Page 1

PRODUCT

T

ECHNICAL INFORMATION

P 1/ 8

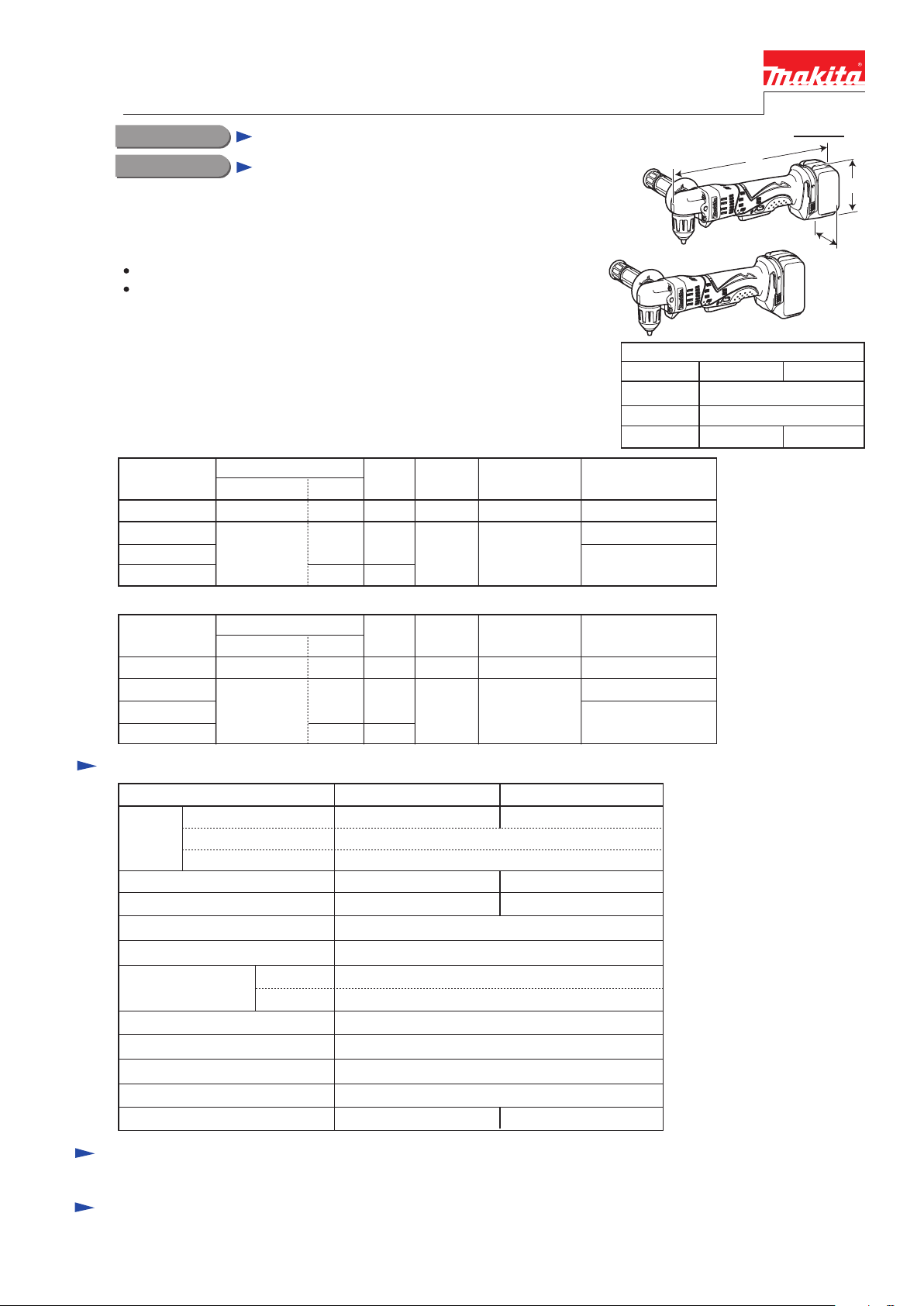

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

BDA341/ BDA351

14.4V/18V Cordless Angle Drill 10mm (3/8")

Battery

Capacity of drill chuck: mm (")

Capacity: mm (")

Electric brake

Variable speed control

Reverse switch

Steel

Wood

No load speed: min-1=rpm

Cell

Voltage: V

Capacity: Ah

Net weight: kg (lbs)

*with Battery BL1430

**with Battery BL1830

Max output: W

Li-ion

14.4

Model BDA341

18

BDA351

3.0

Yes

Yes

Yes

LED job light Yes

1.6 (3.5)* 1.7 (3.7)**

10 (3/8)

25 (1)

0 - 1,800 0 - 1,700

1.5 (1/16) - 10 (3/8)

Drill chuck type Keyless, Single sleeve

230 280

Models BDA341 and BDA351 have been developed as the DC version tools

of Model DA3011F, featuring:

Lightweight design obtained by using Li-ion battery as a power unit

High power 4-pole motor for excellent drilling performance

Sister tools featuring Keyed drill chuck are also available

as Models BDA340/ BDA350.

(See Technical Information of BDA340/ BDA350 for detailed information.)

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 326 (12-7/8)

BDA341 BDA351

79 (3-1/8)

97 (3-13/16) 115 (4-1/2)

These products are available in the following variations.

BDA341Z No

Model No.

type quantity

Charger

Charger

---No

Battery

No

BDA341

DC18RA

BDA341RF 1

Plastic carrying

case

BDA341RFE

2

BL1430

(Li-ion 3.0Ah)

Yes

No

Battery

cover

Battery

cover

No

1

Offered to

Offered to

All countries

All countries except

North America

North America

W

H

L

BDA341

BDA351

BDA341

BDA351Z No

Model No.

type quantity

---No

Battery

No

BDA351

DC18RA

BDA351RF 1

Plastic carrying

case

BDA351RFE

2

BL1830

(Li-ion 3.0Ah)

Yes

No

No

1

All countries

All countries except

North America

North America

BDA351

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may differ by country.

Side grip ........... 1

Battery BL1430 (for BDA341)

Battery BL1830 (for BDA351)

Drill bits for wood

Drill bits for steel

Charger DC24SA (for North America only)

Charger DC24SC (except for North America)

Fast charger DC18RA

Belt clip

Page 2

P 2/ 8

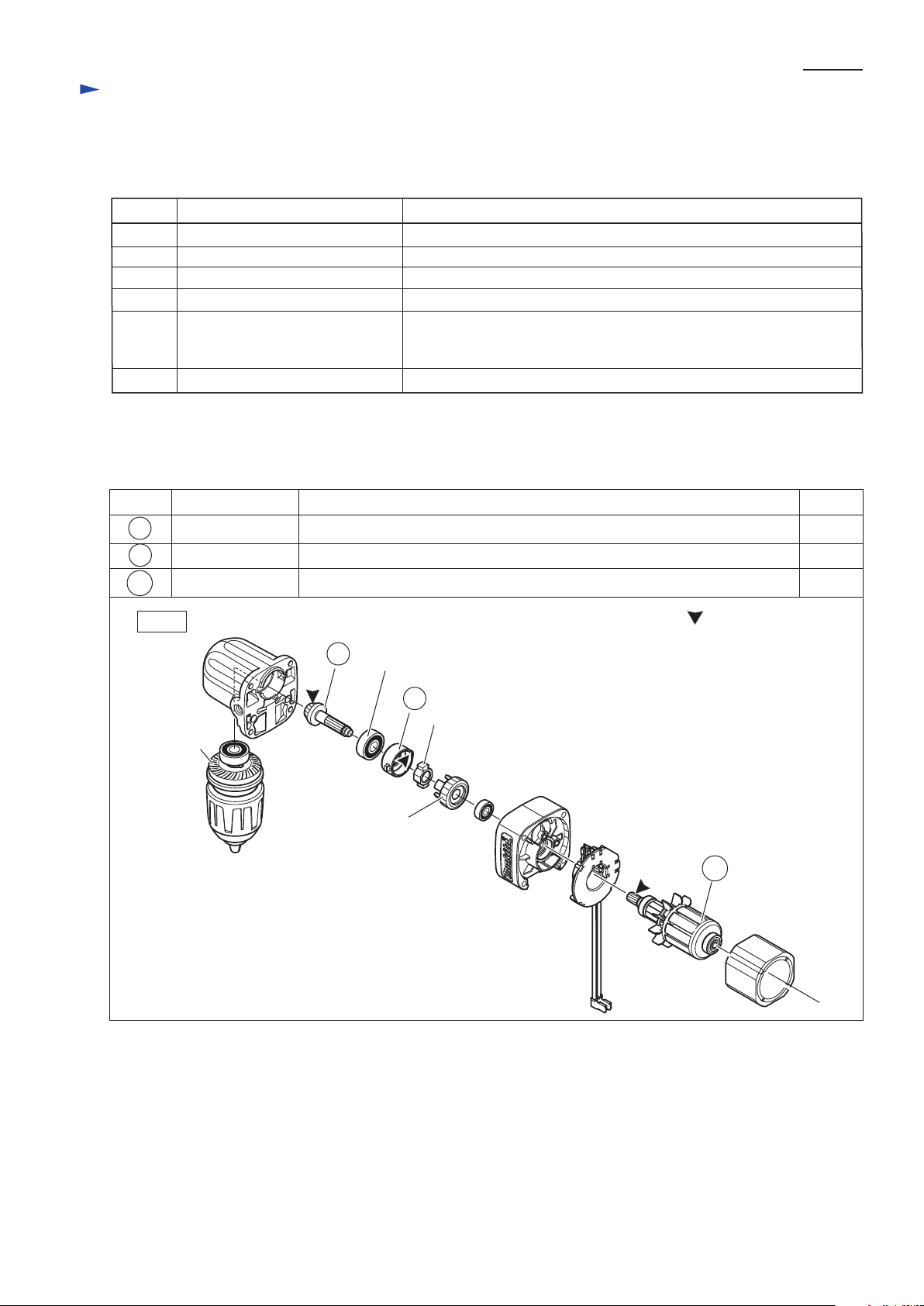

[2] LUBRICATION

Apply Makita grease N. No.2 to the following portions designated with the black triangle to protect parts and product

from unusual abrasion.

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the bit and the battery from the machine for safety before

repair/ maintenance in accordance with the instruction manual!

Repair

Description

Assembling / Disassembling Bearing retainer 36-43

Assembling / Disassembling Bearing retainer 36-43

Assembling Spur gear 29 section to Gear housing

Removing Keyless drill chuck

Removing Ball bearings

Removing Retaining ring S-12

Code No.

Bearing setting pipe 23-15.2

1R029

Drill chuck extractor

1R139

Bearing extractor

1R269

Retaining ring S and R pliers

1R291

Wrench for Bearing retainer

(with expanded claw distance from

30mm to 36mm)

1R292

Adjustable bearing retainer wrench

1R316

Use for

Makita grease N No. 2

Fig. 1

Item No. Description Amount

4g

2g

Spiral bevel gear 9 Teeth portion for smooth engaging with Spiral bevel gear 26

Ball bearing 608ZZ

Lock cam

Spur gear 29

Spiral bevel

gear 26

Portion to lubricate

Lock ring a littleInside where Lock cam contacts

Armature Drive end where engages with Spur gear 29

15

3

5

15

3

5

Page 3

P 3/ 8

R

epair

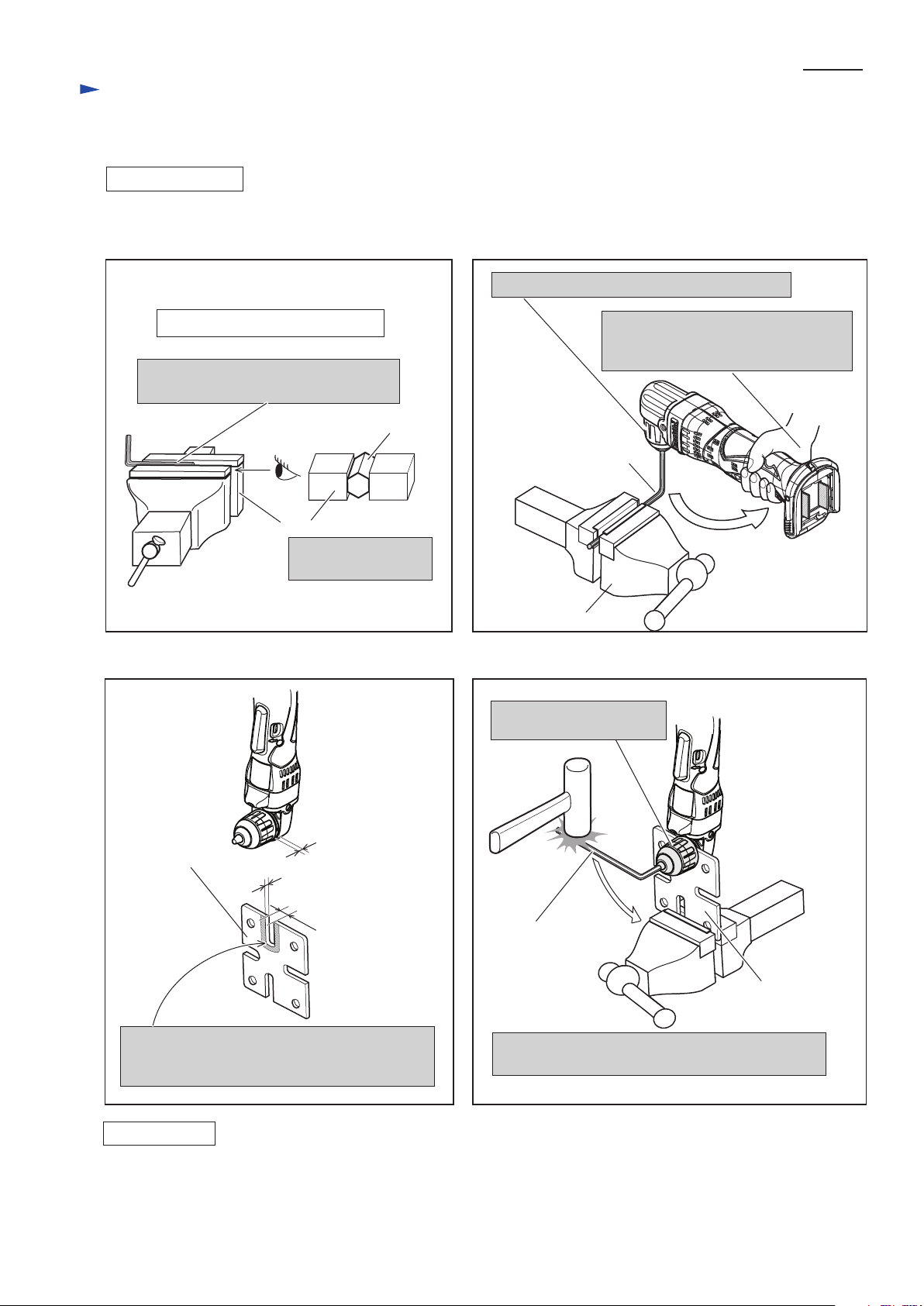

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Keyless Drill Chuck

DISASSEMBLING

Correct setting of Hex Wrench 8

Clamp the long portion of Hex wrench 8

when using vise.

Remove Keyless drill chuck as illustrated in Figs. 2 and 3. If it is difficult to remove in this way, Keyless drill chuck

can be removed as illustrated in Figs.2A and 3A.

Hex wrench 8

Clamp the flat surface

of Hex wrench 8.

Vise

Hex wrench 8

Hex wrench 8

1. Hold Hex wrench 8 with Keyless drill chuck.

2. Firmly gripping the body in the near

of Terminal, turn the machine

counterclockwise.

Fig. 2 Fig. 3

Fig. 2A Fig. 3A

Vise

1R139 modified

as shown in Fig. 2A

1R139

(1) Do the reverse of the disassembling steps. Refer to Figs. 3 and 2., or Figs. 3A and 2A.

(2) Turn the machine or Hex wrench clockwise to tighten Keyless drill chuck. The fastening torque for Drill chuck is

40 - 45 N.m.

14mm

width groove

Make the thickness of this portion thin to 2.5mm

by grinding in order to insert 1R139 into the gap

between chuck and Gear housing.

2.5mm in thickness

Gap between

Keyless drill chuck

and Gear housing

1. Hold Hex wrench 8

with Keyless drill chuck.

2. Turn Hex wrench 8 counterclockwise by striking

with Hammer.

ASSEMBLING

Note: Keyless drill chuck may further turn resisting shaft lock mechanism, while sounding like clutch in work.

This phenomenon does not show any trouble, but Keyless drill chuck is tightened firmly.

Page 4

P 4/ 8

R

epair

DISASSEMBLING

Fig. 6 Fig. 7 Fig. 8

Fig. 9 Fig. 10

[3]-2 Spiral Bevel Gear 26

(1) Remove Keyless drill chuck as illustrated in Figs. 2 and 3 / Figs. 2A and 3A. And disassemble Bearing retainer as

illustrated in Figs. 4 and 5.

(2) Disassemble Spiral bevel gear 26 in the order of Figs. 6to 10.

Remove Gear section by striking

the edge of Gear housing.

Remove Bearing box from

Spindle.

Bearing box can be removed

by hand.

Spiral bevel gear 26

Bearing box

Spindle

Spindle

Ball bearing

6001DDW

Ball bearing

608ZZ

Ball bearing 608ZZ

Retaining

ring S-12

1R269

Bearing box

Spiral bevel

gear 26

Spiral bevel

gear 26

Spiral bevel gear 26 can

be removed by hand.

Then remove Key 4.

Remove Retaining ring S-12

with 1R291.

Remove Ball bearing 608ZZ

with 1R269.

Retaining ring S-12

Key 4

Key 4

1R291

ASSEMBLING

Do the reverse of the disassembling steps.

Note: Do not forget to assemble Key 4 to Spindle. Refer to Fig. 10.

To fit 1R292 to the notch of Bearing

retainer, enlarge this width from 30mm

to 36mm by grinding 1R292.

1R292

notch for fitting

1R292

Bearing retainer

Clamp the machine

with vise.

Remove Bearing retainer 36-43 with 1R292

by turning it clockwise.

1R292

Bearing retainer 36-43

Fig. 4

Fig. 5

Page 5

P 5/ 8

ASSEMBLING

Refer to Figs. 11 to 13.

R

epair

[3]-3. Spur Gear 29, Spiral Bevel Gear 9

4x45 tapping screw (4pcs.)

1R269

Gear housing

Disassemble Gear housing together with

Gear housing cover from Motor housing

by unscrewing 4x45 Tapping screw.

Disassemble Ball bearing

696ZZ from the shaft of

Spiral bevel gear 9 with 1R269.

Remove Gear housing cover

from Gear housing by pulling

off.

Strike the edge of Gear housing

with plastic hammer.

Gear section can be removed

from Gear housing.

Gasket

Motor housing

Gear housing cover

cut

groove of spline

Ring spring 6

Insert the pick between the groove of spline and the near point to

Ring spring’s cut. And Lever up Ring spring with the pick

Ball bearing 696ZZ

Spur gear 29

Spiral bevel

gear 9

Ball bearing

608ZZ

Gear housing cover

Gear housing

Gear section

Fig. 11

Fig. 12

Fig. 13

Lock ring

Lock cam

Pin 3.5

Lock ring

Spur gear 29

Spur gear 29

Strike the work table with

shaft end of Spiral bevel

gear 9.

Spur gear 29 can be disassembled

from the shaft of Spiral bevel

gear 9.

Separate Lock ring

from Spur gear 29.

Lock cam and Pin 3.5 can be

removed from Spur gear 29.

ASSEMBLING

Fig. 15

Fig. 14

Note: Ring Spring 6 has got wider than the size it

was, due to the disassembling step. Therefore,

Correct the size and form by pressing it with

pliers after assembling to the shaft of Spiral

bevel gear 9.

(1) Take the reverse of the disassembling steps. Refer to Figs. 13 and 12, Pay attention to Fig. 14.

(2) Mount the Gear section to Gear housing as illustrated in Fig. 15.

(3) Assemble Gear housing and Gear housing cover to Motor housing by screwing 4x45 Tapping screws. (Fig. 11)

notch

notch

protrusion

1R029

Spur gear 29

Ring spring 6

Ball bearing 696ZZ

Correct the size and form

of Ring ring 6 by pressing

the portions designated in

black arrows.

Shaft of Spiral bevel gear 9

Gear housing

Gear housing

cover

Gasket

Do not forget to mount

Gasket between Gear

housing cover and Gear

housing.

Assemble the Gear section by

pressing spur gear 29 with

1R029, while aligning the

protrusions of Lock ring to

the notches of Gear housing.

Page 6

P 6/ 8

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Motor Section

DISASSEMBLING

(1) Disassemble Gear housing and Gear housing cover from Motor housing by unscrewing 4x45 Tapping screws. (Fig. 11)

(2) Remove Motor section from Housing set (L) in the order of Figs.16 and 17.

(3) When removing Armature from Brush holder, take the steps illustrated in Figs. 18, 19 and 20.

3x16 Tapping screw (5pcs.) Housing set (R)

Separate Housing set (R)

from Housing set (L) by

unscrewing 3x16 Tapping

screws.

Yoke

unit

Motor Section

Armature

Switch lever

Remove Switch lever and Link.

Link

Fig. 16

Fig. 17

Shift the tail of Torsion spring from top of Carbon brush

to the notch of Brush holder. Now Carbon brush is free

from the pressure of Torsion spring.

tail of Torsion spring

notch

notch

Torsion spring

Carbon brush

Carbon brush

Tail of Torsion spring

Carbon brush

Carbon brush

Disconnect Carbon brush from

the commutator of Armature by

pulling up.

Then disssemble Armature and

Yoke unit from Brush holder.

Armature

Armature

Pull off Armature from

Yoke unit.

Yoke unit

Yoke unit

Fig. 18

Fig. 19 Fig. 20

Brush holder complete

Remove York unit, Brush holder complete

and Armature in a set when removing

Motor section.

Brush holder

Page 7

P 7/ 8

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Motor Section (cont.)

ASSEMBLING

Heat sink

Yoke unit

Brush holder

Armature

Protrusion for fitting to

the notch of Yoke unit

notch for fitting

to Housing set (L)

Fitting the notch of Yoke unit to the protrusion of Housing set (L),

assemble the Motor section.

Notch of

Yoke unit

Notch of

Yoke unit

(1) Assemble Armature as illustrated in Fig. 21R.

Note: Pay attention to the position of notch of Yoke unit.

It has to be located on the opposite side of Commutator.

(2) Assemble Brush holder to Armature’s Commutator end.

However, still keep Carbon brush free from the pressure of

Torsion spring of Brush holder in this step.

(2) Assemble the Motor section to Housing set (L) as illustrated

in Figs. 22 and 23.

Commutator

of Armature

Commutator

of Armature

Correct Wrong

Fig. 21R

Fig. 22 Fig. 23

Fig. 21F

Switch side

Housing set (L)

Motor Section

Housing

set (R)

Housing

set (L)

Carbon brush

Brush

holder

complete

Mount Brush holder complete on

Commutator so that the angle of two

Carbon brushes can be 90 degrees as

illustrated above.

90 degrees

[3]-5. Assembling F/R Change Lever

[3]-6. Disassembling Terminal

Protrusion of Switch

for fitting F/R Change

Lever’s concave

Concave of F/R change lever

for fitting to protrusion of

Switch

FET

Fix F/R Change lever to Switch as illustrated in Fig. 24.

Fig. 24

Fig. 25

Stopper

(for firm connection of Flag Terminal)

1. While pushing Stopper with thin screwdriver,

hitch the Flag terminal with the screwdriver.

Flag terminal

Flag terminal for this product is equipped with Stopper for firm connection. Remove Flag terminal as illustrated in Fig. 25.

2. Pull off the Flag terminal.

Page 8

P 8/ 8

Circuit diagram

White

Red

When connecting Lead wires of Brush holder

complete to Switch, connect them as follows.

* Lead wire (black) to M2 Terminal

* Lead wire (red) to M1 Terminal

Terminal

Switch

Switch lever side

LED circuit

FET

Fig. D-1

Connector of

LED circuit

Connector of

Switch

Color index of lead wires' sheath

Black

Wiring diagram

LED circuit has to be put into Housing set (L)

as illustrated below.

Lead wires of LED Circuit has to be guided in Housing set (L)

as illustrated below, and fix them with Lead wire holders.

Connector of LED circuit is connected with

Connector of Switch in the next step.

Lead wire holders

Wiring of LED Circuit

(before setting Switch and other electrical Parts)

Wiring after setting Switch and other electrical parts

Terminal

Switch

Yoke unit

FET Brush holder completeHeat sink

Lead wire holders

Put the extra portion of

Lead wires in this place.

Fix the Lead wires of Connectors

with these Lead wire holders.

Put the extra portion of

Lead wires in this place.

Connector of

Switch side

Connector of

LED side

Armature

Fig. D-2

Fig. D-3

Brush holder complete

Fix Lead wires of Brush holder complete with these Lead wire holders. And put the Lead

wires of Brush holder complete in the position illustrated above, expanding them between

York unit and Brush holder complete.

Loading...

Loading...