Makita BCM2610, BCM4300, BCM3310, BCM3300 User Manual

BCM2600

BCM3300

BCM4300

Instruction Manual

Original Instruction Manual

BCM2310

BCM2610

BCM3310

Read this instruction manual carefully before putting the brushcutter into operation and strictly observe the

Important:

safety regulations!

Keep this Instruction Manual!

Thank you for choosing a MAKITA product!

We trust that you will be a satisfi ed customer. By choos-

ing a MAKITA you have chosen one of the most advanced

brushcutters.

With their two-stroke gasoline engines the brushcutters can

be used anywhere, and with their fuel pump (primer) they are

unusually easy to start. They’re ideal for yardwork and greens

keeping and especially suitable for occasional use. They offer

the latest technology, ergonomic design and high ease of use

at a reasonable price.

To ensure your own safety and to get the maximum performance

out of your MAKITA brushcutter, we urge you to

read this instruction manual carefully before putting the

brushcutter into operation and to strictly observe all of the

safety regulations! Failure to observe these precautions

can lead to severe injury or death!

EU Conformity Declaration

The undersigned, Tamiro Kishima and Rainer Bergfeld, as

authorized by DOLMAR GmbH, declare that the MAKITA

machines,

Type: BCM2310 (351), 2610 (352), 3310 (353)

BCM2600 (352), 3300 (353), 4300 (354)

manufactured by DOLMAR GmbH, Jenfelder Str. 38, 22045

Hamburg, Germany, conforms to the basic safety and health

requirements of the applicable EU Directives:

EU Machinery Directive 98/37/EG.

EU EMC Directive 2004/108/EG.

Outdoor Noise Directive 2000/14/EG.

Starting on 29 Dec. 2009, Directive 2006/42/EG will come into

force, replacing Directive 98/37/EG. This product meets the

requirements of the new Directive.

The most important standards applied to properly meet the

requirements of the above EU Directive were:

EN 11806, EN 14982, EN 61000-4-2, EN 61000-4-3.

The conformity assessment procedure 2000/14/EG was per-

formed per Annex V.

BCM2310: The measured sound power level is 110 db(A), the

guaranteed sound power level is 112 db(A).

BCM2610: The measured sound power level is 110.7 db(A),

the guaranteed sound power level is 112 db(A).

BCM2600: The measured sound power level is 102.8 db(A),

the guaranteed sound power level is 105 db(A).

BCM3310: The measured sound power level is 112.3 db(A),

the guaranteed sound power level is 115 db(A).

BCM3300: The measured sound power level is 103.6 db(A),

the guaranteed sound power level is 105 db(A).

BCM4300: The measured sound power level is 104.7 db(A),

the guaranteed sound power level is 107 db(A).

The technical documentation is on fi le at DOLMAR GmbH, Ab-

teilung FZ, Jenfelder Strasse 38, 22045 Hamburg, Germany.

Hamburg, 11.4. 2008

For DOLMAR GmbH

Tamiro Kishima Rainer Bergfeld

Managing Director Managing Director

2

Table of contents Page

EC declaration of conformity ............................................2

Packing ................................................................................2

Delivery inventory ..............................................................3

Explanation of symbols ..................................................... 3

SAFETY PRECAUTIONS

General precautions .......................................................4

Personal protective equipment .......................................4

Handling fuels / Refuelling ...........................................4-5

Putting into operation ......................................................5

Kickback .........................................................................6

Working behavior / Method of working ............................6

Applications for cutting tools ............................................ 6

Transport and Storage .................................................6-7

Maintenance ...................................................................7

First Aid ...........................................................................7

Technical data .....................................................................8

Components ........................................................................8

PUTTING INTO OPERATION

Handle installation, BCM2600/3300/4300 ......................9

Handle installation, BCM2310/2610/3310 ......................9

Mounting the cutter guard ............................................. 10

Mounting the 4-tooth star blade .................................... 11

Installing the trimmer head ........................................... 11

Adjusting the line ...........................................................12

Replacing the line ..........................................................12

Replacing the line knife ................................................. 12

Fuel mixture / Refuelling ................................................ 13

Putting on the harness ................................................... 14

Balancing the brushcutter ............................................. 14

Quick-release buckle ....................................................14

Start engine .............................................................14-15

Idle adjustment .............................................................15

REPAIR AND MAINTENANCE WORK

Instructions for maintenance ......................................... 16

Sharpening of cutting tools ...........................................16

Cleaning the air fi lter .....................................................17

Replacing and Inspecting the spark plug ...................... 17

Lubricating the gear box ...............................................18

Suction head in the fuel tank ........................................18

Cleaning the muffl er opening ........................................18

Service and maintenance .............................................18

Trouble shooting .............................................................. 18

Extract from the spare part list .......................................19

Service, spare parts and guarantee ...........................19-20

Notes ..................................................................................21

Packing

Your MAKITA brushcutter comes in a cardboard box to protect

it from shipping damage.

Cardboard is a raw material. We encourage you to re-use the

box or recycle it (waste paper).

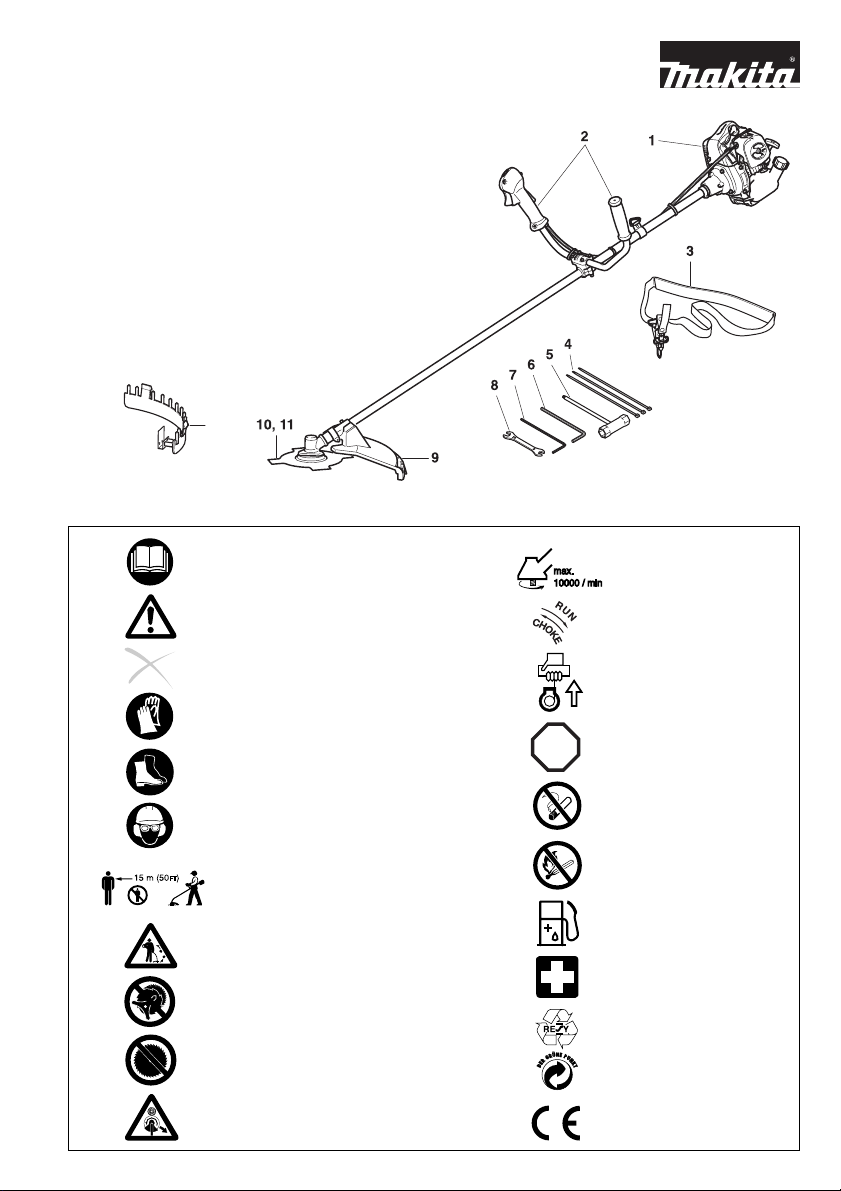

Delivery inventory

1. Brushcutter

2. Handle (version depends on model)

3. Harness

4. Cable ties (only with the BCM2600/3300/4300)

5. Combination tool, AF 17/19

6. Allen key, 4 mm

7. Allen key, 5 mm

8. Wrench, 8/10

9. Guard (cutting attachment guard)

10. Cutting tool

(BCM2600/3300/4300 = 4-tooth star blade, BCM2310/2610/331 = 2-line trimmer head)

11. Tool protection (BCM2600/3300/4300 only)

12. Guard extension

- Instruction Manual (not shown)

If one of these parts is missing when you unpack the brushcutter,

contact your dealer!

Shown: BCM2600

12

Explanation of symbols

You will notice the following symbols on the brushcutter and in the instruction manual.

Read the instruction manual and follow

all warnings and safety instructions!

Particular care and caution!

Forbidden!

Wear protective gloves!

Wear safety shoes!

Wear head, eye, face and hearing protection!

The distance between the machine and

bystanders shall be at least 50 feet!

DANGER:

Beware of thrown objects!

Do not use metal blades!

Do not use saw blades!

CAUTION: Kickback!

(blade thrust)

STOP

Maximum tool rpm

Choke

Start engine

Stop engine!

No smoking!

No open fl ame!

Fuel and oil mixture

First aid

Recycling

CE-Marking

3

SAFETY PRECAUTIONS

General precautions

Proper use: These power brushcutters are intended for cutting

grass or heavy weeds, with the appropriate and permissible cutting tools. A brushcutter may be operated only by one person, and

only out of doors!

Improper use:

The cutting tools permissible for this brushcutter must not be used

to cut heavier material such as shrubs, bushes, heavy growth, or

thickets.

Impermissible users:

Persons who are unfamiliar with this Instruction Manual, minors,

and persons under the infl uence of alcohol, drugs or medication

must not operate this tool.

To ensure correct operation, the user has to read this instruction

manual to make himself familiar with the handling of the brushcutter. Insuffi ciently informed users will risk danger to themselves as

well as others due to improper handling (1).

- It is recommended only to lend the brushcutter to people who

have experience with brushcutters. When lending the brush cutter

to someone else, give him this Instruction Manual as well.

- First-time users should ask their dealer for basic instructions so that they can familiarize themselves with the basic

handling of gasoline-powered brushcutting.

- Children and persons under the age of 18 must not be allowed

to operate the brushcutter. Exceptions may be made for persons over 16 for training purposes under the supervision of a

qualifi ed trainer.

- Always use brushcutters with the utmost care and attention.

- Operate the brushcutter only if you are in good physical condition. Perform all work calmly and carefully. The user must

accept liability for others.

- Never use the brushcutter after consumption of alcohol, drugs

or medication (2).

Personal protective equipment

- The clothing worn should be functional and appropriate, i.e.

it should be tight-fi tting but not cause hindrance. Do not wear

either jewellery or clothing which could become entangled with

bushes or shrubs. Secure hair so it is above shoulder level. If

you have long hair, always wear a hair net!

- In order to avoid head-, eye-, hand- or foot injuries as

well as to protect your hearing, the following protective

equipment and protective clothing must be used during

operation of the brushcutter:

- It is recommended to wear a protective helmet; it is imperative

when working in forests. The protective helmet (1) should be

checked at regular intervals for damage and must be replaced after

5 years at the latest. Use only approved protective helmets.

- The helmet face shield (2) protects your face from fl ying

particles from the cut and other objects. To prevent eye injury,

wear protective goggles in addition to the face shield.

- Wear adequate noise protection equipment to avoid hear-

ing impairment (ear muffs (3), ear plugs etc.). Octave brand

analysis upon request.

- The forestry safety jacket (4) is equipped with special red

coloured shoulder parts. The arms and neck should always be

protected by clothing.

- The protective trousers (5) are made from a nylon fabric

with 22 layers and protects against cuts. We strongly recommend its use. In any case, it is essential that a long pair of

trousers made of tough material be worn during operation of

the brushcutter.

- Protective gloves (6) made of thick leather are part of the

prescribed equipment and must always be worn during operation of the brushcutter.

- Safety shoes or boots (7) fi tted with anti-skid sole, steel toe

caps and leg protection must always be used. Safety shoes

equipped with a protective layer give protection against cuts

and ensure a secure footing.

Handling fuels / Refuelling

- Stop the engine before refuelling.

- Keep away from open fl ame or sparks and do not smoke while

refuelling or mixing fuel.

- Let the engine cool down before refuelling.

- Fuel may contain substances similar to solvents. Eyes and skin

4

should not come in contact with mineral oil products. Always

wear protective gloves when refuelling. Frequently clean and

change protective clothes. Do not breathe in fuel vapors.

Inhalation of fuel vapours can be hazardous to your health.

- Before refuelling the brushcutter make sure it is on its side

in a stabile position.

- Do not spill fuel or oil. When you have spilt fuel or oil immediately clean the brushcutter. Fuel should not come in

contact with clothes. If your clothes come in contact with

fuel, change them at once.

1

2

3

4

5

- Ensure that no fuel or chain oil oozes into the soil (environmental

protection). Use an appropriate base.

- Refuelling is not allowed in closed rooms. Fuel vapors will

accumulate near the fl oor (explosion hazard).

- Carefully tighten the locking screw of the fuel tank and inspect

the fuel cap at regular intervals.

- Change the place before starting the engine (at least 3 meters

from the place of refuelling) (6).

- Fuel cannot be stored for an unlimited period of time. Buy

only as much as will be consumed in the near future.

- Use only approved and marked containers for the transport

and storage of fuel. Ensure children have no access to fuel.

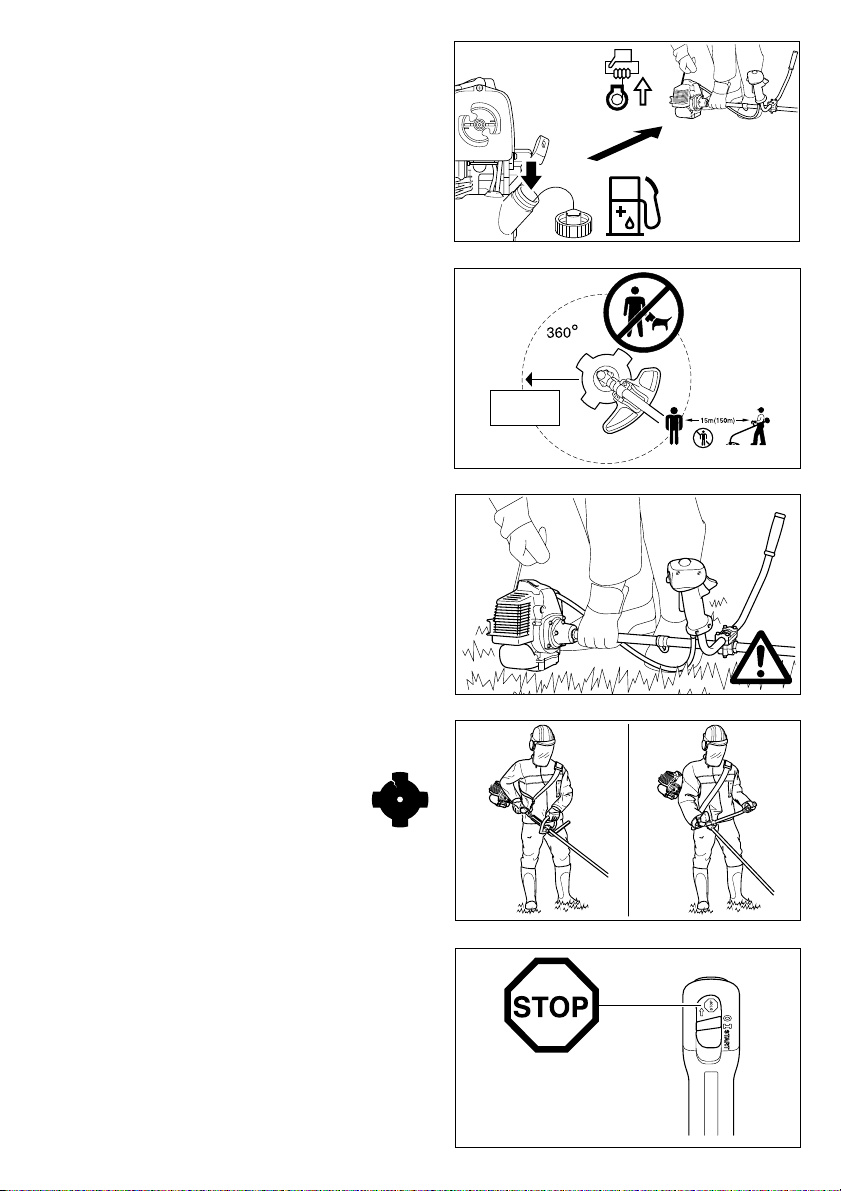

Putting into operation

- Do not work alone. Another person must be nearby in case

of emergencies (within shouting distance).

- Children and other persons must remain more than 15 meters

(50 feet) from the working area. Keep an eye out for animals

as well (7).

- Before use always check that the brushcutter is safe for

operation:

Make sure the cutting tool is securely installed. The throttle

must automatically return to the off position when released,

and the throttle lever lock must work properly. The cutting tool

must not turn during idling. The handles should be clean and

dry. The on/off switch must function properly. The guard must

be undamaged and securely installed in the correct position.

Otherwise you are in danger of injury!

- Start the brushcutter only in accordance with the instructions. Do

not use any other methods for starting the engine (8)!

- Use this brushcutter and its cutting tools only for the uses they

are intended for as specifi ed in the documentation.

- Start the brushcutter only after complete assembly and

inspection. Operation of the device is only permitted after

all the appropriate accessories are attached!

- The cutting tool must be equipped with its appropriate

guard. Never run the cutter without this guard!

- The cutting tool must not turn during idling. If necessary adjust

the idling speed.

- Before starting, make sure that the cutting tool has no contact

with hard objects such as branches, stones etc.

- The engine must be switched off immediately if there are any

noticeable changes in the behavior of the equipment.

- Should the cutting tool hit stones or other hard objects, immediately switch off the engine and inspect the cutting tool.

- Inspect the cutting tool at frequent intervals for damage (detect hairline cracks by means of tapping - noise test). Hairline

cracks can occur in the region of the base of the

teeth after long use. Damaged cutting tools and

cutting tools with hairline cracks must not be

used any longer under any circumstances.

- Operate the brushcutter only with the shoulder strap

attached, which is to be suitably adjusted before putting the

brushcutter into operation. It is essential to adjust the shoulder

strap according to the user’s size to prevent fatigue during use.

Never hold the cutter with one hand during use.

- When working with the brushcutter always hold it with both

hands (9). Keep proper footing and balance at all times.

- Operate the brushcutter in such a manner as to avoid inhalation

of the exhaust gases. Do not start or operate the brush cutter

in closed rooms (risk of gas poisoning). Carbon monoxide is

an odorless gas. Work only in well-ventilated places.

- When taking a break or leaving the brushcutter unattended,

turn off the engine (10) and set the brushcutter down in such

a way that there is no risk of injury to yourself or others.

- Never put the hot brushcutter onto dry grass or onto any combustible materials.

- Shut off the engine during transport or when moving on to a

new location (10).

- Never operate the engine with a faulty exhaust muffl er.

6

Schematic

drawing

15 meters

(50 feet)

7

8

BCM2310

BCM2610

BCM3310

9

● Breaks

● Transport

● Refuelling

● Maintenance

● Tool Replacement

10

3 meters

(10 feet)

BCM2600

BCM3300

BCM4300

5

Kickback

During operation the brushcutter can kickback in an uncontrolled manner. This can happen when the cutting blade (4-

tooth star blade) comes into contact with hard objects such

as stumps, fenceposts, tree trunks, woody brush or large

rocks.

This can fl ing the brushcutter to one side with great force and

speed (injury hazard).

To avoid kickback, observe the following:

- Remove foreign objects from the cutting area and be aware of

plants and objects in the area.

- The cutting tool must be turning at full speed before starting

cuts.

- The danger of kickback is heightened in the darkened area

(illustration), especially if using a metal cutting tool!

Working behavior / Method of working

- Use the brushcutter only in good light and visibility. During the

winter season beware of slippery or wet areas, ice and snow

(risk of slipping). Always ensure a safe footing.

- Never cut above your shoulder height.

- Never stand on a ladder and run the brushcutter.

- Never climb up into trees to perform cutting operations with

the brushcutter.

- Never work on unstable surfaces.

- Make sure the cutting area is free of foreign objects such as

stones and metal items. Foreign particles can rebound (danger

of injury, 12), damage the cutting tool and cause dangerous

kickbacks.

- Before commencing cutting, the cutting tool must have reached

full working speed.

Applications for cutting tools

Employ only the correct cutting tool for the job in hand! Do not use

tools for jobs they are not designed for.

2-line trimmer head (13)

Only for cutting up against walls, fences, trees, posts etc. and at

lawn edges (as an adjunct to a lawnmower).

4-tooth star blade (14)

For cutting grass or heavy weeds. Perform this cutting work by

swinging the brush cutter evenly in half-circles from left to right

(15, similar to a scythe).

11

Caution: Kickback!

12

13

Transport

- When transporting the equipment or moving to another

working location, the brushcutter must be switched off in

order to avoid unintentionally starting the cutting tool.

- Never transport the brushcutter when the cutting tool is

in operation!

- The tool protection included with the equipment must always be

used if the brushcutter is transported over longer distances.

- Ensure that the brushcutter is safely secured so that no fuel

can run out before transporting it in a vehicle. Empty the fuel

tank before transporting the brushcutter.

- Before shipping the brushcutter, completely empty the fuel

tank.

6

14

15

Storage

- The brushcutter must be safely stored in a dry room. Use the

tool protection for metal cutting tools. Keep the brushcutter out

of reach of children.

- If the brushcutter is stored for a long period of time, it should be

given a thorough maintenance check and a complete inspection

at an authorized MAKITA service centre.

- If the brushcutter is stored for a long period of time, the fuel

tank should be completely emptied and the carburetor run dry.

Fuels may only be stored for a limited period of time and could

cause deposits to form in the tank or in the carburetor.

- Fuel remains in reserve canisters should be used for other

engines or disposed of.

Maintenance

- Always make sure the brushcutter is in good working order

before using it. This includes in particular the cutting tool,

guard, harness and fuel system (check for leaks). Particular

attention must be paid to the cutting blades, which must be

correctly sharpened.

CAUTION: Metal cutting tools must be sharpened only at an

authorized service centre!

A tool which has been improperly sharpened can cause

unbalance and thus considerable danger of injury. Apart from

this, the equipment may be damaged due to vibrations.

- When changing the cutting tool, cleaning the brushcutter and

the cutting tool etc., it is essential to switch off the engine

and pull the spark plug cap.

- Replace cracked, bent, warped, damaged or dull cutting

tools immediately. Never straighten or weld damaged cutting

tools.

- Operate the brushcutter with as little noise and pollution as possible. In particular check the correct setting of the carburetor.

- Clean the brushcutter at regular intervals and check that all

screws and nuts are well tightened.

- Never service or store the brushcutter near open fl ames (16)!

- Always store the brushcutter in a locked storage area, with the

fuel tank completely empty and the carburetor run dry.

Observe the accident prevention instructions issued by the

relevant trade associations and insurance companies. Do not

make any modifi cations to the brushcutter - you will only be

putting your own safety at risk!

The performance of maintenance or repair work by the user is

limited to those activities described in this instruction manual. All

other work must be done by the MAKITA customer service (17).

Use only original MAKITA spares and accessories.

The use of non-MAKITA spares, accessories, or cutting tools increases the risk of accident. MAKITA will not accept any liability for

accidents or damage caused by the use of non-approved cutting

tools and fi xing devices of cutting tools, or accessories.

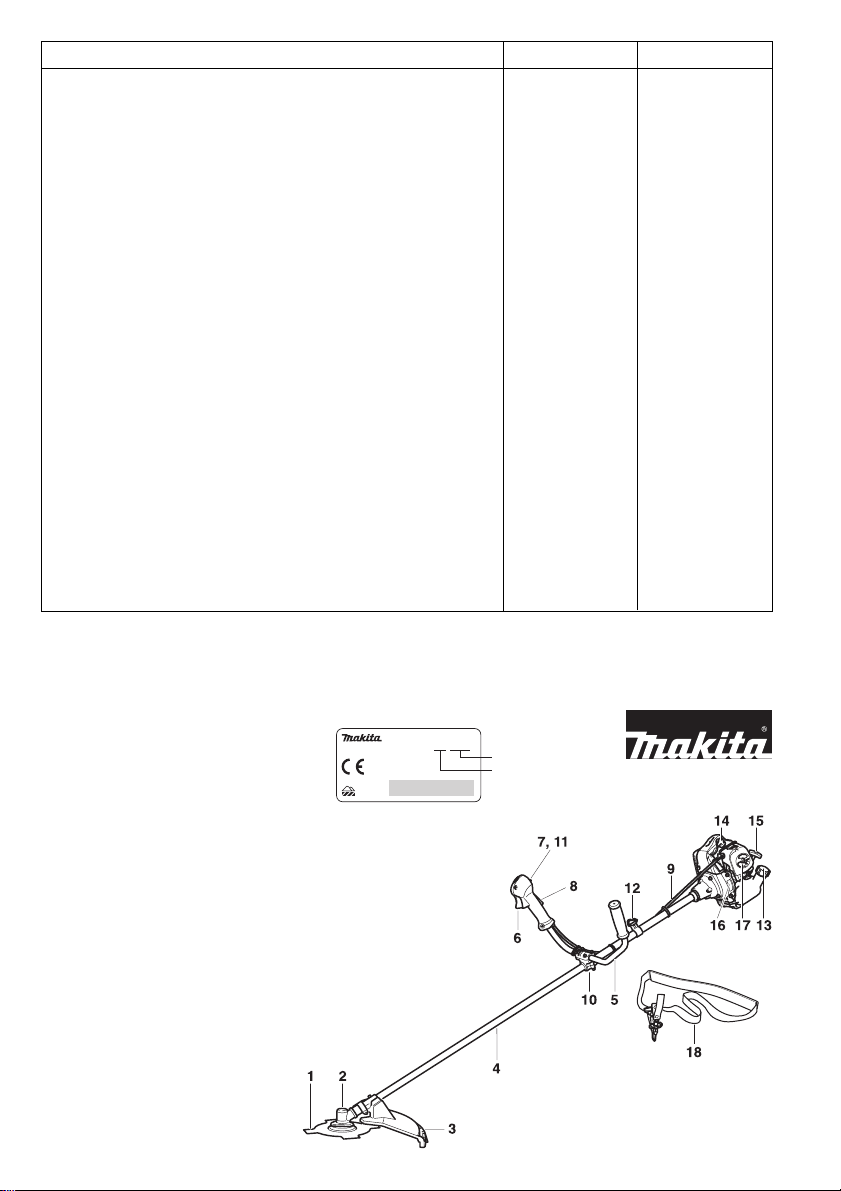

First Aid

A fi rst-aid kit should always be nearby as a precaution in the

event of an accident.

Immediately replace any items taken from the fi rst aid kit.

When calling for help, give the following information:

Place of accident, what happened, number of persons injured,

nature of injuries, your name.

NOTE

Individuals with poor circulation who are exposed to excessive

vibration may experience injury to blood vessels or the nervous

system. Vibration may cause the following symptoms to occur in

the fi ngers, hands or wrists: ”Falling asleep” (numbness), tingling,

pain, stabbing sensation, alteration of skin colour or of the skin. If

any of these symptoms occur, see a physician!

16

SERVICE

17

18

19

7

Technical Data

Displacement cm

Bore mm 31 | 33 | 36 33 | 36 | 40

2310 | 2610 | 3310

3

22.6 | 25.6 | 32.6 25.6 | 32.6 | 42.7

2600 | 3300 | 4300

Stroke mm 30 | 30 | 32 30 | 32 | 34

Rated capacity per ISO 8893 kW 0.7 | 0.8 | 0.97 0.8 | 0.97 | 1.27

Operating speed rpm 8,000 | 8,000 | 7,500 8,000 | 7,500 | 7,500

Maximum engine speed

with one-part metal cutting tool

Maximum spindle speed

with one-part metal cutting tool

1)

rpm 7,370 I 7,370 I 8,100 7,370 I 8,100 I 7,370

1)

rpm 10,000 10,000

Idling speed rpm 3,000 I 3,000 I 2,500 3,000 I 2,500 I 2,500

Carburetor Type diaphragm carburetor diaphragm carburetor

Ignition system Type electronic electronic

Spark plug Type NGK BPMR 8Y NGK BPMR 8Y

Electrode gap mm 0.6 - 0.7 0.6 - 0.7

Sound power level L

Sound pressure level L

Vibration acceleration a

- Right handle (idling speed/maximum speed) m/s

per ISO 10884

WA, eq

at the workplace per ISO 7917

pA, eq

per ISO 7916

hv, eq

- Left handle (idling speed/maximum speed) m/s2

- Round handle (idling speed/maximum speed) m/s2

- Handle on shaft (idling speed/maximum speed) m/s2

Fuel consumption per ISO 8893

Specifi c consumption per ISO 8893

2) 4)

dB(A) 106.8 | 107.8 | 109 99.5 | 100.5 | 102

2) 6)

2) 5)

dB(A) 94.9 | 95.1 | 97.1 89.9 | 92 | 91.4

2

7.5 / 6.1 | 4.6 / 9.5 | 4.7 / 6.5

3)

3)

4.8 / 8.1 | 4.4 / 6.0 | 6.3 / 7.8

kg/h 0.35 | 0.36 | 0.44 0.36 | 0.44 | 0.49

g/kWh 500 | 450 | 454 450 | 454 | 386

5.1 / 5.7 | 2.1 / 6.2 | 4.8 / 5.5

4.0 / 6.2 | 5.0 / 5.3 | 5.3 / 6.5

Fuel tank capacity l 0.6 | 0.6 | 0.8 0.6 | 0.8 | 0.9

Mixture ratio (fuel / MAKITA two-stroke oil)

- when using MAKITA oil 50:1 50:1

- when using Aspen Alkylat (two-stroke fuel) 50:1 (2%) 50:1 (2%)

- when using other oils (quality grade: JASO FC or ISO EGD) 50:1 50:1

Gear ratio 14:19 | 14:19 | 17:21 14:19 | 14:19 | 14:19

Weight (not including guard, cutting tool and fuel) kg 5.1 | 5.1 | 5.9 5.9 | 6.7 | 7.9

1)

The maximum rated speed of the trimmer head is not exceeded when using a MAKITA trimmer head.

2)

Figures derived in equal part from idle and top-speed operation (per EN-ISO 11806).

3)

At max. power.

4)

Uncertainty K

= 2,5 dB(A).

WA

5)

Uncertainty K

= 2,5 dB(A).

pA

6)

Uncertainty K = 2 m/s2.

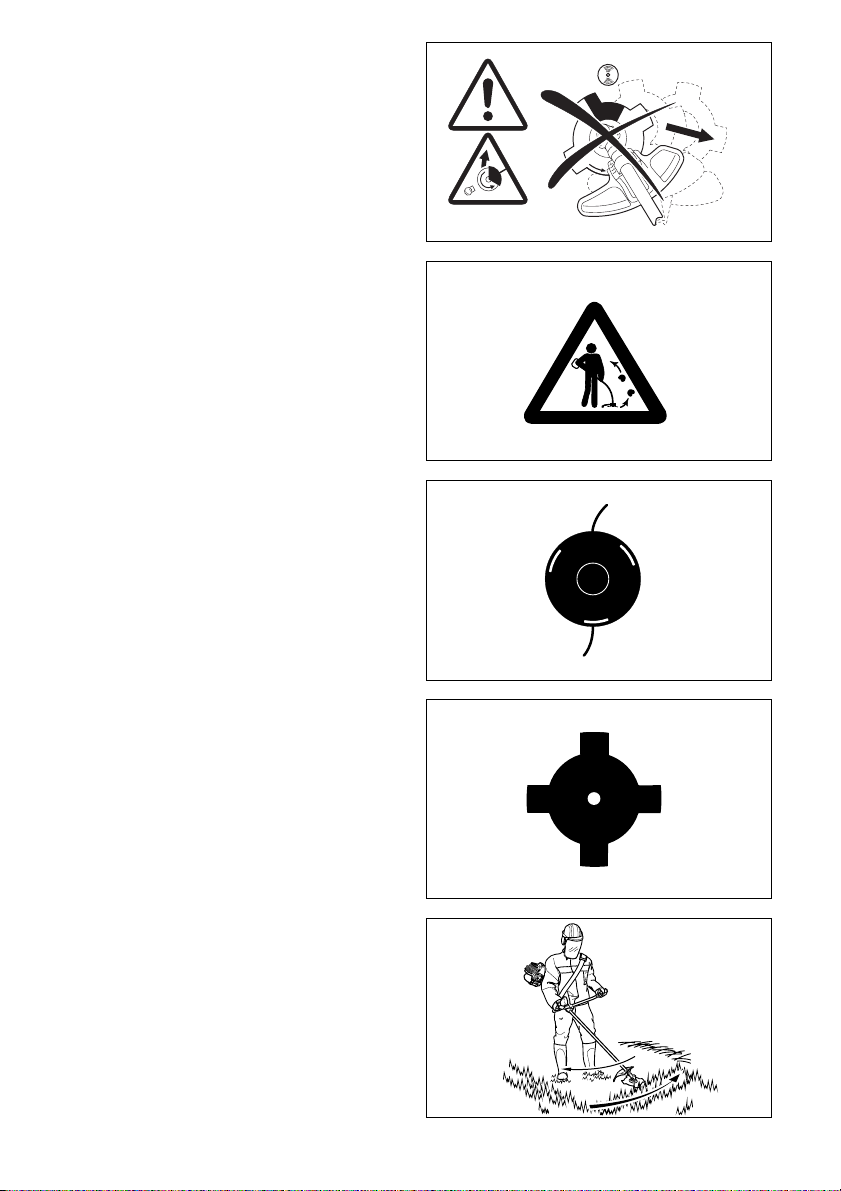

Components

Type plate (BCM2600)

1 Cutting tool

2 Gear box

3 Guard (Cutter guard)

Indicate when ordering spare parts!

4 Shaft tube

5 Handle

6 Throttle (throttle trigger)

7 Combination “start/stop” (O/I) switch, half-throttle lock

8 Safety locking button (throttle trigger lockout)

9 Bowden cable guide

10 Tube handle holder

11 Stop knob for halfway throttle

12 Harness eyelet (suspension point)

13 Fuel tank cap

14 Spark plug cover

15 Starter grip

16 Type plate

17 Choke lever

18 Harness

8

22045 Hamburg

Germany

BCM2600

2008 123456

000.000.000

Serial number

Year of manufacture

Shown: BCM2600

Loading...

Loading...