Page 1

T

ECHNICAL INFORMATION

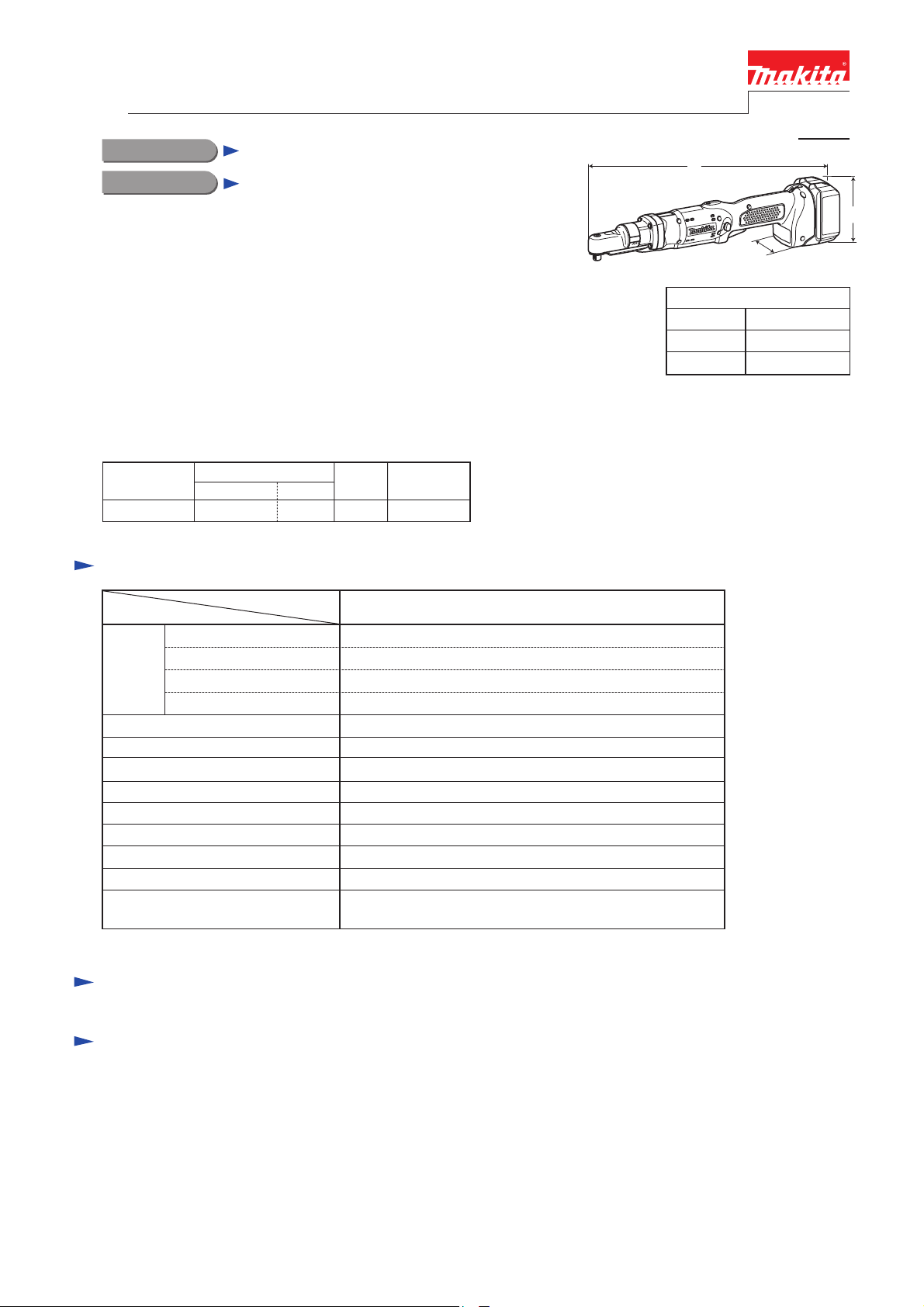

Model No.

Description

BFL201F

Cordless Angle Screwdriver 14.4V

CONCEPT AND MAIN APPLICATIONS

This cordless angle screwdriver for fastening works in assembling line is

developed as an advanced model of BFL200F.

Additionally to the same tool durability and high fastening torque accuracy

as the current series models, these products feature a powerful and efficient

power source and power unit, namely 14.4V/ 3.0Ah Li-ion battery* and

BLDC motor (Brushless DC motor).

*BL1430 and BL1430A can be used,

but 1.3Ah Li-ion battery BL1415 cannot be used.

This product is available in the following specifications

with the model number described below.

Model No.

BFL201FZ No No

Battery

type quantity

No

Battery

cover

No

Charger

PRODUCT

P 1/ 13

L

W

Dimensions: mm (")

Length (L) 429 (16-7/8)

Width (W)

Height (H)

72 (2-13/16)

98 (3-7/8)

H

Specification

Specifications

Voltage: V

Battery

Torque range: N.m (in.lbs) 8 - 20 (71 - 177)

No load speed: rpm= min

Driving shank: mm (")

Soft start

LED Job light

Electric brake

Reversing switch

Torque adjustment

Weight according to

EPTA-Procedure 01/2003* : kg (lbs)

* with Battery BL1430

Capacity: Ah

Cell

Max output: W

Model

-1 360

BFL201F

14.4

3.0

Li-ion

370

Square 9.5 (3/8)

Yes

Yes

Yes

Yes

Yes

1.7 (3.8)

Standard equipment

No

Optional accessories

Battery BL1430

Battery BL1430A

Fast charger DC18RA

Charger DC18SD

Charger DC24SC

Automotive Charger DC18SE

Auto refresh adapter ADP03

Battery protector (for BL1430A)

Protectors (red/ blue/ yellow/ clear)

Torque adjust tool

Angle head set

Page 2

P 2/ 13

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R041 Vise plate Protecting parts when holding in vise

1R034 Bearing setting plate 12.2 Installing Ball bearing 6900LLB

1R145 L-type torx wrench Loosening/tightening M5x10 Torx countersunk head screw

1R173 Retaining ring R pliers RT-1 Removing/installing Retaining ring R-22

1R219 Torque wrench shaft 7-23N.m Installing Bearing retainer

1R220 Ratchet head 9.5 (for 1R219) Installing Bearing retainer

Installing Bearing retainer1R222 Socket adapter

Removing Ball bearing 6900LLB1R269 Bearing extractor

1R288 Screwdriver Magnetizer Magnetizing Screwdriver for removing Steel balls

1R291

1R314 Torx bit VT-25

134861-3 Socket 24-45 Installing Bearing retainer

765027-4

783204-6

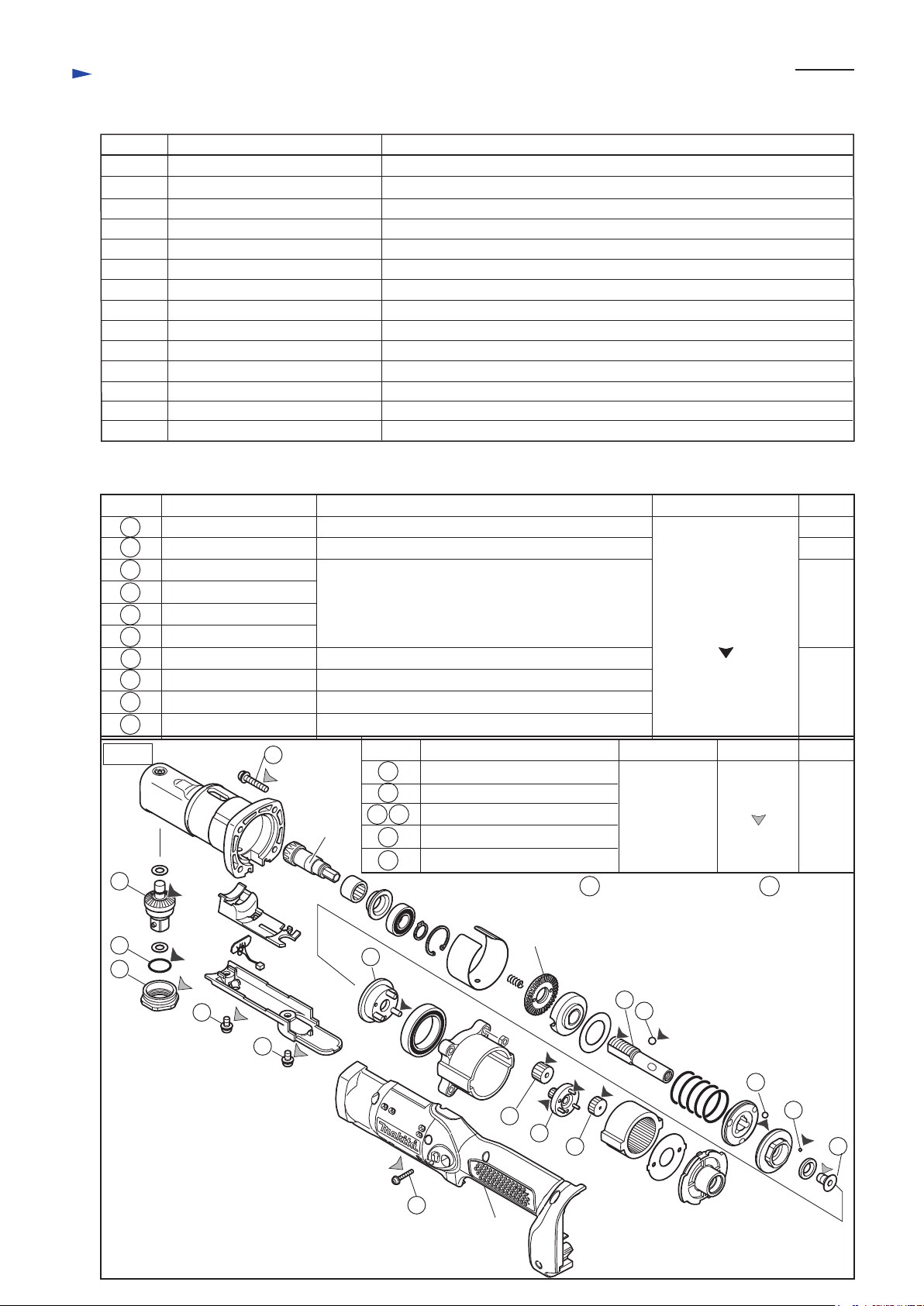

[2] LUBRICATIONS/ GLUING

Apply Makita grease N.No.2/ Loctite 603 to the portions designated by arrows.

Item No.

13

28

14

17

19

35

37

40

41

42

Fig. 1

28

Retaining ring S and R pliers Removing/installing Retaining ring S-10

Loosening/tightening M5x10 Torx countersunk head screw

Torque adjust tool Disassembling Clutch assembly

Hex wrench 6 (flats width: 6mm) Loosening/tightening Adjust ring complete

Description Portion to lubricate

Spindle Left hand where M12 Lock nut contacts

Spindle A complete Gear teeth that engages with Spiral bevel gear 9

Steel ball 5.0 (3pcs.)

Steel ball 4 (3pcs.)

Whole surface

Steel ball 3 (13pcs.)

O ring 14

Three shaft pinsCarrier complete B

Spur gear 18 (3pcs.)

Spur gear 9 complete A

Spur gear 18 (3pcs.)

2

Gear teeth

Gear teeth and three shaft pins

Gear teeth

Item No. Description Portion to glue Adhesive

M4x22 Pan head screw (4pcs.)

2

Spiral

bevel

gear 9

21

25 26

36

86

Torx C.S.H. screw M5x10

M4x8 Pan head screw

Bearing retainer 14-23

M3x20 Pan head screw (7pcs.)

Note: Part No. for 40 is different from that for 42 .

Lubricant Amount

Makita grease N.No.2

Thread

Loctite 603

a little

2g

a little

2g in

total

Amount

a little

35

36

25

26

37

86

40

Housing L

M12 Lock nut

41

42

13

14

17

19

21

Page 3

Repair

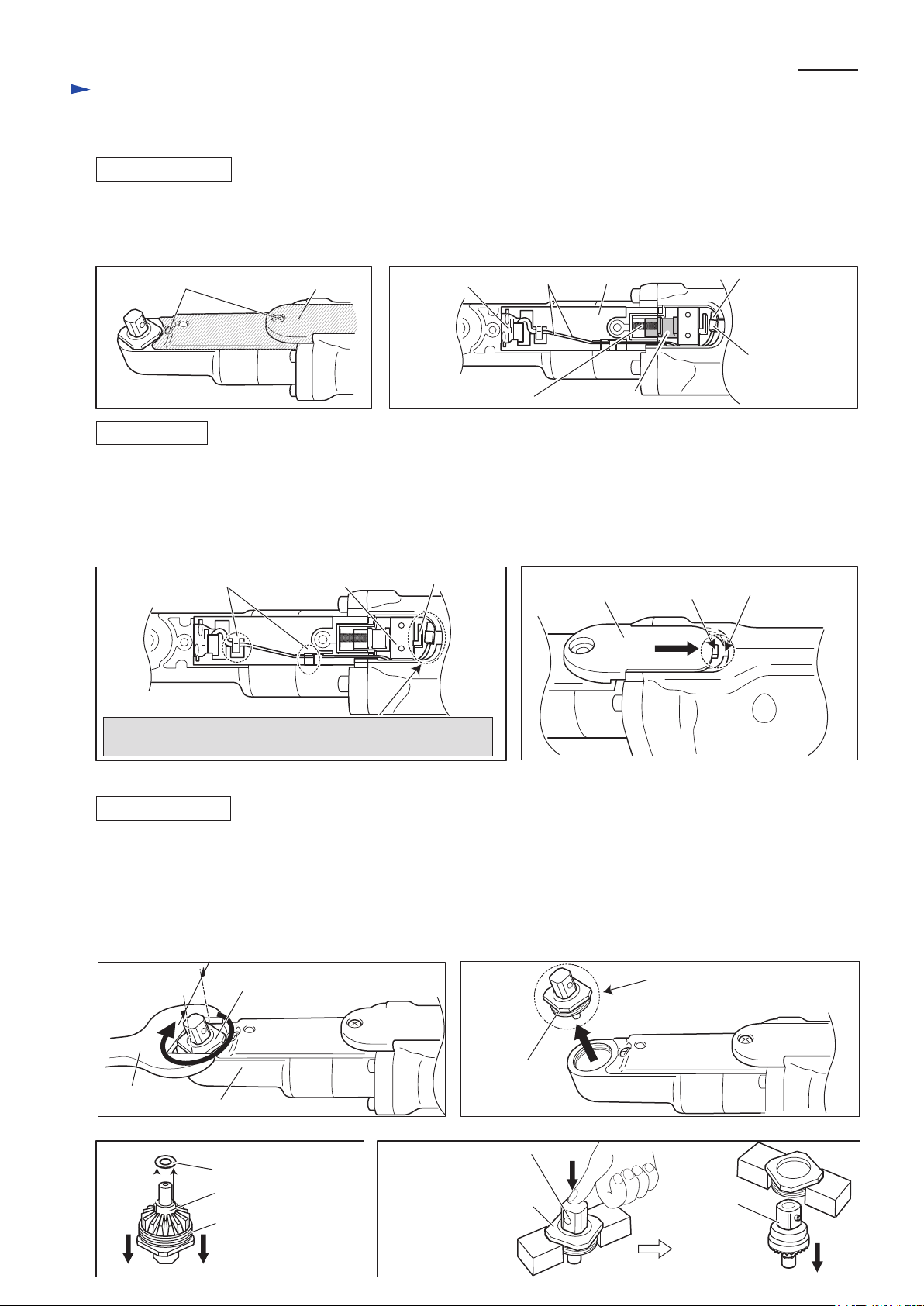

[3] DISASSEMBLY/ASSEMBLY

[3]-1. LED job light section

DISASSEMBLING

1) Remove Light cover by unscrewing two M4x8 Pan head screws. (Fig. 2)

2) Remove LED circuit and its Lead wires from Light holder, and disconnect Connector of LED circuit with that of

Motor control unit. Switch lever and Compression spring 2 can be removed in this step. (Fig. 3)

Fig. 2 Fig. 3

M4x8 Pan head screw (2pcs.) Light cover

ASSEMBLING

1) Connect Connector of LED circuit with that of Motor control unit. and put LED circuit in place on Light holder.

Then fix lead wires with Lead holders as illustrated in Fig. 4.

2) Fitting the protruding portion of Light cover in the notch of Angle head complete, assemble Light cover to

Angle head complete by screwing two M4x8 Pan head screws. (Fig. 5)

Note: Be careful not to pinch the slack portion of Lead wires between Light cover and Angle head complete.

LED circuit

Compression spring 2 Switch lever

RibSwitch unitLead wire holders

Lead wire

Light holder

Fig. 5Fig. 4

Light cover protrusion Notch of Angle

Connector of

Motor control

unit

Connector of

LED circuit

head complete

P 3/ 13

Note: Put Connectors and the slack portion of Lead wires in

this space. Do not put them on Switch unit and the rib.

[3] -2. Spindle A complete section

DISASSEMBLING

1) Remove Bearing retainer 14-23 from Angle head complete by turning clockwise with wrench of 24mm flats width.(Fig. 6)

Spindle A complete section can now be removed by pulling by hand. (Fig. 7)

2) Remove Flat washer 6 from Spindle A complete. (Flat washer 6 may remain in Angle head complete.)

Remove Spindle A complete from Bearing retainer 14-23 by pushing down Bearing retainer 14-23 in the direction of

the arrow by hand. (Fig. 8)

Note: If cannot be removed by hand, disassemble by pressing down Spindle A complete using arbor press. (Fig. 9)

Fig. 6 Fig. 7

Spindle A complete section

Spindle A

complete

Wrench

24mm

Angle head complete

Bearing retainer 14-23

Flat washer 6

Spindle A complete

Bearing retainer 14-23

Bearing

retainer 14-23

Fig. 9Fig. 8

Spindle A complete

Bearing retainer 14-23

Page 4

P 4/ 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Spindle A complete section (cont.)

ASSEMBLING

1) Apply Makita grease N.No.2 to O ring 14. (Fig. 1)

Assemble O ring 14, Flat washer 14 then Spindle complete to Bearing retainer 14-23 as illustrated in Fig. 10.

Note: If you cannot assemble Spindle complete to Bearing retainer 14-23 by hand, do it using arbor press as illustrated in

Fig. 11.

2) Apply about 2g of Makita grease N.No.2 to the Gear room of Angle head complete. (Fig. 1)

Note: Be careful not to put Makita grease N.No.2 on the threaded portion of Angle head complete.

3) Apply Loctite 603 to the threaded portion of Bearing retainer 14-23. (Fig. 1)

Then assemble Flat washer 6 to Spindle complete. (Refer to Fig. 8.)

Assembling of Spindle complete section has been completed.

4) Clamp the flats of Angle head complete securely in a vise to which 1 set of 1R041 is attached, then assemble Spindle A

complete section to Angle head complete by turning Bearing retainer 14-23 counterclockwise using 1R219, 1R220, 1R222

and 134861-3 as illustrated in Fig. 11.

Caution: When clamping Angle head complete, be very careful not to deform it by overtightening.

Fig. 11Fig. 10

1R2191R220

Spindle A complete

1R222

Flat washer 14

O ring 14

Bearing retainer 14-23

134861-3

1R041

Recommended tightening torque:

30 to 50N.m

Page 5

P 5/ 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Spiral bevel gear 9 section

DISASSEMBLING

1) Remove Light cover by unscrewing two M4x8 Pan head screws, then remove Switch lever and Compression spring 2.

(Fig. 12)

2) Remove Angle head complete from Housing by unscrewing four M4x22 (+) Pan head screws, then remove Clutch

section (= Clutch assembly) from Angle head complete. (Fig. 13)

Note: Be careful not to lose Compression spring 5, which may pop out from Clutch section when Clutch section is

removed from Angle head complete. (Fig. 13)

Fig. 13Fig. 12

Angle head complete

Housing

M4x22 (+) Pan head screws (4pcs.)

Switch lever

Compression spring 2

Light cover

3) Using 1R173, remove Retaining ring R-22

that retains Spiral bevel gear 9 section in

Angle head complete. (Fig. 14)

Spiral bevel gear 9 section can now be

removed by tapping the end surface of

Angle head complete with plastic

hammer. (Fig. 15)

4) Remove Retaining ring S-10 using 1R291, then remove Ball bearing 6900LLB using 1R269.

Spacer and Needle bearing 1210 can now be removed from Spiral bevel gear 9. (Fig. 16)

Fig. 16

1R291Retaining ring S-10

Retaining ring R-22

Ball bearing 6900LLB

1R173

1R269

Compression spring 5

Fig. 15Fig. 14

Needle baring 1210

Clutch section

(= Clutch assembly)

Spiral bevel

gear 9 section

Spacer

Spiral bevel gear 9

ASSEMBLING

Do the reverse of the disassembling steps. (Refer to Figs. 16 to 12.)

Note 1: Spacer is not reversible when assembled to Spiral bevel gear 9.

Be sure to assemble as illustrated to left in Fig. 17.

Note 2: Use 1R034 and arbor press when assembling Ball bearing 6900LLB to Spiral bevel gear 9. (Fig. 18)

Fig. 18Fig. 17

Arbor press

[Correct] [Wrong]

Needle baring 1210

Spiral bevel gear 9

Spacer

Spiral bevel gear 9

Needle baring 1210

Spacer

Ball bearing 6900 LLB

1R034

Page 6

P 6/ 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Clutch section

DISASSEMBLING

Note: When repairing Clutch section, it is recommended to entirely replace Clutch assembly with new one.

However, if required to replace component parts of Clutch assembly, follow the disassembling/assembling

procedure described below.

1) Take out Clutch section (=Clutch assembly) from Angle head complete. (Refer to Figs. 12 and 13)

2) Insert 765025-8 into the hole of Adjust ring complete, and turn it counterclockwise to remove M12 Lock nut:

the pressure of Compression spring 19H will be decreased, and M12 Lock nut can now be removed by turning it

clockwise by hand. (Fig. 19)

3) Remove Adjust ring complete, Flat washer 18, Compression spring 19H from Spindle. (Fig. 20)

4) The following Steel balls can be removed as illustrated in Fig. 21:

Steel ball 3 (13pcs.), Steel ball 4 (3pcs.), Steel ball 5.0 (3pcs.)

Note: Use a screwdriver magnetized with 1R288 for easy removal of Steel balls.

5) Insert short leg of hex wrench 6 into the hole of Spindle, and fix long leg of the hex wrench securely in vise.

Insert No.T25 Torx wrench of L type Torx wrench set (1R145) into the socket of M5x10 Torx countersunk head screw.

Then remove the screw by turning M5 Torx wrench counterclockwise as illustrated to left in Fig. 22.

The following parts can now be removed from Spindle: Cam D, Cam A on Torx screw side, Flat washer 7.(right in Fig. 22)

Fig. 19

Fig. 20

Adjust ring complete

M12 Lock nut

765025-8

Fig. 21

Steel ball 4 (3pcs.) and Steel ball 5.0 (3pcs.)

can be removed by moving Cam D towards

the threaded end of Spindle.

Cam D

Clutch section

(=Clutch assembly)

Cam A on Torx

screw side

M12 Lock nut

Compression spring 19H

Adjust ring

complete

Spindle

After removing Steel ball 4 (3pcs.) and Steel ball 5.0 (3pcs.),

Steel ball 3 (13pcs.) can be removed by moving *the Cam on

Torx screw side towards Cam D.

Steel ball 3.0 (13pcs.)

Cam A on Torx screw side

Flat washer 18

Compression

spring 19H

Steel ball 4 (3pcs.) Steel ball 5.0 (3pcs.)

Fig. 22

783204-6

6mm

M5x10 Torx countersunk

head screw

Spindle

T25 Torx wrench (T25 of 1R145)

Spindle

Cam D

Cam D

Cam A on Torx screw side

Flat washer 7

M5x10 Torx countersunk

head screw

Page 7

epair

R

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Clutch section (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note:

When fastening M5x10 Torx countersunk screw to Spindle, do as described in Fig. 23.

Apply Makita grease N. No.2 to all Steel balls and the Spindle's threaded portion for enaging with M12 Lock nut

before assembling. (Fig. 1) Be careful not to put the grease in the threaded hole of Spindle.

Fig. 23

P 7/ 13

M5x10 Torx countersunk head screw

Clean up this threaded portion with gasoline

or kerosene to remove oil or grease.

Clean up this threaded hole with gasoline

or kerosene to remove oil or grease from

the inner threaded portion.

Put about three drops of Loctite 603 in this

threaded hole.

Fix Spindle in vise.

Then fasten M5x10 Torx countersunk head screw to

the recommended torque of 8-10N.m by turning

Spindle

clockwise using 1R219, 1R220, 1R222 and 1R314.

Note: Wipe away any adhesive that might ooze out.

1R219

1R220

1R222

1R314

[3] -5. Gear case section

DISASSEMBLING

1) Remove Light cover, Switch lever and Compression spring 2. See [3] -1 on page 5.

2) Remove four M4x22 Pan head screws to separate Angle head complete from the machine. (See [3] -3 on page 7.)

3) Remove seven M3x20 Pan head screws to separate Housing (L) from (R).

4) Remove Switch unit from Gear case section.

5) Separate Gear case section from Motor control unit by first lifting them up, then turning Motor bracket counterclockwise.

(Fig. 24)

6) Pull off Motor bracket from Rotor, and then pull off Rotor from Motor control unit.

7) Remove Lock washer located in Gear case by turning counterclockwise with pliers or slotted screwdriver. (Fig. 25)

8) Remove Spur gears, Internal gear 47, Carrier complete B and Ball bearing 6805LLB.

Fig. 25Fig. 24

Gear case section

Motor bracket

Motor control unit

Lock washer

Turn Motor bracket counterclockwise, and then

Separate Gear case section from Motor control unit.

Caution for Handling Rotor

When handling or storing multiple Rotors, be sure to provide

the minimum distances specified in Fig. 26 between Rotors.

Rotor is a strongly magnetic body.

Therefore, failure to follow this instruction could result in:

Finger injury caused by pinching between Rotors pulling

each other

Magnetic loss of Rotors

Gear case section

Turn Lock washer counterclockwise using pliers

or slotted screwdriver, and

Remove from Gear case section.

Fig. 26

10.0 mm

(3/8")

15.0 mm

(9/16")

19.9 mm(13/16")

Page 8

P 8/ 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Gear case section (cont.)

ASSEMBLING

1) After applying Makita grease N No.2 to teeth of all Spur gears, shafts of Carrier complete B and shafts of Spur gear 9

complete A, assemble Ball bearing 6805LLB and Carrier complete B to Gear case. (Fig. 2) Then assemble Internal gear

47 and Spur gears from the opposite side.

2) Install Rotor on Motor control unit as described below;

Fix Motor control unit on table or the like, and insert Rotor

slowly into Motor control unit until it touches the surface

of the table. Then lift up Motor control unit gradually

until it stops. (Fig. 26)

Caution:

1. Because Rotor is a strong magnet, be sure to remove metal chips

or debris from it before installation, be very careful not to pinch

your fingers between Rotor and metal parts, etc.

2. Be careful not to shock the printed wiring board of Motor

control unit.

3) Install Lock washer on Gear case, then put Motor bracket on

Gear case, and turn it clockwise to lock in place.

4) Assemble Gear case section and Motor control unit to Housing (R)

so that Lead wires of Motor control unit and the Switch unit

installation portion on Gear case faces the side of the LED - Trigger

switch line. (Fig. 27)

When assembling, fit the boss on Housing (R) in the notch in

Motor control unit. (Fig. 28)

5) Set Switch unit in place on Gear case.

6) Assemble the following parts to Housing (R) in numerical order:

1. Controller of Motor control unit

2. Terminal

3. LED circuit

4. Gear case section to which Motor control unit is assembled

Put Lead wires in place while taking care not to pinch them.

After putting Switch section in place, install Plate and Lens.

Then fasten Housing (L) to (R) with seven M3x20 Pan head screws.

(Fig. 29)

Caution: When disconnecting connectors, do not pull lead wires.

(Fig. 30)

Fig. 26

Fix Motor control unit, and insert Rotor.

Lift up Motor control unit until it stops.

Fig. 27

Gear

case

Switch unit installation portion

Fig. 28

notch

boss

Motor

control

unit

Lead wires

Motor

control

unit

Housing (R)

Fig. 29

Fig. 30

LED circuit

Fix lead wires with

Lead wire holders.

Switch unit

(ON/OFF)

Plate

Lens

Cover

Switch unit for

F/R change

Power supply circuit

rib of Cover

Switch unit

for Clutch

Terminal

Fix lead wires with

lead wire holders.

Face the rib of Cover to

Terminal side and insert

the cover to Housing set.

Terminal

Color of Lead wires

Blue, Black

Yellow, White

Yellow, Blue

Purple, Yellow

Red, Black

Positive: Red

Negative: Black

Page 9

P 9/ 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Switch section

DISASSEMBLING

(1) Remove Light cover, Compression spring 2 and Switch lever illustrated in Fig. 12.

(2) Separate Angle head complete from Housing set as illustrated in Fig. 13. However, no need to remove Clutch assembly.

(3) Remove Housing set (L) and seven M3x20 Pan head screws, and then remove Switch section as illustrated in Fig. 31.

Fig. 31

Housing set (L)

M3x20 Pan head screw (7pcs.)

(4) Remove Switch unit in Trigger while expanding the ribs. (Fig. 32)

(5) Switch unit for rotation reverse can be replaced first by removing

PT3x16 T

Now the following parts can also be replaced:

F/R Change lever, Leaf spring, Switch lever (A), Compression spring 4

apping scre

w, then removing Cover.

Housing set (R).

Switch section

Fig. 32

ribs

ASSEMBLING

(1) Put Leaf spring in place on F/R Change lever, and Compression spring 4

on Switch lever A.

(2) Put F/R Change lever, Switch lever and Switch unit for rotation reverse

in place; at this time, fit the protrusion on F/R Change lever in Switch

lever A. (Fig. 33)

Then, fasten the above parts with PT3x16 Tapping screw while holding

them with Cover.

Switch unit in Trigger

Fig. 33

protrusion on

F/R Change lever

Switch lever A

Page 10

Circuit diagram

Fig. D-1

Terminal

Stator

Motor control unit

Main switch

Switch unit B

(for rotation

reverse)

P 10/ 13

Switch unit A

(for Trigger)

Power supply

circuit

Color index of lead wires' sheath

Black

White

Red

Yellow

Orange

Blue

Purple

Gray

Controller

RF unit

LED circuit

(for display)

Switch unit C

(for clutch)

LED

circuit

(for job

light)

= Tape

= Connector

Page 11

Wiring diagram

Wiring around Controller

Fig. D-2

P 11/ 13

rib (A)

Route Lead wires from

Switch unit (for rotation

reverse) between rib (A)

and rib (C).

rib (B)

Route Lead wires from

Switch unit (for Trigger)

between rib (B) and rib (C).

rib (C)

Put Power supply circuit

with Sponge on Housing (L) side.

Sponge

Switch

Controller

Power supply

circuit

Route Lead wires

(orange, white, blue)

from Controller to Stator

between the two pins.

pin

Put Connectors and

the slack portion of

Lead wires in the space

between ribs (A)- (B)- (C)

and pins- rib (D)- boss.

rib (D)

Connector

boss

Put Connector and Lead

wires from Controller to

Power supply circuit

between the ribs on

Controller.

Put Lead wires from Controller

to Power supply circuit on the

groove on Controller.

groove

RF unit

Terminal

Install Receptacles on Terminal as illustrated below.

Lead wire (black)

Receptacle

Connector

rib

Route Lead wires that connects Power supply circuit

with RF unit between three pins as illustrated below.

pin

Lead wire (red)

pin

Terminal

Page 12

Wiring diagram

[2] Wiring around Stator

Fig. D-3

P 12/ 13

Connector (to LED circuit)

Put Connectors and the slack

portion of Lead wires in the space

between rib (E) and the inside

wall of Housing.

inside wall of Housing

Route the following Lead wires from Controller

between rib (E) and the inside wall of Housing:

*Lead wires to LED circuit

*Lead wires to Switch unit (for Clutch)

At this time, place these Lead wires so that the

tape is positioned beside Printed wiring board.

tape

Route three Lead wires

(orange, white, blue) from

Controller to Stator between

the pin and Stator.

Switch unit (for Clutch)

Connector

rib (E)

Printed wiring board

pin

Stator

Lead wire holder

First, put the following Lead wires

from Controller in place:

*Lead wires to LED circuit

*Lead wires to Switch unit (for Clutch)

Then, fix Lead wires (orange, white, blue)

from Controller to Stator with this Lead

wire holder.

rib (G)rib (F)

Route six Lead wires (orange, black, white,

yellow, blue, red) from Controller to Stator

between rib (F) and rib (G).

Page 13

Wiring diagram

Wiring of Lead wires of LED circuit

Fig. 4

Route Lead wires

under the two tabs.

tabs viewed from

left side

P 13/ 13

LED circuit

tab

Light holder

Route Lead wires between

these ribs.

rib

Connector

Make sure that

Lead wires are tight

between this portion.

Switch unit

Put Connectors and the slack portion

of Lead wires in this space.

Note:

Be careful not to put Connectors or

the slack portion of Lead wires on

the ribs around LED circuit.

Loading...

Loading...