Page 1

T

ECHNICAL INFORMATION

Models No.

Description

DF030D (FD01*)

10.8V Cordless Driver Drill

* Model number for North and Central American

countries except Mexico and Guam

PRODUCT

P 1/ 4

L

CONCEPT AND MAIN APPLICATIONS

Model DF030D is a 10.8V cordless driver drill compact and lightweight

for easy handling, but featuring 2-speed gear selection with variable speed

in each range for a wide range of applications.

Uses new 10.8V Li-ion battery of stick type as a power unit.

This product is available in the following variations.

Model No.

DF030D

DF030DW

DF030DWE

DF030DWEW

The models also includes the accessories listed below in "Standard equipment".

Battery

type quantity

BL1013

(Li-ion 1.3Ah)

2

Charger

DC10WA

Specification

Type of cell

Voltage: V

Battery

Max. output: W

No load speed: min-1 = rpm

Driving shank: mm (")

Capacities: mm (")

Max. fastening torque:

N.m (in.lbs)

Electric brake

Variable speed control by trigger

Mechanical 2-speed

Reverse switch

LED job light

Net weight [with battery BL1013]: kg (lbs)

Capacity: Ah

Charging time (approx.): min.

Low

High

Steel

Wood

Soft joint

Hard joint

Plastic

carrying case

Yes

18 stages + drill modeTorque adjustment

Housing

color

Makita-blue

white

Makita-blue

white

Li-ion

10.8

1.3

50

with DC10WA

115

0 - 350

0 - 1,300

6.35 (1/4) Hex

10 (3/8)

21 (13/16)

14 (120)

24 (210)

0.5 - 3.5 (4 - 30)Clutch torque setting: N.m (in.lbs)

22 (200)Lock torque: N.m (in.lbs)

Yes

Yes

Yes

Yes

Yes

0.88 (1.9)

W

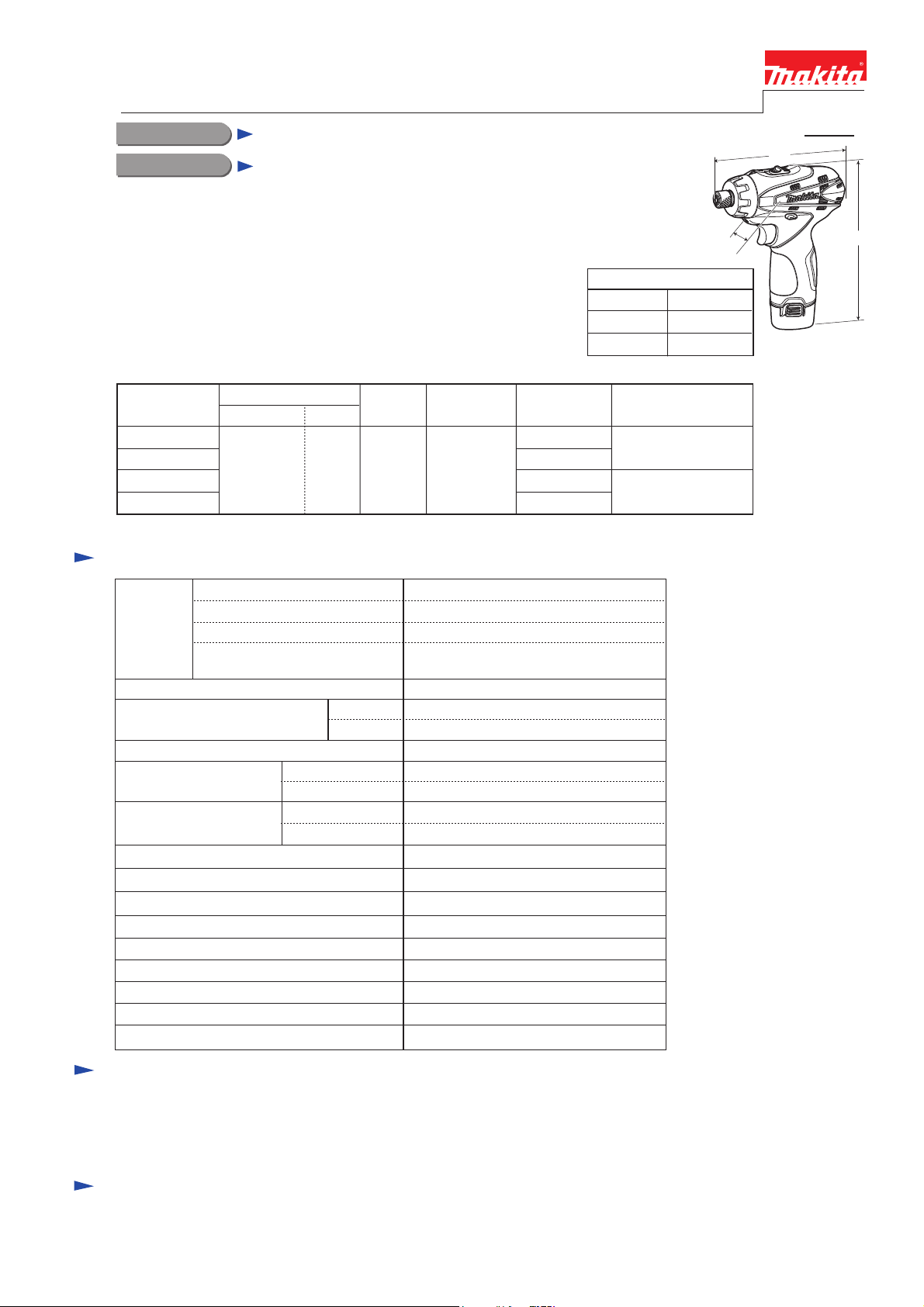

Dimensions: mm (")

Length (L) 157 (6-3/16)

Width (W)

Height (H)

All countries except

the four listed above

53 (2-1/16)

183 (7-1/4)

Offered to

USA, Canada

Mexico, Panama

H

Standard equipment

Phillips bit 2-50 (double-end) ........ 1 pc (for countries using M-type spindle)

Phillips bit 2-45 (double-end) ........ 1 pc (for countries using N-type spindle)

Holster ............................................ 1 pc

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Driver bits, Socket bits, Hex shank drill bits for wood, Hex shank drill bits for steel, Bit piece,

Drill chuck, Charger DC10WA, Battery BL1013

Page 2

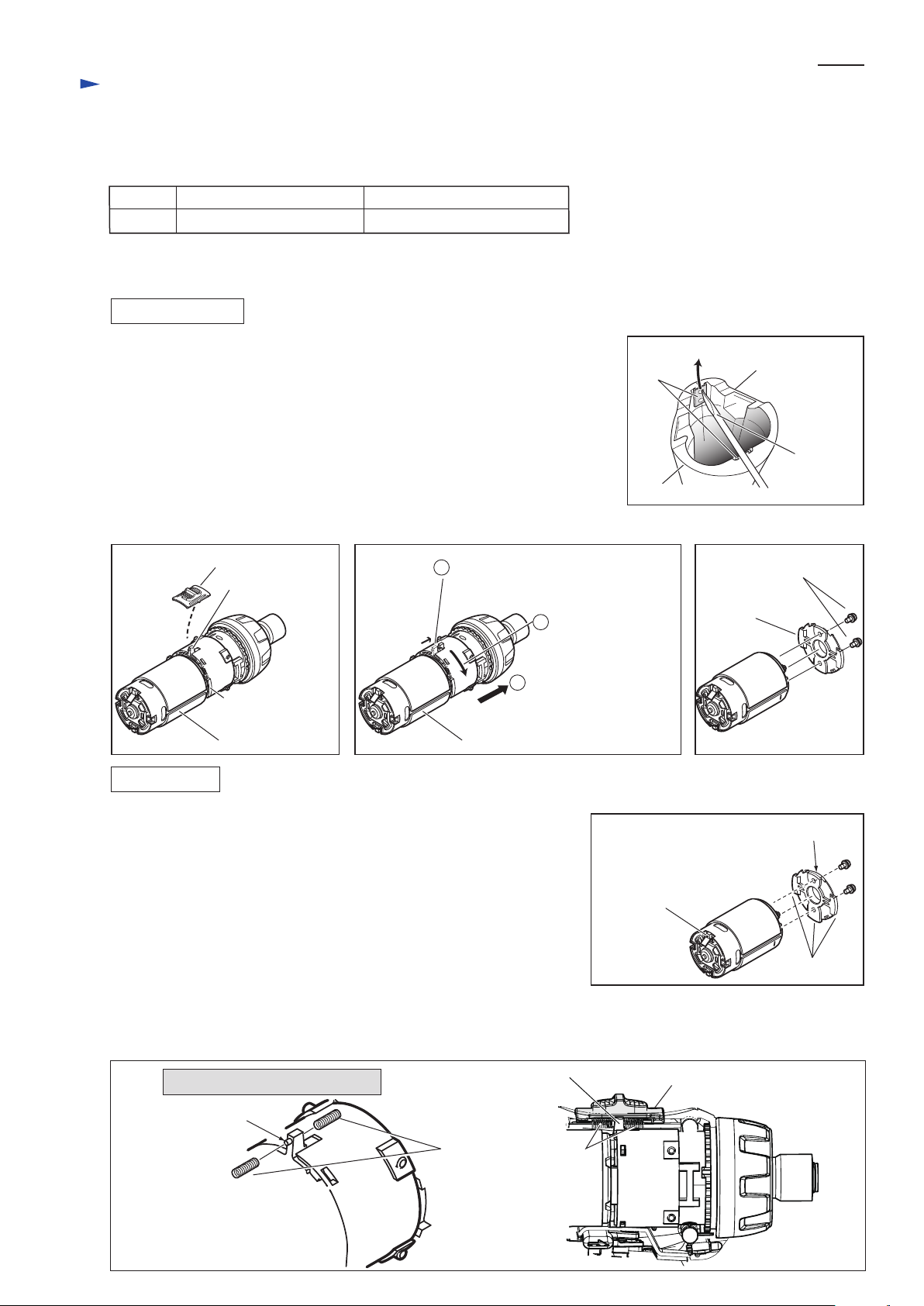

1) Remove two Set plates with which Handles (L) and (R) are assembled to one

another as follows:

Insert a small slotted screwdriver through the punched hole of Set plate and

move Set plate in the direction of the arrow using the screwdriver. (Fig.1)

2) Remove Housing (R) from Housing (L) by loosening six Bind PT3x6 tapping

screws.

3) Remove Speed change lever assembly from Gear assembly. (Fig. 2)

4) Remove DC motor from Gear assembly as illustrated in Fig. 3

5) Separate DC motor from Bracket by loosening two M3x6 Pan head screws.

(Fig. 4)

1) Fix Motor bracket to DC motor with two M3x6 Pan head screws.

Note: Align the red marking on DC motor with non-convex portion of

Motor bracket. (Fig. 5)

2) Fix Gear assembly to DC motor with bracket and turn Gear assembly

clockwise.

Note: Align the change lever of Gear assembly with the red marking on

DC motor. (Fig. 3)

3) Fix Speed change lever assembly to the change lever of Gear assembly as

illustrated in Fig. 2.

Note: Set the change lever of Gear assembly in place between two

Compression springs 4 on the reverse side of Speed change lever

assembly, and insert the emboss of the change lever into one of

Compression spring 4. (Fig. 6)

Repair

P 2/ 4

[2] DISASSEMBLY/ASSEMBLY

[3]-1. DC Motor, Gear Assembly, Speed Change Lever Assembly

Fig. 2 Fig. 4Fig. 3

DISASSEMBLING

ASSEMBLING

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the bit and the battery from the machine for safety before

repair/ maintenance in accordance with the instruction manual!

DescriptionCode No. Use for

1R291 Removing/ Installing Bit sleeve

Fig. 1

Handle (R)

Handle (L)

small slotted

screwdriver

Set plate

(2pcs.)

Retaining ring S and R pliers

Speed change lever assembly

convex portion of

Motor bracket

change lever of

Gear assembly

change lever of

Gear assembly

Emboss of change lever

of Gear assembly

DC motor

Turn Gear assembly

counterclockwise.

Pull out Gear assembly

from DC motor with

Bracket.

DC motor

Motor bracket

M3x6 Pan head screws

(2pcs.)

1

Shift the change lever of Gear

assembly to the high speed position.

2

3

Fig. 5

Fig. 6

non-convex portion

Compression spring 4

Speed change lever assembly

red marking on

terminal of positive

pole

convex portions

Viewed from the upper position

Page 3

(4) After installing the assembled parts in place of Housing L, shift Speed change lever assembly to either low speed

position or high speed position.

(5) Fixing Housing (R) to Housing (L) with six Bind PT3x16 tapping screws.

(6) Insert two Set plates in place. (Fig. 1)

Set Leaf spring in place. (Fig. 8)

Note: Do not face the center edge of Leaf spring to Housing L.

Link the notch of F/R change lever and the protrusion of Switch,

then install them in Housing L. (Fig. 9)

Repair

P 3/ 4

[2] DISASSEMBLY/ASSEMBLY

[3]-1. DC Motor, Gear Assembly, Speed Change Lever Assembly (cont.)

ASSEMBLING

Fig. 9

Fig. 8

Fig. 7

[3]-3. Assembling Leaf Spring

[3]-4. Assembling F/R Change Lever

[3]-2. Disassembling Bit Holder of Gear Assembly

Sleeve

Ring spring 10

(1) While pushing the top of sleeve by your thumb to prevent Compression spring 13

from popping out from Bit holder, expand Ring spring 10 using 1R291 and raise

the opposite of the expanded Ring spring 10 by your index finger. (Fig. 7)

(2) Ring spring 10 can be removed.

And Flat washer 11, Compression spring 13, Bit sleeve and Steel ball 3 (2pcs.)

can be removed.

1R291

Leaf spring

center edge

Housing L

notch of F/R change lever

protrusion of Switch

Circuit diagram

Fig. D-1

SwitchTerminal

White

DC motor

red marking

Red

Color index of lead wires' sheath

Black

+ +

- -

M1

M2

LED

Page 4

P 4/ 4

Wiring diagram

Fig. D-2

Fig. D-3

Pay attention to the directions of lead wires and connect Flag receptacles

to electrical parts.

Refer to the following illustration.

Fig. D-4

Before installing Switch in Housing R, route Lead wires as illustrated below and connect two Connectors.

Do not ride their Lead wires on ribs.

Route Lead wires between ribs. Insert Connectors between

their Lead wire holders.

Bend the terminals of DC motor

as illustrated.

Flag receptacles and

Lead wires have to

be far from DC motor.

Do not ride them

on the ribs.

Lead wires holders

Do not ride Lead wires on their embosses.

Face the glue-attached portion of LED

to DC motor side.

Terminal DC motor

Connector

Lead wire holders

LED

Lead wires in this area

must be tight.

red marking

Connector

(To Switch)

Loading...

Loading...