Page 1

T

ECHNICAL INFORMATION

Models No.

BFL300F, BFL400F, BFL401F

NEW TOOL

P 1 / 13

Description

Cordless Angle Screwdriver 14.4V

CONCEPT AND MAIN APPLICATIONS

Models BFL300F and BFL400F have been developed

as specialist tools for industrial assembly applications,

featuring high torque capacity of 30N.m (BFL300F)/

40N.m (BFL400F).

Their brief advantages are;

*High precision fastening

*DC brushless motor for increased no load speed

*14.4V, 2.7Ah Ni-MH battery equipped with new type

battery cells for more efficient energy supply to motor

Model BFL401F is a sister tool designed for Italy.

These models do not include battery and charger.

Specification

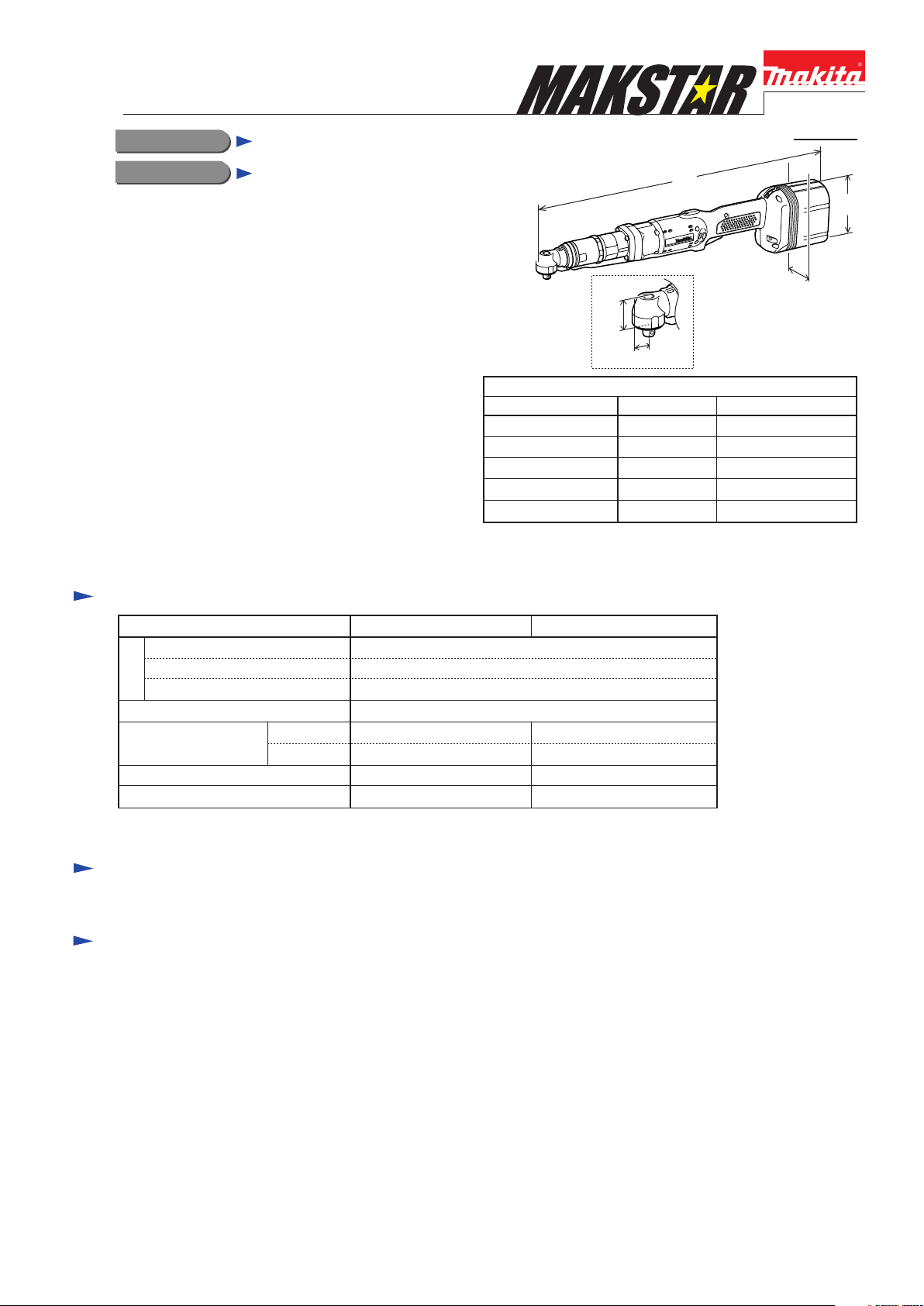

HH

Model No.

Length (L)

Width (W)

Height (H)

Head height (HH)

Center height (CH)

L

CH

Dimensions: mm (")

BFL300F

506 (20) 510 (20-1/16)

73 (2-7/8)

104 (4-1/8)

31.5 (1-1/4)

16 (5/8)

*Battery is optional.

BFL400F/ BFL401F

104 (4-1/8)

34 (1-5/16)

H

W

73 (2-7/8)

18 (11/16)

BFL300F

Voltage: V

Capacity: Ah

Battery

Cell

Capacity 9.5mm (3/8") Square drive*

Fastening torque: N.m

No load speed: min.-1=rpm

Net weight: kg (lbs)

*Note: 12.7mm (1/2") with optional Spindle G complete

Hard joint

Soft joint

16 - 30 25 - 40

16 - 30 25 - 40

400 260

2.3 (5.1) 2.4 (5.3)

Ni-MH

BFL400F/ BFL401FModel No.

14.4

2.7

Standard equipment

No (however, with Protector for some countries, and with Torque adjust tool for some countries)

Optional accessories

Ni-MH battery BH1427

Chargers DC24SA, DC14SA, DC14SC

Automatic refreshing adapter ADP03

Switch lever set (paddle switch)

Spindle G complete (12.7mm square drive)

Protectors Red, Blue, Yellow, Clear

Torque adjust tool

Page 2

Repair

Warning: Always be sure to disconnect battery cartridge from the machine before starting repair.

Note: See the instruction manual for safety instructions, safety rules and operating instructions.

-- Contents --

[1] Necessary Repair Tools ..................................................................................... III - 1

[2] Grease and Adhesive ......................................................................................... III - 1

[3] Disassembling/ Assembling .............................................................................. III - 2

[3] -1. Disassembling/ Assembling of Job Light Section ................................... III - 2, 3

[3] -2. Disassembling/ Assembling of Bearing Retainer .................................... III - 3

[3] -3. Disassembling/ Assembling/ Adjustment of Angle Head Section ........... III - 3, 4

[3] -4. Disassembling/ Assembling of Clutch Case Section ............................... III - 4, 5

[3] -5. Disassembling/ Assembling of Clutch Section ........................................ III - 5

[3] -6. Disassembling/ Assembling of Gear Case Section .................................. III - 5 -7

[3] -7. Disassembling/ Assembling of Switch Section ........................................ III - 7, 8

[1] NECESSARY REPAIR TOOLS

(Code No.) (Tool Name)

1R004 Retaining Ring Pliers ST-2

1R005 Retaining Ring Pliers RT-2N

1R006 Retaining Ring Pliers RT-2E

1R008 Tips for Retaining Ring Pliers

1R033 Bearing setting Plate 10.2

1R219 Torque Wrench Shaft 7-23N.m

1R220 Ratchet Head 9.5

1R222 Socket Adapter

(Code No.) (Tool Name)

1R223 Torque Wrench Shaft 20-90N.m

1R269 Bearing Extractor

1R291 Retaining Ring S and R Pliers

1R341 Spanner Head

134844-7 Socket 27-50 Ass'y

134848-9 Socket 27-50 Ass'y

765025-8 Torque Adjust Tool

P 2 / 13

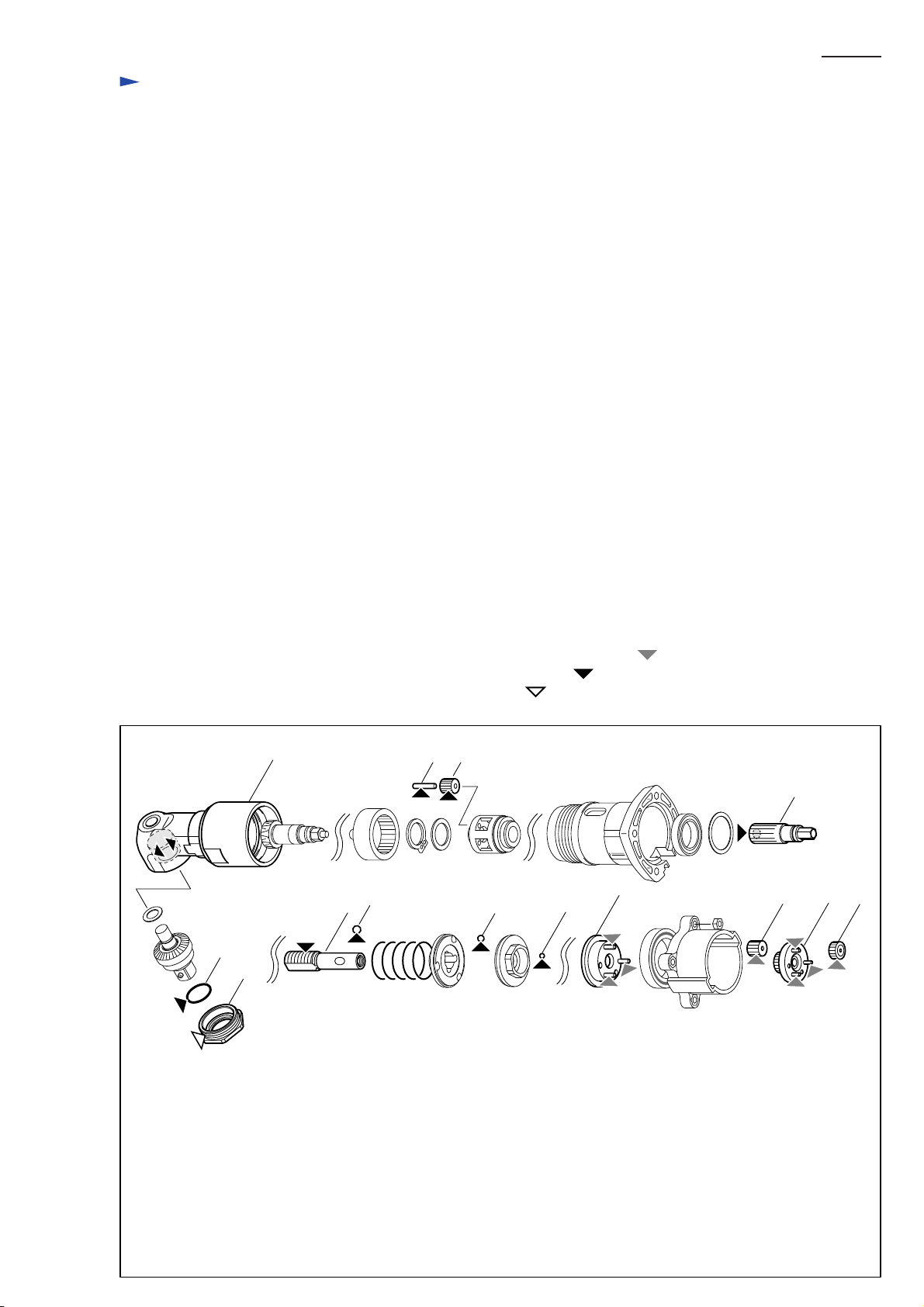

[2] LUBRICATION AND ADHESIVE

See the parts breakdown below.

Apply 2.0g of Makita Grease N. No.2 to the portions designated with the mark of .

Apply Makita seal lubricant to the portions designated with the mark of .

Apply Loc-Tite 603 to the portions designated with the mark of .

Fig. 1

63

64

10

39

40

2221

48

43 45

31

51 52 53

The portions to lubricate with Makita

Seal Lubricant No. 101

10. Gear room of Angle Head Complete

21. Pin 3 (5 pcs)

22. Teeth of Spur Gear 14

31. Hole on Spur Gear 21

39. Threads on Spindle

40. Steel Ball 5.0 (3 pcs)

43. Steel Ball 4 (3 pcs)

45. steel ball 3 (13 pcs)

63. O Ring 15

The portions to lubricate with Makita Grease N No.2

48. Three gear shafts of Carrier Complete (A)

51. Spur Gear 13 (3 pcs)

52. Spur Gear 20 Complete

53. Spur Gear 15 (3 pcs)

The portions to apply Loc-Tite 603

36. Threaded portion of Bearing Retainer 15-26

Page 3

P 3 / 13

[3] DISASSEMBLING/ ASSEMBLING

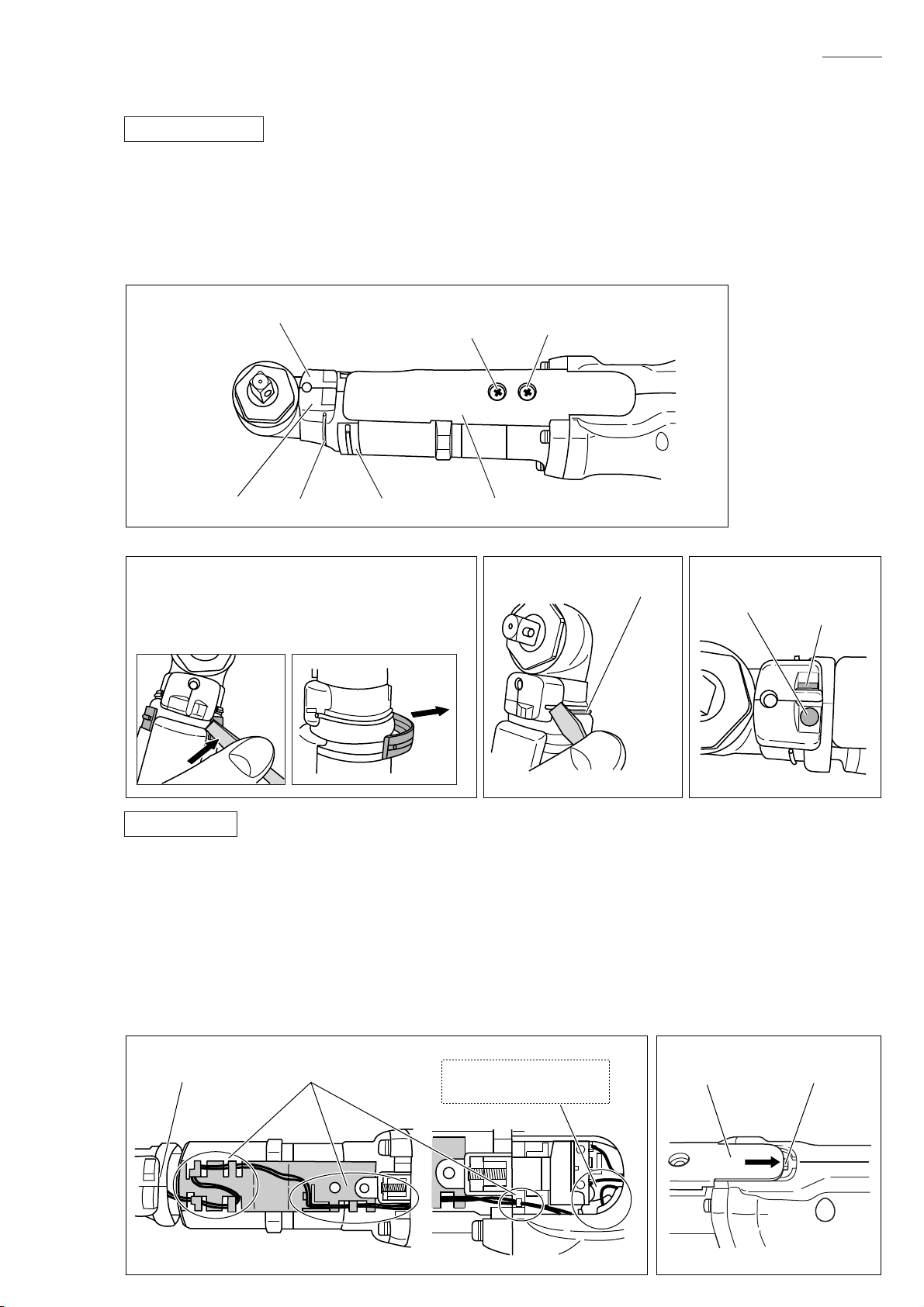

[3] -1. Disassembling/ Assembling of Job Light Section

DISASSEMBLING

*Shown in Fig. 2 are the parts of Job light section.

1) Remove Lead cover (on which Ring spring 36 is installed) and Ring spring 29 using a slotted screwdriver. (Figs. 3, 4)

2) Remove Light covers (R) and (L) while pushing the portion designated with the gray circle to unlock the tab on

Light cover (R) from the slot in (L). (Fig. 5)

3) Separate Switch cover from the tool by removing two M4x8 Pan head screws.

4) Remove Lead wires and LED circuit from Lead wire holders and Light cover (R), and disconnect Connector. (Fig. 6)

Fig. 2

Light cover (L)

Light cover (R)

Fig. 3 Fig. 4 Fig. 5

Push the end face of Lead cover using a slotted

screwdriver till it is lifted up as illustrated to left

below. Now Lead cover can be removed by pulling

in the direction o the arrow as illustrated to right.

Ring spring 29

Pan head screw M4x8

(for fixing Ring 38)

Lead cover Switch cover

Pan head screw M4x8

(for fixing Switch cover)

Ring spring 29

Push here.

tab

ASSEMBLING

1) Fix Lead wires securely with Lead wire holders, and then install LED circuit on Light cover (R).

At this time, put the sag of Lead wires in place as illustrated to right in Fig. 6.

2) Push the tab on Light cover into the cut in Housing before fastening screws. And then fasten Switch cover with two

M4x8 Pan head screws. Be careful not to pinch the Lead wires at this time. (Figs. 2, 7)

3) Install Light covers (R) and (L) while locking the tab on Light cover (R) in the slot in (L), then Ring spring 29. (Fig. 5)

Ring spring 29 can be easily installed by fixing one end on the groove in Light cover, then pushing toward Light cover

while expanding the other end. (Fig. 8)

4) Being careful not to pinch the Lead wires from LED circuit, install Lead cover (on which Ring spring 36 is installed)

as illustrated in Fig. 9.

Fig. 6 Fig. 7

LED circuit Lead wire holders Switch cover tab

Put the sag of Lead wires

in this portion.

Page 4

P 4 / 13

[3] -1. Disassembling/ Assembling of Job Light Section (cont.)

Fig. 8 Fig. 9

Lead cover

Ring spring 36

Lead wire

Ring spring 29

[3] -2. Disassembling/ Assembling of Bearing Retainer

DISASSEMBLING

Turn Bearing retainer clockwise using a 27mm spanner for BFL300F/ 32mm

spanner for BFL400F and BFL401F. Now Bearing retainer can be removed

by pushing it down as illustrated in Fig. 10.

ASSEMBLING

1) After applying Makita seal lubricant No.101 to O ring 15, put O ring 15 and

Bearing retainer in place on Spindle complete.

2) Put 2g of Makita seal lubricant No.101 in the gear room of Angle head complete.

At this time, be careful not to put the grease on the threaded portion of Angle head complete.

3) Apply Loctite 603 to the threaded portion of Bearing retainer, and screw it into Angle head complete.

At this time, remember to put Flat washer 5 in place.

4) Fasten Bearing retainer to the recommended torque of 30 - 50N.m by turning counterclockwise with the following tools;

1R219, 1R220, 1R222, 134844-7 (for BFL300F), 134848-9 (for BFL400F/ BFL401F)

Fig. 10

Bearing retainer

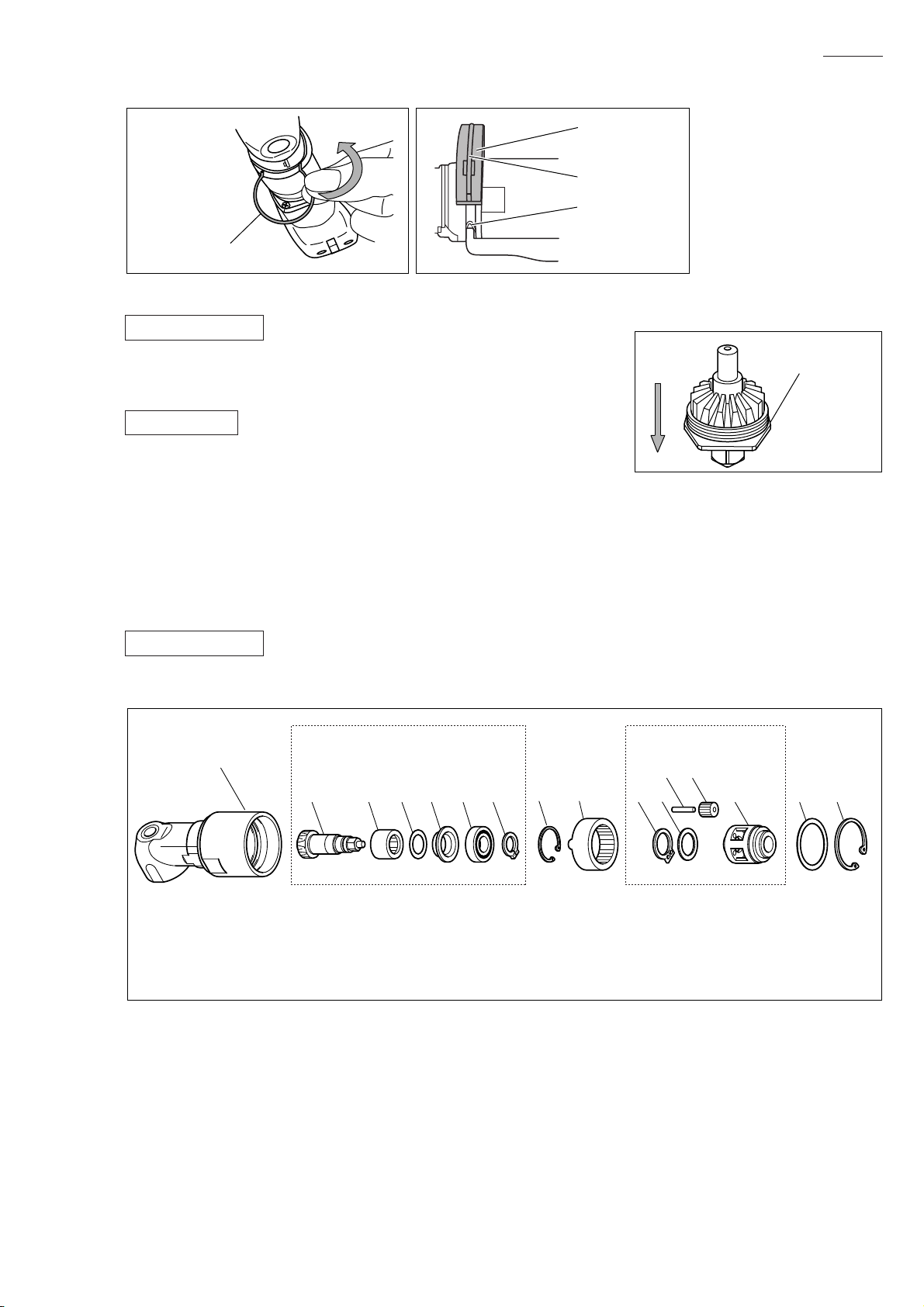

[3] -3. Disassembling/ Assembling/ Adjustment of Angle Head Section

DISASSEMBLING

*Shown in Fig. 11 are the parts of Angle head section.

Fig. 11

10

10) Angle head complete

11) Spiral bevel gear 9

12) Needle bearing 1212

13) Thin washer 12

14) Spacer

1) Remove Light covers (R) and (L), Ring spring 29, Lead cover and Switch cover. (Refer to [3] -1.)

2) Fix Angle head by clamping its two flats using adjustable wrench or vise, and remove Hex nut M36-41 by turning

in the direction of the arrow with 1R223 and 1R341. (Figs. 12, 13)

Caution: When clamping Bearing retainer, be very careful not to deform it by overtightening.

3) Remove Angle head complete by turning counterclockwise.

4) Remove Retaining ring R-32 using 1R006 or the like, then Flat washer 26, Internal gear 50 and Carrier section.

5) Remove Retaining ring S-14 from Carrier section using 1R291 or the like. Now the following parts can be replaced;

Flat washer 14, Pin 3 (5pcs), Spur gear 14 (5pcs)

Note: Pin 3 can be pulled out easily by using a magnet.

6) Remove Retaining ring R-22 located inside Angle head complete using 1R005 or the like.

7) Remove Spiral bevel gear 9 section by hitting the end face of Angle head complete. (Fig. 14)

8) Remove Retaining ring S-10 from Spiral bevel gear 9 section using 1R004, 1R008 or the like.

Now the following parts can be replaced by removing Ball bearing 6900LLB with 1R269 or the like:

Spiral bevel gear 9, Spacer, Thin washer 12, Needle bearing 1212

Spiral bevel gear 9 section Carrier section

21 22

11 12 13 14 15 16 17 18 19 20 23 24 25

15) Ball bearing 6900LLB

16) Retaining ring S-10

17) Retaining ring R-22

18) Internal gear 50

19) Retaining ring S-14

20) Flat washer 14

21) Pin 3 (5pcs)

22) Spur gear 14 (5pcs)

23) Carrier

24) Flat washer 26

25) Retaining ring R-32

Page 5

[3] -3. Disassembling/ Assembling/ Adjustment of Angle Head Section (cont.)

Fig. 12 Fig. 13 Fig. 14

P 5 / 13

two flats

Angle head complete

ASSEMBLING

1) Assemble Needle bearing 1212, Thin washer 12 and Spacer to Spiral

bevel gear 9.

Caution: Spacer is not reversible when assembled to Spiral bevel gear 9.

Be sure to place as illustrated in Fig. 11.

2) Press-fit Ball bearing 6900LLB to Spiral bevel gear 9 using arbor press

and 1R033. Assemble Retaining ring S-14 to Spiral bevel gear 9

to complete assembling of Spiral bevel gear 9 section.

And then insert Spiral bevel gear 9 section into Angle head complete.

3) Assemble Retaining ring R-22 to Spiral bevel gear 9.

4) Put Internal gear 50 in Angle head complete so that the protrusions on

Internal gear 50 fit in the matching holes on Angle head complete.

(Fig. 15)

5) Assemble Spur gear 14 and Pin 3 (5 pcs each) to Carrier, and then Thin washer 14 and Retaining ring S-14 to complete

Carrier section.

6) Insert Carrier section into Angle head complete, and apply 1.5g of Makita seal lubricant No.101 to Spur gear 14.

7) Install Flat washer 26 and Retaining ring R-32.

No.1R223

No.1R341

Adjustable wrench

Fig. 15

protrusion

Internal gear 50

matching hole

Angle head complete

ADJUSTMENT

1) Fasten Angle head complete and Hex nut M36-41 to Clutch case section to the full by hand.

2) Turn Angle head complete counterclockwise to adjust to a desired angle.

3) Being very careful not to turn Angle head complete, fix it securely by turning Hex nut M36-41 clockwise with 1R223

and 1R341 to the recommended torque of 30 -50N.m.

4) Make sure that Lead wires are fixed in place with Lead wire holders as illustrated in Fig. 6.

Then, being careful not to pinch Lead wires, install Lead cover.

[3] -4. Disassembling/ Assembling of Clutch Case Section

DISASSEMBLING

*Shown in Fig. 16 are the parts of Clutch case

section.

1) Remove Angle head section. (Refer to [3]-1, 3.)

2) Remove Compression spring 2 and Switch lever.

3) Clutch case, Clutch assembly and Compression

spring 5 can be removed by removing four

M4x22 Pan head screws.

4) Remove Retaining ring R-26 using 1R006

or the like.

5) Push out Spur gear 21, and then, after removing

Flat washer 21 using slotted screwdriver or

the like, push out Ball bearing 6803ZZ.

6) Remove Retaining ring S-10 using 1R004 and

1R008 or the like, then Ball bearing 6000DDW

using 1R269 or the like.

Now Spur gear 21 can be replaced.

7) Remove Hex nut M36-41 by turning

counterclockwise. Remove Ring 38, and now

Clutch case can be replaced.

Fig. 16

28

69 70 71

28) Clutch case

29) Ball bearing 6803ZZ

30) Flat washer 21

31) Spur gear 21

32) Ball bearing 6000DDW

33) Retaining ring S-10

29 30 31 32 33 34 35

34) Retaining ring R-26

35) Compression spring 5

69) P.H. Screw M4x22 (4pcs)

70) Compression spring 2

71) Switch lever

Page 6

[3] -4. Disassembling/ Assembling of Clutch Case Section (cont.)

ASSEMBLING

1) Press-fit Ball bearing 6000DDW to Spur gear 21 using arbor press and 1R033 or the like,

then install Retaining ring S-10 on Spur gear 21.

2) Into Clutch case, insert first Ball bearing 6803ZZ, next Flat washer 21, and third Spur gear 21.

Then install Retaining ring R-26.

Remark: Remember to place Compression spring 5 between Clutch case and Clutch assembly.

3) Put an appropriate amount of Makita seal lubricant in the hole on Spur gear 21. (Fig. 1)

[3] -5. Disassembling/ Assembling of Clutch Section

Note: When repairing Clutch section, it is recommended to entirely replace Clutch assembly with fresh one.

However, if required to replace component parts of Clutch assembly, follow the disassembling/assembling

procedure described below

P 6 / 13

DISASSEMBLING

1) Remove Clutch case section, and take Clutch section out of

the machine. (Refer to [3]-1, 3, 4.)

2) Insert Torque adjust toll into the hole of Adjust ring complete,

and turn it counterclockwise to remove Lock nut M12.

Decrease in the pressure of Compression spring 19 allows

you to remove Lock nut M12 by turning it clockwise by

hand. (Fig. 17)

3) Remove Adjust ring complete, Flat washer and Compression

spring 19 from Spindle.

4) While shifting the positions of Cam A and Cam D, replace

Steel ball 3.0 (13 pcs.), Steel ball 4.0 (3 pcs.)

and Steel ball 5.0 (3 pcs.).

Steel balls can be removed easily by using a magnet.

ASSEMBLING

1) Apply Makita seal lubricant No. 101 to Steel ball 5.0

(3 pcs.), Steel ball 4.0 (3 pcs.) and Steel ball 3.0

(13 pcs.), and set these Steel balls in place on the Cams.

(Fig. 18)

2) Apply Makita seal lubricant No. 101 to the male threads

on Spindle, and then assemble Compression spring 19,

Flat washer and Adjust ring complete to Spindle,

and then secure Lock nut M12 to Spindle by turning it

counterclockwise using Torque adjust tool, etc.

Fig. 18

Fig. 17

Adjust ring complete

Flat washer

Cam D

Cam A

Compression spring 19

Steel ball 3.0 (13 pcs)

Lock nut M12

Turn Torque adjust tool

counterclockwise.

Steel ball 5.0 (3 pcs)

Cam A

Threads on Spindle

[3] -6. Disassembling/ Assembling of Gear case Section

DISASSEMBLING

1) Remove Switch lever, Switch cover and Compression spring 2. (Refer to [3] -1.)

2) Remove four M4x22 Pan head screws to separate Clutch case from the machine.

3) Remove seven M3x20 Pan head screws to separate Housing (L) from (R).

4) Remove switch unit from Gear case.

5) Separate Gear case section from Motor control unit by lifting up them, then turning

Motor bracket counterclockwise. (Fig. 19)

6) Pull off Motor bracket from Rotor, and then pull off Rotor from Motor control unit.

7) Remove Lock washer located in Gear case by turning counterclockwise with pliers

or slotted screwdriver. (Fig. 20)

8) Remove Spur gears, Internal gear, Carrier complete and Ball bearing 6805LLB.

Cam D

Steel ball 4.0 (3 pcs)

Page 7

[3] -6. Disassembling/ Assembling of Gear Case Section (cont.)

Fig. 20Fig. 19

P 7 / 13

Gear case section

Turn Motor bracket counterclockwise, and then

Separate Gear case section from Motor control unit.

ASSEMBLING

1) After applying Makita grease N No.2 to teeth of all Spur gears, shafts of Carrier complete and shafts of Spur gear 20

complete, assemble Ball bearing 6805LLB and Carrier complete (A) to Gear case. (Fig. 1)

And then assemble Internal gear 47 and Spur gears from the opposite side.

2) Install Rotor on Motor control unit as described below;

Fix Motor control unit on table or the like, and insert Rotor slowly into Motor control unit till it touches the surface of

the table. Then lift up Motor control unit gradually till it stops. (Fig. 21)

Caution: 1. Because Rotor is a strong magnet, be sure to remove metal chips or debris from it before installation,

and be very careful not to pinch your fingers between Rotor and metal parts, etc.

2. Be careful not to shock the printed wiring board of Motor control unit.

3) Install Lock washer on Gear case. Then put Motor bracket on Gear case, and turn it clockwise to lock in place.

4) Assemble Gear case section and Motor control unit to Housing (R) so that the lead wires of Motor control unit and the

Switch unit installation portion on Gear case face the side of the LED - Trigger switch line. (Fig. 22)

When assembling, fit the boss on Housing (R) in the notch in Motor control unit. (Fig. 23)

Fig. 21

Motor bracket

Motor control unit

Fig. 22

Lock washer

Gear case section

Turn Lock washer counterclockwise using pliers

or slotted screwdriver, and

Remove from Gear case section.

Fix Motor control unit, and insert Rotor.

Lift up Motor control unit till it stops.

5) Set Switch unit in place on Gear case.

6) Assemble the following parts to Housing (R) in numerical

order:

1. Controller of Motor control unit

2. Terminal

3. LED circuit

4. Assembly of Gear case section and Motor control unit

Put lead wires in place while taking care not ot pinch them.

After putting Switch section in place, install Plate and Lens.

Then fasten Housing (L) to (R) with seven M3x20 Pan head

screws. (Fig. 24)

Caution: When disconnecting connectors, do not pull lead

wires. (Fig. 25)

Gear case Motor control unit

Switch unit

installation portion Lead wires

Fig. 23

Motor control unit

notch

boss

Housing (R)

Page 8

[3] -6. Disassembling/ Assembling of Gear Case Section (cont.)

Fig. 24

Plate

Lens

Fix lead wires with lead wire holders.

P 8 / 13

Fix lead wires with lead wire holders.

Fig. 25

LED circuit Switch unit in Trigger Switch unit for

Switch unit for Clutch Buzzer circuit Terminal

rotation reverse

Terminal

Color of Lead Wires

Blue, Black

Yellow, White

Yellow, Blue

Purple, Yellow

Red, White

Positive: Red, Negative: Black

[3] -7. Disassembling/ Assembling of Switch Section

Although Switch section can be disassembled, you can also use Switch assembly to entirely replace Switch section.

DISASSEMBLING

1) Remove Clutch case section and Housing (L).

(Refer to [3] -1, 6.)

2) Remove Switch unit in Trigger while expanding

the ribs. (Fig. 26)

3) Switch unit for rotation reverse can be replaced by

removing PT3x16 Tapping screw, then removing

Cover.

Now the following parts can also be replaced:

F/R Change lever, Leaf spring, Switch lever (A),

Compression spring (A)

Fig. 26

ribs

Switch unit in Trigger

Page 9

[3] -7. Disassembling/ Assembling of Switch Section (cont.)

P 9 / 13

ASSEMBLING

Put Leaf spring in place on F/R Change lever, and Compression

spring 4 on Switch lever (A).

Put F/R Change lever, Switch lever and Switch unit for rotation

reverse in place. At this time, fit the protrusion on F/R Change

lever in Switch lever (A). (Fig. 27)

Then, while pushing these parts with Cover, fasten with PT3x16

Tapping screw.

Fig. 28

protrusion on F/R Change lever

Switch lever (A)

Page 10

Circuit diagram

Fig. 28

P 10/ 13

Motor control unit

Terminal

Stator

Controller

Main switch

Switch unit B

(for rotation

reverse)

Switch unit A

(for Trigger)

Buzzer

circuit

Color index of lead wires' sheath

Black

White

Red

Yellow

Orange

Blue

= Tape

= Connector

LED PWB

(for display)

Switch unit C

(for clutch)

LED

circuit

(for job

light)

Page 11

Wiring diagram

[1] Wiring Around Controller

Fig. 29

P 11/ 13

rib (A)

Route the lead wires from

Switch unit (for rotation

reverse) between rib (A)

and rib (C).

rib (B)

Route the lead wires from

Switch unit (for Trigger)

between rib (B) and rib (C).

rib (C)

Route the lead wires (orange,

white, blue) from Controller

to Stator between the two pins.

pin

Switch

Place Connectors and the sag

of lead wires in the space

between ribs (A)- (B)- (C)

and pins- rib (D)- boss.

rib (D)

Connector

boss

Controller

Put the lead wires from

Controller to Buzzer on

the groove in Controller.

groove

Install Receptacles on

Terminal as illustrated

to right.

Lead wire (black)

Lead wire (red)

Buzzer

circuit

Put Connector and the lead

wires from Controller to

Buzzer between the ribs

on Controller.

Connector

rib

Terminal

Receptacles

Terminal

Page 12

Wiring diagram

[2] Wiring Around Stator

Fig. 30

P 12/ 13

Connector (to LED circuit)

Place Connectors and the sag

of lead wires in the space

between rib (E) and the inside

wall of Housing.

inside wall of Housing

Route the following lead wires from Controller

between rib (E) and the inside wall of Housing;

*wires to LED circuit

*wires to switch unit (for Clutch)

At this time, place the lead wires so that the tape

is positioned beside Printed wiring board.

tape

Switch unit (for Clutch)

Connector

rib (E)

Printed wiring board

pin

Route the three lead wires

(orange, white, blue) from

Controller to Stator between

the pin and Stator.

lead wire holder

First, put the following lead wires from Controller

in place;

*wires to LED circuit

*wires to switch unit (for Clutch)

Then, with the lead wire holder, fix the lead

wires (orange, white, blue) from Controller to

Stator.

Stator

rib (G)rib (F)

Route the six lead wires (orange, black, white,

yellow, blue, red) from Controller to Stator

between rib (F) and rib (G).

Page 13

Wiring diagram

[3] Wiring the Lead Wires from LED Circuit on Lead Holder

Fig. 31

Make the lead wires so that

they cannot be pulled to

disconnect LED circuit from

Controller when Switch

cover is installed.

tab

P 13/ 13

LED circuit

tab

Hook the lead wires

on the five tabs of

Lead holder.

Remark:

Do not place the lead

wires over the tabs.

Route the lead wires

under the pin.

pin

Route the lead wires

beside rib (K) and

Switch unit (for Clutch).

rib (K)

Route the lead wires between

rib (H) and rib (I), and then

rib (I) and rib (J).

rib (H)

rib (I)

rib (J)

tab

Put Connector and the sag

of the lead wires in the space

between Housing and rib (L).

rib (L)

Switch unit (for Clutch)

Connector

Loading...

Loading...