Page 1

T

Models No.

ECHNICAL INFORMATION

BPT351 (LXTP01*1)

PRODUCT

P 1/ 15

Description

Cordless Pin Nailer

*1 Model number for North and Central American countries

CONCEPT AND MAIN APPLICATIONS

Model BPT351 has been developed as a 18V Cordless Pin Nailer

with more working capacity than that of 14.4V Model BPT350.

Its features and benefits are the same as BPT350

except for 18V Li-ion battery.

This model is available in the following variations.

Model No.

BPT351RFE

(LXTP01)

BPT351RFX No

BPT351Z

(LXTP01Z)

BPT351ZX

All models also include the accessories listed below in "Standard equipment".

Charger

DC18RA

No No No No

Battery

Type Quantity

BL1830 2

Specification

Specifications

Voltage: V 18

Battery

Pin nails

(23Ga)

Magazine capacity: pcs.

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

*2 with battery BL1815

*3 with battery BL1830

Length: mm (")

Diameter: mm (") 0.6 (1/32)

Model No.

(11/16, 1, 1-3/16, 1-3/8)

1.9*

Plastic

carrying case

Yes

BPT351 (LXTP01)

1.3/ 3.0Capacity: Ah

24/ 54Energy capacity: Wh

Li-ionCell

22 with DC18RACharging time: min.

18, 25, 30, 35

130

2/ 2.1*3 (4.2*2/ 4.6*3)

Systainer

case

No

Yes

No

Yes

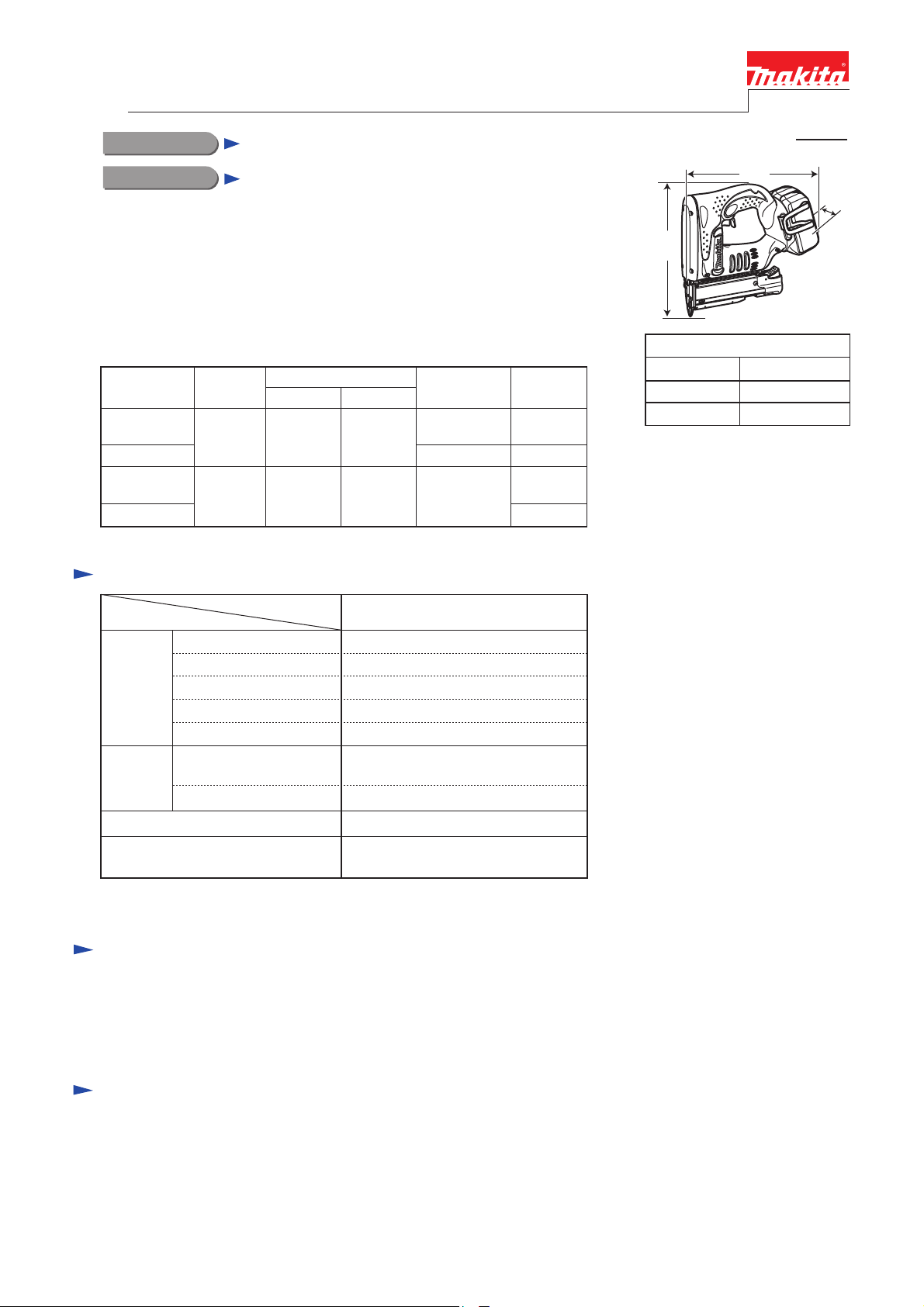

H

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

L

W

249 (9-3/4)

79 (3-1/8)

227 (8-15/16)

Standard equipment

Safety goggles ......................... 1

Nose adapter ............................ 1

Hex wrench 3 .......................... 1

Belt clip ................................... 1

Note: The standard equipment for the tool shown above may vary by country.

Optional accessories

Pin nails; 18mm (11/16"), 25mm (1"), 30mm (1-3/16"), 35mm (1-3/8")

Fast Charger DC18RA

Li-ion Battery BL1815

Li-ion Battery BL1830

Page 2

P 2/ 15

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

783201-2

1R220 Ratchet head 9.5

1R222 Socket adapter

1R228

1R254 Torque wrench shaft 2-6N.m

134873-0 Bit adapter

1R266 Spring pin extractor M2

1R268

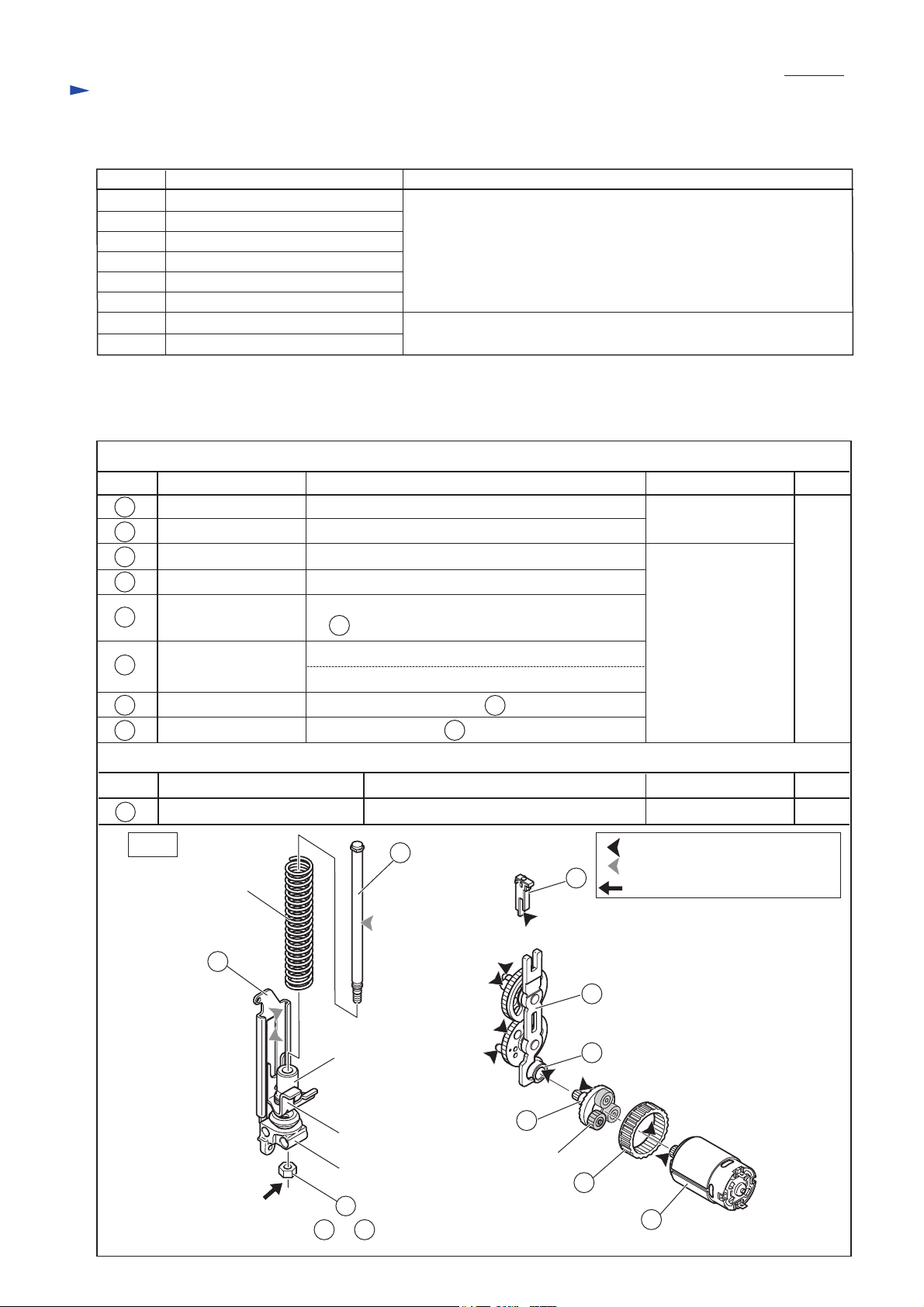

[2] LUBRICANT AND ADHESIVE APPLICATION

Apply the following lubricants to protect parts and product from unusual abrasion.

Apply the following adhesive.

Item No. Description Portion to lubricate Lubricant

11

59 DC motor Pinion gear

61 Internal gear 69 Teeth that engages with Spur gear 27

64

66 Spur gear 55 complete

67 Plane bearing 10 Inside surface that contacts 64 Spur gear 7 complete

89 Cam block Portion that contacts 66 Spur gear 55 complete

Hex. wrench 3 (standard equipment)

1/4" Hex. shank bit for M4

Spring pin extractor M3

screwing / unscrewing Hex socket head bolt and M3x4 Pan head screw

disassembling magazine section

LUBRICANT

Rail Grooves of both sides where Hammer slides

Guide bolt Shaft surface except thread portion13

Spur gear 7 complete

Teeth that engages with the lower gear

of 66 Spur gear 55 complete

Teeth

Pin and cam portions

Amount

Molybdenum disulfide

lubricant

a little

Makita grease N No.2

Item No. Description

34

Compression spring 17

M6 Hex nut

Fig. 1

11

Screw to with Loctite 272 put on the thread.

Thread

Spring holder

Hammer

Holder

34

13

34

ADHESIVE

Portion to apply adhesive

13

64

Spur gear 27

(3pcs.)

89

61

Adhesive

: Makita grease N No.2

: Molybdenum disulfide lubricant

: Loctite 272

66

67

59

Amount

a littleLoctite 272

Page 3

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Replacing Driver

(1) Remove four Bind PT3x16 Tapping screws and Front cover. (Fig. 2)

(2) Remove Upper plate as drawn in Fig. 3.

(3) Remove Pin 4 for connecting Driver and Hammer. (Fig. 4)

(4) Remove Driver as drawn in Fig. 5.

Fig. 2 Fig. 3 Fig. 4 Fig. 5

Front cover

Bind PT3x16

Tapping screw

(4pcs.)

Slide Upper plate

upward.

Slide Driver upward.

Hammer

Pin 4

Driver

P 3/ 15

Note: A few of pin nails often remain in the tool, and if so, it is impossible to insert Driver into Driver guide.

(5) Remove two M4x6 Hex socket head bolts and Driver guide cover. Remove the jammed pin nails. (Fig. 6)

(6) Slide the new Driver into the groove of Driver guide. (Fig. 7)

Note: If M4x10 Hex socket head bolt(s) are loosened, the stroke of Driver guide may tilt.

In that case, slide Driver into the groove of Driver guide before securing M4x10 Hex socket head bolt(s),

and then secure M4x10 Hex socket head bolt(s).

(7) Insert Pin 4 for connecting Driver and Hammer.

(8) Set Driver guide cover in place with two M4x6 Hex socket head bolts.

(9) Slide the side ends of Upper plate into the guides of Housing set. (Fig. 8)

(10) Assemble Front cover to Housing set with four Bind PT3x16 Tapping screws.

Fig. 6 Fig. 7

Jammed pin nail

M4x10 Hex

socket head bolt

Driver guide cover

M4x6 Hex socket head bolt

Driver

Fig. 8

Upper plate

The guides on Housing set

Page 4

P 4/ 15

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Replacing Switch, LED circuit and Terminal

(1) Do the steps (1), (2), (3) and (4) of the previous page.

(2) Insert Battery and pull the trigger to locate Hammer at

lowest position to release tension of Compression spring 17.

Remove Battery after this procedure is finished.

Go to the next step without changing spring position

in case Switch or DC motor is disorder.

(3) Separate housing R by removing Tapping screws and Pan head

screws drawn in Fig. 9 while holding trigger section

to prevent spring from jumping out.

(4) Switch, LED circuit and Terminal now can be removed.

[3] -3. Replacing Motor

(1) Remove Front cover and Housing R as drawn in Fig. 2 and Fig. 9.

(2) Remove M4x6 Hex socket head bolt. Pull out Upper rail complete, and then separate Magazine ass'y from Housing L

by removing two M4x10 Hex socket head bolts. (Fig. 10)

(3) Dismantle Housing R by removing 8 pcs. of Bind PT3x16 Tapping screws, 2 psc of M4x14 Pan head screw and

a M4x35 PAn head screw. Now DC motor can be removed provided Compression spring 17 has no tension.

(4) When Motor or Switch is out of order, Hammer of Spring section often stops in the halfway position and

Compression spring 17 remains compressed. It is impossible to remove DC motor from Housing L.

In this condition, remove 2pcs. of Bin PT3x16 Tapping screw (Fig.11), and insert slotted screwdriver into the gap

between Housing L and Rail of Spring section, and then lever up Spring section with the slotted screwdriver

as drawn in Fig. 12.

Note • Cover Spring section with cloth in order not to pinch your finger.

• Hold Spring section by hand to prevent Compression spring 17 from jumping out.

(5) Remove Motor from Housing L.

Fig. 9

Bind PT3x16 Tapping

screw for Housing L and R

(8pcs.)

Housing R

M4x14 Pan head screw (2pcs.)

Hold trigger section so

as not to spring out.

Housing L

(The reverse

of Housing R)

M4x35 Pan

head screw

Fig. 10

M4x10 Hex socket

head bolt (2pcs.)

Housing R

Fig. 11 Fig. 12

Spring section

Holder

Cushion

Guide bolt

Hammer

M4x6 Hex socket head bolt

Hammer stops in

the halfway position

Compression

Rail

spring 17

Cover Spring section with cloth and hold them by hand.

Holder

Housing L

Upper rail complete

Compression spring 17

Bind PT3x16 Tapping screw (2pcs.)

Housing L

Rail

Slotted screwdriver

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Trigger Section

DISASSEMBLING

(1) Remove Front cover and Housing R. (Fig. 2 and Fig. 9)

(2) Remove the parts around trigger section in the following order. (Fig. 13)

1. Safety trigger 2. Light switch arm 3. Link plate 4. Torsion spring 4 5. Pin 2.5 (3pcs.) 6. Pin 3

(3) Disassemble guide plate in order of Figs. 14, 15 and 16.

Fig. 13

1. Safety trigger

2. Light switch arm

3. Link plate

4. Torsion spring 4

Fig. 14

Two Torsion springs 3

(One is hooked with the other.

Refer to Figs. 33 and 34.)

P 5/ 15

5. Pin 2.5

Disconnect the hooks.

6. Pin 3

Fig. 15 Fig. 16

Swing arm

Guide plate

Turn swing arm.

Trigger

Trigger

(Projection to hook

the short end of Tortion

spring 3: Refer to Fig. 33.)

Guide plate can be pulled out

from Trigger.

[3] -5. Spring Section

DISASSEMBLING

(1) Install Battery BL1430. Slide Sliding door section of Magazine to make anti-fire mechanism invalid.

Pull Trigger in a blink and release it until Hammer reaches the lowest position. (Fig. 17)

Note: Be sure to remove Battery BL1430 after the above step.

(2) After removing Housing R and Front cover, separate Spring section from Housing L by removing Two Bind

PT3x16 Tapping screws . (Fig. 18)

Fig. 17 Fig. 18

Housing R Housing L

Spring holder

Rail

Housing L

Compression

spring 17

Hammer

Cushion

Spring section

Compression

spring 17

Guide bolt

Hammer

Cushion

Holder

Bind PT3x16

Tapping screw

Page 6

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Spring Section (cont.)

DISASSEMBLING

(3) Disassemble the Spring section in order of Fig. 19, 22. Spring section is removed as drawn in Fig. 23.

Fig. 19 Fig. 20

Guide bolt

P 6/ 15

Wrench 8

Turn guide bolt counterclockwise

while gripping holder by a gloved

hand and remove M6 hex nut,

Holder with Rail and

Flat washer 6 from Guide bolt.

Fig. 21 Fig. 22

Compression

spring 17

Spring holder

Rail

Holder

M6 Hex nut

Flat washer 8

Cushion

Flat washer 6

Guide bolt

Guide bolt

Cushion

Hammer

Cushion is fit into the groove of

Guide bolt firmly. Therefore, twist

Cushion to pull it off from the groove.

Spring holder

Turn compression spring 17 counterclockwise

while holding Spring holder with gloved

hands.

Spring holders is removed from Compression

spring 17.

Fig. 23

M6 Hex. nut

Spring holder

Holder

Rail Cushion

Flat washer 6

Compression spring 17

After removing Guide bolt and Flat washer 8, remove Spring

holder of the opposite side in the same way drawn in Fig. 21.

Note: When inserting Spring holder into Compression spring 17,

turn Compression spring 17 clockwise and twist Spring

holder to set in place.

Hammer

Flat washer 8

Spring holder Guide bolt

Page 7

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Spring section (cont.)

ASSEMBLING

(1) Take the reverse steps of the disassembling procedure for Spring section.

(2) Fix Spur gear 55 complete with Flat washer 4 and Bind PT3x16 Tapping screw.

Install Spring section in Housing L while adjusting Roller position of Spur gear 55 complete

to under the hook portion of hammer (Fig. 24).

(3) Fix Spring section with Bind PT3x16 Tapping screw and mount driver guide, driver, and driver guide cover

to Housing R. (Fig. 25)

P 7/ 15

Fig. 24

Bind PT3x16 Tapping screw

Flat washer 4

Roller portion of

Spur gear 55

Hook portion of

Hammer

Spring section

Fig. 25

Hook portion

of Hammer

Roller

(The position

is lower than

that of the hook

portion of hammer)

Spring section

Bind PT3x16

Tapping screw

Page 8

P 8/ 15

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Motor and Gear Section

ASSEMBLING

(1) Assemble Cam block section to Spur gear 55 complete. (Fig. 26) Usually, there is no need to disassemble Cam block

section for repair.

Note: Put Makita grease N No.2 to the inner and the outer surface of Internal gear 69,

the pins of Spur gear 7 complete and the teeth of Spur gear 55 complete.

(2) Mount the following parts on Housing L (Fig. 27);

Spur gear 55 complete, Cam block section, Lock arm section and two Leaf springs

Note: When disassembling Lock arm section, do not remove M3x4 Pan head screw. It becomes easy to set gear

section in place.

Regarding two Leaf springs, install them in the space for Internal gear 69 as drawn in Fig. 28.

(3) Face the rim portion of Internal gear 69 oposit side of DC motor and assemble Internal gear section (Fig. 29).

(4) Install Anti back plate to Spur gear 7 complete with the direction described in Fig. 30

and mount them in Housing L. (Fig. 31) Be sure to put Roller portion of Spur gear 55 complete under

the hook of Hammer.

Fig. 26

Cam block section (with Push pin,

Spring pin 2-8 and Compression spring 2.4

Spur gear 55

complete

Fig. 28

Lock arm section

(with Pin 5 and

M3x4 Pan head

screw )

Leaf spring

for Internal

gear 69

Fig. 27

Space of Housing L for

Internal gear 69

Distance A

Distance B

Leaf spring

Center line

Leaf spring

Distance A= Distance B

Fig. 29

Internal gear 69

Rim portion

Lock arm

Pin 5

Flat washer 12

Spur gear 27 (3pcs.)

Cam block

Spur gear

55 complete

DC motor

Spur gear 7

complete

Fig. 30

Spur gear 7

complete

Housing L

Tails of Anti back plate

Caution: If using the tool on condition that Roller portion of Spur gear 55 complete is put on the hook of Hammer

by mistake, DC motor runs without transmitting the torque to gear section.

Fig. 31

Hook of Hammer

Roller portion of

Spur gear 55 complete

Internal gear 69

DC Motor

Anti back plate

Rim portion of

Internal gear 69

Spur gear 55 complete

Put Plane bearing 10 on

Spur gear 55 complete.

Install Plane bearing 10

into the hook of

Plane

bearing 10

Spur gear 55 complete.

Hook of Spur gear 55 complete

Page 9

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Switch Mechanism

ASSEMBLING

(1) Insert Guide plate and Compression spring 4 into Trigger. (Fig. 32)

(2) Hook the short end of Torsion spring 3 with Swing arm, and then insert the

Torsion spring 3 into Swing arm. (Fig. 33)

(3) Insert Swing arm into Guide plate so that Pin 2.5 can be passed through

the grooves of Guide plate in the next step. (Figs. 32 and 33)

(4) Pass Pin 2.5 through the holes of Trigger and the grooves of Guide plate

while setting two Torsion springs 3 as drawn in Figs. 14 and 33 and secure

Pin 2.5 with two Stop rings E-2.0.

Fig. 33

short end of

Torsion spring 3

for Swing arm

long end of Torsion

spring 3 for hooking

the other Torsion

spring 3

Swing arm

Trigger

Guide plate

Stop ring E-2.0

Swing arm

Housing R side

Torsion spring 3

Guide plate

Fig. 32

Guide plate

The groove

of Guide plate

to pass Pin 2.5

Inserting position of Guide plate and

Compression spring 4 to Trigger

Viewed from the upper side of

the assembled Trigger Section

Torsion spring 3

Compression

spring 4

Trigger

Housing R side

Stop ring E-2.0

Compression

spring 4

P 9/ 15

Torsion spring 3 between

Stop ring E-2.0

Housing L side

: The components of Trigger set

(5) Hook one Torsion spring 3 with the other (Ref. Fig. 33) as drawn in Fig. 34.

Note: Torsion spring 3 for Swing arm is different from Torsion spring 3 for Guide plate and Switch arm.

(6) Hook the projection of Trigger with the notch of Lock arm. (Figs. 34 and 35)

(7) Install Trigger section in Housing L while compressing Compression spring 4 to put it on the rib of Housing L as

drawn in Fig. 35.

(8) After putting Switch arm in Guide plate, insert Pin 2.5 through the holes of Guide plate and Switch arm.

Pay attention to the direction of Switch arm. Refer to Fig. 36.

(9) Install Torsion spring 4 for Guide plate and Switch arm (Ref. Fig. 33) as drawn in Fig 37.

Fig. 34 Fig. 35

Projection of Trigger

(for Lock arm)

Pin 2.5

Long end of Torsion spring 3

(come from inside of Swing arm)

Trigger and Stop ring E-20

(Hook the shot end to

the projection of Trigger.

Refer to Fig. 14.)

long end of Torsion

spring 3

(located out of

Trigger)

Trigger

Pin 2.5

Housing L side

Compression

spring 4

Projection of Trigger hooked with notch of Lock arm

Stop ring E-2.0

Rib of Housing L

for compression

spring 4

Fig. 36

Switch arm

Pin 2.5

Note: Switch arm has to be assembled

so as to contact Push pin.

Otherwise, the machine does not

run even if Switch trigger is pulled.

Guide plate

Fig. 37

(1) Put short end of Torsion spring 4

on Guide plate.

(2) Put short end of

Torsion spring 4

on Guide plate.

Page 10

Repair

P 10/ 15

[3] DISASSEMBLY/ASSEMBLY

Fig. 38

[3] -6. Switch Mechanism (cont.)

ASSEMBLING

(7) Insert the remaining two Pins 2.5 firmly into Housing set L until they stop

as drawn in Fig. 38.

(8) Install Link plate to Housing L with Pin 3 through Link plate. (Fig. 39)

(9) Insert the projection of Light switch arm into Compression spring 2

firmly. And then insert the axis of Light switch arm into hole of Housing

L and push Compression spring 2 to the emboss of Housing L. (Fig. 40)

(10) Set Torsion spring 4 in place. Install Safety trigger and Torsion spring 4

to Housing L with Pin 3 as drawn in Fig. 41.

All the components are assembled as drawn in Fig. 42.

(11) Fasten the two positions with two Bind PT3x16 tapping screws as drawn

in Fig. 43 before assembling Housing R to Housing L.

Note: Avoid loosening M3x4 Pan head screw that fastens Lock arm and Pin 5

as much as possible.

If loosening is inavoidable, pretighten M3x4 Pan head screw with Loctite 242 put on the thread and finish the all

reassembling work. After that, check the trigger’s smooth action and finally tighten the screw when the smooth

action can be obtained.

Fig. 40

Axis of

Light switch arm

Compression spring 2

Fig. 39

Fig. 43

Pin 2.5

(Ref. Figs. 34 and 35)

Pin 2.5 (2pcs.)

Pin 3

Link plate

Hole of Housing L

for Light switch arm

Fig. 41 Fig. 42

Pin 3

Torsion spring 4

Safety trigger

Emboss of Housing L

Bind PT3x16

tapping screw

(2pcs.)

M3x4 Pan

head screw

Page 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Magazine

DISASSEMBLING

(1) Loosen M4x6 Hex socket head bolt three turns, then pull out Upper rail section

from Magazine . (Fig. 44)

(2) Remove large Compression spring 3 that is put on Nail guide holder. (Fig. 45)

(3) Remove Stopper with small Compression spring 3 from Pusher. (Fig. 45)

(4) Pusher is just inserted into the slit of Shoulder pin 5-7. Therefore, Pull Pusher

out straight from the slit side of Shoulder pin 5-7. (Fig. 45)

(5) Loosen M4x10 Pan head screw three turns so that Upper rail section has a

clearance to push down three Nail stoppers and remove their hooks from Nail

guide holder in the next step.

Note: Do not remove the screw. This is because the complete removing will

cause the removal of Slide door cap and all the small Springs in

the magazine section.

Fig. 46Fig. 45

Action (3) Action (4)

Pusher

Pusher

P 11/ 15

Fig. 44

M4x6

Hex

socket

head bolt

Magazine

Upper rail section

Stopper

Compression

spring 3

Action (2)

Shoulder pin 5-7

Compression spring 3 put on the rod of Nail guide holder

(6) Remove three Nail stoppers in order. Push each Nail stopper with Slotted screwdriver to remove the hook from

the slot of each Nail stopper. (Fig. 47)

Nail guide holder is removed.

(7) Use 1R266 to remove Spring pin 2-8. (Fig. 48) Use 1R267 to remove Spring pins 3-10 and 3-18. (Fig. 49)

Fig. 47

Slotted

screwdriver

Nail stopper (3pcs.)

Leaf spring

Upper rail complete

three hooks of Nail stoppers

M4x10 Pan

head screw

three slots of Nail guide holder to hook the Nail stopper

Fig. 48 Fig. 49

Spring pin 2-8

Spring pin 3-18 Spring pin 3-10

Page 12

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Magazine (cont.)

Points of ASSEMBLING

• Be sure to check that Nail stoppers work properly as drawn in Figs. 50 and 51.

Fig. 50

Nail guide holder

Nail stoppers are

in Nail guide holder.

Pusher

Nail guide holder

P 12/ 15

When Nail guide holder

is pushed into Magazine,

Nail stoppers rise to

Pusher side.

Pusher

Any Nail stoppers must not be stuck in the groove of Nail guide holder.

Check if all Nail stoppers come back to original position with spring tension

when you release Nail guide holder.

Fig. 51

When pushing down Nail guide holder against workbench and

pressing the designated points of Nail stoppers, Nail stoppers

have to be returned back without any interferes.

If Leaf spring under Nail stoppers is not completely seated on

the bottom, some Nail stoppers are caught in the bottom side.

When the above trouble happens, pull and return the nail stoppers

several times, and then find out the nail stoppers’ smoothest

position.

Action of Nail guide holder

Pressure to Nail guide holder

• When installing Slide door cap into Upper rail complete,

press Slide door cap fully in the direction of an arrow drawn in

Fig. 52 and tighten M4x10 Pan head screw at the same time.

• While facing the slot of Shoulder pin 5-7 to the magazine side

as drawn in Fig. 45, install Pusher to Upper rail complete.

Workbench

Fig. 52

Slide door

cap

Lever

Upper rail

complete

Page 13

P 13/ 15

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Fastening Torque

Item No. Description Fastening Torque

29 2.5 N.m

27 4.0 N.m

12 4.0 N.mM4x10 Hex socket head bolt for assembling Driver guide and Holder

51

57 Pan head screw M3x4 for assembling Pin 5 and Lock arm 1.0 N.m

Fig. 53

Driver guide cover

M4x14 Hex socket head bolt for assembling Driver guide and Magazine

M4x6 Hex socket head bolt for assembling Driver guide and Driver guide cover

Hex socket head bolt M3x10 for assembling Magazine and Lower rail 1.0 N.m

51

Pin 5

Lock arm

12

29

27

Driver guide

57

Spacer

Magazine

Circuit diagram

Fig. D-1

Color index of lead wires' sheath

Black

White

Red

Orange

Switch put under ON-OFF Switch

(for Upper dead point detection)

COM

NO

Switch

(for ON-OFF)

COM

NO

Red marking

for distinction

of + Terminal

NO

Switch

(for LED circuit)

COM

Lower rail

DC motor

Terminal

LED

circuit

Page 14

Wiring diagram

Fig. D-2

P 14/ 15

Wiring to Switch

Flag connector

Housing L side

Connect Flag connector to Switch at direction described above.

Fig. D-3

Lead wire (orange)

Wiring to DC motor

Red marking for distinction of + Terminal

Terminal with

Red marking

Flag connector

Housing set (L) side

Lead wire (red)

Lead wire (black)

Terminal without red marking

Connect Flag connectors with Lead wires at direction described above.

Connect Flag connector with lead wire (red) to Terminal with red marking.

Fig. D-4

Wiring to Terminal

Lead wires (black)

Lead wires (orange)

Mark of Poles

Flag connector

Flag connector with lead wires (black) has to be connected to - Terminal

so that the lead wires pass over the mark of - poles.

Flag connector with lead wires (orange) has to connected to + Terminal

so that the lead wires face the opposite side against the mark of + poles.

Terminal

Page 15

Wiring diagram

Fig. D-5

P 15/ 15

Lead wire (red)

to + Terminal of

DC motor

Guide Lead wire (red) of Upper dead point

detection switch to DC motor while passing

the wire between boss A and lead wire

holder A.

Fix lead wire (black) of ON-OFF switch

with lead wire holder A.

Pass the following lead wires between rib

and inner wall of Housing L.

*Lead wire (orange) for connecting

ON-OFF switch with terminal

*Lead wire (orange) for connecting

Switch for LED circuit with Terminal

*Lead wire (red) for connecting

LED circuit with Switch for LED circuit

*Lead wire (red) for connecting

Start point regulator and DC motor

Boss A

Lead wire

holder A

Lead wire (black) for connecting ON-OFF switch

and Upper dead point detection switch

Lead wire

holder A

Switch put under ON-OFF Switch

(for Upper dead point detection)

Switch (for ON-OFF)

Switch (for ON-OFF) put on

Upper dead point detection switch

See Fig. D-5.

See Fig. D-6.

Terminal

See Fig. D-7.

LED circuit

Fig. D-6 Fig. D-7

Lead wire holder B

Lead wire (red) of

Upper dead point

detection switch

LED lead wire (red)

[It is thinner than

Lead wire (red) of

Upper dead point

detection switch.]

Rib

Lead wire holder B

to Terminal

Light switch arm

Switch for LED circuit

DC motor

to Switch for

LED circuit

Rib B

Rib A

Wall of Housing L

Pile lead wire (red) of Upper dead point detection switch

on LED lead wire (red), and then pass these lead wires

between lead wire holder B and the wall of Housing L.

LED circuit

Lead wires (red and black) of LED circuit pass

between Rib A and Rib B so as not to put them

on the LED circuit.

Loading...

Loading...