Page 1

T

ECHNICAL INFORMATION

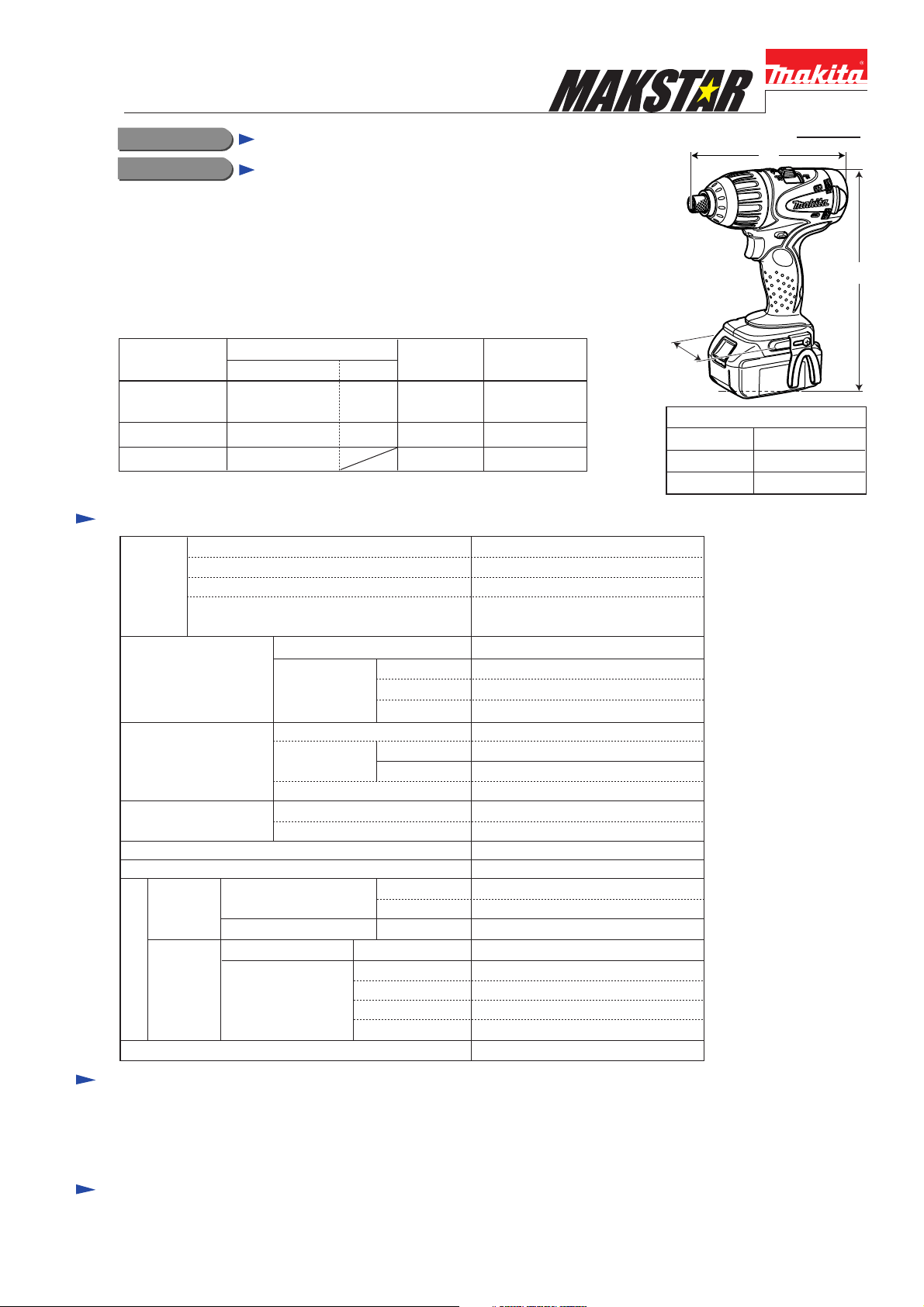

Models No.

Description

BTP140

Cordless 4 Mode Impact Driver

CONCEPT AND MAIN APPLICATIONS

Model BTP140 has been developed as the 18V sister tool to Model BTP130.

Uses BL1830, 18V slide-on type Li-ion battery as a power unit,

and features the same high performance and versatility as Model BTP130.

This new product is available in the following variations.

Model No.

BTP140SFE

BTP140*

BTP140RFE BL1830 DC18RA2 Yes

BTP140Z No No No

Specification

Voltage: V 18

Capacity: Ah

Battery

Max. fastening torque:

N.m (in.lbs)

No load speed:

min-1=rpm

Impacts per minute:

min-1=ipm

Torque setting on clutch (screwdriver) mode

Clutch torque range: N.m (in.lbs) 0.5 - 2.0 (4.4 - 17.7)

Capacity

Net weight: kg (lbs) [with BL1830]

Cell

Charging time: min.

Drilling:

mm (")

Fastening

Drill mode

Percussion-drill mode

Screwdriver mode

Impact-driver mode

Battery

type quantity

BL1830 DC18SC

*Model name for USA, Canada, Mexico, Panama

Impact-driver mode

Drill mode

Impact-driver mode 0 - 2,300

Drill mode

Screwdriver mode 0 - 2,300

Impact-driver mode 0 - 3,200

Percussion-drill mode

2 Yes

Small screw M4

Small screw

Standard bolt

High tensile bolt

Coarse-thread

Charger

Soft joint

Hard joint 50 (443)

Lock torque 10 (88.5)

Low

High

Wood 21 (13/16)

Steel

Masonry

Plastic

carrying case

3.0

Li-ion

approx. 45 with DC18SC

approx. 22 with DC18RA

140 (1,240)

10 (88.5)

0 - 700

0 - 2,300

0 - 27,600

16

10 (3/8)

8 (5/16)

M4 - M8

M5 - M14

M5 - M12

22 - 125mm

1.8 (3.9)

W

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

PRODUCT

P 1 /16

L

H

186 (7-3/8)

79 (3-1/8)

246 (9-11/16)

Standard equipment

Belt clip ................................... 1

Plastic carrying case ................ 1

Keyless chuck .......................... 1 (for North American countries only)

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Assorted bits, Assorted drill chucks, Adjustable locator, Keyless chuck, Bit piece

Charger DC18SC, Charger DC18RA, Charger DC24SA, Charger DC24SC, Li-ion battery BL1830

Shoulder belt for plastic carrying case

Page 2

P 2 /16

Repair

CAUTION: Remove the saw blade from the machine for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

1R003 Retaining ring pliers for shaft Removing/attaching Retaining ring from/to Shaft

1R045 Gear extractor (large) Disassembling Hammer section

1R212 Tip for retaining ring pliers Modular use with 1R003

1R282 Round bar for arbor 8-50 Modular use with 1R045

1R288 Screwdriver magnetizer Magnetizing screwdriver with which Steel balls are removed.

1R291 Retaining ring S and R pliers Disassembling Bit holder section

1R346 Center attachment for 1R045 Modular use with 1R045

1R351 Anvil holding jig Removing Anvil from Gear case

1R357 Cam A setting jig Assembling Cam A

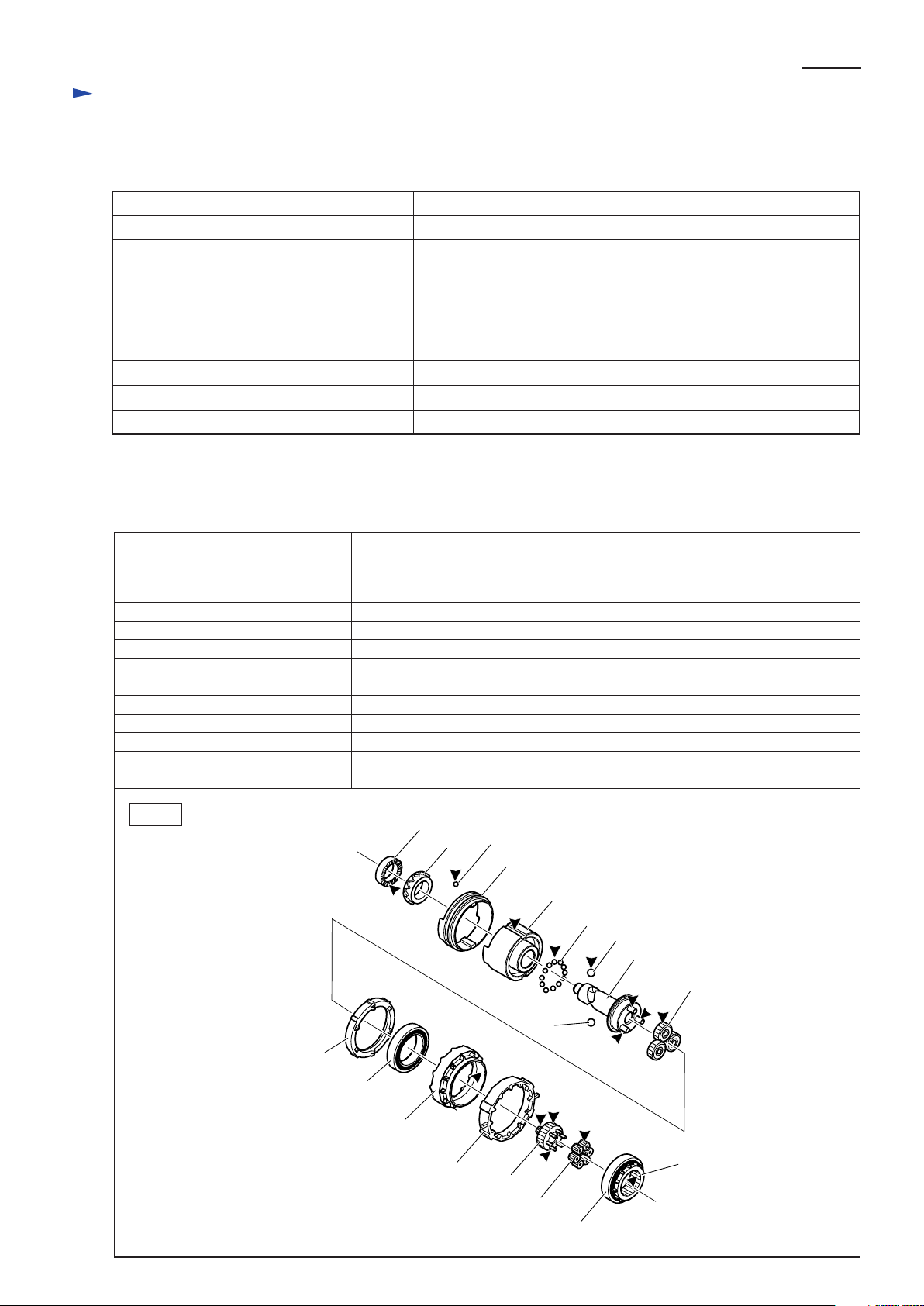

[2] LUBRICATION

Apply Makita grease N. No.2 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion.

Item No. Description Portion to lubricate

40

42

58

59

63

64

68

70

71

72

75

Fig. 1

Cam A Surface that contacts Cam B

Steel ball 3.5 (16 pcs) Whole surface

Hammer Groove that contacts Ring 40

Steel ball 3.5 (23 pcs) Whole surface

Steel ball 5.6 (2 pcs) Whole surface

Spindle complete Three axes for (70) Spur gear 22

Internal gear 50

Spur gear 22 (3 pcs)

Spur gear 7 complete

Spur gear 10 (6 pcs)

Internal gear 38

Inside surface that contacts (70) Spur gear 22

Teeth portion

Teeth portion and six axes for (72) Spur gear 10

Teeth portion

Teeth portion

40

Cam B

42

Ring 40

58

59

63

64

70

Clutch cam

Ball bearing 6805LLB

Clutch change lever

63

68

75

71

72

Ball Bearing 6805LLB

Page 3

P 3 /16

Repair

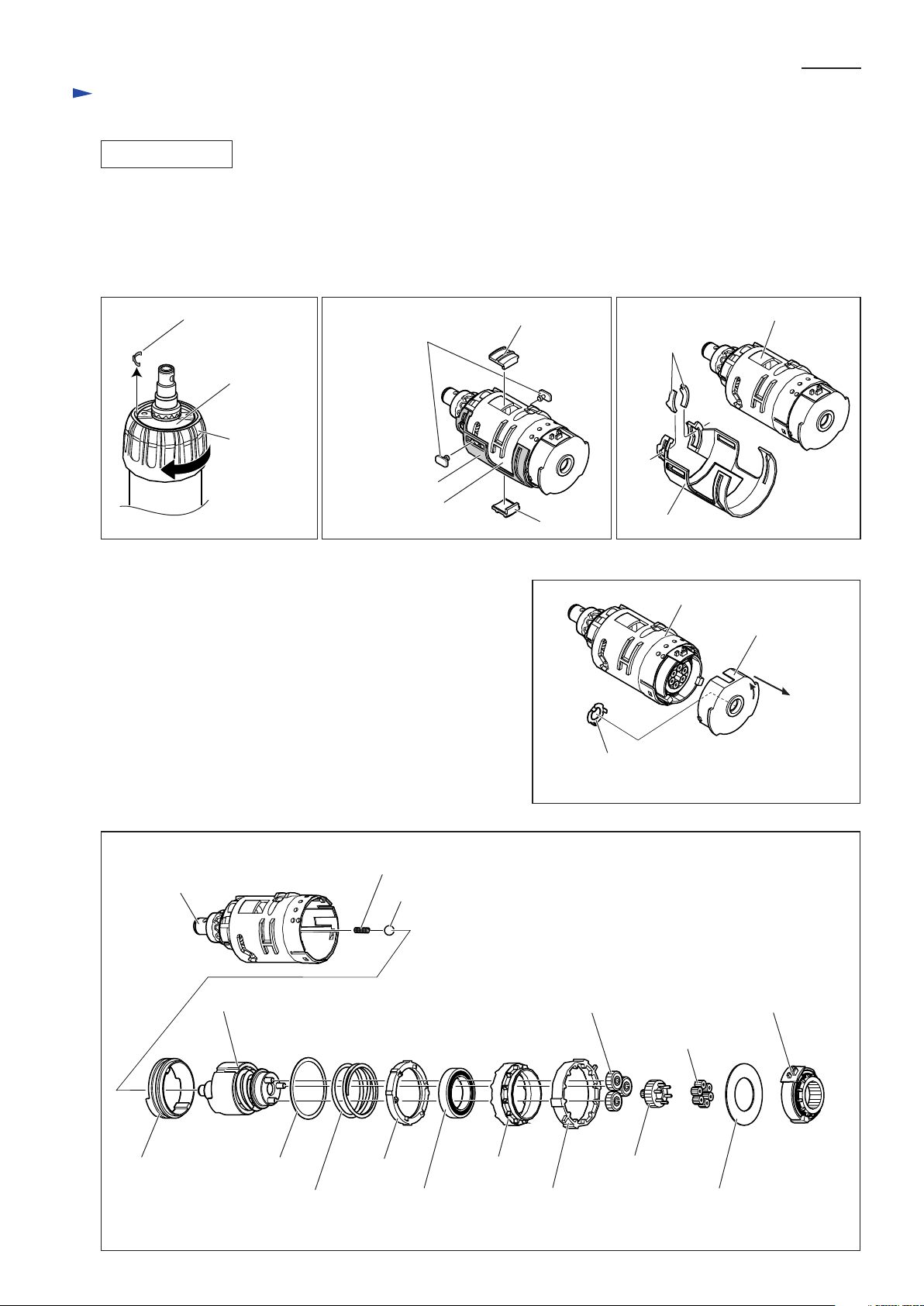

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Impact Assembly

DISASSEMBLING

1) Remove Rear cover by unscrewing two 3x16 Tapping screws and Housing R by unscrewing nine 3x16 Tapping screws.

The machine can now be disassembled as illustrated in Fig. 2.

2) Remove Ring spring 11 from the groove on Anvil. Component parts of Chuck section can now be removed from Anvil.

(Fig. 3)

3) Remove Bumper and two M4x16 Pan head screws. Hammer case can now be removed together with Ball bearing

6802LLB and Retaining ring R-24. (Fig. 4)

Fig. 2

Impact assembly

Housing L

Fig. 3

Chuck section

Compression spring 13

Ring spring 11 Sleeve

Motor section

Steel ball 3.5

groove

Anvil

Tapping screw 3x16 (9 pcs)

Housing R

Rear Cover

Tapping screw 3x16 (2 pcs)

Impact assembly

Anvil

Flat washer 12

Fig. 4

Pan head screw M4x16 (2 pcs)

Bumper

Hammer case Impact assembly

Steel ball 3.5

Two M4 Hex nuts are press-fitted in Gear case of

Impact assembly. Be careful not to get them out

of place when removing the Pan head screws.

Forcing the Pan head screws out of Gear case will

cause the Nuts to fall inside of gear case.

Hex nut M4 Gear case

Page 4

P 4 /16

Repair

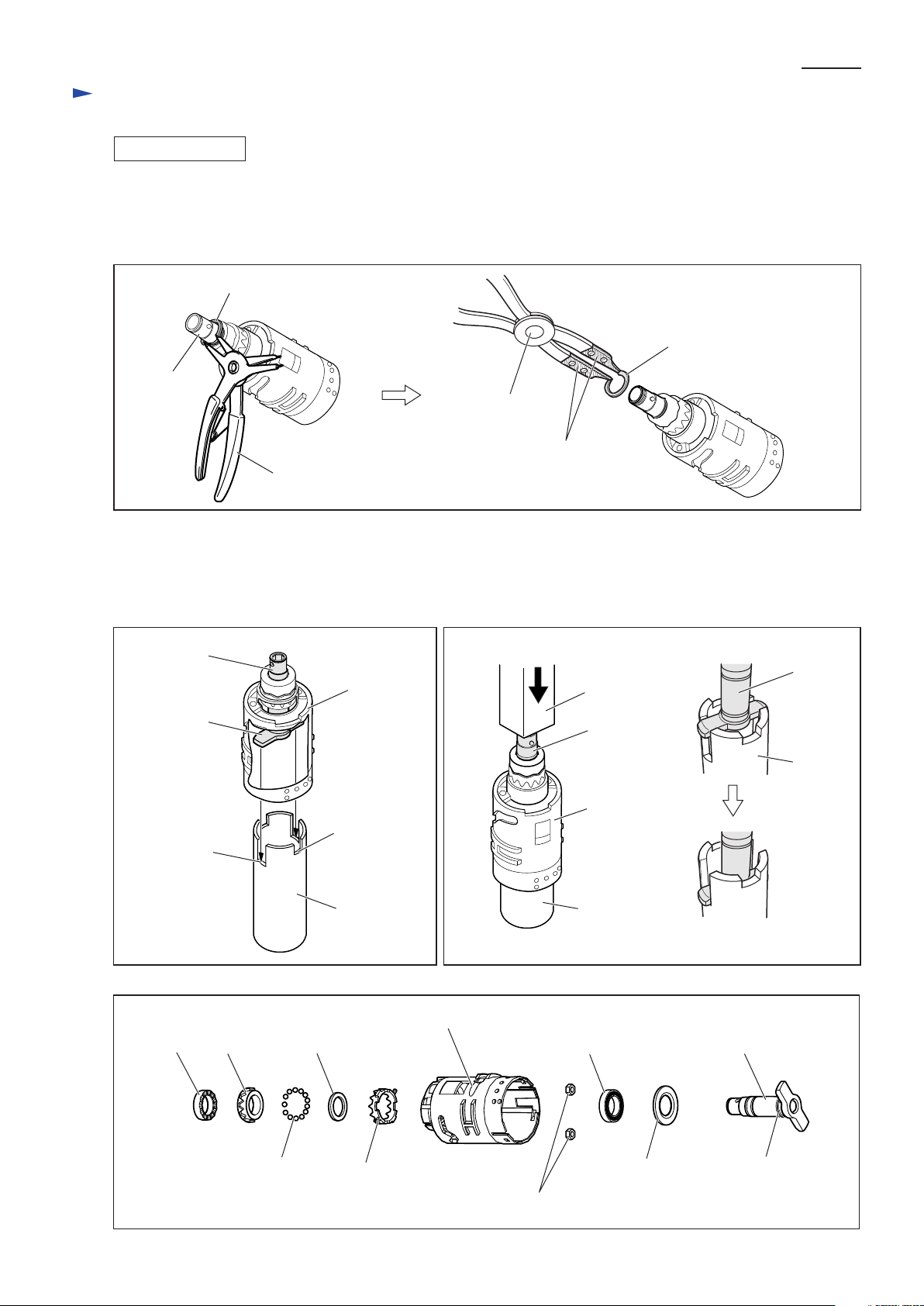

[3] -1. Impact Assembly (cont.)

DISASSEMBLING

4) Remove Leaf spring from the space between Gear case and Change ring. Remove Change ring from Gear case

while turning clockwise. (Fig. 5)

5) Remove Pusher U from Gear case, and Pusher L from Change case. Remove two assemblies of Guide and Shoulder

pin-3-6. (Fig. 6)

6) Remove Change case from Gear case. Remove two Plate A's from Change case. (Fig. 7)

Fig. 5 Fig. 6 Fig. 7

Leaf spring

Gear case

Change ring

7) Pull off Motor bracket from Gear case by turning a little bit

counterclockwise. (Fig. 8)

8) Impact assembly can now be disassembled as illustrated in Fig. 9.

assembly of Guide

and Shoulder pin 3-6

Change case

Gear case

Pusher U

Pusher L

Fig. 8

Gear case

Plate A

Change case

Gear case

Motor bracket

Washer 10 comes with Motor bracket

when Motor bracket is removed.

Fig. 9

Ring 40

Anvil

Hammer section

Flat washer 40

Compression Spring 4, removed from Anvil

Steel ball 7.1, removed from Anvil

Spur gear 22 (3pcs)

Clutch cam

Ball bearing 6805LLBCompression spring 41

Internal gear 50

Clutch change lever Flat washer 25

Speed change lever complete

Spur gear 10 (6pcs)

Spur gear 7 complete

Page 5

Repair

[3] -1. Impact Assembly (cont.)

DISASSEMBLING

9) Slide Retaining ring WR-15 a little out of the groove on Anvil using 1R291.

Then remove Retaining ring WR-15 from Anvil using 1R003 to which 2pcs of 1R212 are attached. (Fig. 10)

Note: Retaining ring WR-5 cannot be removed if it is stuck under Cam A.

If so, see Press-fitting Cam A in place on Anvil in page 5.

Fig. 10

Retaining ring WR-15

Retaining ring WR-15

Anvil

1R003

1R212

1R291

P 5 /16

10) Fit the T-shaped end of Anvil in the deep notch in 1R351. (Fig. 11)

11) Remove Anvil from Gear case by pressing down using arbor press. (Fig. 12)

12) The parts around Anvil can now be removed as illustrated in Fig. 13. Two M4 Hex nuts can also removed in this step.

Note: Be careful not to lose small parts such as Steel ball 3.5.

Fig. 11 Fig. 12

Anvil

Anvil

Gear case

T-shaped end

shallow notch

deep notch

1R351

Fig. 13

Arbor press

Anvil

1R351

Gear case

1R351

Cam BCam A

Steel ball 3.5

(16 pcs)

Flat washer 15

Gear case

Ball bearing 6802LLB

Hex nut M4

Anvil

O ring 12.5Nylon washer 15Hammer change lever

Page 6

P 6 /16

Repair

[3] -1. Impact Assembly (cont.)

DISASSEMBLING

Press-fitting Cam A in place on Anvil

Retaining ring WR-5 cannot be removed if it is stuck under Cam A. If so, put off Cam A from Retaining ring WR-5 by

press-fitting Cam A in place using 1R351, 1R357 and arbor press. (Fig. 14)

Fig. 14

1) Fit the T-shaped end of Anvil in the shallow

notches of 1R351.

2) Put 1R357 through Anvil and on Cam A

with the face A on the Cam side.

1R357

face B

face A

Cam A

Gear case

deep notch

face A

face B face A

T-shaped end

of Anvil

shallow notch

face B

3) Press down Cam A using arbor press until it stops

when the face B of 1R357 is flush with the upper end

surface of Anvil.

Arbor press

Anvil

1R357

Retaining ring

WR-15

Cam A

1R351

ASSEMBLING

1) Mount Ball bearing 6802LLB, Nylon washer 15 and two M4 Hex nuts to Gear case. (Fig. 15)

2) Fit O Ring 12.5 in the groove on Anvil, and set the T-shaped end of Anvil in the shallow notch of 1R351. (Fig. 16)

3) Put Gear case through Anvil on 1R351. (Fig. 17)

Fig. 15 Fig. 16

Gear case

Ball bearing 6802LLB

Nylon washer 15

Hex nut M4

O Ring 12.5

Anvil

shallow notch

1R351

Fig. 17

Gear case

Anvil

O Ring 12.5

1R351

Page 7

Repair

[3] -1. Impact Assembly (cont.)

ASSEMBLING

4) Fitting the projection of Hammer in the slit of Gear case,

assemble Hammer change lever to Gear case. (Fig. 18)

5) Put Flat washer 15 through Anvil and into Gear case. (Fig. 19)

6) Put sixteen 3.5 Steel balls in the space between Anvil and

Hammer change lever, and put Cam B through Anvil and on

Hammer change lever. (Fig. 20)

Note: Cam B is not reversible when assembled to Hammer

change lever. Be sure to place as illustrated in Fig. 21.

Fig. 18

Hammer change lever

projection

slit

1R351

P 7 /16

Fig. 19

Flat washer 15

Fig. 20

Cam B

Steel ball 3.5

(16 pcs)

Hammer change lever

When sixteen 3.5 Steel balls are put

in place correctly, there is a space

equivalent to half of the Steel ball.

7) See Fig. 22. Put Cam A through Anvil and on Cam B. Put 1R357 on Cam A with the face B on the Cam side.

Press down Cam A using arbor press until it stops when the face A of 1R357 is flush with the upper end surface of Anvil.

Remove 1R357 from Anvil.

8) Fit Retaining ring WR-15 in the groove on Anvil while expanding Retaining ring WR-15 using 1R291 and 1R003 to

which 2pcs of 1R212 are attached. (Fig. 23)

Fig. 22 Fig. 23

Arbor press

face A

1R357

face B

Fig. 21

Cam B

Correct Wrong

1R212

1R003

face A

face B

1R291

face B face A

Cam A

Anvil

Cam B

Retaining ring WR-15

1R351

Page 8

P 8 /16

Repair

[3] -1. Impact Assembly (cont.)

ASSEMBLING

9) See Fig. 24. Assemble two Plate A's to Change case by sliding in the direction of the black arrows until they stop.

10) Assemble Change case to Gear case by fitting the two projections of Hammer change lever in the space on each side of

Change case. (Fig. 25)

Fig. 24 Fig. 25

Plate A

[A]

[B]

Change case

As illustrated to right, a space is

provided between Plate A and

Change case on each side for

inserting the projection of Hammer

change lever.

11) Hold Gear case with the bit holding side down, and put Ring 40 into Gear case so that the cam portions of Ring 40 is

engaged with the T-shaped end of Anvil. (Fig. 26)

12) Fit Pusher U and Pusher L to Gear case in the openings on Gear case as illustrated in Fig. 27.

Note: Be careful not to confuse Pusher R and Pusher L. A letter "U" is marked on the back of Pusher U while there is

no mark of identification on Pusher L.

Fig. 26

cam positions

Plate A assembled

correctly to Change case

viewed from the side [A]

space

Change case

Plate A

viewed from the side [B]

space

Fig. 27

projections of

Hammer change lever

Plate A

Change case

Pusher U

opening

Gear case

Ring 40

Anvil

13) While pressing Pusher U and Pusher L with fingers, mount two assemblies of Guide pin and Shoulder pin 3-6 to

Ring 40 which is mounted in Gear case in Fig. 25, by inserting the two Shoulder pins into the periphery groove of

Ring 40 through the slits of Gear case and Change case. (Fig. 28)

Fig. 28

You can see the periphery groove

of Ring 40 through the slits of

Gear case and Change case.

periphery groove

T-shaped end of Anvil,

engaged with Ring 40

opening

Pusher L

Pusher U

H-shaped projections

assembly of Guide

and Shoulder pin 3-6

Gear case

Ring 40

assembly of Guide

and Shoulder pin 3-6

Change case

Pusher L

Page 9

P 9 /16

Repair

[3] -1. Impact Assembly (cont.)

ASSEMBLING

14) While pressing Pusher U and Pusher L with fingers, fit the female threads on the inside of Change ring to the male

threads on Pusher U and Pusher L. Turn Change ring counterclockwise until it stops. (Fig. 29)

Note: If Change ring cannot be turned, check whether or not the Pushers are correctly mounted as illustrated in Fig. 28

on page 7.

15) Put Leaf spring in place between Gear case and Change ring. (Fig. 30)

Fig. 29 Fig. 30

Change ring

female threads

male threads

Gear case

Pusher L

16) Assemble Ball bearing 6802LLB and Retaining ring R-24 to Hammer case, and secure Hammer case to gear case with

two M4x16 Pan head screws. Put Compression spring 4, then Steel ball 7.1 into the hole of Spindle. (Fig. 31)

Note: Be careful not to get two M4 Hex nuts out of place when tightening the Pan head screws. (Fig. 4 in page 2)

17) Grasping the pins on Spindle complete with pliers, assemble Hammer section to Gear case with the raised portions

fitting in the groove on Hammer. (Fig. 32)

Fig. 31 Fig. 32

Pan head screw M4x16 (2 pcs)

Anvil

Pusher U

Steel ball 7.1

Leaf spring

raised portions groove on Hammer

Change ring

Gear case

pin on Spindle complete

Hammer case

18) Put Flat washer 40 and Compression spring 41 into Gear case. Then insert Clutch cam with the six raised portions on

the Clutch cam's periphery fitting in the corresponding grooves on the inside surface of Gear case.

Put Internal gear 50 into Gear case. (Fig. 33)

Note: Clutch cam is not reversible when assembled to Gear case. Be sure to place so that the cam side faces towards

Internal gear 50. (Fig. 33)

19) Assemble Clutch change lever to Gear case as illustrated in Fig. 34.

Fig. 33 Fig. 34

Flat washer 40

raised portions

There are six

projections on

the cam side.

raised portions

Compression spring 4

Compression spring 41

Clutch cam

Internal gear 50

Ring 40 Hammer section

Clutch change lever

Change case

Slide the two projections on Clutch change lever

along the slits on gear case until they stops.

Then put them through the slits on Change case.

pliers

projections

Page 10

Repair

[3] -1. Impact Assembly (cont.)

ASSEMBLING

20) See Fig. 35.

Put three 22 Spur gears through the pins on Spindle complete. Put Flat washer 25 on Internal gear 50.

Engage Spur gear 7 complete with three 22 Spur gears.

Mount Speed change ring complete to Gear case.

Put six 10 Spur gears through the six pins on Spur gear 7 complete.

Note: Be sure that every gear is engaged with adjacent gear(s).

Fig. 35

Flat washer 25Gear case

P 10 /16

Spur gear 22

(3 pcs)

21) Insert the notch on Motor bracket through the projection on Gear case until Motor bracket is set a little bit apart from

Gear case. (Fig. 36)

22) By turning Motor bracket, fit the projection on Motor bracket to the groove on gear case. Insert Motor bracket into

Gear case until it stops. Then secure Motor bracket to Gear case by turning clockwise. (Fig. 37)

Fig. 36 Fig. 37

projection notch

Spur gear 7 complete

*includes Ball bearing 6805LLB and Internal gear 38

groove

*Speed change

ring complete

Gear case

projection

Spur gear 10

(6 pcs)

Speed change ring complete

Motor bracket

Page 11

P 11 /16

Repair

[3] -2. Hammer Section

DISASSEMBLING

1) Take out Hammer section from the machine. (See Figs. 2 to 9.)

2) Install the following repair tools on Hammer section as illustrated in Fig. 38: 1R045; 1R346; 1R282

3) Hold Hammer section as illustrated in Fig. 39. Press down Hammer to the full by turning the handle of 1R045 in the

direction of the black arrow. Then adjust the opening for Steel ball insertion to the top of cam groove on Spindle by

turning the handle in the opposite direction. Two 5.6 Steel balls can now be removed from Spindle using tweezers or

a slotted screwdriver magnetized with 1R288.

4) Hold Hammer section as illustrated in Fig. 38, and release 1R045 from Hammer section by turning the handle.

Caution: Do not hold gear extractor as illustrated in Fig. 39 when releasing the Hammer section.

Failure to follow this instruction could cause most of twenty-four 3.5 steel balls to fall out of Hammer.

Fig. 38 Fig. 39

tighten

Spindle

loosen

1R045

top of cam groove

on Spindle

1R346

1R282

5) Remove Spindle complete, Cup washer 24 and Compression spring 24 from Hammer. (Fig. 40)

6) Remove Flat washer 24 and twenty-three 3.5 Steel balls from Hammer. (Fig. 41)

Fig. 40 Fig. 41

opening for Steel

ball insertion

Steel ball 5.6

Hammer

Compression

spring 24

Hammer

ASSEMBLING

Do the reverse of the disassembling steps.

(Refer to Figs. 41, 40, 39.)

Note: Make sure that twenty-three 3.5 Steel balls

are prepared before mounting. (Fig. 42)

Spindle complete

Cup washer 24

Fig. 42

There is a space equivalent to two 3.5 Steel balls in Hammer

when twenty-three 3.5 Steel balls are correctly mounted.

Steel ball 3.5: 23 pcs

Hammer

Steel ball 3.5 (23 pcs)

Flat washer 24

Hammer

Page 12

Repair

[3] -3. Motor Section

DISASSEMBLING

1) Take out Motor section by disassembling the the product

as illustrated in Fig. 2 on page 2.

2) Shift the tail of Torsion spring from Carbon brush onto the

notch on Brush holder to remove the suppressing force of

Torsion spring. And disconnect Carbon brush from

Commutator by pulling them off halfway. (Fig. 43)

It is not necessary to remove Carbon brush completely.

3) Separate Armature-Yoke unit assembly from Brush holder

complete. (Fig. 44)

4) Remove Armature from Yoke unit. (Fig. 45)

Fig. 44 Fig. 45

P 12 /16

Fig. 43

Carbon brush

Torsion spring

put on the notch

of Brush holder

Yoke unit Armature

Brush holder complete

ASSEMBLING

1) Assemble Motor section.

Note 1:

Yoke unit is not reversible when assembled to Armature. Be sure to assemble with the notch of Yoke unit on the

drive-end of Armature. (Fig. 46) If assembled wrong, Motor section could not be assembled to Housing (L).

Note 2:

Yoke unit is a strong magnet. When assembling Armature to Yoke unit, be sure to hold the commutator portion

as illustrated to left in Fig. 47. If you hold the Armature core as illustrated to right, your fingers could be pinched

between Yoke unit and the fan of Armature that is pulled strongly by the magnet force.

Fig. 46

Fig. 47

Put Armature-Yoke unit assembly

as illustrated below.

Yoke unit

Pull down Yoke unit

towards the work bench.

Notch

[Wrong][Correct] [Wrong][Correct]

Your fingers could be

pinched and injured.

Page 13

Repair

[3] -3. Motor Section (cont.)

ASSEMBLING

2) Assemble Armature-Yoke unit assembly to Brush holder complete as illustrated in Fig. 48.

3) Assemble Motor section to Impact assembly. (Fig. 49)

Note: Make sure that the gear on Armature is engaged with six 10 Spur gears in Impact assembly.

4) Slide Plate C of Mode change lever assembly towards Lever until it stops. (Fig. 50)

Fig. 48 Fig. 50Fig. 49

P 13 /16

Yoke unit

Armature

Brush holder

complete

5) Set Impact assembly to drill mode by turning Change case as illustrated in Fig. 51.

Note: Be careful not to put the projection of Clutch change lever out of the slit of

Change case when turning Change case.

6) Assemble Mode change lever assembly (including Plate B and Plate C) to Impact assembly as illustrated in Fig. 52.

Fig. 51

projection of

Clutch change lever

Change case

gear on Armature shaft

Impact assembly

Motor section

Lever

Plate C

Mode change

lever assembly

Clutch change lever

in Drill mode

Fig. 52

[Speed change ring complete]

two small bosses

Gear case

ends of Change case

space B

space A

one large boss

Motor bracket

Fit the width A of Mode change lever to the space A on gear case.

width A: from rib A1 to rib A2

space A: between the ends of Gear case

Put rib B in the space B on Speed change ring complete.

space B: between the two small bosses and one large boss

[Mode change lever assembly]

(viewed from top)

rib A1

rib B

Mode change lever*

width A

rib A2

Plate B

Plate C

*The portions drawn in broken lines

are positioned on the back of plate C.

Page 14

Repair

[3] -4. Switch Section

P 14 /16

ASSEMBLING

Mount F/R Change lever to Switch by fitting the prong

portion of F/R Change lever to the boss on Switch as

illustrated in Fig. 53., and assemble them to Housing L.

Fig. 53

prong portion

F/R Change lever

boss

Switch

[3] -6. Inner Section (Motor Section and Impact Assembly)

ASSEMBLING

1) While holding Mode change lever assembly so that

it does not fall off Gear case, mount Inner Section

(Motor section and Impact assembly) to Housing L

by fitting the notch of Yoke unit to the projection of

Housing L. (Fig. 54)

2) See Fig. 55.

After installation of Inner section, make sure that;

A) The flat portion of Brush holder complete is at

90 degrees to the surface of Housing L.

B) Yoke unit is put in four ribs on Housing L.

C) The top of the projection of Gear case faces

towards Switch.

Fig. 54

notch of Yoke unit

Mode change lever assembly

Yoke unit

Fig. 55

Brush holder complete viewed from rear

flat portion of

Brush holder complete

edge surface of

Housing L

90 degrees

projection

Housing L

A) Brush holder complete

B) ribs to hold Yoke unit

Yoke

unit

Gear case

Housing L

Brush holder complete

Switch

B) ribs to hold Yoke unit

C) projection of Gear case

Page 15

Circuit diagram

Fig. 56

Color index of lead wires' sheath

Black

Red

Orange

Blue

P 15 /16

Brush holder complete

LED Job light

Connector

Switch

Light

circuit

Terminal

Page 16

Wiring diagram

Fig. 57

Wiring of Lead Wires of Light Circuit

P 16 /16

Lead wires (red, black)

of Light circuit

Lead wire holder

pin

boss

rib for holding Impact assembly

LED

Light circuit

Terminal

*The Lead wires (red, black) of Light circuit

must be tight in the circled area.

*Be careful not to route Lead wires (red, black)

on the rib for holding Impact assembly.

Do not cross the Lead wires (red, black)

in the circled area.

Fix the Lead wires (red, black) with these

Lead wire holders, and route between the pin

and the boss.

Put Light circuit in place

so that the orange Lead wire

faces towards the Terminal side.

Switch side

Lead wire

(orange)

Terminal side

Wiring of Lead Wires of Switch and Brush Holder Complete

Assemble each Connecting terminal

to Switch at approx. 20

vertical.

approx. 20

Connector

With these Lead wire holders,

fix the Lead wires connected

to each Connector.

Put the following lead wires between the rib

and Light circuit.

*Lead wires (red, black) from Terminal

to Connector

*Lead wire (blue) from Switch to Connector

degrees

degrees to the

Brush holder complete

Lead wire holder

Connector

Lead wire holder

Switch

Be careful not to route

the lead wires on the

wall of Housing L in the

circled area.

Light circuit

rib

Loading...

Loading...