Makita BDF441, BDF441SFE, BDF441SFE3 Technical Information

T

ECHNICAL INFORMATION

Model No.

Description

BDF441

Cordless Driver Drill 13mm (1/2")

CONCEPT AND MAIN APPLICATIONS

Model BDF441 has been developed as an upgraded sister model of Model 6339D

with the design concept of "More Control and Maneuverability".

Features lightweight and compact design achieved by using 4-pole motor and

Lithium-ion battery as power unit.

Also features the same advantages as BDF440:

Rubberized soft grip contoured to perfectly fit operator hand and angled

to provide best tool balance

All metal gear construction

Job light with afterglow function

Single sleeve chuck

This new product will be available in the following variations.

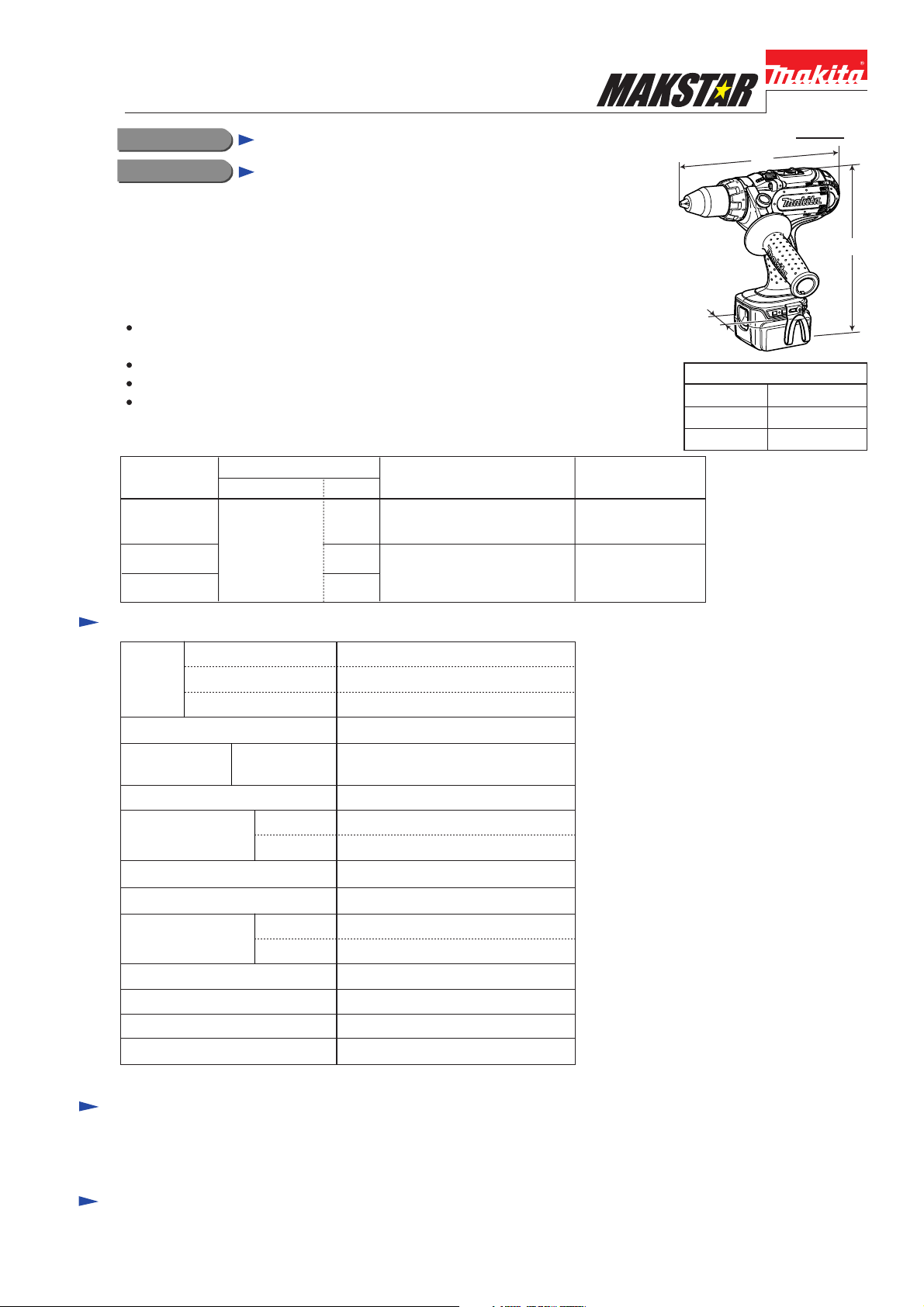

PRODUCT

L

W

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

238 (9-3/8)

78 (3-1/16)

P 1 / 7

H

255 (10)

Model No.

BDF441

BDF441SFE

BDF441SFE3 3

(Li-ion 3.0Ah)

Battery

type quantity

BL1430

2

2

DC18SC (Low voltage areas)

DC14SC (High voltage areas)

Specification

Voltage: V

Battery

Max output (W) 265

No load speed:

min-1=rpm

Capacity of drill chuck: mm (")

Capacity: mm (")

Torque setting

Max. clutch torque: N.m (ft.lbs)

Max. fastening

torque: N.m (ft.lbs)

Electric brake

Variable speed control

Reversing switch

Net weight*: kg (lbs)

Capacity: Ah

Cell

1st/ 2nd/ 3rd

0 - 300/ 0 - 600/ 0 - 1,700

1.5 - 13 (1/16 - 1/2)

Steel

Wood

16 stage + drill mode

1.0 - 5.9 (0.7 - 4.3)

Soft joint

Hard joint

Charger Offered to

DC18SC

14.4

3.0

Li-ion

13 (1/2)

50 (2)

32 (23.6)

70 (51.6)

Yes

Yes

Yes

2.0 (4.4)

USA, Canada

Mexico, Panama

All countries except

those listed above

*Includes battery BL1430

Standard equipment

Philips bit 2-45 ....... 2 pc

Bit holder................ 1 pc

Note: The standard equipment for the tool shown above may differ by country.

Belt clip................... 1 pc

Grip assembly.......... 1 pc

+ Screw M4x12 .............. 2 pc

Plastic carrying case ..... 1 pc

Optional accessories

Charger DC14SA

Charger DC14SC

Charger DC18SC

Charger DC24SA

Charger DC24SC

Li-ion battery BL1430

Assorted drill bits for wood

Assorted drill bits for metal

P 2 / 7

Repair

CAUTION: Remove the battery cartridge from the machine for safety before repair/maintenance !

[1] NECESSARY REPAIRING TOOLS

Description Use for

Hex wrench 10 Removing /mounting Drill chuck

Plastic hammer Removing Drill chuck

[2] LUBRICATION

It is not required to lubricate the gear section because the portion is replaced as a factory-lubricated gear unit.

[3] DISASSEMBLY/ASSEMBLY

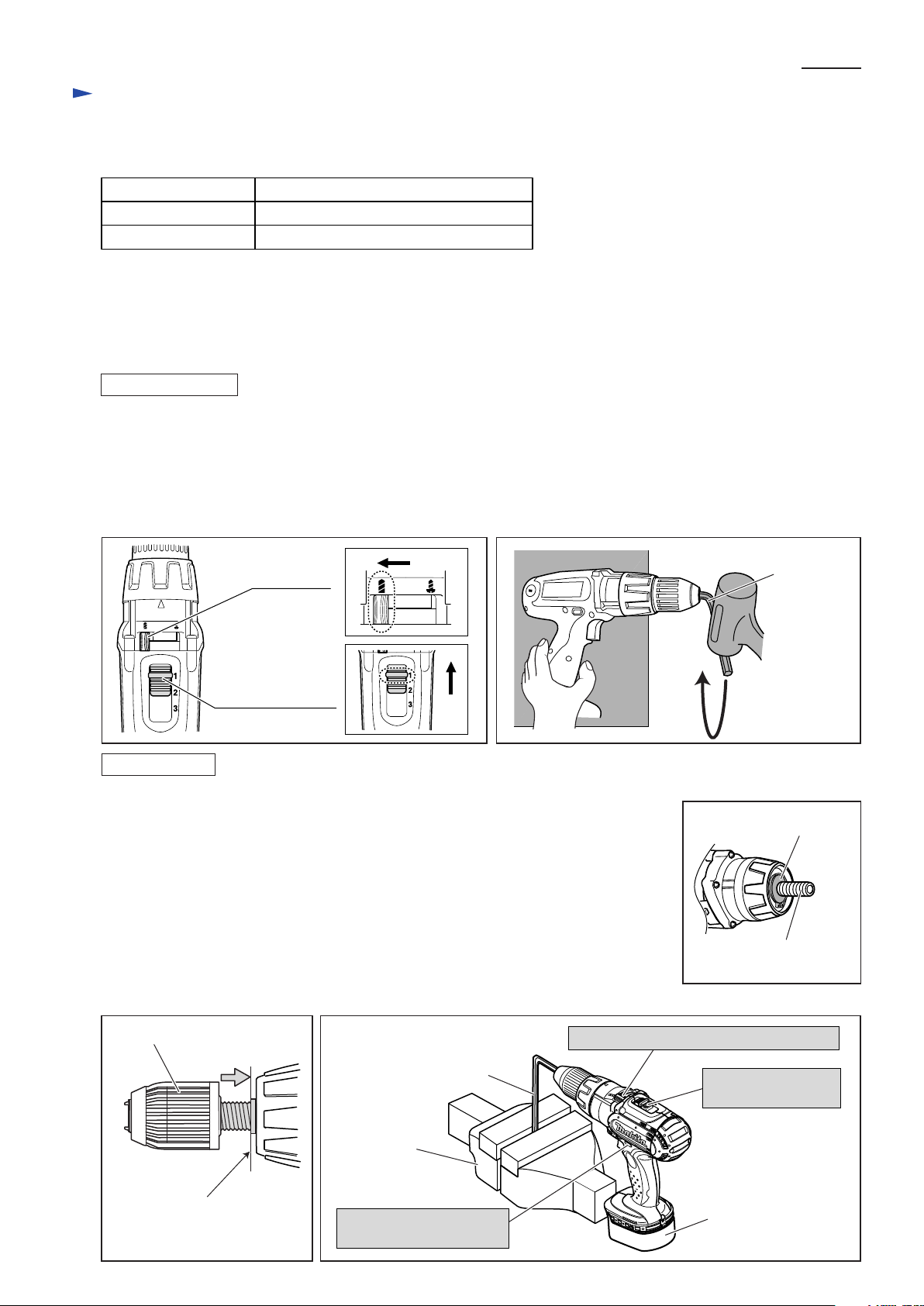

[3] -1. Drill Chuck

DISASSEMBLING

Note: It is required to remove Drill chuck when replacing Gear assembly, but you need not when replacing only Housing.

1) Open the jaws of Drill chuck fully, and remove the chuck screw (Flat head screw M6x22, left-handed and threadlocker

coated) by turning clockwise with impact driver in Forward rotation mode.

2) Insert a hex wrench into Drill chuck. Then set the Speed change lever in 1st speed, and Action mode change lever in

Drill mode as illustrated in Fig. 1. Holding the machine on work bench firmly, turn Drill chuck counter clockwise

by tapping the hex wrench. Now Drill chuck can be removed from Spindle. (Fig. 2)

Fig. 1

Fig. 2

Action mode

change lever

Speed change lever

ASSEMBLING

1) Make sure that Flat washer 13 is set in place before installing Drill chuck. (Fig. 3)

1) Turn Drill chuck clockwise until it sits on the end of the threaded portion of Spindle.

(Fig. 4)

2) See Fig. 5. Insert a hex wrench into drill chuck, and fix the other end of hex wrench

in vise. Install battery. Then set the Action mode change lever in Drill mode,

the Speed change lever in 1st speed, and F/R change lever in Forward rotation mode.

3) Slowly pull the switch trigger to rotate Spindle until the motor is locked.

Note: Pull the trigger so that Spindle reaches full speed in one second.

Important: Be sure to release the switch trigger just after Spindle is locked.

4) Secure Drill chuck with the chuck screw by turning counterclockwise with impact driver.

Note: If you reuse the removed chuck screw, apply threadlocker to threaded portion.

Fig. 4 Fig. 5

Hex wrench

Fig. 3

Flat washer 13

threaded portion

of Spindle

Drill chuck

End of the threaded

portion of Spindle

Hex wrench

Vise

F/R change lever:

in Forward rotation mode

Action mode change lever: in Drill mode

Speed change lever:

in 1st speed

Battery

Repair

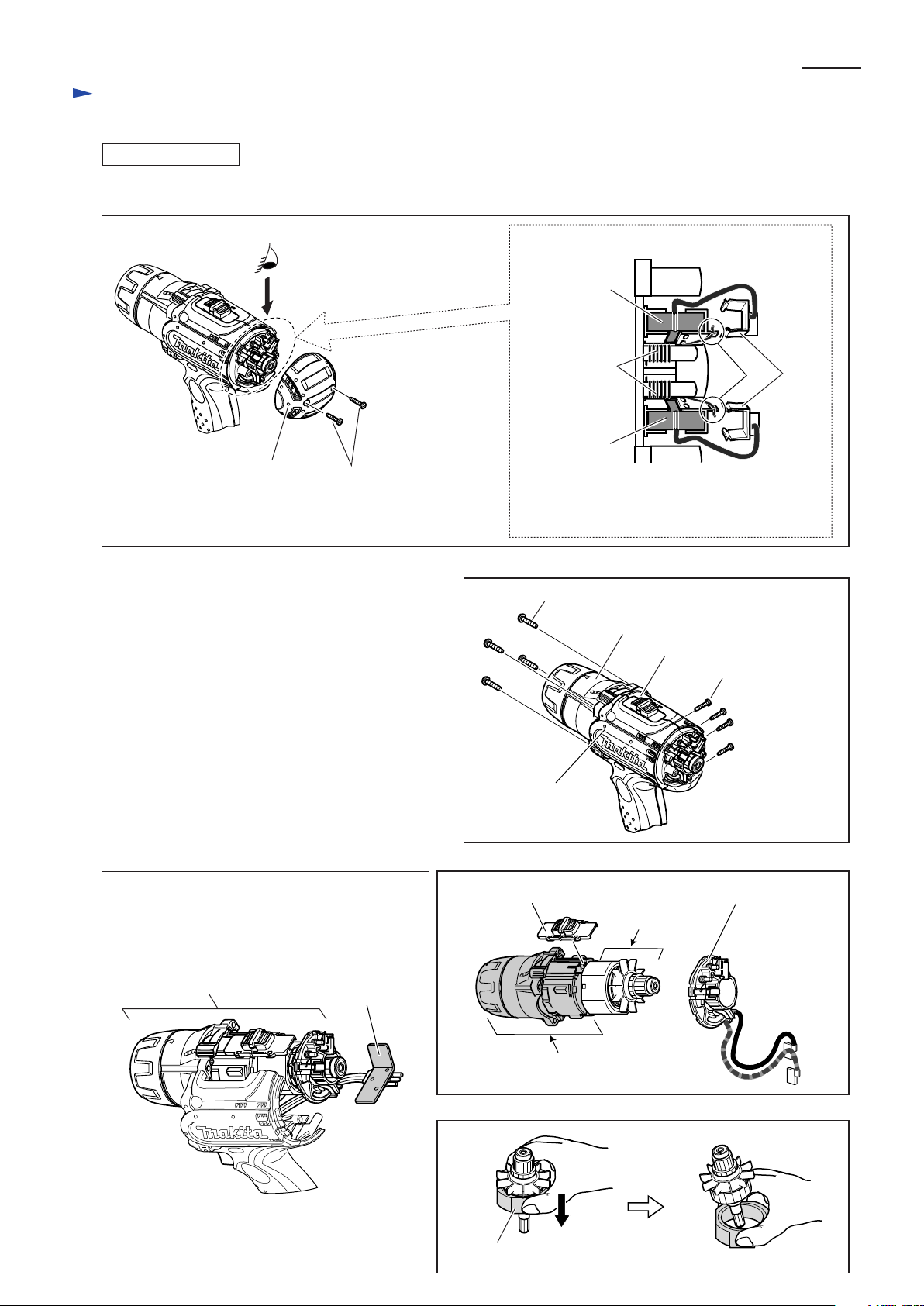

[3] -2. Gear Assembly and Motor Section

DISASSEMBLING

1) Remove Rear cover and take off Carbon brush from Brush holder complete. (Fig. 6)

Fig. 6

P 3 / 7

A

Rear cover

2) Unscrew four PT4x20 Tapping screws to disconnect

Gear assembly from Housing. Then by removing

eight PT3x16 Tapping screws, separate Housing R

from Housing L. (Fig. 7)

3) Pull off Heat sink from Yoke unit of the Motor section.

Then remove the assembly of the Gear section and

the Motor section from housing L. (Fig. 8)

3) Remove Brush holder complete from Armature,

then separate the Motor section from the Gear section.

(Fig. 9)

4) Put the Motor section on a work bench so that the

drive end of Armature touches the work bench.

Then separate yoke unit from armature by pulling it

down towards the work bench. (Fig. 10)

Tapping screw

bind PT 3x16

Fig. 7

Housing L

[Brush holder section (View from A)]

Carbon brush

Torsion spring

Carbon brush

1. Move the tail of Torsion spring onto the notch

of Brush holder.

2. Then pull off Receptacle from Brush holder.

Tapping screw bind PT4x20 (4 pcs)

Gear section (= Gear assembly)

Housing R

1 2

Tapping screw bind

PT3x16 (8 pcs)

Fig. 8 Fig. 9

Speed change lever assembly Brush holder complete

Assembly of the Gear section

and the Motor section

Heat sink

Fig. 10

Yoke unit

Motor section

Gear section

Loading...

Loading...