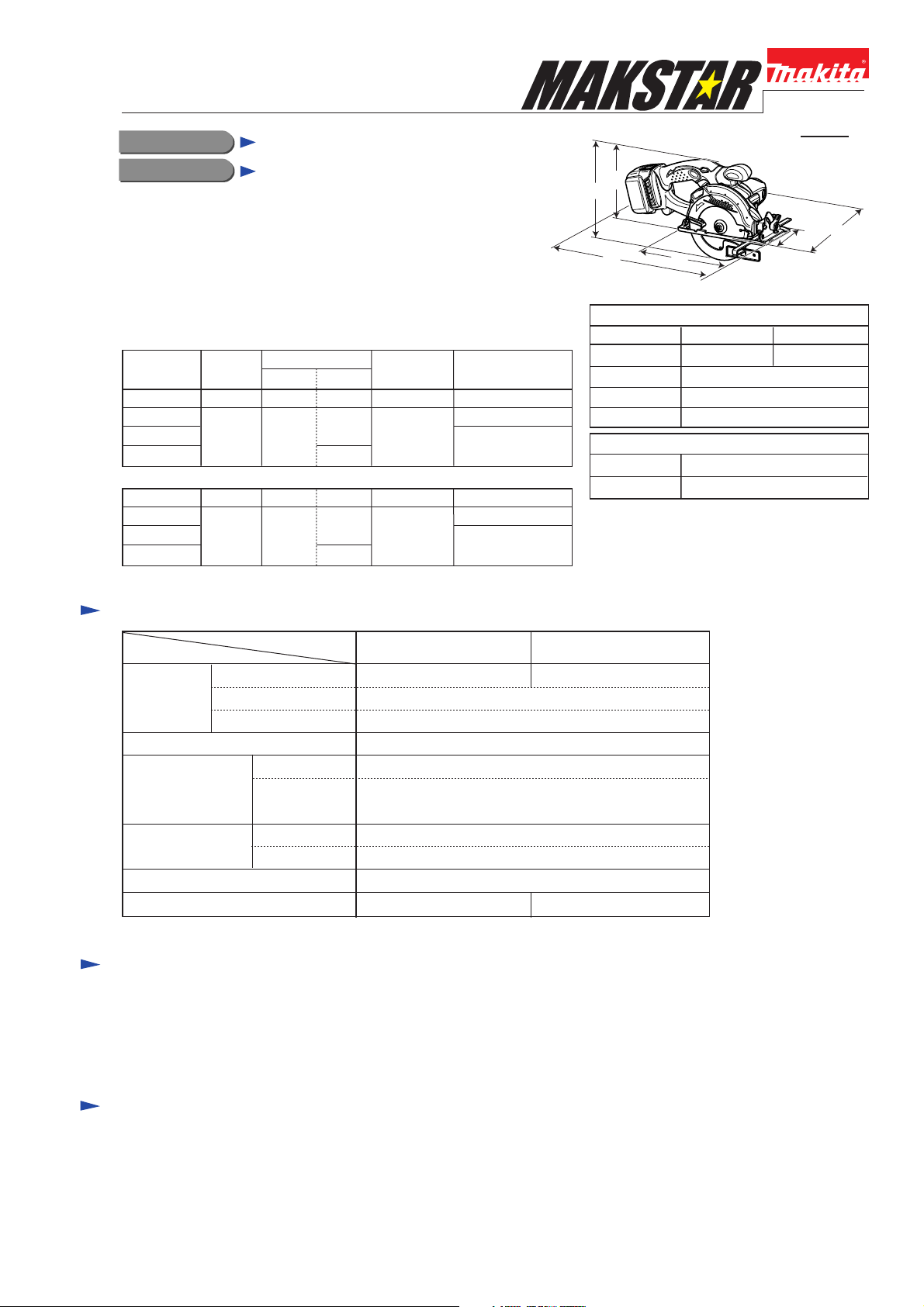

Makita BSS500Z, BSS500, BSS500RFE, BSS500RF, BSS501Z Technical Information

...

T

ECHNICAL INFORMATION

Model No.

Description

BSS500, BSS501

Cordless Circular Saw 136mm (5-3/8")

CONCEPT AND MAIN APPLICATIONS

Models BSS500 and BSS501 have been added to the lineup of

MAKSTAR Cordless Circular Saw, featuring compact and

lightweight design for high maneuverability and easy handling.

PRODUCT

P 1 /14

H2

H1

W1

W2

L1

(The image illustrated above is Model BSS500.)

L2

These products are available in the following variations.

BSS500

Model No.

BSS500Z

BSS500

BSS500RFE

BSS500RF

BSS501

BSS501Z

BSS501

BSS501RFE

BSS501RF

The items listed below in "Standard Equipment" also come with the above items.

Charger

Battery

type quantity

No No

BL1430DC18RA

No No No All countries

BL1830DC18RA

No

2

1

No

2

1

Plastic

carrying case

No All countries

North America

Yes

Yes

All countries except

North America

North America

All countries except

North America

Offered to

Specification

Specifications

Voltage: V

Battery

No load speed: rpm= min.-1

Size of blade:

mm (")

Max. cutting

capacities: mm (")

Electric brake

Net weight: kg (lbs)

*with Battery BL1430 **with Battery BL1830

Capacity: Ah

Cell

Diameter

Hole diameter

at 0

at 45 degrees

Model

degree

3.0

Li-ion

3,600

136 (5-3/8)

North American countries: 15.88 (5/8)

Other countries: 20 (13/16)

51 (2)

35 (1-3/8)

Yes

2.5 (5.5)* 2.6 (5.7)**

Length (L1)

Width (W1)

Height (H1)

Height (H2)

Length (L2)

Width (W2)

BSS501BSS500

1814.4

Dimensions: mm (")

BSS500 BSS501

359 (14-1/8) 364 (14-3/8)

183 (7-1/4)

201 (7-7/8)

145 (5-3/4)

Base Size: mm (")

213 (8-3/8)

109 (4-1/4)

Standard equipment

TCT Saw blade 136mm, 16T ............................ 1

Hex wrench 5 ..................................................... 1

Guide rule .......................................................... 1

Dust nozzle (for European countries only) ....... 1

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Fast charger DC18RA

Charger DC18SC

Charger DC24SA (for North America only)

Charger DC24SC (for all countries except North America)

Li-ion battery BL1430 (for BSS500)

Li-ion battery BL1830 (for BSS501)

TCT Saw blade for wood 136mm, 16T

Dust nozzle

Repair

CAUTION: Remove the battery, SAW BLADE from the machine for safety

before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R003

1R027

1R028

1R031

1R032

1R037

1R263

1R269

1R278 Round bar for arbor 4-50

1R281 Round bar for arbor 7-50

1R291

1R356 Bearing plate 10mm (for arbor press)

1R212 Tip for Retaining ring pliers

Retaining Ring S Pliers ST-2N

Bearing setting pipe 18-10.2

Bearing setting pipe 20-12.2

Bearing setting pipe 28-20.2

Bearing setting plate 8.2

Bearing setting plate 20.2

Bearing extractor (2 pcs)

Bearing extractor

Retaining ring S and R pliers Removing/installing Retaining ring

Wrench for bearing retainer1R316

90 degree set square1R208

Removing Retaining ring WR-26

Assembling Ball bearing 6900ZZ and Helical gear 15 to Gear shaft

Assembling Helical gear 35 to Gear shaft

Supporting Bearing box section when removing Helical gear 23,

Sleeve 10, and Ball bearing 6900ZZ from Spindle

Supporting Gear shaft when assembling Helical gear 35,

Ball bearing 6900ZZ and Helical gear 15 to Gear shaft

Removing Helical gear 35, Ball bearing 6900ZZ and Helical gear 15

from Gear shaft

Removing Bearing box section

Removing Ball bearing 604ZZ and 696ZZ

Removing Ball bearing 604ZZ

Removing Helical gear 15 and Ball bearing 6900ZZ

Removing/installing Bearing retainer 14-23

Removing Ball bearing 604ZZ

adjustment for accuracy of 90 degree/45 degree cut

Removing Retaining ring WR-26

P 2 /14

[2] LUBRICATION

Apply the following grease to protect parts and product from unusual abrasion:

Makita grease N. No.2 to the following portions designated with the black triangle

Machine oil to the following portions designated with the gray triangle

Item No.

19

51

Fig. 1

Description

Handle R

Thickness ring

Helical gear 23

3g to the gear room for Helical gear 23 and Helical gear 15

3g to the gear room located on the opposite side for Helical gear 35

and Pinion gear of Armature shaft

Surface that contacts Safety cover complete

Portion to lubricate Lubricant

19

(viewed from the opposite side)

19

Helical gear 15

Helical gear 35

Safety cover complete

51

Repair

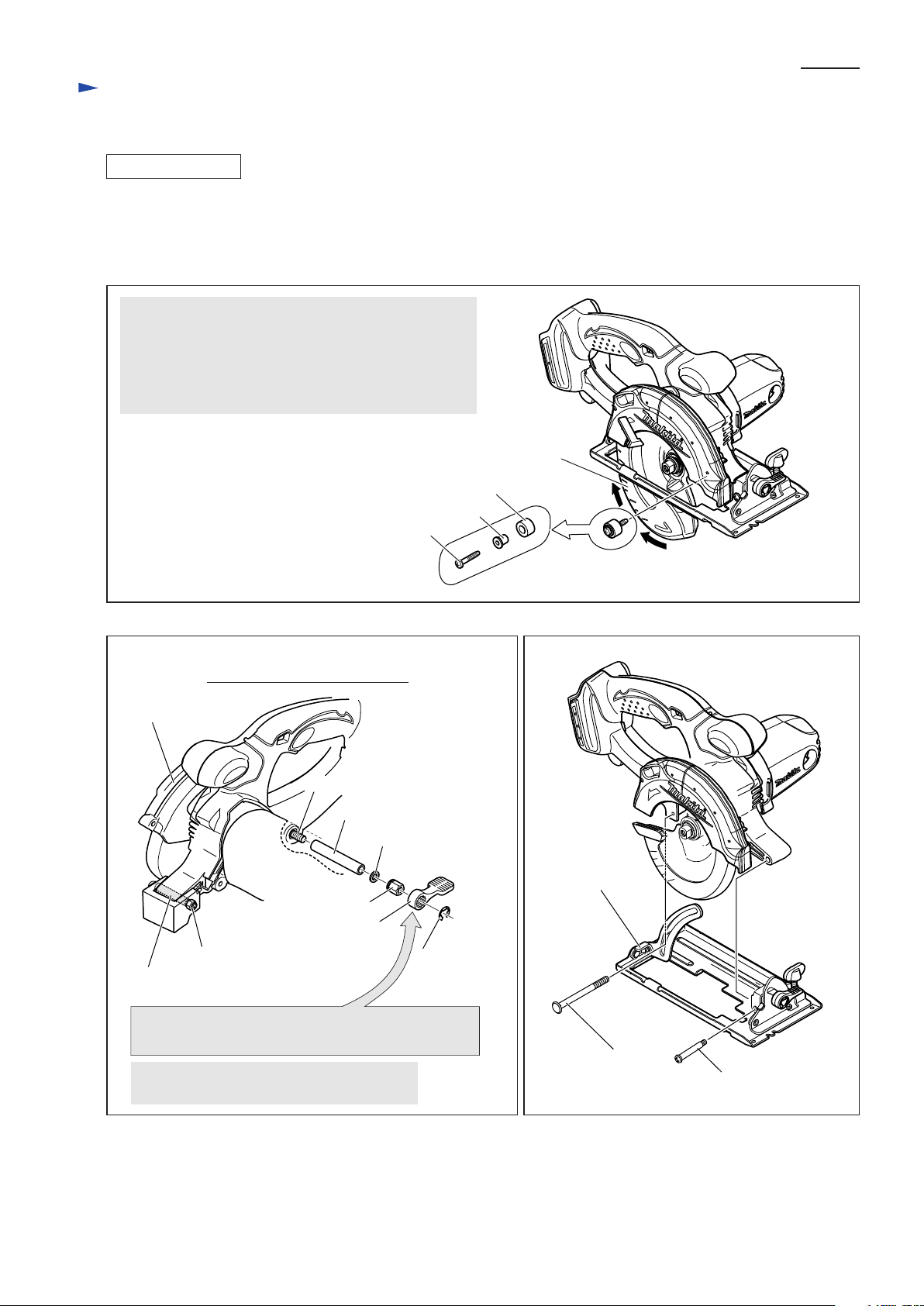

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Base

DISASSEMBLING

Base is joined to Motor section and Saw section with the following screws and nuts:

*at Hinge portion: Pan head screw M5, Hex lock nut M5-8

*at Depth guide portion: Flat head square neck bolt M6x75, Hex nut M6

Remove them in the order of Fig. 2, 3, 4.

Fig. 2

Turn Safety cover in the direction of the arrow

to obtain enough space for you to remove

Rubber sleeve 6.

Keeping Safety cover in the position,

remove Sleeve 4 and Rubber sleeve 6 from Blade case

by unscrewing Tapping screw 4x25.

Safety cover

Rubber sleeve 6

Sleeve 4

Tapping screw 4x25

P 3 /14

Fig. 3

Handle and Motor housing

viewed from Motor housing side

Safety cover

Flat head square neck bolt M6x75

Pipe 6

Flat washer 6

Hex nut M6

Lever 40

Hex lock nut M5-8

Pan head screw M5

For easy removal of Hex nut M6, loosen Hex nut M6

using Lever 40 as a wrench before removing Lever 40.

Remove Hex lock nut M5-8 from Pan head

screw M5.

Stop ring E-8

Fig. 4

Base

Flat head square

neck bolt M6x75

Pan head screw M5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Base (cont.)

ASSEMBLING

1) Do the Reverse of the disassembling Steps.

2) After assembling Base to the machine, adjust the following portion for smooth adjustment of cut depth.

A. Pan head screw M5 in the Hinge portion of Base

Must be tightened so that the Machine can move along

Depth guide smoothly without rattling. (Fig. 3 and 4)

B. Lever 40

Must be installed so that it can be locked at an angle of

between 0 and 30 degrees from the Centerline towards

Switch side when the Cut depth is set to the Maximum.

(Fig. 5)

Also do Adjustment for Accuracy of 90 degree and

45 degree Cut. (See page 11 for details.)

Fig. 5

Base

Depth guide

30 degrees

Center line of Handle

Lever 40

P 4 /14

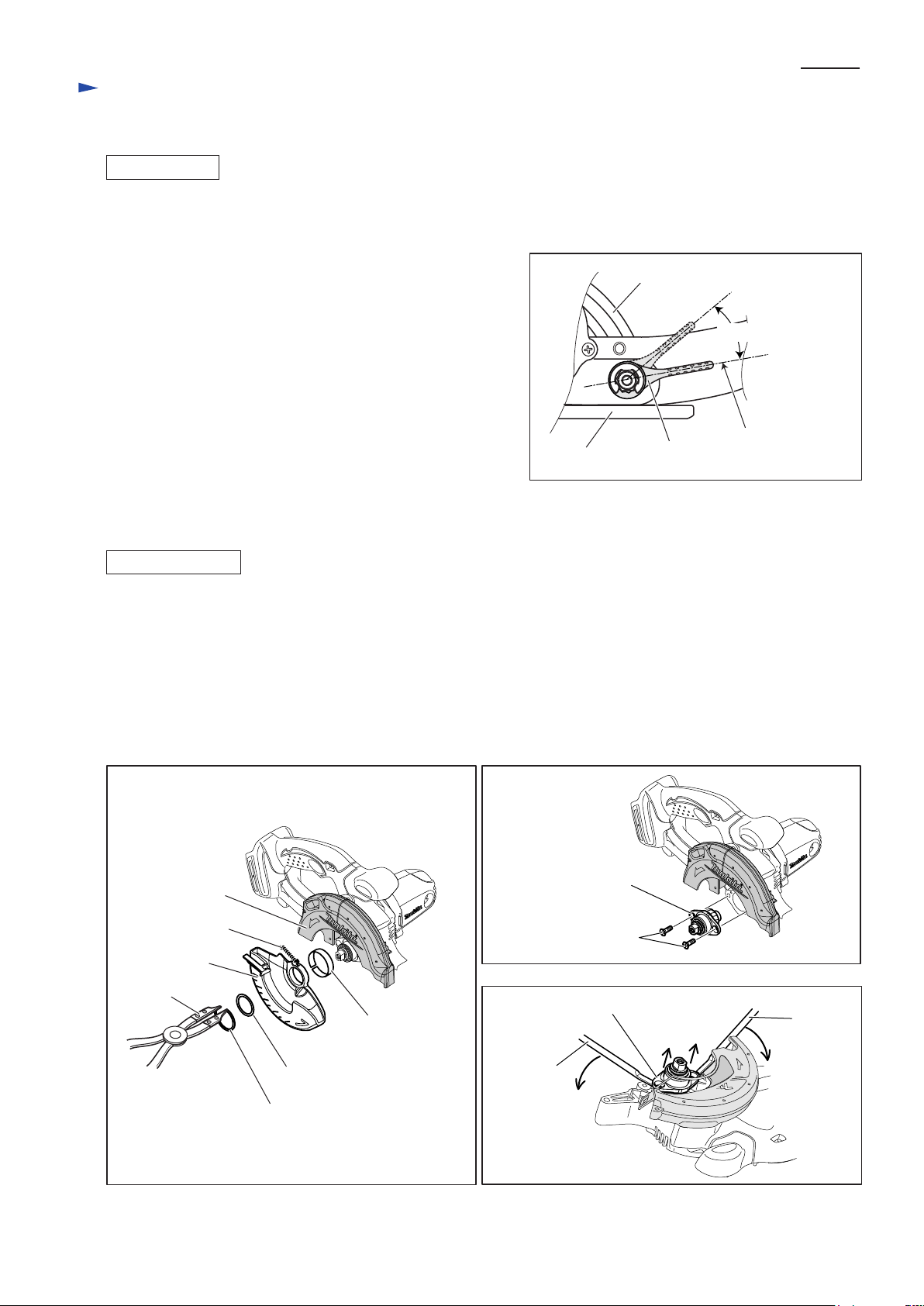

[3] -2. Safety Cover Complete and Bearing Box Section

DISASSEMBLING

1) Remove Rubber sleeve. (Fig. 2)

2) By removing Retaining ring WR-26 with 1R212, the following parts can be removed (Fig. 6):

Flat washer 26, Safety cover, Tension spring 4, Thickness ring.

Note : Safety cover complete can be separated from Blade case by unhooking the end of Tension spring 4 from

Blade case.

3) By unscrewing two M5x16 Countersunk head screws, Bearing box section can be removed by hand. (Fig. 7)

If cannot be removed by hand, lever off using a pair of 1R263 as illustrated in Fig. 7A.

Note: It is recommended to use cordless impact driver for removing the screws because threadlocker is

applied to them.

Fig. 6

Blade case

Tension spring 4

Safety cover

1R212

Thickness ring

Fig. 7

Bearing box

Countersunk head

screw M5x16

Fig. 7A

Bearing box section

1R263

Flat washer 26

Retaining ring WR-26

1R263

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Safety Cover Complete and Bearing Box Section (cont.)

DISASSEMBLING

P 5 /14

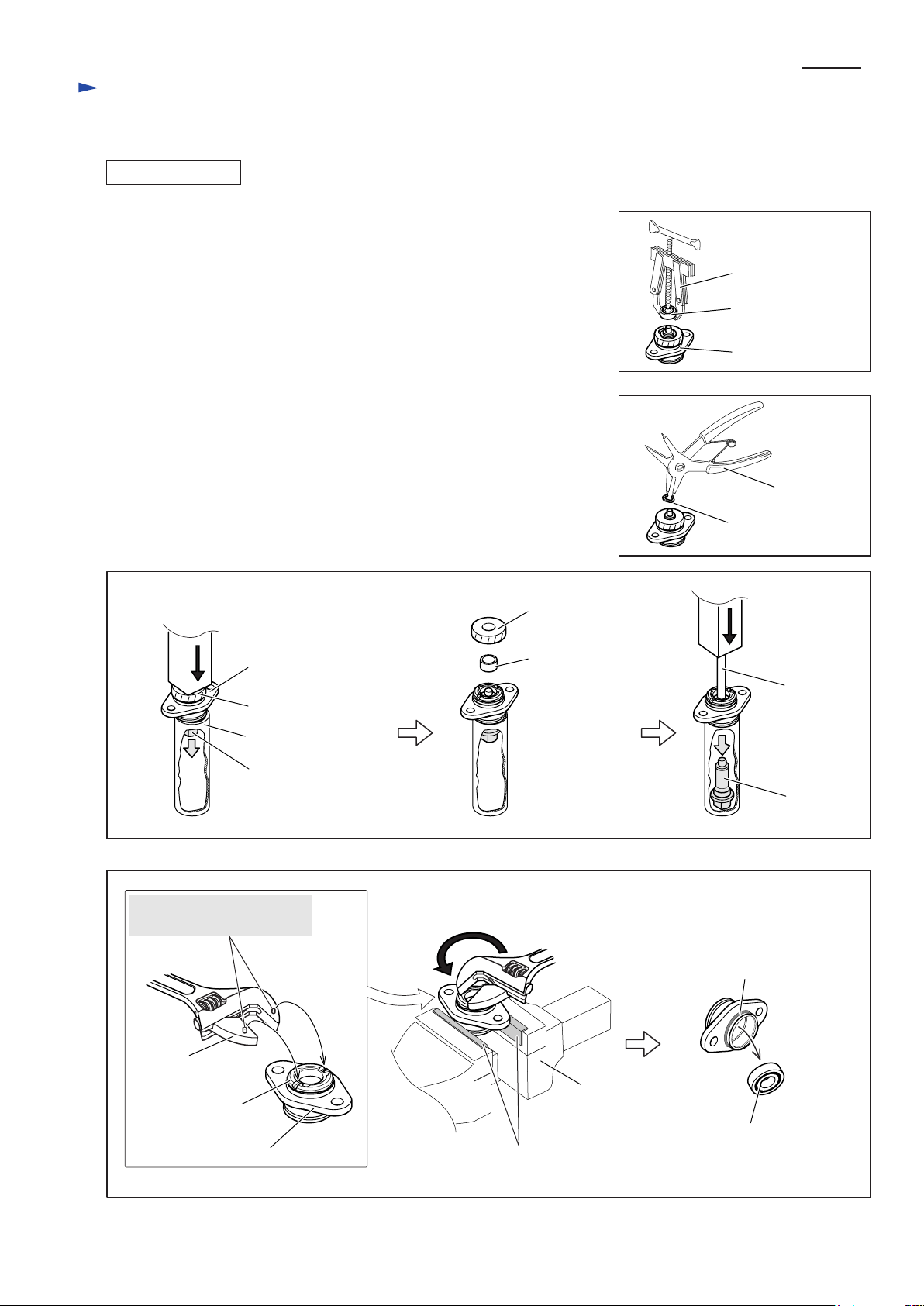

4) Remove Ball bearing 696ZZ from Bearing box section with 1R269. (Fig. 8)

5) Remove Retaining ring S-10 with 1R291. (Fig. 9)

6) Remove Spindle by doing the steps below (Fig. 10):

1. Put Bearing box section on 1R031 with Helical gear 23 side up.

2. Remove Helical gear 23 and Sleeve 10 by pressing the end face of

Spindle using arbor press.

3. Apply 1R281 to the end face of Spindle, and press it using arbor press.

Spindle can now be removed from Bearing box section.

Important: Ball bearing 6900DDW in Bearing box section will always

be damaged in these steps.

Do not forget to replace with new one.

7) Attach a pair of 1R041 to vise. Fix Bearing box section in vise.

Remove Bearing retainer 14-23 from Bearing box by turning counter clockwise with 1R316. Damaged Ball bearing 6900DDW can now be

removed. (Fig. 11)

Fig. 10

Helical gear 23

Fig. 8

1R269

Ball bearing 696ZZ

Bearing box section

Fig. 9

1R291

Retaining ring S-10

Fig. 11

Fit these pins in the groove

of Bearing retainer 14-23.

1R316

Bearing retainer

14-23

Bearing box

Bearing box section

Helical gear 23

1R031

Spindle

1R041

Sleeve 10

1R281

Spindle

O ring 26

Vise

Ball bearing 6900DDW,

damaged in the previous step

Loading...

Loading...