse breaker is

off.

(2) Turn the fuel cock to the vertical

(open) position

(3) Turn the key switch to the

"START"

position.

If the engine won't start, turn the

switch back to

"RUN" position and then

wait for approximately 10 seconds to

try it again.

NOTE :

■

You might have to keep the starter

running for at least 3 to 5 seconds,

since the engine incorporates the

mechanism in it where the ignition

circuit is activated by the increase of

hydraulic pressure.

■

In the following occasion, two or three

trials may be required for starting the

engine :

(1) The very first starting of a new

generator.

(2) After the refueling of the engine

which has been stopped due to fuel

shortage.

(3) Starting after the oil filter change.

(4) Warm the engine up for a minute or

two. Longer time would be needed

in cold weather.

−11−

CLOSE

STOP

OPEN

RUN

STOP

RUN

ON

OFF

START

CLOSE

START

Page 23

USING ELECTRIC POWER

WARNING

■

Make sure that the appliance is switched OFF before connecting it to

the generator.

■

Do not move the generator while it is running.

■

Be sure to ground the generator if the connected appliance is

grounded. Failure to ground unit may lead to electrical shock.

CONTROL PANEL

TERMINAL

VOLTMETER

PILOT LAMP HOUR METERNO-FUSE BREAKER

110

0

220

120

240

CONNECTOR

FOR REMOTE CONTROL

OIL PURESSURE

WARNING LAMP

KEY SWITCH

IDLE CONTROL

SWITCH

AC RECEPTACLEEARTH (GROUND)

−12−

Page 24

(1) AC APPLICATION

(a) Ground the generator, using the

ground terminal located at the side of

the panel.

(b) Before starting the engine, check that

the no-fuse breaker of the generator

and the power switches of the

appliances are turned off.

Grounding spike

(c) Connect the plugs of the appliances to

the receptacles before starting the

engine. If you wish to use for a long

period of time, connecting to the output

terminal is recommended.

(d) Start the engine and check that the

voltage meter is indicating correct

voltage.

ON

OFF

−13−

Page 25

■

Check the amperage of the receptacles used referring to TABLE 1, and be

sure not to take a current exceeding the specified amperage.

■

Be sure that the total wattage of all appliances dose not exceed the rated

output of the generator.

Style Ampere Receptacle AC plug Description

GFCI (Ground Fault

Circuit Interrupter)

Receptacle, duplex

(REC1)

up to 20A

NEMA

5-20R

NEMA

5-20P

up to 30A

up to 30A

up to 50A

WARNING

■

To take power out from the TWIST

LOCK RECEPTACLE, insert the

plug into the receptacle, and turn

it clockwise to the lock position.

■

Be sure to ground the generator if

the connected electrical device Is

grounded.

NEMA

L5-30R

NEMA

L14-30R

TABLE 1

NEMA

L5-30P

NEMA

L14-30P

Locking Receptacle

(REC2)

Locking Receptacle

(REC3)

Locking Receptacle

(REC4)

TWIST

NOTE :

When the no-fuse breaker turns off during operation, the generator is over loaded

or the appliance is defective. Stop the generator immediately, check the appliance

and / or generator for overloading or detect and have repaired as necessary by

Makita dealer or service shop.

−14−

Page 26

CAUTION

[

]

The duplex 120V receptacle is protected by a GFCI (Ground Fault Circuit

Interrupter). GFCI shuts off the output current from the duplex 120V

receptacle when a ground fault occurs in the generator or the appliance.

Please note that other receptacles are not protected by GFCI.

GFCI RECEPTACLE

After starting the engine, check the GFCI for proper functioning by the following

test procedure.

■

Push blue TEST button, The red RESET button will pop out exposing the word

TRIP. Power is now off at the outlets protected by the GFCI, indicating that the

device is functioning properly.

■

If TRIP dose not appear when testing, do not use the generator. Call a

qualified electrician.

■

To restore power, push RESET button.

WARNING

If the RESET button pops out during operation, stop the generator

immediately and call a qualified electrician for checking generator and

the appliances.

(2) CONNECTING TO DOMESTIC CIRCUIT (HOUSE WIRING)

WARNING

This generator is neutral grounded type.

If a generator is to be connected to residential or commercial power

lines, such as a stand-by power source during power outage, all

connections must be made by a licensed electrician.

Failure in connection may result in death, personal injury, damage to

generator, damage to appliances, damage to the building's wiring or fire.

−15−

Page 27

(a) When connecting a Makita generator to a house wiring, generator output power

must be taken from the 240V-4P receptacle.

(b) Install a transfer switch.

A transfer switch must be installed to transfer the load from the commercial

power source to the generator. This switch is necessary to prevent accidents

caused by the recovery from power outage. Use a transfer switch of the correct

capacity.

Install transfer switch between the meter and the fuse or AC breaker box.

CAUTION

[

If the neutral wire of house wiring is grounded, be sure to ground the

ground terminal of the generator, Otherwise an electric shock may occur

to the operator.

]

UTILITY HIGH LINE

CONNECTING BOX

240V

RECEPTACLE

MAIN POWER LINE

TRANSFER SWITCH

−16−

Page 28

Utility high line

eter box

House circuit breaker

XWY

X

WY

Transfer

switch

XWY

Generator

Generator

(W)

OR

(X)(

)

Y

(G)

240V

4P- Receptacle

(c) Operating the generator.

■

Set the full power switch to 120V/240V side.

■

Turn the house AC breaker off before starting the generator.

■

Start the generator and warm it up.

■

Turn the house AC breaker on.

Y

120V

appliance

120V

appliance

(W)

W

X

(X)(Y)

(G)

240V

4P- Receptacle

240V

appliance

CAUTION

[

]

Do not start the generator with electrical appliance (s) connected and

with their switches on.

Otherwise the appliance (s) may be damaged by the surge voltage at

starting.

−17−

Page 29

NOTE :

When the no-fuse breaker turns off during

operation, the generator is over loaded or

the appliance is defective. Stop the

generator immediately, check the

appliance and / or generator for

overloading or detect and have repaired

as necessary by Makita dealer or service

shop.

(d) Turn the breaker on to see if the pilot

lamp lights up.

(e) Turn on the switch of the appliance.

ON

OFF

PILOT LAMP

−18−

Page 30

(3) IDLE CONTROL SWITCH

IDLE

CONTROL SWITCH

automatically reduces engine speed when load is OFF,

and automatically increases engine speed to rated r.p.m. when load is ON.

IDLE

CONTROL SWITCH

provides fuel economy and low noise operation at no-

load running.

(1) HOW TO USE

SWITCH

■

Start the engine with IDLE

SWITCH

off.

IDLE

CONTROL

ON

CONTROL

NOTE :

Warm up the engine without a load for a

few minutes.

■

Turn IDLE

CONTROL SWITCH

on.

OFF

(2) CHECKING THE OPERATION

When

IDLE

CONTROL SWITCH does not operate normally, please check following :

■

Overloaded ?

Please make it sure that the generator is not overload.

NOTE :

Most induction loads such as electric motors require three to five times more

wattage than their ratings during starting.

This starting wattage should not exceed the rated output of the generator for

proper operation of IDLE

■

Turn IDLE

CONTROL SWITCH

CONTROL SWITCH

off when the IDLE

.

CONTROL SWITCH

does

not work normally under the rated output.

NOTE :

The IDLE

40W. In such cases turn the IDLE

CONTROL SWITCH

may not operate when the applied load is under

CONTROL SWITCH

off.

−19−

Page 31

STOPPING THE GENERATOR

(1) Turn off the power switch of the

electric equipment.

(2) Turn the no-fuse breaker to off.

(3) Unplug the cord from receptacle of the

generator.

(4) Allow the engine to run at no-load for

about 3 minutes to cool down before

stopping.

(5) Turn the key switch to the STOP

position.

STOP

STOP

RUN

RUN

START

ON

OFF

START

(6) Close the fuel cock.

CLOSE

CLOSE

OPEN

−20−

Page 32

6. WATTAGE INFORMATION

Some appliances need a "surge" of energy when starting.

This means that the amount of electrical power needed to start the appliance may

exceed the amount needed to maintain its use.

Electrical appliances and tools normally come with a label indicating voltage,

cycles/Hz, amperage (amps) and electrical power needed to run the appliance or

tool.

Check with your nearest dealer or service center with questions regarding power

surge of certain appliances or power tools.

■

Electrical loads such as incandescent lamps and hot plates require the same

wattage to start as is needed to maintain use.

■

Loads such as fluorescent lamps require 1.2 to 2 times the indicated wattage

during start-up.

■

Loads for mercury lamps require 2 to 3 times the indicated wattage during

start-up.

■

Electrical motors require a large starting current. Power requirements depend

on the type of motor and its use. Once enough "surge" is attained to start the

motor, the appliance will require only 50% to 30% of the wattage to continue

running.

■

Most electrical tools require 1.2 to 3 times their wattage for running under load

during use. (For example, a 9,000 watt generator can power a 3,200 to 7,000

watt electrical tool.)

■

Loads such as submersible pumps, air conditioners and air compressors

require a very large force to start. They need 3 to 5 times the normal running

wattage in order to start. (For example, a 5,000 watt generator would only be

able to drive a 1,800 to 3,100 watt pump.)

■

If the power consumption of electrical appliances exceeds the operating range

or if there is short circuit or other problems in the appliances, the AC breaker

could trip "OFF" or the rotation of the generator could be abnormally reduced.

In this case, stop the generator to see if the power consumption of the

appliances is too large and if there is a problem in the appliances.

■

The frequency (the number of the generators rotation) was adjusted before the

time of shipment. Changing the frequency could result in the generators

breakdown, so refrain from changing it.

−21−

Page 33

To determine the total wattage required to run a particular electrical appliance or

tool, multiply the voltage figure of the appliance/tool by the amperage (amps)

figure of same. The voltage and amperage (amps) information can be found on a

name plate which is normally attached to electrical appliances and tools.

Applicable Wattage (W)

Applications

Incandescent lamp, Heater 9,500

Fluorescent lamp, Electric tool 4,700

Pump, Compressor 2,400

G12010R

60 Hz

NOTE :

■

The above wattage chart is general guide only. Refer to your specific

appliance for correct wattage.

■

When you use two or more alternating current outlets at a time, be careful that

the sum of the appliances' power consumption does not exceed the value

specified in the above chart.

VOLTAGE DROP IN ELECTRIC EXTENSION CORDS

When a long electric extension cord is used to connect an appliance or tool with

the generator, a certain amount of voltage drop occurs in the extension cord which

lessens the effective voltage available to the appliance or tool.

The chart below has been prepared to illustrate the approximate voltage loss when

an extension cord of 300 feet (approx. 100 meters) is used to connect an

appliance or tool to the generator.

Nominal

cross

section

mm

0.75 18 7 30/0.18 2.477 2.5V 8V

1.27 16 12 50/0.16 1.486 1.5V 5V 7.5V 12V 15V 18V

A.W.G.

2

2.0 14 17 37/0.26 0.952 1V 3V 5V 8V 10V 12V 15V

3.5 12 to 10 23 45/0.32 0.517

5.5 10 to 8 35 70/0.32 0.332

Allowable

current

No. A 1A 3A 5A 8A 10A 12A 15A

No.of strands

/ strands dia.

No./mm

Resistance

Ω/100m

Current Amp.

12.5V

─ ─ ─ ─

1.5V 2.5V 4V 5V 6.5V 7.5V

─

1V 2V 2.5V 3.5V 4V 5V

─

−22−

─

Voltage drop

Page 34

7. SPARK ARRESTER

SPARK ARRESTER

In a dry or wooded area, it is recommendable to use the product with a spark arrester.

Some areas require the use of a spark arrester. Please check your local laws and

regulations before operating your

product

The spark arrester must be cleaned regularly to keep it functioning as designed.

A clogged spark arrester :

● Prevents the flow of exhaust gas

● Reduces engine output

● Increases fuel consumption

● Makes starting difficult

If the engine has been running, the muffler and the spark arrester will be very hot.

Allow the muffler to cool before cleaning the spark arrester.

MUFFLER

SPARK

ARRESTER

SCREEN

SCREW

.

How to remove the spark arrester

1. Remove the flange bolts from the

muffler cover and remove the muffler

cover.

2. Remove the special screw from the

spark arrester and remove the spark

arrester from the muffler.

SPARK ARESSTER SCREEN

Clean the spark arrester screen

Use a brush to remove carbon deposits

from the spark arrester screen.

Be careful to avoid damaging the screen.

The spark arrester must be free of

breaks and holes. Replace the spark

arrester if it is damaged.

Install the spark arrester, and muffler

protector in the reverse order of

disassembly.

−23−

Page 35

8. MAINTENANCE SCHEDULE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION CONTROL DEVICES

AND SYSTEMS MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIR

ESTABLISHMENT OR INDIVIDUAL.

DAILY INSPECTION

Before running the generator, check the following service items:

Safe surroundings

Leakage of gasoline and engine oil

Clean air cleaner element

Enough gasoline

Excessive vibration,noise

Enough clean engine oil

Loose or broken bolts and nuts

PERIODIC MAINTENANCE

Periodic maintenance is vital to safe and efficient operation of your generator.

Check the table below for periodic maintenance intervals.

IT IS ALSO NECESSARY FOR THE USER OF THIS GENERATOR TO

CONDUCT THE MAINTENANCE AND ADJUSTMENTS ON THE EMISSIONRELATED PARTS LISTED BELOW TO KEEP THE EMISSION CONTROL

SYSTEM EFFECTIVE.

The emission control system consists of the following parts :

(1) Carburetor and internal

parts

(2) Cold start enrichment

system, if applicable

(3) Intake manifold, if

applicable

The maintenance schedule indicated in the table is based on the normal generator

operation. Should the generator be operated in extremely dusty condition or in

heavier loading condition, the maintenance intervals must be shortened depending

on the contamination of oil, clogging of filter elements, wear of parts, and so on.

(4) Air cleaner elements

(5) Spark plug

(6) Magneto or electronic

ignition system

(7) Spark advance/retard

system, if applicable

−24−

(8) Exhaust manifold, if

applicable

(9) Hoses, belts,

connectors, and

assemblies

Page 36

(Periodic Maintenance Schedule table)

Maintenance Items

Clean generator and check bolts and nuts

Check and refill engine oil

Change engine oil (*Note 1)

Replace engine oil filter (*Note 1)

Check battery electrolyte fluid level

Clean spark plug

Clean air cleaner

Replace air cleaner element

Clean fuel strainer

Clean and adjust spark plug and electrodes

Replace spark plug

Spark arrester

Remove carbon from cylinder head

Clean and adjust carburetor

Clean engine base (oil pan)

Check and adjust valve clearance

Check and replace carbon brushes

Replace fuel lines

Overhaul engine (*Note 2)

Every 8

hours

(Daily)

● (Daily)

●

(Refill daily to

upper level)

*Note 1 : Initial oil change should be performed after first twenty (20) hours of operation.

Thereafter change oil every hundred (100) hours.

Before changing oil, check for a suitable way to dispose of old oil.

Do not pour it down into sewage drains, onto garden soil or into open streams.

Your local zoning or environmental regulations will give you more detailed

instructions on proper disposal.

*Note 2 : As to the procedures for these items, please refer to the SERVICE MANUAL or

consult your nearest Makita service dealer.

*Note 3 : More frequent oil changing, oil filter replacement and air cleaner service on

replacement may be necessary depending on operating conditions.

This would include dusty environment, high ambient temperature, heavy engine

loading.

Every

20

hours

●

(Initial)

●

(Initial)

Every

hours

Every

50

hours

(Every 100 hours)

●

●

●

●

(Every 100 hours)

●

200

●

●

●

●

Every

500

hours

●

●

●

●

●

●

Every

1000

hours

(Yearly)

−25−

●

●

Page 37

9. "HOW-TO" MAINTENANCE

ENGINE OIL CHANGE

■ Initial oil change

・・・・・After 20 hours of operation

■ Thereafter

・・・・・Every 100 hours of operation

1. When changing oil, stop the engine and

loosen the drain plug.

2. Re

-install the drain plug before refilling

oil.

3. Refer to the recommended oil table on

page 6.

4. Always use the best grade and clean

oil. Contaminated oil, poor quality oil

and shortage of oil cause damage to

engine or shorten the engine life.

Oil capacity

・・・・・

0.41 US-gal (Upper level)

1.55 liters (Upper level)

ENGINE OIL FILTER

REPLACEMENT

■ Initial engine oil filter replacement

should be performed after 20 hours of

operation. Thereafter replace the engine

oil filter every 200 hours.

OIL DRAIN PLUG

(ON BOTH SIDE)

OIL FILTER

OIL FILLER CAP

■ When installing a new oil filter, apply oil

to O-ring, attach the oil filter in position

and tighten 2/3 turns by hand or with

wrench after touching the O-ring to the

sealing surface of engine.

■ Run the engine for a minute ; stop the

engine and check for oil leakage around

the oil filter and recheck the oil level.

−26−

CAUTION

To prevent injury, pay attention

to the spilled hot engine oil

when replacing engine oil filter.

Page 38

SERVICING AIR CLEANER

Air cleaner coverKnob

A dirty air cleaner element will cause

starting difficulty, power loss, engine

malfunctions, and shorten engine life

extremely.

Always keep the air cleaner element

clean. Replaced the air cleaner element

set more often in dusty environments.

The air cleaner paper inner element and

urethane foam outer element can be

removed after removing knob and air

cleaner cover. When installing, set the

paper element and urethane foam on the

thane foam

Grommet

Element

air cleaner base. Check that the grommet

is in position, and then install the cover

with knob tightened securely.

■ Urethane Foam cleaning

Wash and clean the urethane foam in

kerosene. Saturate in a mixture of 3

parts kerosene and 1 part engine oil, and

then squeeze to remove excess oil.

Clean or replace the urethane foam

element every 50 hours. (more often in dusty environments)

■ Paper element

Clean by tapping gently to remove dirt and blow off dust. Never use oil.

Clean or replace the paper element every 50 hours of operation, and replace

element set every 200 hours.

CLEANING AND ADJUSTING

SPARK PLUG

(a) Unplug the high-voltage cables

(located at the outlet panel and leadacid battery).

(b) Using the supplied plug wrench and

handle, turn it counterclockwise until it

comes off.

(c) Clean the area around the mounting

hole.

−27−

0.03 in.

(0.7 to 0.8 mm)

Page 39

(d) Clean the electrodes if they are dirty.

Adjust the clearance to 0.03 in. (0.7-

0.8 mm). Replace it with a new one if

the abrasion has developed to the

degree where a flat surface cannot be

obtained on its projection.

If the electrodes turn black, also

inspect the air cleaner.

(e) Attach and tighten the plug with the

specified torque : 25 to 30 Nm (2.5 to

3.0 kg-m).

(f) After checking that the contact area

inside the plug cap is not corroded,

connect the high-voltage cables.

CLEANING FUEL STRAINER

Dirt and water in the fuel are removed by

the fuel strainer.

(a) Remove the strainer cup and throw

away water and dirt.

(b) Clean the screen and strainer cup

with gasoline.

(c) Tightly fasten the cup to main body,

making sure to avoid fuel leak.

Spark plug

NGK BPR5ES (CHAMPION RN11YC)

FUEL HOSE REPLACEMENT

WARNING

Take extreme caution when replacing

fuel hose ; gasoline is flammable.

Replace the fuel hose every 1,000 hours

or every year.

If fuel hose leak is found, replace the fuel

hose immediately.

−28−

Page 40

CHECKING CARBON BRUSH

If the brush become excessively worn, its

contact pressure with the slip ring

changes and causes a roughened surface

on the slip ring, resulting in irregular

generator performance.

Check the brush every 500 hours or if

generator performance is irregular.

If the brush is 0.2 in.(5 mm) long or less,

replace it with a new one.

(a) Remove the brush cover.

(b) Disconnect the wire connector and

remove the brush.

(c) Carefully note the brush direction and

relative position with the slip ring when

installing new brush.

BRUSH

HOLDER

15 to 5 mm

(0.6" to 0.2")

FLANGE

BOLT

BRUSH

BRUSH

HOLDER

SCREW

BRUSH

COVER

−29−

Page 41

10. PREPARATION FOR STORAGE

The following procedures should be followed prior to storage of your generator for

a period of 6 months or longer.

■

Drain fuel from fuel tank and strainer

(cup) carefully by disconnecting the

fuel line. Gasoline left in the fuel tank

will eventually deteriorate making

engine-starting difficult.

■

In order to remove the fuel in the

carburetor, run the engine at no-load

until it stops.

■

Disconnect the terminal of the battery.

■

Change engine oil.

■

Check for loose bolts and screws, tighten them if necessary.

■

Clean generator thoroughly with oiled cloth. Spray with preservative if

available. NEVER USE WATER TO CLEAN GENERATOR !

■

Store generator in a well ventilated, low humidity area.

SCREW for DRAIN

−30−

Page 42

11. TROUBLESHOOTING

When generator engine fails to start after several attempts, or if no electricity is

available at the output receptacles, check the possible causes in accordance with

the following table. If your generator still fails to start or generate electricity,

contact your nearest Makita dealer or authorized service center for further

information or corrective procedures.

Possible causes

Fuel piping

Blown fuse

Problem

Low battery

Deteriorated fuel

Leakage

Clogging

Clogging of Air cleaner

Low oil level

Faulty spark plug

Clogging of Cooling air intake

Overload by connected appliance

Incorrect or poor connection of wires

Insufficient capacity of extension cable

Carbon brushes are excessively worn

Starter won't run

Starter runs, but Engine won't start.

Rotation decreased

Unstable rotation

Breaker turned off

During operation

Low power

× ×

× × × × ×

× × × × × ×

× ×××

×

×

×

×

× × × × × × ×

−31−

× ×

Page 43

12. WIRING DIAGRAM

Auto choke

(

Bimetal

Ignition coil

Exciting

coil

(

)

AVR

)

-

Blk15

Battery 12V

Winding

Y

Y

Field

Blk

Fuel cut

Charge

coil

Blk

+

Idle

solenoid

Blk/Y

Electric

starter

Regulator

R15

Blk

AC Winding 1AC Winding 2

Blu

R

CONTROL BOXGENERATOR

R

R

Blk/W

Blk

Grn

W

W

Org

R

Magnetic

switch

Gry

Oil pressure

switch

W

W

VHr

CONTROL BOX

Idle control

switch

AC output

receptacle

(120V) REC1

PL

Voltmeter

LGrn

R/W

Blk/W

Blk

(AC output)

LBlu

2

1

53

4

Idle

control

unit

Org

R

Grn/Y

Grn/Y

LBlu

to earth

terminal

ST Relay

Blk

Idle

unit

control

w w

R

AC otuput

receptacle(120V)

Pilot lamp

1

Electronic control unit

Y

LBlu

Org

OFF

ON

START

AC output

receptacle

(120/240V) REC3

Grn/Y

REC2

2133124115106

987

Brn

-

M+M B

Grn/Y

LBlu

Grn

Gry W

AC output

receptacle

(120/240V) REC4

Grn

Gry

L.IG

W

W

ST

Connector

(

Oil pressure

warning lamp

(

Red

Org

Grn/Y

Grn/Y

Org

Grn

Gry

Key

switch

Remote control

W

)

WW

W

)

BrushBrush

Auxiliary Winding

LGrn

Brn

W W

No-fuse breaker

AVR

Grn/Y Grn/Y

Wiring color cord

:

Blk/W Black/White Grn Green W White

:

Blu Blue Grn/W Green/White Y Yellow

:

LBlu Light blue Org Orange Pik Pink

:

Brn Brown Gry Gray Grn/Y Green/Yellow

:

−32−

Y

Y

:

:

:

:

:

Exciting coil

(Engine)

Auto idle unit

Grn/Y

to Key switch

Grn/Y

Earth(Ground)

terminal

Blk/RBlk Black Brn/W Brown/White R Red

:

:

:

:

:

R/W

LGrn

Black/Red

:

Red/White

:

Light green

:

Page 44

Makita Corporation

3-11-8, Sumiyoshi-cho

Anjo, Aichi 446-8502 Japan

PRINTED IN JAPAN

October 2004 CE-SK 100

Loading...

Loading...