Page 1

Cordless Driver Drill

Instruction Manual

Akku-Bohrschrauber

Betriebsanleitung

Akumulatorowa wiertarko-wkrętarka

Instrukcja obsługi

fiðð³ý³ÝČ²þ×Þ˛Č=Š×šÝş=г׳−þŁš×²

ÊÞ¹²×³ð¾¦ć=−þ=Ćð¹−ݳ˛²˛¾¦¦

BDF442/BDF452

Page 2

1

3

2

4

12

5

AB

6

34

7

8

9

10

56

11

12

13

78

2

Page 3

14

15

16

910

18

19

17

11 12

20

21

22

13 14

24

25

15

23

3

Page 4

ENGLISH

Explanation of general view

1. Red part

2. Button

3. Battery cartridge

4. Switch trigger

5. Lamp

6. Reversing switch lever

7. Speed change lever

8. Adjusting ring

9. Graduation

10. Pointer

11. Sleeve

12. Bit holder

13. Bit

14. Groove

15. Screw

16. Hook

17. Limit mark

18. Rear cover

19. Screws

20. Recessed part

21. Spring

22. Arm

23. Carbon brush cap

24. Hole

25. Carbon brush cap

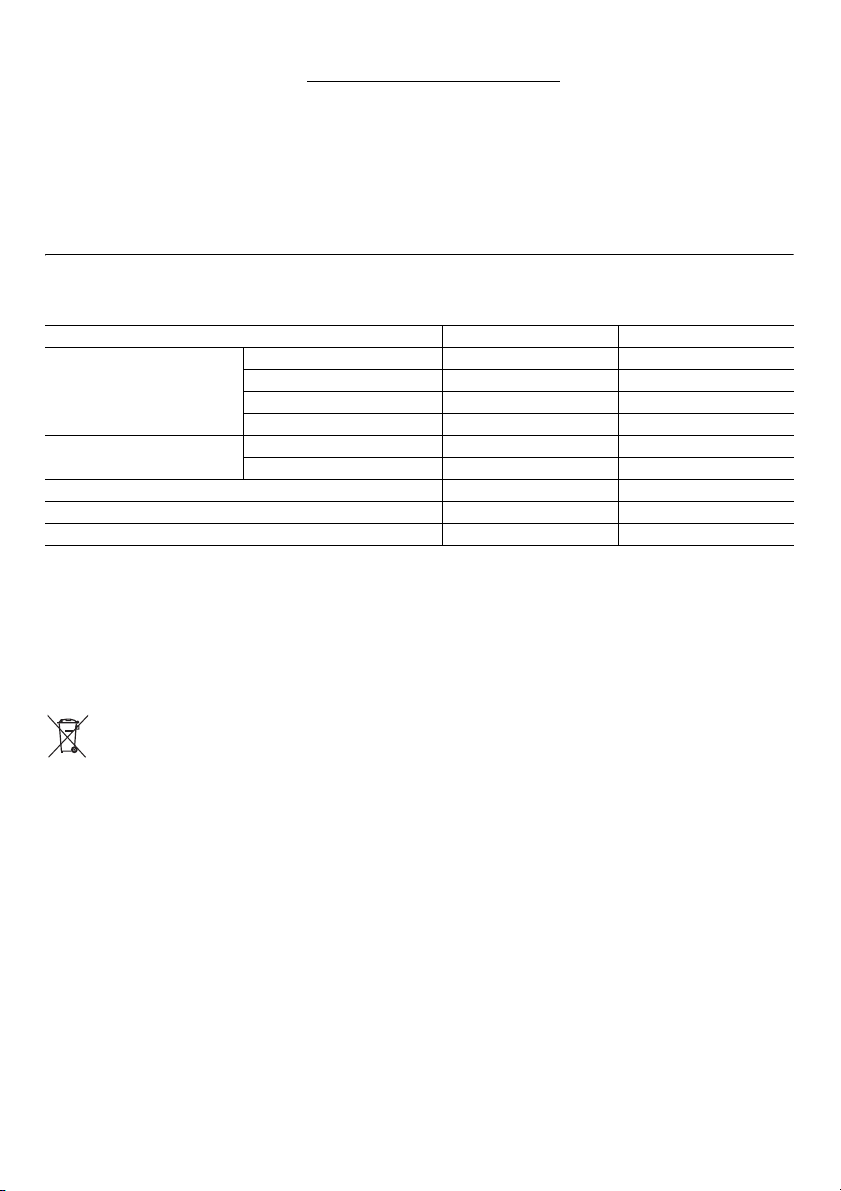

SPECIFICATIONS

Model BDF442 BDF452

Steel 13 mm 13 mm

Capacities

No load speed (min

Net weight (with type of battery cartridge) 1.7 kg (BL1430) 1.8 kg (BL1830)

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

Symbols

The following show the symbols used for the equipment.

Be sure that you understand their meaning before use.

Only for EU countries

Do not dispose of electric equipment together with

household waste material!

In observance of European Directive 2002/96/EC on

waste electrical and electronic equipment and its

implementation in accordance with national law, electric

equipment that have reached the end of their life must be

collected separately and returned to an environmentally

compatible recycling facility.

Intended use

The tool is intended for drilling and screw driving in wood,

metal and plastic.

-1

)

Overall length 197 mm 197 mm

Rated voltage D.C. 14.4 V D.C. 18 V

Wood 38 mm 38 mm

Wood screw 6 mm x 75 mm 10 mm x 89 mm

Machine screw M6 M6

High (2) 0 - 1,400 0 - 1,500

Low (1) 0 - 400 0 - 400

END001-1

GENERAL SAFETY RULES GEA002-3

WARNING! Read all instructions. Failure to follow all

instructions listed below may result in electric shock, fire

and/or serious injury. The term “power tool” in all of the

warnings listed below refers to your mains-operated

(corded) power tool or battery-operated (cordless) power

tool.

SAVE THESE INSTRUCTIONS.

Work area safety

1. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

ENE034-1

3. Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

4

Page 5

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

Personal safety

9. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

10. Use safety equipment. Always wear eye

protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

11. Avoid accidental starting. Ensure the switch is in

the off-position before plugging in. Carrying power

tools with your finger on the switch or plugging in

power tools that have the switch on invites accidents.

12. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

13. Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

14. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

15. If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of these

devices can reduce dustrelated hazards.

Power tool use and care

16. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

17. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

18. Disconnect the plug from the power source and/or

the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

19. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

20. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

21. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

22. Use the power tool, accessories and tool bits etc.

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

Battery tool use and care

23. Ensure the switch is in the off position before

inserting battery pack. Inserting the battery pack into

power tools that have the switch on invites accidents.

24. Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

25. Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

26. When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws, or other small metal objects that

can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or a fire.

27. Under abusive conditions, liquid may be ejected

from the battery, avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or

burns.

Service

28. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

29. Follow instruction for lubricating and changing

accessories.

30. Keep handles dry, clean and free from oil and

grease.

SPECIFIC SAFETY RULES GEB002-2

DO NOT let comfort or familiarity with product (gained

from repeated use) replace strict adherence to drill

safety rules. If you use this power tool unsafely or

incorrectly, you can suffer serious personal injury.

1. Hold power tools by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

5

Page 6

2. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

3. Hold the tool firmly.

4. Keep hands away from rotating parts.

5. Do not leave the tool running. Operate the tool

only when hand-held.

6. Do not touch the drill bit or the workpiece

immediately after operation; they may be

extremely hot and could burn your skin.

7. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation and

skin contact. Follow material supplier safety data.

SAVE THESE INSTRUCTIONS.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

IMPORTANT SAFETY

INSTRUCTIONS ENC007-2

FOR BATTERY CARTRIDGE

1. Before using battery cartridge, read all

instructions and cautionary markings on (1)

battery charger, (2) battery, and (3) product using

battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively shorter,

stop operating immediately. It may result in a risk

of overheating, possible burns and even an

explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any

conductive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

7. Do not incinerate the battery cartridge even if it is

severely damaged or is completely worn out. The

battery cartridge can explode in a fire.

8. Be careful not to drop or strike battery.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery

cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room

temperature at 10°C - 40°C (50°F - 104°F). Let a hot

battery cartridge cool down before charging it.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

Installing or removing battery cartridge

(Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the

tool while sliding the button on the side of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If you can see the red part on

the upper side of the button, it is not locked completely.

Insert it fully until the red part cannot be seen. If not, it

may accidentally fall out of the tool, causing injury to

you or someone around you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Switch action (Fig. 2)

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

Lighting up the front lamp (Fig. 3)

CAUTION:

• Do not look in the light or see the source of light

directly.

Pull the switch trigger to light up the lamp. The lamp

keeps on lighting while the switch trigger is being pulled.

The lamp goes out 10 -15 seconds after releasing the

trigger.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of lamp, or it may lower

the illumination.

Reversing switch action (Fig. 4)

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the A

side for clockwise rotation or from the B side for

counterclockwise rotation.

6

Page 7

When the reversing switch lever is in the neutral position,

the switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

Speed change (Fig. 5)

To change the speed, first switch off the tool and then

slide the speed change lever to the “2” side for high speed

or “1” side for low speed. Be sure that the speed change

lever is set to the correct position before operation. Use

the right speed for your job.

CAUTION:

• Always set the speed change lever fully to the correct

position. If you operate the tool with the speed change

lever positioned halfway between the “1” side and “2”

side, the tool may be damaged.

• Do not use the speed change lever while the tool is

running. The tool may be damaged.

Adjusting the fastening torque (Fig. 6)

The fastening torque can be adjusted in 17 steps by

turning the adjusting ring so that its graduations are

aligned with the pointer on the tool body. The fastening

torque is minimum when the number 1 is aligned with the

pointer, and maximum when the marking is aligned with

the pointer.

The clutch will slip at various torque levels when set at the

number 1 to 16. The clutch is designed not to slip at the

marking.

Before actual operation, drive a trial screw into your

material or a piece of duplicate material to determine

which torque level is required for a particular application.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out any

work on the tool.

Installing or removing driver bit or drill bit

(Fig. 7)

Turn the sleeve counterclockwise to open the chuck jaws.

Place the bit in the chuck as far as it will go. Turn the

sleeve clockwise to tighten the chuck.

To remove the bit, turn the sleeve counterclockwise.

Installing bit holder (Optional accessory)

(Fig. 8)

Fit the bit holder into the protrusion at the tool foot on

either right or left side and secure it with a screw.

When not using the driver bit, keep it in the bit holders.

Bits 45 mm long can be kept there.

Hook (Optional accessory) (Fig. 9)

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool.

To install the hook, insert it into a groove in the tool

housing on either side and then secure it with a screw.

To remove, loosen the screw and then take it out.

OPERATION

CAUTION:

• Always insert the battery cartridge all the way until it

locks in place. If you can see the red part on the upper

side of the button, it is not locked completely. Insert it

fully until the red part cannot be seen. If not, it may

accidentally fall out of the tool, causing injury to you or

someone around you.

Hold the tool firmly with one hand on the grip and the

other hand on the bottom of the battery cartridge to

control the twisting action.

Screwdriving operation (Fig. 10)

CAUTION:

• Adjust the adjusting ring to the proper torque level for

your work.

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the switch trigger

as soon as the clutch cuts in.

CAUTION:

• Make sure that the driver bit is inserted straight in the

screw head, or the screw and/or bit may be damaged.

NOTE:

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting of the workpiece.

See the chart.

Nominal diameter of wood

screw (mm)

3.1 2.0 - 2.2

3.5 2.2 - 2.5

3.8 2.5 - 2.8

4.5 2.9 - 3.2

4.8 3.1 - 3.4

5.1 3.3 - 3.6

5.5 3.7 - 3.9

5.8 4.0 - 4.2

6.1 4.2 - 4.4

Drilling operation

First, turn the adjusting ring so that the pointer points to

the marking. Then proceed as follows.

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide screw

makes drilling easier by pulling the bit into the workpiece.

Drilling in metal

To prevent the bit from slipping when starting a hole,

make an indentation with a center-punch and hammer at

the point to be drilled. Place the point of the bit in the

indentation and start drilling.

Recommended size of pilot

hole (mm)

7

Page 8

Use a cutting lubricant when drilling metals. The

exceptions are iron and brass which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool

performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole break through. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back

out. However, the tool may back out abruptly if you do

not hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for 15

minutes before proceeding with a fresh battery.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

Replacing carbon brushes (Fig. 11)

Replace when they wear down to the limit mark. Keep the

carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove two screws then remove the

rear cover. (Fig. 12)

Raise the arm part of the spring and then place it in the

recessed part of the housing with a slotted bit screwdriver

of slender shaft or the like. (Fig. 13)

Use pliers to remove the carbon brush caps of the carbon

brushes. Take out the worn carbon brushes, insert the

new ones and replace the carbon brush caps in reverse.

(Fig. 14)

Make sure that the carbon brush caps have fit into the

holes in brush holders securely. (Fig. 15)

Reinstall the rear cover and tighten two screws securely.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers, always

using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Drill bits

• Screw bits

8

• Bit holder

•Hook

• Various type of Makita genuine batteries and chargers

• Automatic refreshing adapter

• Plastic carrying case

For Model BDF442

For European countries only

Noise and Vibration

The typical A-weighted sound pressure level is 71 dB (A).

Uncertainty is 3 dB (A).

The noise level under working may exceed 85 dB (A).

The typical weighted root mean square acceleration value

is not more than 2.5 m/s

These values have been obtained according to EN60745.

For Model BDF452

For European countries only

Noise and Vibration

The typical A-weighted sound pressure level is 70 dB (A).

The noise level under working may exceed 85 dB (A).

The typical weighted root mean square acceleration value

is not more than 2.5 m/s

These values have been obtained according to EN60745.

EC-DECLARATION OF CONFORMITY

Model; BDF442, BDF452

We declare under our sole responsibility that this product

is in compliance with the following standards of

standardized documents;

EN60745, EN55014 in accordance with Council

Directives, 2004/108/EC, 98/37/EC.

Responsible Manufacturer:

Makita Corporation

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Authorized Representative in Europe:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15

8JD, ENGLAND

Wear ear protection.

2

.

Wear ear protection.

2

.

CE2006

Tomoyasu Kato

Director

ENG003-2

ENG001-2

ENH102-6

Page 9

DEUTSCH

Erklärung der Gesamtdarstellung

1. Roter Bereich

2. Taste

3. Akkublock

4. Ein/Aus-Schalter

5. Lampe

6. Umschalthebel

7. Hebel zur Änderung der Drehzahl

8. Justierungsring

9. Einteilung

10. Zeiger

11. Kranz

12. Werkzeughalter

13. Einsatz

14. Rille

15. Schraube

16. Einhängeclip

17. Verschleißmarkierung

18. Hintere Abdeckung

19. Schrauben

20. Abgestufter Bereich

21. Feder

22. Arm

23. Kohlebürstenkappe

24. Loch

25. Kohlebürstenkappe

TECHNISCHE ANGABEN

Modell BDF442 BDF452

Stahl 13 mm 13 mm

Kapazität

Leerlauf-Drehzahl (min

• Aufgrund unserer fortschreitenden Forschungen und Entwicklungen sind Änderungen an den hier wiedergegebenen

Angaben ohne Vorankündigung vorbehalten.

• Hinweis: Technische Daten können in den einzelnen Ländern unterschiedlich sein.

Symbole

Im Folgenden sind die Symbole dargestellt, die im

Zusammenhang mit diesem Werkzeug verwendet

werden. Es ist wichtig, dass Sie deren Bedeutung vor

dem Einsatz des Werkzeugs kennen.

Nur für EU-Länder

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäß Europäischer Richtlinie 2002/96/EG über Elektro-

und Elektronik- Altgeräte und Umsetzung in nationales

Recht müssen verbrauchte Elektrowerkzeuge getrennt

gesammelt und einer umweltgerechten Wiederverwertung

zugeführt werden.

Verwendungszweck

Das Werkzeug wurde für das Bohren und Schrauben in

Holz, Metall und Kunststoff entwickelt.

-1

)

Gesamtlänge 197 mm 197 mm

Nettogewicht (mit Akkublock) 1,7 kg (BL1430) 1,8 kg (BL1830)

Nennspannung Gleichspannung 14,4 V Gleichspannung 18 V

Holz 38 mm 38 mm

Holzschraube 6 mm x 75 mm 10 mm x 89 mm

Maschinenschraube M6 M6

Hoch (2) 0 - 1.400 0 - 1.500

Niedrig (1) 0 - 400 0 - 400

END001-1

ALLGEMEINE

SICHERHEITSREGELN GEA002-3

WARNUNG! Lesen Sie alle Anweisungen. Werden nicht

alle der unten aufgeführten Anweisungen befolgt, besteht

die Gefahr eines Stromschlags, Brands und/oder das

Risiko schwerer Verletzungen. Der Begriff

„Elektrowerkzeug“ bezieht sich in allen unten

aufgeführten Warnhinweisen auf Ihr netzbetriebenes

Elektrowerkzeug (mit Kabel) oder Ihr akku- bzw.

batteriebetriebenes Elektrowerkzeug (ohne Kabel).

BEWAHREN SIE DIESE

ANWEISUNGEN SORGFÄLTIG

AUF.

Sicherheit am Arbeitsplatz

ENE034-1

1. Achten Sie auf ein sauberes und gut beleuchtetes

Arbeitsumfeld. In unordentlichen und dunklen

Bereichen können schnell Unfälle passieren.

2. Betreiben Sie keine Elektrowerkzeuge in

explosionsgefährdeter Umgebung, wie etwa in der

Nähe von brennbaren Flüssigkeiten, Gasen oder

Staub. Bei Elektrowerkzeugen treten Funken aus, die

Staub und Dämpfe entzünden können.

3. Halten Sie Kinder und Zuschauer auf Abstand,

wenn Sie ein Elektrowerkzeug bedienen.

Ablenkung kann zum Verlust der Beherrschung des

Werkzeugs führen.

9

Page 10

Elektrische Sicherheit

4. Die Stecker des Elektrowerkzeugs müssen zur

Steckdose passen. Nehmen Sie niemals

Änderungen am Stecker vor. Verwenden Sie keine

Adapterstecker bei geerdeten Elektrowerkzeugen.

Originalstecker und passende Steckdosen reduzieren

das Risiko eines Stromschlags.

5. Vermeiden Sie Körperkontakt mit geerdeten

Oberflächen, wie Rohren, Kühlern, Heiz- und

Kühlelementen. Wenn Ihr Körper geerdet ist, besteht

ein erhöhtes Risiko eines Stromschlags.

6. Das Elektrowerkzeug darf weder Regen noch

Feuchtigkeit ausgesetzt werden. Wenn Wasser in

ein Elektrowerkzeug eindringt, erhöht dies das Risiko

eines Stromschlags.

7. Missbrauchen Sie das Stromkabel nicht.

Verwenden Sie nie das Kabel, um das

Elektrowerkzeug zu transportieren, heranzuziehen

oder den Stecker herauszuziehen. Halten Sie das

Kabel von Hitze, Öl, scharfen Kanten und

beweglichen Teilen fern. Beschädigte oder

verwickelte Kabel erhöhen das Risiko eines

Stromschlags.

8. Verwenden Sie ein dafür geeignetes

Verlängerungskabel, wenn Sie das

Elektrowerkzeug im Freien betreiben. Die

Verwendung eines für den Gebrauch im Freien

vorgesehenen Verlängerungskabels vermindert das

Risiko eines Stromschlags.

Persönliche Sicherheit

9. Bleiben Sie wachsam, achten Sie auf das, was Sie

tun, und gebrauchen Sie Ihren gesunden

Menschenverstand, wenn Sie ein Elektrowerkzeug

benutzen. Betreiben Sie Elektrowerkzeuge nicht,

wenn Sie müde sind oder unter dem Einfluss von

Drogen, Alkohol oder Medikamenten stehen. Ein

Moment der Unachtsamkeit kann beim Umgang mit

Elektrowerkzeugen zu schweren Personenschäden

führen.

10. Verwenden Sie eine Sicherheitsausrüstung.

Benutzen Sie immer eine Schutzbrille. Den

Umständen angepasste Sicherheitsausrüstung wie

Staubmasken, rutschfreie Sicherheitsschuhe, Helme

und Hörschutz vermindern persönliche Verletzungen.

11. Vermeiden Sie einen versehentlichen Start des

Werkzeugs. Vergewissern Sie sich, dass das Gerät

ausgeschaltet ist, bevor Sie es einstöpseln. Der

Transport des Geräts mit dem Finger auf dem

Schalter und das Einstöpseln eingeschalteter

Elektrowerkzeuge können zu Unfällen führen.

12. Entfernen Sie alle Einstell- und sonstigen

Schlüssel, bevor Sie das Elektrowerkzeug

einschalten. Auf den rotierenden Teilen des

Elektrowerkzeugs belassene Schlüssel können zu

Verletzungen führen.

13. Bleiben Sie innerhalb Ihres Standbereichs. Achten

Sie jederzeit auf sicheren Stand und Balance. Dies

ermöglicht die bessere Kontrolle des

Elektrowerkzeugs in unvorhergesehenen Situationen.

14. Tragen Sie geeignete Kleidung. Tragen Sie keine

weite Kleidung oder Schmuck. Halten Sie Haar,

Kleidung und Handschuhe fern von beweglichen

Teilen. Weite Kleidung, Schmuck und langes Haar

können sich in den beweglichen Teilen verfangen.

10

15. Falls Geräte zum Absaugen und Sammeln von

Staub vorhanden sind, schließen Sie diese an und

verwenden Sie sie ordnungsgemäß. Die

Verwendung dieser Geräte reduziert

staubverbundene Gefahren.

Verwendung und Pflege von Elektrowerkzeugen

16. Überlasten Sie das Elektrowerkzeug nicht.

Benutzen Sie das für die jeweilige Anwendung

geeignete Elektrowerkzeug. Das richtige Werkzeug

erfüllt seinen Zweck am besten und sichersten in dem

Leistungsbereich, für den es hergestellt wurde.

17. Verwenden Sie kein Elektrowerkzeug, das sich

nicht mit dem Schalter ein- und ausschalten lässt.

Jedes Elektrowerkzeug, dessen Schalter nicht

funktioniert, stellt eine Gefahr dar und muss repariert

werden.

18.

Ziehen Sie den Stecker aus der Steckdose bzw.

nehmen Sie den Akku aus dem Gerät, bevor Sie

Einstellungen am Elektrowerkzeug vornehmen,

Zubehör wechseln oder das Gerät lagern. Diese

präventiven Sicherheitsmaßnahmen reduzieren das

Risiko eines versehentlichen Starts.

19. Lagern Sie Elektrowerkzeuge, die nicht in

Gebrauch sind, außerhalb der Reichweite von

Kindern und erlauben Sie niemandem, der mit

dem Betrieb oder der Bedienungsanleitung des

Elektrowerkzeugs nicht vertraut ist, dieses zu

benutzen. In den Händen ungeübter Benutzer sind

Elektrowerkzeuge gefährlich.

20. Pflegen Sie Elektrowerkzeuge. Prüfen Sie das

Elektrowerkzeug auf fehlerhafte Verbindungen,

festsitzende bewegliche Teile, Defekte und alle

andere Bedingungen, die die Funktionsweise des

Geräts beeinträchtigen können. Lassen Sie bei

einer Beschädigung das Elektrowerkzeug vor dem

Gebrauch reparieren. Viele Unfälle werden durch

schlecht gewartete Elektrowerkzeuge verursacht.

21. Halten Sie die Schneidwerkzeuge scharf und

sauber. Ordentlich gewartete Schneidwerkzeuge mit

scharfen Schneidkanten verhaken nicht so schnell

und sind einfacher in der Handhabung.

22. Verwenden Sie das Elektrowerkzeug, das Zubehör,

die Werkzeugmeißel usw. gemäß diesen

Anweisungen und in einer dem

Verwendungszweck des Werkzeugs

angemessenen Weise und beachten Sie dabei die

Arbeitsbedingungen und die durchzuführende

Arbeit. Die Verwendung eines Elektrowerkzeugs für

Arbeitsgänge, für die es nicht konzipiert wurde, kann

zu Gefahrensituationen führen.

Verwendung und Pflege von akkubetriebenen

Werkzeugen

23. Vergewissern Sie sich vor dem Einsetzen des

Akkusatzes, dass sich der Schalter in der Position

„Aus“ (Off) befindet. Wird der Akkublock in

Elektrowerkzeuge eingesetzt, deren Schalter sich auf

der Position „Ein“ (On) befindet, besteht eine erhöhte

Unfallgefahr.

24. Der Akku darf nur mit dem vom Hersteller

angegebenen Ladegerät aufgeladen werden. Ein

Ladegerät, das sich für den einen Akkutyp eignet,

kann bei der Verwendung mit einem anderen Akku

eine Brandgefahr darstellen.

Page 11

25. Elektrowerkzeuge dürfen nur mit den dafür

speziell vorgesehenen Akkus verwendet werden.

Die Verwendung anderer Akkus kann eine

Verletzungs- und Brandgefahr darstellen.

26. Wenn der Akku nicht verwendet wird, darf er nicht

in der Nähe von anderen metallischen

Gegenständen wie Büroklammern, Münzen,

Nägeln, Schrauben oder sonstigen metallischen

Gegenständen aufbewahrt werden, da die Gefahr

besteht, dass sich die Kontakte berühren. Ein

Kurzschluss bei den Akkukontakten kann

Verbrennungen verursachen oder eine Brandgefahr

darstellen.

27. Bei falschem Gebrauch kann Flüssigkeit aus dem

Akku austreten; vermeiden Sie in diesem Fall

jeglichen Körperkontakt mit der Flüssigkeit. Wenn

Sie versehentlich damit in Berührung geraten,

waschen Sie die betroffene Stelle gründlich mit

Wasser ab. Suchen Sie darüber hinaus einen Arzt

auf, wenn die Flüssigkeit in das Auge gerät. Die

aus dem Akku austretende Flüssigkeit kann

Hautreizungen oder Verbrennungen verursachen.

Service

28. Lassen Sie das Elektrowerkzeug ausschließlich

von Fachpersonal unter Verwendung von

Originalersatzteilen warten. Auf diese Weise ist die

Sicherheit des Elektrowerkzeugs gewährleistet.

29. Befolgen Sie die Anweisungen hinsichtlich

Schmiermittel und Austauschzubehör.

30. Achten Sie darauf, dass die Griffe trocken, sauber

und frei von Öl und Schmiermittel sind.

BESONDERE

SICHERHEITSREGELN

Lassen Sie sich NIE durch Bequemlichkeit oder (aus

fortwährendem Gebrauch gewonnener) Vertrautheit

mit dem Gerät dazu verleiten, die Sicherheitsregeln

für das Gerät zu missachten. Wenn dieses

Elektrowerkzeug fahrlässig oder nicht

ordnungsgemäß verwendet wird, kann es zu

schweren Personenschäden kommen.

1. Halten Sie Elektrowerkzeuge an den isolierten

Griffflächen, wenn Sie unter Bedingungen

arbeiten, bei denen das Schneidwerkzeug

versteckte Verkablung oder das eigene Kabel

berühren kann. Der Kontakt mit einem Strom

führenden Kabel leitet diesen an die metallenen Teile

des Werkzeugs weiter und verursacht einen

Stromschlag beim Bediener.

2. Achten Sie jederzeit auf einen festen Stand.

Achten Sie darauf, dass sich niemand unter Ihnen

befindet, wenn Sie das Werkzeug an erhöhten

Orten verwenden.

3. Halten Sie das Werkzeug mit festem Griff.

4. Halten Sie Ihre Hände von den beweglichen Teilen

fern.

5. Lassen Sie das Werkzeug nicht laufen. Das

Werkzeug darf nur dann in Betrieb sein, wenn es

festgehalten wird.

6. Berühren Sie kurz nach dem Betrieb nicht den

Bohreinsatz oder das Werkstück. Diese können

extrem heiß sein und zu Verbrennungen führen.

GEB002-2

7. Einige Materialien enthalten Chemikalien, die

giftig sein können. Vermeiden Sie das Einatmen

von Staub und den Kontakt mit der Haut. Befolgen

Sie die Sicherheitshinweise des

Materialherstellers.

BEWAHREN SIE DIESE

ANWEISUNGEN SORGFÄLTIG

AUF.

WARNUNG:

MISSBRAUCH oder Missachtung der in diesem

Handbuch enthaltenen Sicherheitshinweise kann zu

schweren Personenschäden führen.

WICHTIGE SICHERHEITSREGELN

ENC007-2

FÜR AKKUBLOCK

1. Lesen Sie vor der Verwendung des Akkublocks

alle Anweisungen und Sicherheitshinweise für (1)

das Akkuladegerät, (2) den Akku und (3) das

Produkt, für das der Akku verwendet wird.

2. Der Akkublock darf nicht zerlegt werden.

3. Falls die Betriebsdauer erheblich kürzer wird,

beenden Sie den Betrieb umgehend. Andernfalls

besteht die Gefahr einer Überhitzung sowie das

Risiko möglicher Verbrennungen und sogar einer

Explosion.

4. Wenn Elektrolyt in Ihre Augen gerät, waschen Sie

diese mit klarem Wasser aus, und suchen Sie

sofort einen Arzt auf. Andernfalls können Sie Ihre

Sehfähigkeit verlieren.

5. Vermeiden Sie einen Kurzschluss des

Akkublocks:

(1) Die Kontakte dürfen nicht mit leitendem

Material in Berührung kommen.

(2) Der Akkublock darf nicht in einem Behälter

aufbewahrt werden, in dem sich andere

metallischen Gegenstände wie beispielsweise

Nägel, Münzen usw. befinden.

(3) Der Akkublock darf weder Feuchtigkeit noch

Regen ausgesetzt werden.

Ein Kurzschluss des Akkus kann zu hohem

Kriechstrom, Überhitzung, möglichen

Verbrennungen und sogar zu einer Zerstörung

des Geräts führen.

6. Werkzeug und Akkublock dürfen nicht an Orten

aufbewahrt werden, an denen die Temperatur 50°C

(122°F) oder höher erreichen kann.

7. Selbst wenn der Akkublock schwer beschädigt

oder völlig verbraucht ist, darf er nicht angezündet

werden. Der Akkublock kann in den Flammen

explodieren.

8. Lassen Sie den Akku nicht fallen, und vermeiden

Sie Schläge gegen den Akku.

11

Page 12

BEWAHREN SIE DIESE

ANWEISUNGEN SORGFÄLTIG

AUF.

Tipps für den Erhalt der maximalen AkkuNutzungsdauer

1. Laden Sie den Akkublock auf, bevor er ganz

entladen ist.

Beenden Sie stets den Betrieb des Werkzeugs,

und laden Sie den Akkublock auf, sobald Sie eine

verringerte Werkzeugleistung bemerken.

2. Ein voll aufgeladener Akkublock darf niemals

erneut geladen werden. Durch Überladungen wird

die Lebensdauer des Akkus verkürzt.

3. Laden Sie den Akkublock bei einer

Zimmertemperatur von 10°C - 40°C (50°F - 104°F)

auf. Lassen Sie einen heißen Akkublock vor dem

Aufladen abkühlen.

FUNKTIONSBESCHREIBUNG

ACHTUNG:

• Schalten Sie das Werkzeug stets aus, und entfernen

Sie den Akkublock, bevor Sie Einstellungen oder eine

Funktionsprüfung des Werkzeugs vornehmen.

Montage und Demontage des Akkublocks

(Abb. 1)

• Schalten Sie das Werkzeug stets aus, bevor Sie den

Akkublock einsetzen oder entfernen.

• Zur Entfernung des Akkublocks müssen Sie diesen aus

dem Werkzeug herausziehen, während Sie die Taste

an der Seite des Blocks schieben.

• Zum Einsetzen des Akkublocks müssen Sie die Zunge

des Akkublocks an der Rille im Gehäuse ausrichten

und in die gewünschte Position schieben. Setzen Sie

den Block immer ganz ein, bis er mit einem Klick

einrastet. Wenn Sie den roten Bereich oben auf der

Taste sehen können, ist der Block nicht ganz

eingerastet. Setzen Sie ihn ganz ein, bis der rote

Bereich nicht mehr zu sehen ist. Andernfalls kann der

Block versehentlich aus dem Werkzeug fallen und Sie

oder Personen in Ihrem Umfeld verletzen.

• Wenden Sie beim Einsetzen des Akkublocks keine

Gewalt an. Wenn der Block nicht leicht hineingleitet,

wird er nicht richtig eingesetzt.

Bedienung des Schalters (Abb. 2)

ACHTUNG:

• Achten Sie vor dem Einsetzen des Akkublocks in das

Werkzeug darauf, dass sich der Ein/Aus-Schalter

korrekt bedienen lässt und beim Loslassen auf die

Position „OFF“ (AUS) zurückkehrt.

Betätigen Sie zum Starten des Werkzeugs einfach den

Ein/Aus-Schalter. Die Drehzahl des Werkzeugs wird

durch erhöhten Druck auf den Ein/Aus-Schalter

gesteigert. Lassen Sie zum Ausschalten des Werkzeugs

den Ein/Aus-Schalter los.

Einschalten der Frontlampe (Abb. 3)

ACHTUNG:

• Schauen Sie nicht direkt in das Licht oder in die

Lichtquelle.

Ziehen Sie zum Einschalten der Lampe die

Auslöseschaltung. Die Lampe leuchtet so lange, wie die

Auslöseschaltung gezogen ist. Nach dem Loslassen des

Auslösers erlischt die Lampe nach 10 - 15 Sekunden.

HINWEIS:

• Wischen Sie Schmutz auf der Lampenlinse mit einem

trockenen Tuch ab. Achten Sie darauf, die

Lampenlinse nicht zu zerkratzen, da dies die

Beleuchtungsstärke mindern kann.

Bedienung des Umschalters (Abb. 4)

Dieses Werkzeug verfügt über einen Umschalter, mit dem

die Drehrichtung geändert werden kann. Für eine

Drehbewegung im Uhrzeigersinn muss der

Umschalthebel von der Seite A nach unten gedrückt

werden, und für eine Drehbewegung gegen den

Uhrzeigersinn von der Seite B.

Wenn sich der Umschalthebel in der neutralen Position

befindet, kann die Auslöseschaltung nicht gezogen

werden.

ACHTUNG:

• Überprüfen Sie vor jedem Betrieb immer die

Drehrichtung.

• Der Umschalter darf nur betätigt werden, wenn das

Werkzeug ganz angehalten wurde. Wenn Sie die

Drehrichtung ändern, solange das Werkzeug noch

läuft, kann es beschädigt werden.

• Ist das Werkzeug nicht in Gebrauch, muss der

Umschalthebel immer auf die neutrale Position gestellt

werden.

Änderung der Drehzahl (Abb. 5)

Schalten Sie zum Ändern der Drehzahl zunächst das

Werkzeug aus, und schieben Sie dann den Hebel zur

Änderung der Drehzahl auf „2“ (hohe Drehzahl) oder „1“

(niedrige Drehzahl). Überprüfen Sie vor dem Betrieb des

Werkzeugs, ob sich der Hebel zur Änderung der Drehzahl

in der richtigen Position befindet. Verwenden Sie die für

Ihre Arbeit geeignete Drehzahl.

ACHTUNG:

• Stellen Sie den Hebel zur Änderung der Drehzahl

immer ganz in die richtige Position. Wenn Sie das

Werkzeug betreiben und sich dieser Hebel zwischen

der Einstellung „1“ und „2“ befindet, kann das

Werkzeug beschädigt werden.

• Der Hebel zur Änderung der Drehzahl darf nicht

betätigt werden, solange das Werkzeug läuft.

Andernfalls kann das Werkzeug beschädigt werden.

Einstellen des Anzugsdrehmoments

(Abb. 6)

Das Anzugsdrehmoment kann in 17 Stufen eingestellt

werden, indem der Justierungsring so gedreht wird, dass

seine Einteilungsschritte am Zeiger auf dem

Werkzeugkörper ausgerichtet sind. Das

Anzugsdrehmoment ist minimal eingestellt, wenn die Zahl

12

Page 13

1 am Zeiger ausgerichtet ist, und maximal, wenn die

Markierung am Zeiger ausgerichtet ist.

Wenn eine Zahl zwischen 1 und 16 eingestellt ist, rutscht

die Kupplung an verschiedenen Drehmomentstufen

durch. Die Kupplung ist so konzipiert, dass sie an der

Markierung nicht durchrutscht.

Schrauben Sie vor dem eigentlichen Betrieb eine

Probeschraube in Ihr Material bzw. in ein Materialduplikat,

um zu ermitteln, welche Drehmomentstufe für eine

bestimmte Anwendung erforderlich ist.

MONTAGE

ACHTUNG:

• Schalten Sie das Werkzeug stets aus, und entfernen

Sie den Akkublock, bevor Sie Arbeiten am Werkzeug

ausführen.

Einsetzen oder Entfernen des Dreh- oder

Bohreinsatzes (Abb. 7)

Drehen Sie den Kranz gegen den Uhrzeigersinn, um die

Spannfutterbacken zu öffnen. Schieben Sie den Einsatz

so weit wie möglich in das Spannfutter. Drehen Sie den

Kranz im Uhrzeigersinn, um das Spannfutter anzuziehen.

Wenn Sie den Einsatz entfernen möchten, müssen Sie

den Kranz gegen den Uhrzeigersinn drehen.

Einsetzen des Werkzeughalters

(Optionales Zubehör) (Abb. 8)

Setzen Sie den Werkzeughalter in den Vorsprung an der

linken oder rechten Seite des Werkzeugfußes ein sichern

Sie ihn mit einer Schraube.

Wenn Sie den Dreheinsatz nicht verwenden, bewahren

Sie ihn in den Werkzeughaltern auf.

Einsätze bis zu einer Länge von 45 mm können dort

aufbewahrt werden.

Einhängeclip (Optionales Zubehör)

(Abb. 9)

Der Einhängeclip ist nützlich, wenn Sie das Werkzeug

vorübergehend aufhängen möchten.

Er kann an jeder Seite des Werkzeugs befestigt werden.

Setzen Sie den Einhängeclip zur Montage in eine Rille am

Werkzeuggehäuse (die Seite ist beliebig), und befestigen

Sie diesen mit einer Schraube.

Zur Entfernung müssen Sie nur die Schraube lockern und

den Einhängeclip herausnehmen.

BETRIEB

ACHTUNG:

• Schieben Sie den Akkublock stets vollständig ein, bis

er einrastet. Wenn Sie den roten Bereich oben auf der

Taste sehen können, ist der Block nicht ganz

eingerastet. Setzen Sie ihn ganz ein, bis der rote

Bereich nicht mehr zu sehen ist. Andernfalls kann der

Block versehentlich aus dem Werkzeug fallen und Sie

oder Personen in Ihrem Umfeld verletzen.

Halten Sie zur besseren Kontrolle beim Drehen das

Werkzeug fest mit einer Hand am Griff und der anderen

Hand an der Unterseite des Akkublocks.

Schraubendreherbetrieb (Abb. 10)

ACHTUNG:

• Stellen Sie den Justierungsring auf die für Ihre Arbeit

geeignete Drehmomentstufe.

Setzen Sie die Spitze des Dreheinsatzes in den

Schraubenkopf, und üben Sie Druck auf das Werkzeug

aus. Starten Sie das Werkzeug langsam, und erhöhen Sie

nach und nach die Drehzahl. Lassen Sie die

Auslöseschaltung los, sobald die Kupplung greift.

ACHTUNG:

• Vergewissern Sie sich, dass der Dreheinsatz gerade im

Schraubenkopf sitzt. Andernfalls kann die Schraube

und/oder der Einsatz beschädigt werden.

HINWEIS:

• Bohren Sie beim Drehen von Holzschrauben Löcher

für die Schrauben vor, damit das Drehen vereinfacht

wird und das Werkstück nicht splittert. Siehe Tabelle.

Nenndurchmesser der

Holzschraube (mm)

3,1 2,0 - 2,2

3,5 2,2 - 2,5

3,8 2,5 - 2,8

4,5 2,9 - 3,2

4,8 3,1 - 3,4

5,1 3,3 - 3,6

5,5 3,7 - 3,9

5,8 4,0 - 4,2

6,1 4,2 - 4,4

Empfohlene Größe des

vorgebohrten Lochs (mm)

Bohrbetrieb

Drehen Sie zunächst den Justierungsring so, dass der

Zeiger auf die Markierung gerichtet ist. Gehen Sie

anschließend wie folgt vor.

Bohren in Holz

Beim Bohren in Holz werden die besten Ergebnisse mit

Holzbohrern erzielt, die mit einer Leitspindel ausgestattet

sind. Die Leitspindel vereinfacht den Bohrprozess, indem

sie den Einsatz in das Werkstück zieht.

Bohren in Metall

Damit der Bohrer beim Beginn einer Lochbohrung nicht

abrutscht, machen Sie mit einem Körner eine Einkerbung,

und hämmern Sie auf den Punkt, an dem gebohrt werden

soll. Setzen Sie die Spitze des Einsatzes in die

Einkerbung, und starten Sie den Bohrvorgang.

Verwenden Sie beim Bohren in Metall einen

Schneideschmierstoff. Ausgenommen hiervon sind Eisen

und Messing; diese Metalle sollten trocken gebohrt

werden.

ACHTUNG:

• Der Bohrvorgang kann durch übermäßigen Druck auf

das Werkzeug nicht beschleunigt werden. Dieser

übermäßige Druck beschädigt im Gegenteil die Spitze

Ihres Einsatzes, vermindert die Leistung des

Werkzeugs und verkürzt dessen Lebensdauer.

• Beim Lochdurchschlag wirken enorme Kräfte auf das

Werkzeug/den Einsatz. Halten Sie das Werkzeug fest,

13

Page 14

und seien Sie vorsichtig, wenn der Einsatz das

Werkstück durchbricht.

• Ein festsitzender Einsatz kann einfach wieder

herausgezogen werden, indem die Drehrichtung mit

dem Umschalter geändert wird. Es kann jedoch zu

einem abrupten Rückschlag des Werkzeugs kommen,

wenn Sie es nicht ganz fest halten.

• Befestigen Sie kleine Werkstücke immer in einem

Schraubstock oder einer ähnlichen Haltevorrichtung.

• Wenn das Werkzeug bis zur vollständigen Entladung

des Akkus betrieben wurde, lassen Sie es 15 Minuten

liegen, bevor Sie mit einem neuen Akku fortfahren.

WARTUNG

ACHTUNG:

• Schalten Sie das Werkzeug stets aus und entfernen

Sie den Akkublock, bevor Sie Inspektionen oder

Wartungsarbeiten am Werkzeug vornehmen.

Ersetzen der Kohlebürsten (Abb. 11)

Ersetzen Sie diese, wenn sie bis zur Verschleißgrenze

abgenutzt sind. Halten Sie die Kohlebürsten sauber und

sorgen Sie dafür, dass sie locker in den Halterungen

liegen.

Beide Kohlebürsten sollten gleichzeitig ersetzt werden.

Verwenden Sie nur identische Kohlebürsten.

Entfernen Sie die beiden Schrauben mit einem

Schraubendreher, und entfernen Sie dann die hintere

Abdeckung. (Abb. 12)

Heben Sie den Federarm, und setzen Sie diesen dann mit

der schlanken Spitze eines Schlitzschraubendrehers oder

einem ähnlichen Gegenstand in den abgestuften Bereich

des Gehäuses. (Abb. 13)

Entfernen Sie die Kohlebürstenkappen der Kohlebürsten

mit einer Zange. Entnehmen Sie die verbrauchten

Kohlebürsten, legen Sie die neuen ein und bringen Sie die

Kohlebürstenkappen in umgekehrter Reihenfolge wieder

an. (Abb. 14)

Vergewissern Sie sich, dass die Kohlebürstenkappen fest

in den Öffnungen der Bürstenhalter sitzen. (Abb. 15)

Setzen Sie die hintere Abdeckung wieder ein, und ziehen

Sie die beiden Schrauben fest an.

Um die SICHERHEIT und ZUVERLÄSSIGKEIT des

Produkts zu gewährleisten, sollten Reparaturen,

Wartungsarbeiten und Einstellungen nur durch von Makita

autorisierte Servicecenter durchgeführt und immer

Makita-Ersatzteile verwendet werden.

ZUBEHÖR

ACHTUNG:

• Für das in diesem Handbuch beschriebene MakitaWerkzeug werden folgende Zubehör- und Zusatzteile

empfohlen. Die Verwendung anderer Zubehör- und

Zusatzteile kann zu Personenschäden führen.

Verwenden Sie Zubehör- und Zusatzteile nur für den

vorgesehenen Zweck.

Informationen zu diesem Zubehör erhalten Sie bei einem

Makita-Servicecenter in Ihrer Nähe.

• Bohreinsätze

• Schraubendrehereinsätze

• Werkzeughalter

• Einhängeclip

• Verschiedene Arten von Makita-Originalakkus und Ladegeräten

• Adapter mit automatischer Aktualisierungsfunktion

• Plastiktragekoffer

Für das Modell BDF442

Nur für europäische Länder

Geräusche und Vibrationen

Der typische Schalldruck beträgt 71 dB (A).

Die Abweichung beträgt 3 dB (A).

Unter Arbeitsbedingungen kann der Schalldruck 85 dB (A)

überschreiten.

Der typische effektive Beschleunigungswert beträgt

höchstens 2,5 m/s

Diese Werte wurden entsprechend der Norm EN60745

gewonnen.

Für das Modell BDF452

Nur für europäische Länder

Geräusche und Vibrationen

Der typische Schalldruck beträgt 70 dB (A).

Unter Arbeitsbedingungen kann der Schalldruck 85 dB (A)

überschreiten.

Der typische effektive Beschleunigungswert beträgt

höchstens 2,5 m/s

Diese Werte wurden entsprechend der Norm EN60745

gewonnen.

EG-KONFORMITÄTSERKLÄRUNG

Modell; BDF442, BDF452

Wir erklären unter unserer alleinigen Verantwortlichkeit,

dass sich dieses Produkt in Übereinstimmung mit den

folgenden Normen der Normdokumente

EN60745, EN55014 befindet sowie in Übereinstimmung

mit den Ratsverordnungen 2004/108/EC, 98/37/EC.

Verantwortlicher Hersteller:

Makita Corporation

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Autorisierte Vertretung in Europa:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15

8JD, ENGLAND

Tragen Sie Gehörschutz.

2

.

Tragen Sie Gehörschutz.

2

.

CE2006

Tomoyasu Kato

Director

ENG003-2

ENG001-2

ENH102-6

14

Page 15

POLISH

Objaśnienia do widoku ogólnego

1. Czerwony element

2. Przycisk

3. Akumulator

4. Język spustowy przełącznika

5. Lampka

6. Dźwignia przełącznika zmiany

kierunku obrotów

7. Dźwignia zmiany prędko

8. Pierścień regulacyjny

ści

9. Skala

10. Strzałka

11. Tule ja

12. Uchwyt na końcówki

13. Wiertło

14. Rowek

15. Wkręt

16. Zaczep

17. Znak granicy zużycia

18. Osłona tylna

19. Wkręty

20. Gniazdo

21. Sprężyna

22. Ramię

23. Nasadka szczotki węglowej

24. Otwór

25. Nasadka szczotki węglowej

DANE TECHNICZNE

Model BDF442 BDF452

Stal 13 mm 13 mm

Maks. średnica wiercenia

Prędkość bez obciążenia

•Ze względu na stale prowadzone prace badawczo-rozwojowe, podane tu dane techniczne mogą ulec zmianie bez

powiadomienia.

• Uwaga: W innych krajach urządzenie może mieć odmienne parametry techniczne.

Symbole

Poniżej przedstawiono symbole stosowane w przypadku

omawianego urządzenia. Przed przystąpieniem do

używania narzędzia należy koniecznie zapoznać się z ich

znaczeniem.

Dotyczy tylko państw UE

Nie wyrzucaj urządzeń elektrycznych wraz z odpadami z

gospodarstwa domowego!

Zgodnie z Europejską Dyrektywą 2002/96/ WE w sprawie

zużytego sprzętu elektrotechnicznego i elektronicznego

oraz dostosowaniem jej do prawa krajowego,zużyte

urządzenia elektryczne należy posegregować i

zutylizować w sposób przyjazny dla środowiska.

Przeznaczenie

Narzędzie przeznaczone jest do wiercenia w drewnie,

metalu i tworzywach sztucznych oraz do wkręcania

wkrętów we wspomniane materiały.

-1

(min.

)

Całkowita długość 197 mm 197 mm

Ciężar netto (z danym typem akumulatora) 1,7 kg (BL1430) 1,8 kg (BL1830)

Napięcie znamionowe stałe 14,4 V stałe 18 V

Drewno 38 mm 38 mm

Wkręt do drewna 6 mm x 75 mm 10 mm x 89 mm

Wkręt do elementów

metalowych

Wysoka (2) 0 - 1 400 0 - 1 500

Niska (1) 0 - 400 0 - 400

END001-1

OGÓLNE ZASADY

M6 M6

BEZPIECZEŃSTWA GEA002-3

UWAGA! Należy zapoznać się z wszystkimi

zaleceniami. Niezastosowanie się do podanych poniżej

instrukcji może prowadzić do porażenia prądem

elektrycznym, pożaru i/lub poważnych obrażeń ciała.

Pojęcie „elektronarzędzie”, występujące we wszystkich

wymienionych poniżej ostrzeżeniach, odnosi się do

elektronarzędzi zasilanych z sieci energetycznej (z

przewodem zasilającym) lub do elektronarzędzi

akumulatorowych (bezprzewodowych).

INSTRUKCJĘ OBSŁUGI NALEŻY

ZACHOWAĆ.

Bezpieczeństwo w miejscu pracy

1. W miejscu pracy należy utrzymywać czystość i

ENE034-1

zadbać o dobre oświetlenie. Nieporządek i słabe

oświetlenie sprzyjają wypadkom.

2. Elektronarzędzi nie wolno używać w miejscach

zagrożonych wybuchem, na przykład w obecności

łatwopalnych cieczy, gazów lub pyłów.

Elektronarzędzia wytwarzają iskry, które mogą

spowodować zapalenie się pyłu lub oparów.

3. Nie należy uruchamiać elektronarzędzia, gdy w

pobliżu znajdują się dzieci lub osoby postronne.

Chwila nieuwagi może spowodować utratę kontroli.

15

Page 16

Zasady bezpieczeństwa dotyczące urządzeń

elektrycznych

4. Wtyczka przewodu zasilającego elektronarzędzia

musi pasować do gniazda elektrycznego. Nie

wolno dokonywać żadnych przeróbek wtyczki. W

przypadku elektronarzędzi wymagających

uziemienia nie wolno stosować żadnych

przejściówek. Oryginalne wtyczki i właściwie

dopasowane gniazda zmniejszają ryzyko porażenia

prądem elektrycznym.

5. Należy unikać kontaktu z powierzchniami

uziemionych przedmiotów, jak rury, grzejniki,

kuchenki, czy lodówki. Gdy ciało jest uziemione,

wzrasta ryzyko porażenia prądem elektrycznym.

6. Elektronarzędzia należy chronić przed deszczem i

wilgocią. Woda, która dostanie się do środka,

zwiększa ryzyko porażenia prądem elektrycznym.

7. Przewodu zasilającego używać wyłącznie zgodnie

z jego przeznaczeniem. Nie wolno wykorzystywać

go do przenoszenia lub przyciągania narzędzia,

ani do wyciągania wtyczki z gniazda

elektrycznego. Przewód należy trzymać z dala od

źródeł ciepła, oleju, ostrych krawędzi lub

znajdujących się w ruchu podzespołów.

Uszkodzone lub poplątane przewody zasilające

zwiększają ryzyko porażenia prądem elektrycznym.

8. W przypadku używania elektronarzędzia na

dworze należy skorzystać z przedłużacza do

zastosowań zewnętrznych. Tylko taki przedłużacz

zmniejsza ryzyko porażenia prądem elektrycznym.

Bezpieczeństwo osobiste

9. Podczas pracy z elektronarzędziem zachować

czujność, obserwować wykonywane operacje i

kierować się zdrowym rozsądkiem. Nie wolno

używać elektronarzędzia, gdy jest si

albo pod wpływem narkotyków, alkoholu bądź

leków. Chwila nieuwagi podczas pracy może

spowodować poważny wypadek.

10. Używać sprzętu ochronnego. Zawsze należy nosić

okulary ochronne. Maska przeciwpyłowa, buty

antypoślizgowe, kask, ochraniacze na uszy używane

w odpowiednich warunkach zmniejszają ryzyko

doznania obrażeń.

11. Unikać przypadkowego uruchomienia urządzenia.

Przed wetknięciem wtyczki do gniazda sieciowego

należy się upewnić, że urządzenie jest wyłączone.

Przenoszenie elektronarzędzia z palcem na

przełączniku lub podłączanie przewodu zasilającego

przy włączonym przełączniku grozi wypadkiem.

12. Przed włączeniem elektronarzędzia należy usunąć

wszelkie klucze, które były wykorzystywane do

regulacji. Klucz pozostawiony na obracaj

elemencie elektronarzędzia może spowodować

poważne obrażenia ciała.

13. Nie wolno sięgać narzędziem zbyt daleko. Stać

pewnie, aby nie stracić równowagi. Taka postawa

pozwala uniknąć utraty kontroli nad narzędziem w

nieoczekiwanych sytuacjach.

14. Ubranie powinno być właściwie dobrane. Nie

wolno zakładać luźnych części garderoby ani

biżuterii. Włosy, ubranie i rękawice należy trzymać

z dala od ruchomych części. Luźne części ubrania,

biżuteria i długie włosy mogą zostać pochwycone.

ę zmęczonym

ącym się

15. Jeżeli narzędzie jest przystosowane do

podłączenia urządzeń do odsysania lub

odbierania pyłu, nale

prawidłowo podłączone i właściwie używane.

Wspomniane urządzenia obniżają poziom zagrożeń

wynikających z zapylenia.

Użytkowanie elektronarzędzi i dbałość o nie

16. Elektronarzędzi nie wolno przeciążać. Używać

tylko właściwego narzędzia przeznaczonego do

danego zastosowania. Pozwoli ono wykonać pracę

lepiej i bezpieczniej, w przewidzianym przez

projektanta tempie.

17. Nie wolno używać elektronarzędzia z

uszkodzonym przełącznikiem zasilania.

Elektronarzędzie z uszkodzonym przełącznikiem jest

niebezpieczne i wymaga naprawy.

18. Przed przystąpieniem do wykonywania regulacji,

wymiany osprzętu lub przed odłożeniem narzędzia

na swoje miejsce należy zawsze wyjąć wtyczkę

przewodu zasilającego z gniazda i/lub odłączyć

akumulator. Taki e dzia łania prewencyjne zmniejszają

ryzyko przypadkowego uruchomienia

elektronarzędzia.

19. Nieużywane elektronarzędzia należy chronić przed

dziećmi. Nie wolno również zezwalać na

korzystanie z nich osobom, które nie znają

danego narzędzia albo nie zapoznały się z jego

instrukcją obsługi. Elektronarzędzia w rękach

użytkowników bez przeszkolenia mogą być

niebezpieczne.

20. O elektronarzędzia trzeba dbać. Kontrolować je

pod kątem nieprawidłowego ustawienia lub

zablokowania elementów ruchomych, pęknięć lub

innych usterek, które mogą mieć wpływ na

działanie urządzenia. W przypadku stwierdzenia

uszkodzenia nale

Niedbalstwo jest przyczyną wielu wypadków.

21. Narzędzia do cięcia powinny być zawsze czyste i

naostrzone. Właściwie konserwowane narzędzia do

cięcia z ostrymi krawędziami tnącymi rzadziej się

zakleszczają i łatwiej je prowadzić.

22. Elektronarzędzie, osprzęt, końcówki robocze itp.

należy stosować zgodnie z niniejszą instrukcją i w

sposób właściwy dla danego typu narzędzia,

mając na uwadze warunki i rodzaj pracy do

wykonania. Używanie elektronarzędzia do innych,

niezgodnych z przeznaczeniem celów może stwarzać

niebezpieczną sytuację.

Użytkowanie narzędzi akumulatorowych i dbałość o

nie

23. Przed włożeniem akumulatora należ

czy przełącznik znajduje się w pozycji wyłączenia.

Wkładanie akumulatora do elektronarzędzi z

włączonym przełącznikiem sprzyja wypadkom.

24. Akumulator należy ładować wyłącznie przy użyciu

ładowarki określonej przez producenta. Ładowarka

przeznaczona do jednego typu akumulatora może

stwarzać zagrożenie pożarem, gdy będzie używana

do ładowania innego akumulatora.

25. Do zasilania elektronarzędzi należy używać tylko

specjalnie do tego celu przeznaczonych

akumulatorów. Używanie innych akumulatorów

może grozić wypadkiem lub pożarem.

ży upewnić się, że są one

ży zlecić jego naprawę.

y upewnić się,

16

Page 17

26. Gdy akumulator nie jest używany, należy chronić

go przed kontaktem z metalowymi przedmiotami,

typu spinacze, monety, klucze, gwoździe, wkręty

lub innymi metalowymi drobiazgami, które mogą

spowodować zwarcie styków akumulatora.

Zwarcie styków akumulatora z kolei grozi

poparzeniami lub pożarem.

27. W przypadku niewłaściwych warunków

eksploatacji może dojść do wycieku elektrolitu z

akumulatora; nie należy go dotykać. W razie

przypadkowego kontaktu przemyć wodą. W

przypadku kontaktu z oczami dodatkowo zwrócić

się o pomoc lekarską. Ciecz z akumulatora może

powodować podrażnienie lub poparzenia.

Naprawy

28. Naprawę elektronarzędzi należy zlecać

wykwalifikowanemu personelowi technicznemu,

który stosuje wyłącznie oryginalne części

zamienne. Pozwoli to zachować niezmienny poziom

bezpieczeństwa elektronarzędzia.

29. Postępować zgodnie z instrukcjami dotyczącymi

smarowania i wymiany elementów wyposażenia.

30. Uchwyty powinny być zawsze suche, czyste, bez

pozostałości oleju lub smaru.

SZCZEGÓŁOWE ZASADY

BEZPIECZEŃSTWA GEB002-2

NIE WOLNO pozwolić, aby wygoda lub rutyna (nabyta

w wyniku wielokrotnego używania narzędzia)

zastąpiły ścisłe przestrzeganie obowiązujących zasad

bezpieczeństwa. Używanie elektronarzędzia w

sposób niebezpieczny lub niewłaściwy grozi

poważnymi obrażeniami ciała.

1. W przypadku wykonywania operacji, podczas

których narzędzie tnące może mieć kontakt z

ukrytymi przewodami elektrycznymi bądź

własnym przewodem zasilającym,

elektronarzędzia należy trzymać za izolowane

uchwyty. Zetknięcie z przewodem elektrycznym pod

napięciem spowoduje, że również odsłonięte

elementy metalowe narzędzia znajdą się pod

napięciem, grożąc porażeniem operatora prądem

elektrycznym.

2.

Podczas pracy należy zadbać o dobre oparcie dla

nóg.

W przypadku pracy na pewnej wysokości upewnić

się, czy przypadkiem na dole nie przebywają

jakieś osoby.

3. Narzędzie trzymać mocno i pewnie.

4. Nie wolno zbliżać rąk do obracających się części.

5. Nie wolno pozostawiać uruchomionego narzędzia.

Narzędzie można uruchomić dopiero wówczas,

gdy jest przytrzymywane rękoma.

6. Bezpośrednio po zakończeniu pracy nie wolno

dotykać wiertła ani obrabianego elementu. Mogą

one być bardzo gorące, grożąc poparzeniem

skóry.

7. Niektóre materiały zawierają substancje

chemiczne, które mogą być toksyczne. Należy

zachować ostrożność, unikając wdychania pyłów i

kontaktu ze skórą. Postępować zgodnie z kartą

charakterystyki dostawcy materiału.

INSTRUKCJĘ OBSŁUGI NALEŻY

ZACHOWAĆ.

UWAGA:

NIEWŁAŚCIWE UŻYTKOWANIE narzędzia lub

niestosowanie się do zasad bezpieczeństwa

podanych w niniejszej instrukcji obsługi może

prowadzić do poważnych obrażeń ciała.

WAŻNE ZASADY

BEZPIECZEŃSTWA

ENC007-2

DOTYCZĄCE AKUMULATORA

1. Przed użyciem akumulatora zapoznać się z

wszystkimi zaleceniami i znakami ostrzegawczymi

na (1) ładowarce, (2) akumulatorze i (3) wyrobie, w

którym będzie używany akumulator.

2. Akumulatora nie wolno rozbierać.

3. Jeżeli czas pracy uległ znacznemu skróceniu,

należy natychmiast przerwać pracę. Może bowiem

dojść do przegrzania, ewentualnych poparzeń, a

nawet eksplozji.

4. W przypadku przedostania się elektrolitu do oczu,

przemyć je wodą i niezwłocznie uzyskać pomoc

lekarską. Może on bowiem spowodować utratę

wzroku.

5. Nie wolno zwierać akumulatora:

(1) Nie dotykać styków materiałami

przewodzącymi prąd.

(2) Unikać przechowywania akumulatora w

pojemniku z innymi metalowymi przedmiotami,

typu gwoździe, monety itp.

(3) Chronić akumulator przed deszczem.

Zwarcie prowadzi do przepływu prądu

elektrycznego o dużym natężeniu i przegrzania

akumulatora, co w konsekwencji mo

poparzeniami, a nawet awarią urządzenia.

6. Narzędzia i akumulatora nie wolno przechowywać

w miejscach, w których temperatura osiąga bądź

przekracza 50°C.

7. Akumulatorów nie wolno palić, również tych

poważnie uszkodzonych lub całkowicie zużytych.

W ogniu mogą one bowiem eksplodować.

8. Chronić akumulator przed upadkiem i

uderzeniami.

że grozić

INSTRUKCJĘ OBSŁUGI NALEŻY

ZACHOWAĆ.

Wskazówki dotyczące zachowania maksymalnej

trwałości akumulatora

1. Akumulator naładować zanim ulegnie

całkowitemu rozładowaniu.

W przypadku stwierdzenia spadku mocy narzędzia

przerwać pracę i naładować akumulator.

2. Nie wolno ładować w pełni naładowanego

akumulatora. Zbyt długie ładowanie skraca okres

eksploatacji.

3. Akumulator ładować w temperaturze mieszczącej

się w przedziale 10°C - 40°C. Gdy akumulator jest

17

Page 18

gorący, przed przystąpieniem do jego ładowania

odczekać, aż ostygnie.

OPIS DZIAŁANIA

UWAGA:

• Przed przystąpieniem do regulacji lub przeglądu

narzędzia upewnić się, czy jest ono wyłączone i czy

został wyjęty akumulator.

Wkładanie lub wyjmowanie akumulatora

(Rys. 1)

• Przed włożeniem lub wyjęciem akumulatora należy

koniecznie wyłączyć narzędzie.

•Aby wyjąć akumulator, należy przesunąć przycisk

znajdujący się z boku i wysunąć akumulator.

•Aby włożyć akumulator, wystarczy wyrównać występ

na akumulatorze z rowkiem w obudowie i wsunąć go

na swoje miejsce. Akumulator wsunąć do oporu, aż

wskoczy na swoje miejsce, co jest sygnalizowane

delikatnym kliknięciem. Jeżeli element w kolorze

czerwonym w górnej części przycisku jest widoczny,

akumulator nie został całkowicie zablokowany. Należy

go wsunąć do oporu, aż czerwony element przestanie

być widoczny. W przeciwnym razie może przypadkowo

wypaść z narzędzia, raniąc operatora lub osoby

postronne.

• Przy wkładaniu akumulatora nie wolno używać siły.

Jeżeli akumulator nie wchodzi swobodnie, nie został

prawidłowo wł

Mechanizm przełącznika (Rys. 2)

UWAGA:

• Przed włożeniem akumulatora do narzędzia należy

zawsze sprawdzić, czy język spustowy przełącznika

działa prawidłowo i po zwolnieniu powraca do pozycji

„OFF” (wyłączone).

Aby uruchomić narzędzie, należy pociągnąć za język

spustowy przełącznika. Prędkość narzędzia rośnie wraz

ze zwiększaniem nacisku na język spustowy. W celu

zatrzymania urządzenia wystarczy zwolnić język

spustowy przełącznika.

Zapalanie lampki czołowej (Rys. 3)

UWAGA:

• Nie wolno zaglądać do lampki lub kierować wzroku

bezpośrednio na źródło światła.

W celu zapalenia lampki należy pociągnąć za język

spustowy. Lampka świeci dopóki język spustowy

przełącznika jest naciskany. Lampka gaśnie po 10 – 15

sekundach od momentu zwolnienia języka spustowego.

UWAGA:

• Do czyszczenia soczewki lampki powinno się używać

suchej szmatki. Należy przy tym zachować ostrożność,

aby nie porysować powierzchni soczewki lampki, gdyż

można w ten sposób zmniejszyć natężenie światła.

Mechanizm zmiany kierunku obrotów

(Rys. 4)

Omawiane narzędzie jest wyposażone w przełącznik

umożliwiający zmianę kierunku obrotów. W celu

uzyskania obrotów zgodnych z ruchem wskazówek

18

ożony.

zegara należy nacisnąć dźwignię przełącznika zmiany

kierunku obrotów po stronie A, natomiast by uzyskać

obroty przeciwne do ruchu wskazówek zegara, wystarczy

nacisnąć dźwignię przełącznika po stronie B.

Gdy dźwignia przełącznika zmiany kierunku obrotów

znajduje się w położeniu neutralnym, język spustowy

przełącznika jest zablokowany.

UWAGA:

• Przed uruchomieniem narzędzia należy zawsze

sprawdzić ustawienie kierunku obrotów.

• Kierunek obrotów można zmieniać tylko wówczas, gdy

urządzenie całkowicie się zatrzyma. Zmiana kierunku

obrotów przed zatrzymaniem się narzędzia grozi jego

uszkodzeniem.

• Gdy narzędzie nie będzie używane, należy zawsze

ustawić dźwignię przełą

obrotów w położeniu neutralnym.

cznika zmiany kierunku

Zmiana prędkości obrotowej (Rys. 5)

Aby zmienić prędkość, najpierw wyłącz narzędzie, a

następnie przesuń dźwignię zmiany prędkości do pozycji

„2”, aby uzyskać wysoką prędkość, lub do pozycji „1”, aby

uzyskać niską prędkość. Przed przystąpieniem do pracy

upewnij się, czy dźwignia zmiany prędkości obrotowej jest

ustawiona we właściwej pozycji. Do wykonania

konkretnego zadania używaj właściwej prędkości.

UWAGA:

•Dźwignię zmiany prędkości należy zawsze ustawiać

dokładnie w wybranej pozycji. W przypadku

uruchomienia narzędzia przy dźwigni zmiany prędkości

ustawionej w połowie między pozycją

dojść do uszkodzenia narzędzia.

• Nie wolno korzystać z dźwigni zmiany prędkości, gdy

narzędzie jest w ruchu. Narzędzie może bowiem ulec

uszkodzeniu.

„1” i „2” może

Regulacja momentu dokręcania (Rys. 6)

Moment dokręcania można regulować w zakresie 17

ustawień poprzez obrót pierścienia regulacyjnego w taki

sposób, aby wybrane ustawienie na pierścieniu pokryło

się ze strzałką na obudowie narzędzia. Moment

dokręcania ma wartość minimalną, gdy strzałka wskazuje

numer 1, a maksymalną po wyrównaniu strzałki ze

znakiem .

Sprzęgło ślizga się przy różnych wartościach momentu

dla ustawień od 1 do 16. Jego konstrukcja powoduje, że

nie ślizga się przy ustawieniu na .

Przed przystąpieniem do pracy należy przeprowadzić

próbę wkręcania w dany element lub inny element z tego

samego materiału, aby ustalić poziom momentu

obrotowego wymagany w danym zastosowaniu.

MONTAŻ

UWAGA:

• Przed przystąpieniem do jakichkolwiek czynności

związanych z obsługą narzędzia należy koniecznie

upewnić się, czy jest ono wyłączone i czy akumulator

został wyjęty.

Page 19

Montaż i demontaż wiertła lub końcówki

do wkręcania (Rys. 7)

Obróć tuleję w kierunku przeciwnym do ruchu wskazówek

zegara, aby rozsunąć szczęki uchwytu. Wsuń do oporu

końcówkę do uchwytu wiertarskiego. W celu zaciśnięcia

końcówki w uchwycie obróć tuleję w kierunku zgodnym z

ruchem wskazówek zegara.

Aby wyjąć końcówkę obróć tuleję w kierunku przeciwnym

do ruchu wskazówek zegara.

Montaż uchwytu na końcówki

(wyposażenie opcjonalne) (Rys. 8)

Wpasuj uchwyt na końcówki w występ w stopie narzędzia

z prawej bądź z lewej strony i przymocuj go wkrętem.

Jeżeli końcówka do wkręcania nie jest używana, należy

trzymać ją w uchwycie.

Można w nim przechowywać końcówki o długości 45 mm.

Zaczep (wyposażenie opcjonalne) (Rys. 9)

Zaczep ten służy do chwilowego zawieszania narzędzia.

Można go zamontować z jednej lub z drugiej strony

narzędzia.

Aby zamontować zaczep, wsuń go w rowek w obudowie

znajdujący się z obu stron, a następnie przykręć go

wkrętem.

Aby zdemontować zaczep, poluzuj wkręt i ściągnij

zaczep.

OBSŁUGA

UWAGA:

• Akumulator należy wsunąć do oporu, aż wskoczy na

swoje miejsce. Jeżeli element w kolorze czerwonym w

górnej części przycisku jest widoczny, akumulator nie

został całkowicie zablokowany. Należy go wsunąć do

oporu, aż czerwony element przestanie być widoczny.

W przeciwnym razie może przypadkowo wypaść z

narzędzia, raniąc operatora lub osoby postronne.

Trzymaj narzędzie mocno za uchwyt jedną dłonią, a

drugą za spód akumulatora, aby nie dopuścić do

obracania się narzędzia.

Operacja wkręcania (Rys. 10)

UWAGA:

• Ustaw pierścień regulacyjny w pozycji odpowiadającej

właściwemu dla danej operacji momentowi.

Wsuń ostrze końcówki do wkręcania do gniazda we łbie

wkrętu i dociśnij narzędzie. Uruchom narzędzie powoli, a

następnie stopniowo zwiększaj prędkość. Gdy tylko

sprzęgło zadziała, zwolnij język spustowy przełącznika.

UWAGA:

•Końcówka do wkręcania powinna być prostopadła do

łba wkrętu, w przeciwnym razie wkręt i/lub końcówka

mogą ulec uszkodzeniu.

UWAGA:

• W przypadku osadzania wkrętów w drewnie należy

wcześniej ponawiercać otwory prowadzące. Ułatwiają

one wkręcanie i zapobiegają pękaniu elementu.

Zapoznaj się z tabelą.

Nominalna średnica wkrętu

do drewna (mm)

3,1 2,0 - 2,2

3,5 2,2 - 2,5

3,8 2,5 - 2,8

4,5 2,9 - 3,2

4,8 3,1 - 3,4

5,1 3,3 - 3,6

5,5 3,7 - 3,9

5,8 4,0 - 4,2

6,1 4,2 - 4,4

Zalecany rozmiar otworu

prowadzącego (mm)

Operacja wiercenia

Najpierw obróć pierścień regulacyjny tak, aby strzałka

wskazywała znak . Następnie postępuj zgodnie z

poniższym opisem.

Wiercenie w drewnie

W przypadku wiercenia w drewnie najlepsze rezultaty

uzyskuje się stosując wiertła zakończone wkrętem

prowadzącym. Wkręt prowadzący ułatwia wiercenie,

ponieważ wciąga wiertło w nawiercany element.

Wiercenie w metalu

Aby uniknąć ześlizgiwania się wiertła na początku

operacji, za pomocą punktaka i młotka wykonać

wgłębienie w miejscu, w którym ma być wykonany otwór.

Ustawić końcówkę wiertła we wgłębieniu i rozpocząć

wiercenie.

W przypadku wiercenia w metalach należy stosować płyn

obróbkowy. Wyjątek stanowią żelazo i mosią

wierci się na sucho.

UWAGA:

• Nadmierne dociskanie narzędzia nie przyspiesza

operacji wiercenia. Zbyt duży docisk może się tylko

przyczynić do uszkodzenia ostrza wiertła, obniżenia

wydajności narzędzia i skrócenia czasu jego

eksploatacji.

• W momencie przebijania otworu na narzędzie/wiertło

wywierana jest olbrzymia siła. Gdy wiertło zaczyna

przebijać na wylot otwór w elemencie, należy

zachować ostrożność i mocno trzymać narzędzie.

• Zakleszczone wiertło można w prosty sposób

wyciągnąć z otworu, zmieniając za pomocą

przełącznika kierunek obrotów i wykręcając je.

Podczas wycofywania narzędzia mogą jednak

wystąpić problemy z jego opanowaniem, jeżeli nie

będzie mocno przytrzymywane.

•Małe elementy należy koniecznie mocować w imadle

lub podobnym uchwycie.

•Jeżeli narz

rozładowania akumulatora, należy je odstawić na 15

minut, zanim praca zostanie podjęta na nowo z

użyciem innego naładowanego akumulatora.

ędzie jest używane bez przerwy aż do

dz, w których

19

Page 20

KONSERWACJA

UWAGA:

• Przed przystąpieniem do przeglądu narzędzia lub jego

konserwacji upewnić się, czy jest ono wyłączone i czy

akumulator został wyjęty.

Wymiana szczotek węglowych (Rys. 11)

Potrzebę wymiany szczotek sygnalizuje znak granicy

zużycia. Szczotki węglowe powinny być czyste, aby

można je było swobodnie wsunąć do opraw.

Obie szczotki węglowe wymieniać równocześnie. Używać

wyłącznie identycznych szczotek węglowych.

Za pomocą śrubokręta wykręć dwie śruby, następnie

ściągnij tylną osłonę. (Rys. 12)

Korzystając z cienkiego śrubokręta płaskiego lub