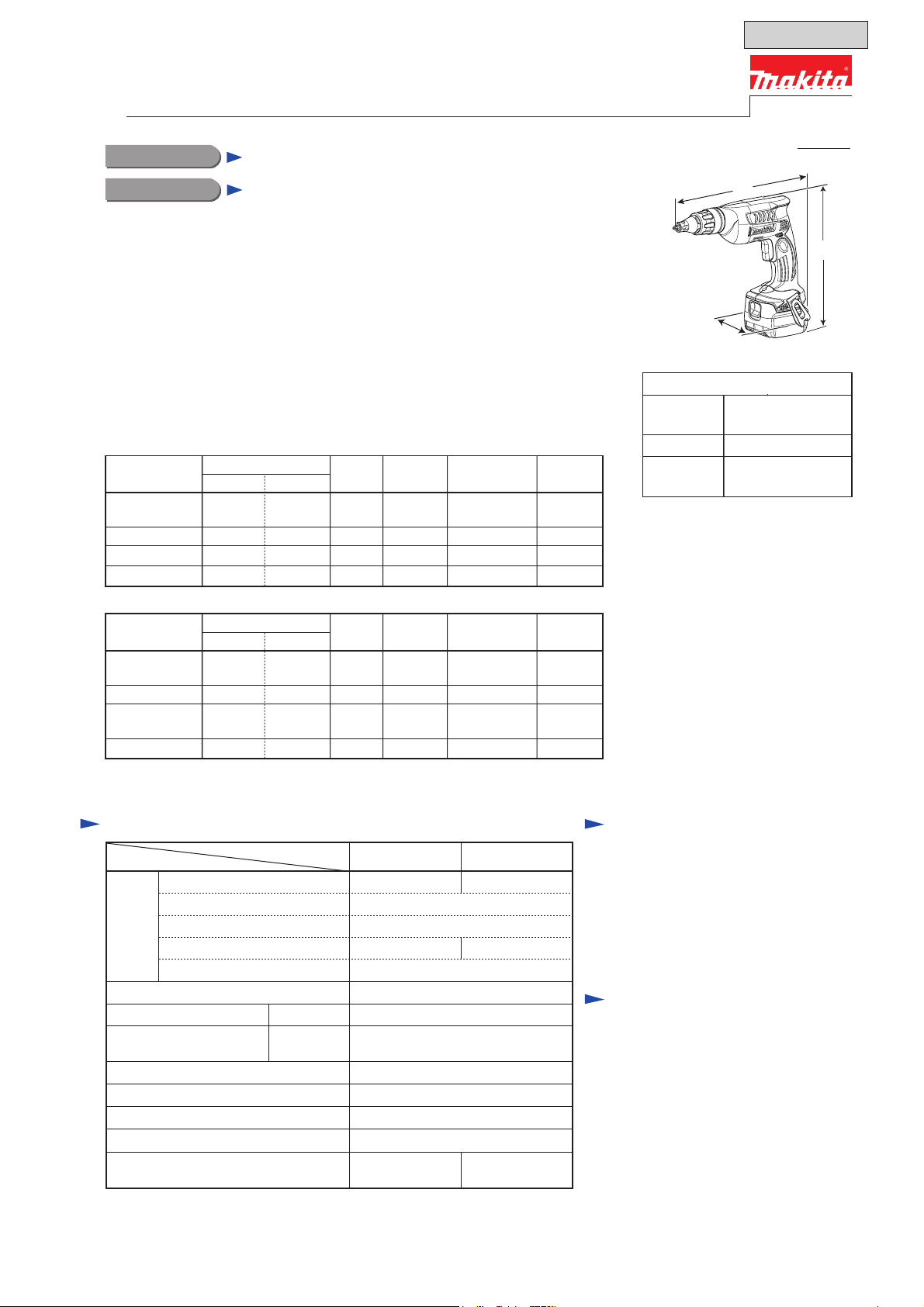

Makita BFS441Z, BFS441RFE, BFS441ZX, BFS441RFX, BFS451Z Technical Information

...

OFFICIAL USE

for ASC & Sales Shop

T

ECHNICAL INFORMATION

Models No.

Description

BFS441 , BFS451

Cordless Screwdriver

CONCEPT AND MAIN APPLICATIONS

Models BFS441 and BFS451 are pistol grip Cordless Screwdrivers

with variable speed control switch, compact and lightweight body,

well balanced tool design for easy handling and maneuverability,

featuring the following main benefits:

● Best possible tool body for screwdriving

● Compatible with both 1.3Ah and 3.0Ah batteries

● Single LED job light with afterglow function

This model is available in the following variations.

BFS441

Model No.

BFS441Z

BFS441ZX

BFS441RFE

BFS451

Model No.

Battery

Type Quantity

No No NoNoNo No

No No YesNoNo No

BL1430 DC18RA NoYes

BL1430 DC18RA YesNo

Battery

Type Quantity

Battery

cover

2 1

2 1BFS441RFX

Battery

cover

Charger

Charger

carrying case

carrying case

Plastic

Plastic

Systainer

case

Systainer

case

PRODUCT

P 1/14

L

H

W

(The image above is BFS441.)

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

*2: with Magnetic connect bit 60

*3: with Magnetic connect bit 76

*4: with BL1415 or BL1815

*5: with BL1430 or BL1830

281 (11-1/8)*2

296 (11-5/8)*3

80 (3-1/8)

224 (8-7/8)*

241 (9-1/2)*5

4

BFS451Z

BFS451ZX

BFS451RFE

All models also include the accessories listed below in "Standard equipment".

No No NoNoNo No

No No YesNoNo No

DC18RA NoYes

BL1830

BL1830 DC18RA YesNo

2

2 1BFS451RFX

1

Specification

Specification

Voltage: V

Capacity : Ah

Battery Cell

Energy capacity: Wh

Charging time (approx.): min. 15/ 22 with DC18RA

Driver bit: mm (")

Capacities: mm (")

[drywall]

Electric brake Yes

Reverse switch

Variable speed control by trigger

LED job light

Weight according to

EPTA-Procedure 01/2003*

*6: With Battery

Model BFS451BFS441

6: kg (lbs)

14.4 18

1.3/ 3.0

Li-ion

19/ 44 24/ 54

0 - 4,000No load speed: min.-1 = rpm

6.35 (1/4) HexShank

4 (5/32)Diameter

Yes

Yes

Yes

1.4/ 1.6

(3.2/ 3.6)

1.5/ 1.7

(3.3/ 3.8)

Standard equipment

Phillips bit 2-25 ............................ 2

Magnetic connect bit

6.35-60 or 6.35-76 ........................ 1

Belt clip

Note: The standard equipment for

the tool shown above may vary

by country.

........................................ 1

Optional accessories

Phillips bit 1-25

Phillips bit 2-25

Phillips bit 3-25

Magnetic connect bit 6.35-60

Magnetic connect bit 6.35-76

Battery BL1415 for BFS441

Battery BL1430 for BFS441

Battery BL1815 for BFS451

Battery BL1830 for BFS451

Fast charger DC18RA

Charger DC24SC

except North American countries)

Charger DC18SD

Automotive charger DC18SE

(for all countries

P 2/14

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

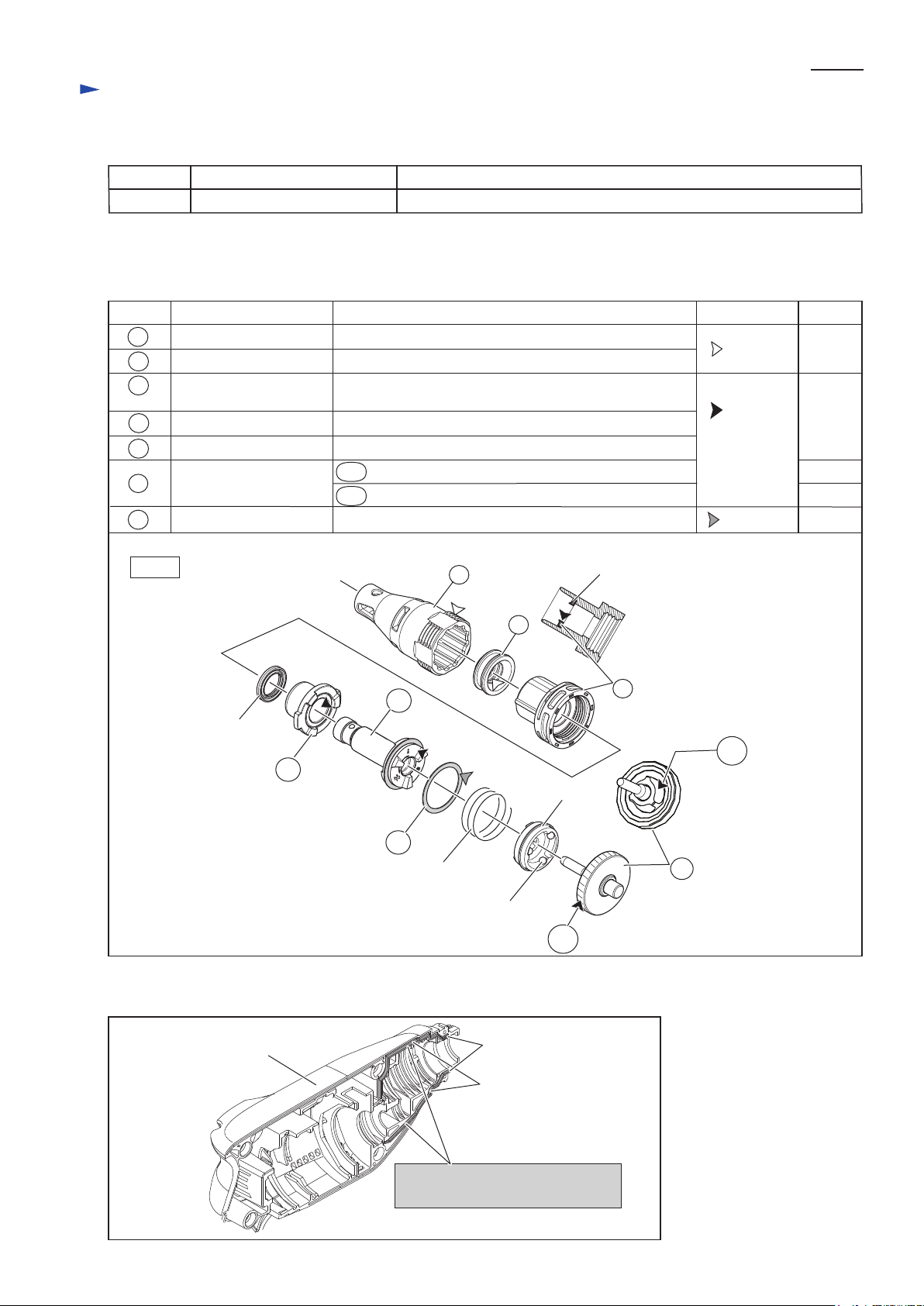

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICANT AND ADHESIVE APPLICATION

Fig. 1

Code No. Description Use for

1R269 Bearing extractor (small) removing Ball bearing 608ZZ

Item No.

Apply the following lubricants to protect parts and product from unusual abrasion. (Fig. 1)

Description Lubricant

VG32

3g

a little

a little

a little

a littleVG100

AmountPortion to lubricate

7

4

3

10

11

Clutch cam

X ring 14

Apply adhesive ThreeBond 1215 to the ribs surrounding gear room of Housing (L) complete. (Fig. 2)

Steel ball 4

18

18A

18A

18B

18B

Compression

spring 25

3

Locator complete Thread portion

4

Makita

grease

FA No.2

Internal surface

Internal surface

7 Locator base Internal surface of Dust seal 13 that Spindle 125S

complete contacts

10

Spindle 125S complete Surface that Clutch cam contacts

11 Flat washer 25 Surface that Compression spring 25 contacts

17 Bearing complete

Gear complete

Teeth portion

Concave for Steel ball 4

17

18

Dust seal sleeve

Dust seal 13

Fig. 2

Housing (L) complete

Apply 1g “ThreeBond 1215”

on the ribs surrounding gear room.

ribs

Apply the bond up to

the end of the ribs.

P 3/14

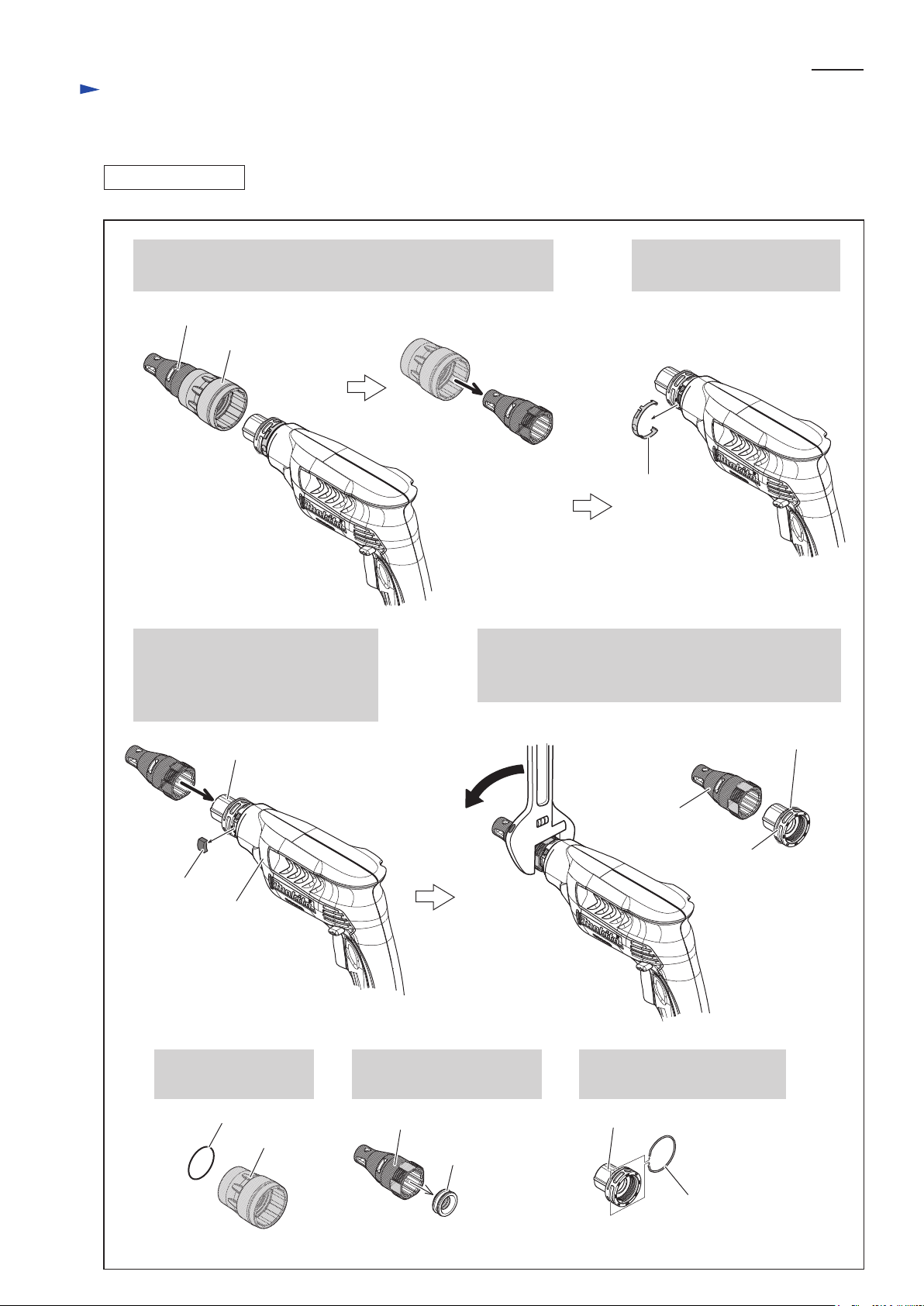

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Locator Section

DISASSEMBLING

1. Pull off Locator complete and Lock ring from Housing,

then remove Locator complete from Lock ring.

Locator complete

Lock ring

Leaf spring

Fig. 3

2. Remove Leaf spring with

slotted screwdriver.

3. Remove Rubber plate from

Housing (L) complete.

4. Mount Locator complete back

to Locator base complete.

Rubber plate

Remove Seal ring 30

from Lock ring

Remove Dust seal sleeve

from Locator complete.

Remove ring spring 33

from Locator base complete.

Housing (L) complete

Locator base complete

5. Grip flat portion of Locator complete with

adjustable wrench, then turn it clockwise

to remove Locator base complete from Housing.

Locator base

complete

Ring spring 33

Locator

complete

Locator complete

Dust seal sleeve

Lock ring

Ring spring 33

Seal ring 30

Locator base complete

P 4/14

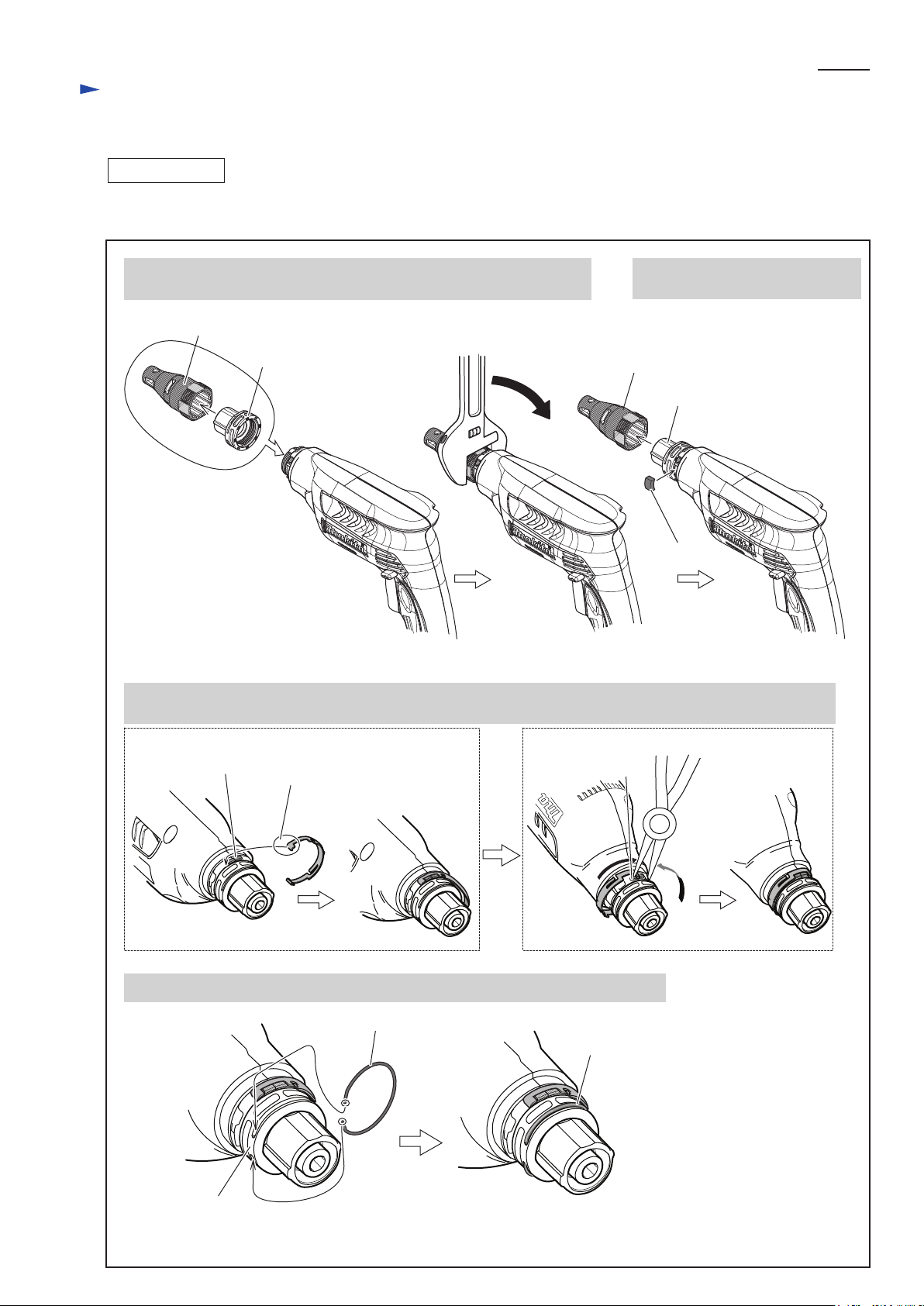

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Locator Section

ASSEMBLING

Rubber plate

1) Assembling of Locator base complete, Locator complete, Leaf spring and related parts. (Fig. 4)

1. Mount Locator complete to Locator base complete and fix them

to Housing set by tightening counterclockwise with adjustable wrench.

2. Remove Locator complete again,

then put Rubber plate in place.

Locator base complete

Locator base complete

Locator complete

3. Fit the tab of Leaf spring to Housing top as described below, then fix the other tab of Leaf spring to

Housing bottom with pliers.

4. Fix Ring spring 33 in the groove on Locator base complete as described below.

tab of

Leaf spring

Locator complete

Ring spring 33

Ring spring 33

Fig. 4

Locator base

complete

protrusion on

Housing top

protrusion on

Housing bottom

P 5/14

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Locator Section

ASSEMBLING

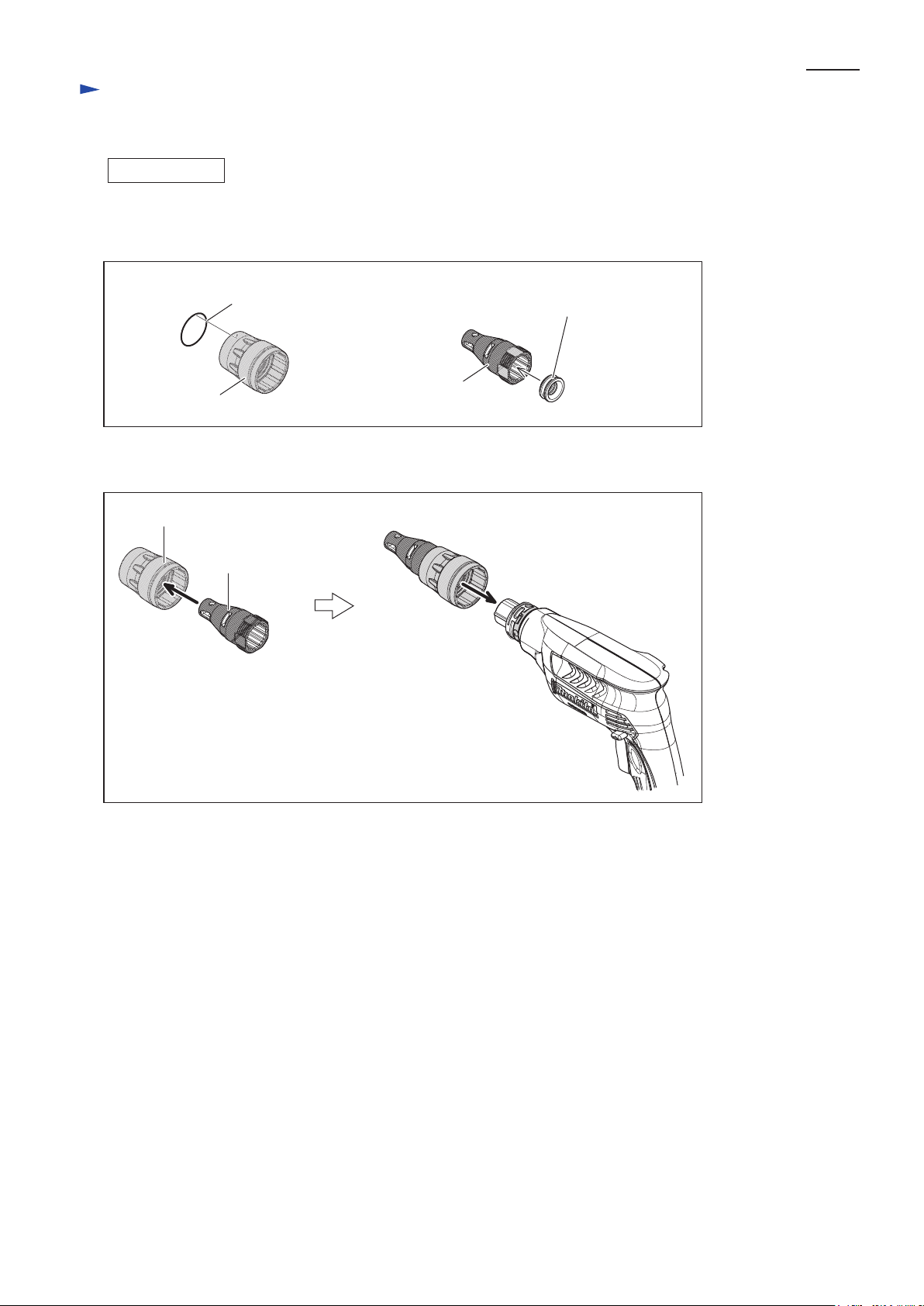

2) Make sure to put Seal ring 30 in Lock ring and Dust seal sleeve in Locator complete

before mount them on Housing. (Fig. 5)

Dust seal sleeve

Seal ring 30

Lock ring

Locator complete

Fig. 5

Locator complete

Lock ring

Fig. 6

3) Insert Locator complete into Lock ring and mount them on Housing. (Fig. 6)

Loading...

Loading...