Page 1

GASOLINE BLOWER

SOUFFLEUR A ESSENCE

SOPRADOR DE GASOLINA

MAKITA CA Statement

BBX7600CA

MAKITA non CA Statement

English / Français / Español

BBX7600

INSTRUCTION MANUAL

INSTRUCTIONS D’EMPLOI

INSTRUCCIONES DE MANEJO

Important:

Read this instruction manual carefully before putting the Blower into operation and

strictly observe the safety regulations! Preserve instruction manual carefully!

Importante :

Lisez attentivement ce manuel utilisateur avant de mettre en route le souffleur et

respectez scrupuleusement les consignes de sécurité.

Conservez soigneusement ce manuel.

Importante:

Lea bien este manual antes de poner el soplador en funcionamiento, y observe

estrictamente las medidas de seguridad. Conserve este manual de instrucciones.

Page 2

English

Thank you very much for selecting the Makita blower. We are pleased

to be able to offer you the Makita blower, which is the result of a long

development program and many years of knowledge and experience.

The blower models BBX7600 / BBX7600CA combines the advantages

of state-of-the-art technology with ergonomic design. They are of lightweight, handy, compact and represent professional equipment for a

great variety of applications.

Please read, understand and follow this booklet, which refers in detail

to the various points that will demonstrate its outstanding performance.

This will assist you to safety obtain the best possible results from your

Makita Blower.

Table of Contents

Symbols ............................................................................................... 2

Safety instructions............................................................................. 3-5

Technical data ...................................................................................... 6

Designation of parts ............................................................................. 7

Assembly instructions .......................................................................8-9

Before starting the engine............................................................. 10-11

Operation ......................................................................................12-13

Adjustment of idling............................................................................ 13

Operation method .............................................................................. 14

Inspection and maintenance .........................................................15-17

Storage.......................................................................................... 17-18

Troubleshooting ................................................................................. 19

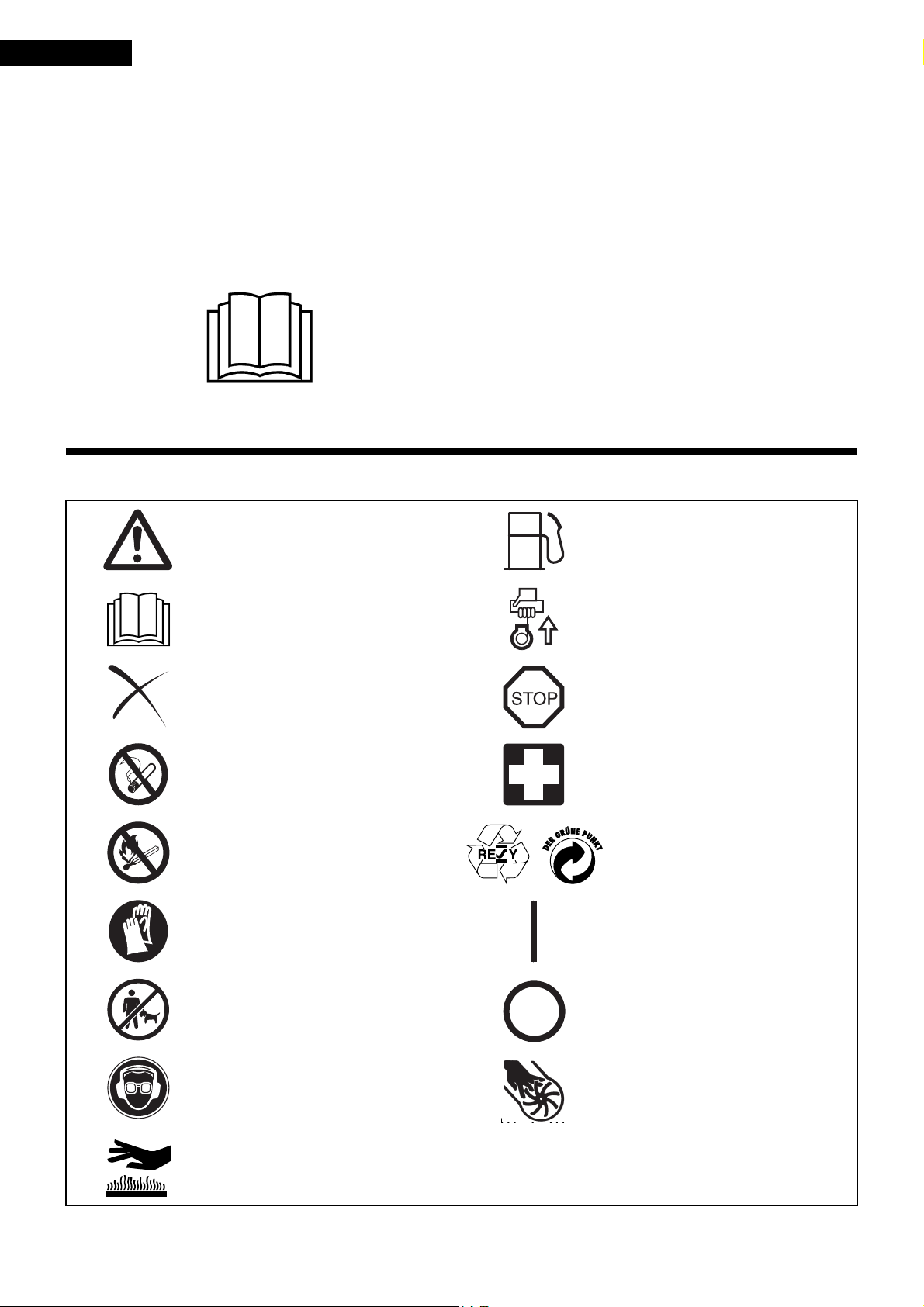

SYMBOLS

It is very important to understand the following symbols when reading this instructions manual.

Page

WARNING/DANGER Fuel (Gasoline)

Read, Understand and Follow Instruction

Manual

Forbidden Emergency Stop

No Smoking First Aid

No Open Flame Recycling

Protective Gloves must be Worn ON/START

Engine-manual Start

Keep the Area of Operation

Clear of All Persons and Pets

Wear Eye and Ear Protection

Hot surfaces - Burns to fingers or hands

OFF/STOP

Severing of fingers or hand,

impeller blade

2

Page 3

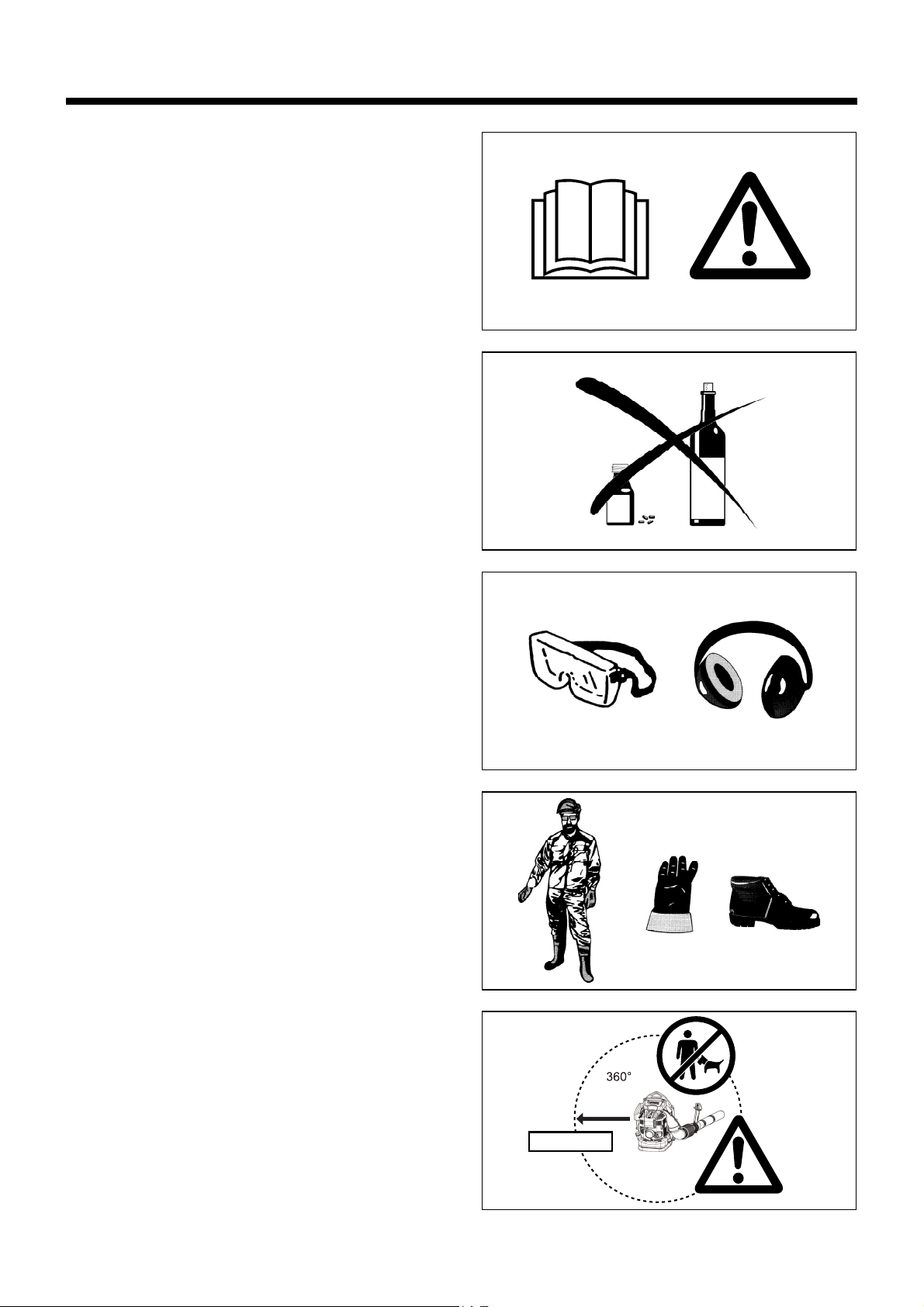

SAFETY INSTRUCTIONS

(1)

(2)

(3)

(4)

(5)

15 meters

General Instructions

• To ensure correct and safe operation, the user must read, understand

and follow this instruction manual to assure familiarity with the handling

of the blower (1). Users insufficiently informed will risk danger to

themselves as well as others due to improper handling.

• It is recommended only to loan the blower to people who have proven

to be experienced with blowers.

• Always hand over the instruction manual.

• First-time users should ask the dealer for basic instructions to

familiarize oneself with the handling of a blower.

• Children and young persons aged under 18 years must not be allowed

to operate the blower. Persons over the age of 16 years may however

use the tool for the purpose of being trained only while under the direct

supervision of a qualified trainer.

• Use blowers with the utmost care and attention.

• Operate the blower only if you are in good physical condition.

• Perform all work conscientiously and carefully. The user has to accept

responsibility for others.

• Never use the blower while under the influence of alcohol or drugs (2).

• Do not use the unit when you are tired.

• Save these instructions for future referral.

Personal Protective Equipment

• The clothing worn should be functional and appropriate, I. e. It should

be tight fitting but not cause a hindrance. Do not wear jewelry, clothing

or long hair which could be drawn into the air intake.

• In order to avoid head-, eye-, hand- or foot injuries as well as to protect

your hearing the following protective equipment and protective clothing

must be used during operation of the blower.

Pay particular attention to the following regulations

• Clothing must be sturdy and snug-fitting, but allow complete freedom

of movement. Avoid loose-fitting jackets, flared or cuffed pants,

scarves, unconfined long hair or anything that could be drawn into the

air intake. Wear overalls or long pants to protect your legs.

Do not wear shorts. (4)

• Blower noise may damage your hearing. Wear sound barriers (ear

plugs or ear mufflers) to protect your hearing. Continual and regular

users should have their hearing checked regularly. (3)

• Use of gloves when working with the blower is recommended.

Wear sturdy shoes with non-slip soles. (4)

• Proper eye protection is a must. Even though the discharge is directed

away from the operator, ricochets and bounce-backs can occur during

blower operation. (3)

• Never operate a blower unless wearing goggles or properly fitted

safety glasses with adequate top and side protection which comply

with ANSI Z 87. 1 (or your applicable national standard).

Starting up the blower

• Please make sure that there are no children or other people within a

working range of 15 meters (5), also pay attention to any animals in the

working vicinity. Never use the blower in urban areas.

• Before operating, always check that the blower is safe for operation:

Check the security of the throttle lever. The throttle lever should be

checked for smooth and easy action. Check for proper functioning of

the throttle lever lock. Check for clean and dry handles and test the

function of the l-O switch. Keep handles free of oil and fuel.

3

Page 4

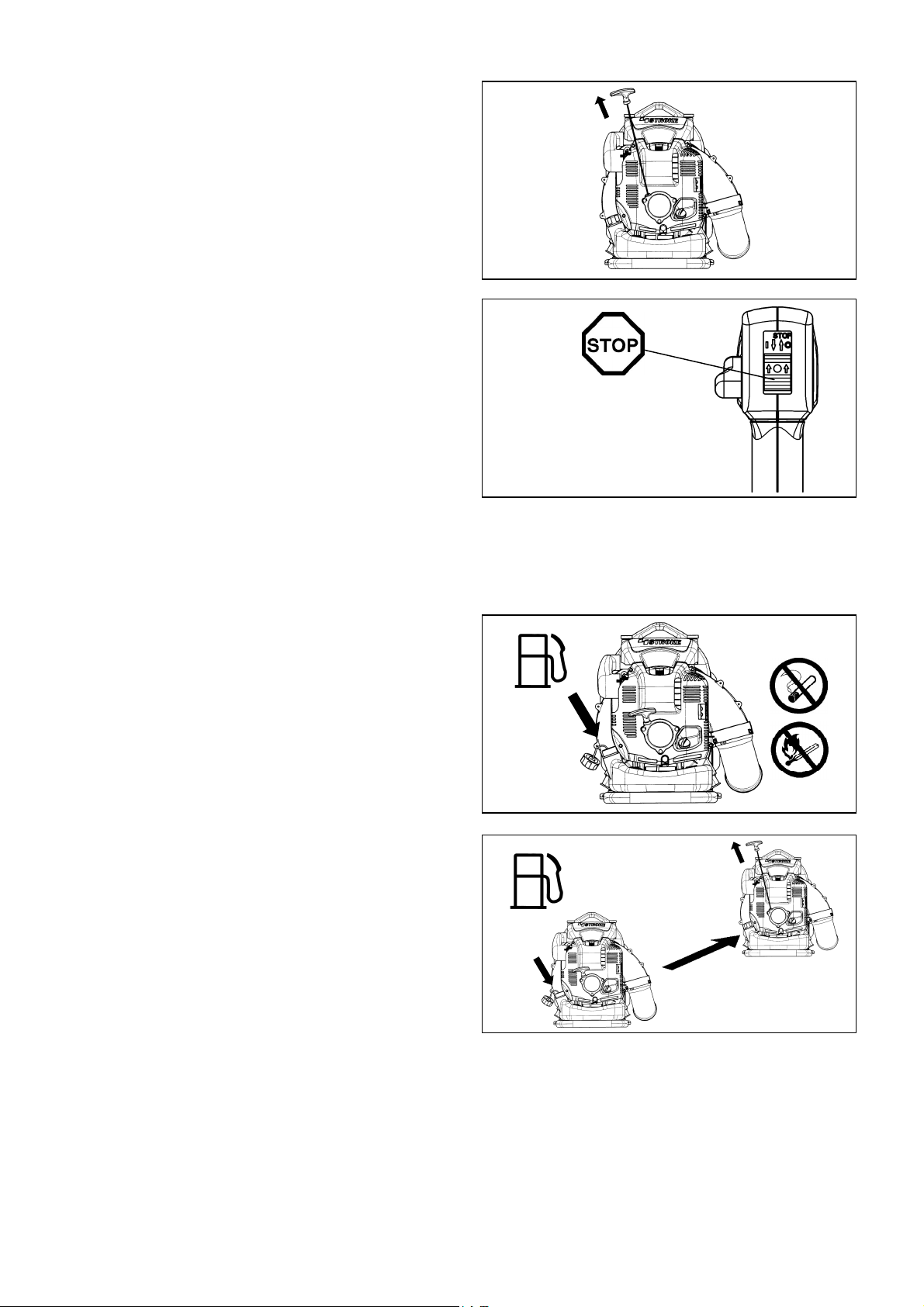

Start the Blower only in accordance with the instructions.

(6)

(7)

(8)

(9)

3 meters

• Resting

• Transport

• Refuelling

• Maintenance

• Tool Replacement

Do not use any other methods for starting the engine (6) !

• Use the blower and the tools supplied only for applications specified.

• Start the blower engine only after the entire tool has been assembled.

Operation of the tool is permitted only after all the appropriate

accessories are attached.

• The engine is to be switched off immediately if there are any engine

problems.

• When working with the blower, always wrap your fingers tightly around

the handle, keeping the control handle cradled between your thumb

and forefinger. Keep your hand in this position to have your machine

under control at all times. Make sure your control handle is in good

condition and free of moisture, pitch, oil or grease.

Always ensure a safe, well-balanced footing.

• Operate the blower in such a manner as to avoid inhalation of the

exhaust gases. Never run the engine in enclosed rooms (risk of

suffocation and gas poisoning). Carbon monoxide is an odorless gas.

Always ensure there is adequate ventilation.

• Switch off the engine when resting or leaving the blower unattended.

Place it in a safe location prevent danger to others, setting fire to

combustible materials, or damage to the machine.

• Never lay the hot blower onto dry grass or onto any combustible

materials.

• All protective parts and guards supplied with the machine must be

used during operation.

• Never operate the engine with a faulty exhaust muffler.

• Shut off the engine during transport (7).

• Position the blower safely during car or truck transportation to avoid

fuel leakage.

• When transporting the blower, ensure that the fuel tank is completely

empty.

Refuelling

• Shut off the engine during refuelling (7), keep well away from open

flame (8) and do not smoke.

• Avoid skin contact with petroleum products. Do not inhale fuel vapor.

Always wear protective gloves during refuelling. Change and clean

protective clothing at regular intervals.

• Take care not to spill either fuel or oil in order to prevent soil

contamination (environmental protection). Clean the blower

immediately after fuel has been spilt. Allow wet cloths to dry before

disposing in properly, covered container to prevent spontaneous

combustion.

• Avoid any fuel contact with your clothing. Change your clothing

immediately if fuel has been spilled on it (fire hazard).

• Inspect the fuel cap at regular intervals making sure that it stays

securely fastened.

• Carefully tighten the locking screw of the fuel tank. Change locations to

start the engine (at least 3 meters away from the place of refuelling)

(9).

• Never refuel in closed rooms. Fuel vapors accumulate at ground level

(risk of explosions)

• Only transport and store fuel in approved containers. Make sure stored

fuel is not accessible to children.

• Do not attempt to refuel a hot or a running engine.

4

Page 5

Method of operation

(10)

(11)

(12)

• Use the blower only in good light and visibility. During cold seasons

beware of slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

• Never work on unstable surfaces or steep terrain.

• To reduce the risk of personal injury, do not direct air blast towards

bystanders, since the high pressure of the air flow could injure eyes

and could blow small objects at great speed.

• Never insert any foreign object into the air intake of the machine or into

the nozzle of the blower. It will damage the fan wheel and may cause

serious injury to the operator or bystanders as a result of the object or

broken parts being thrown out at high speed.

• Pay attention to the direction of the wind, i.e., do not work against the

wind.

• To reduce the risk of stumbling and loss of control, do not walk

backward while operating the machine.

• Always shut off the engine before cleaning or servicing the unit or

replacing parts.

Maintenance instructions

• Be kind to the environment. Operate the blower with as little noise and

pollution as possible. In particular, check the correct adjustment of the

carburetor.

• Clean the blower at regular intervals and check that all screws and

nuts are securely tightened.

• Never service or store the blower in the vicinity of open flames, sparks,

etc. (11).

• Always store the blower in a well-ventilated locked room and with an

emptied fuel tank.

Observe and follow all relevant accident prevention instructions issued

by the trade associations and by insurance companies. Do not perform

any modifications to the blower as this will risk your safety.

The performance of maintenance or repair work by the user is limited to

those activities as described in this instruction manual. All other work is

to be done by Authorized Service Agents.

Use only genuine spare parts and accessories supplied by Makita.

Use of non-approved accessories and tools means increased risk of

accidents and injuries. Makita will not accept any liability for accidents or

damage caused by the use of any non-approved attachment or accessories.

First Aid

In case of accident make sure that a well-stocked first-aid kit is available

in the vicinity of the operations. Immediately replace any item taken from

the first aid kit.

When asking for help, please give the following information:

• Place of accident

• What happened

• Number of injured persons

• Extent of injuries

• Your name

Packaging

The Makita blower is delivered in a protective cardboard box to prevent

shipping damage. Cardboard is a basic raw material and is therefore

consequently reusable or suitable for recycling (waste paper recycling).

5

Page 6

TECHNICAL DATA

Model

Mass (without blower pipe) (kg) 10.2 (22.4lbs)

Dimension (without blower pipe L x W x H) (mm) 350 × 430 × 495 (13.7 × 16.9 × 19.5 in)

Max. engine speed (min

Idling speed (min

Engine displacement (mL) 75.6 (4.61 cu,in)

Fuel Automobile gasoline

Fuel tank capacity (L) 1.9 (64.2 fl.oz)

Engine oil

Engine oil volume (L) 0.22 (7.4 fl.oz)

Carburetor (Diaphragm-carburetor) WALBRO WYK

Ignition system Solid state ignition

Spark plug NGK CMR6A

Electrode gap (mm) 0.7 - 0.8 (0.028 - 0.031 in)

Noise Level (50Feet per ANSI B175-2-2000) (dB(A)) 74

Notes:

1. Use the oil and spark plug specified by Makita.

2. This specification is subject to change without prior notice.

(For Canada)

NOTE: This spark ignition system complies with the Canadian standard ICES-002.

-1

) 7,200

-1

) 2,800

SAE 10W-30 oil of API Classification, Class SF or higher

(4-stroke engine for automobile)

BBX7600

BBX7600CA

6

Page 7

DESIGNATION OF PARTS

OPTION

DESIGNATION OF PARTS DESIGNATION OF PARTS DESIGNATION OF PARTS DESIGNATION OF PARTS

1. Stop switch 8. Choke Lever 15. Plug Cover 22. Blower Pipe

2. Control Handle 9. Starter Handle 16. Spark Plug 23. Blower Nozzle L=200

3. Trigger Lever 10. Fuel Tank 17. Oil Cap 24. Hose Band ø100

4. Cruise Control Lever 11. Fuel Tank Cap 18. Oil Drain Bolt 25. Hose Band ø76

5. Primer Pump 12. Muffler 19. Elbow 26. Blower Nozzle L=450

6. Element Cover 13. Shoulder Strap 20. Flexible Pipe

7. Knob Bolt 14. Air Inlet Net 21. Swivel Pipe

7

Page 8

ASSEMBLY INSTRUCTIONS

(5)

(4)

(1)

(2)

(3)

(6)

(7)

(8)

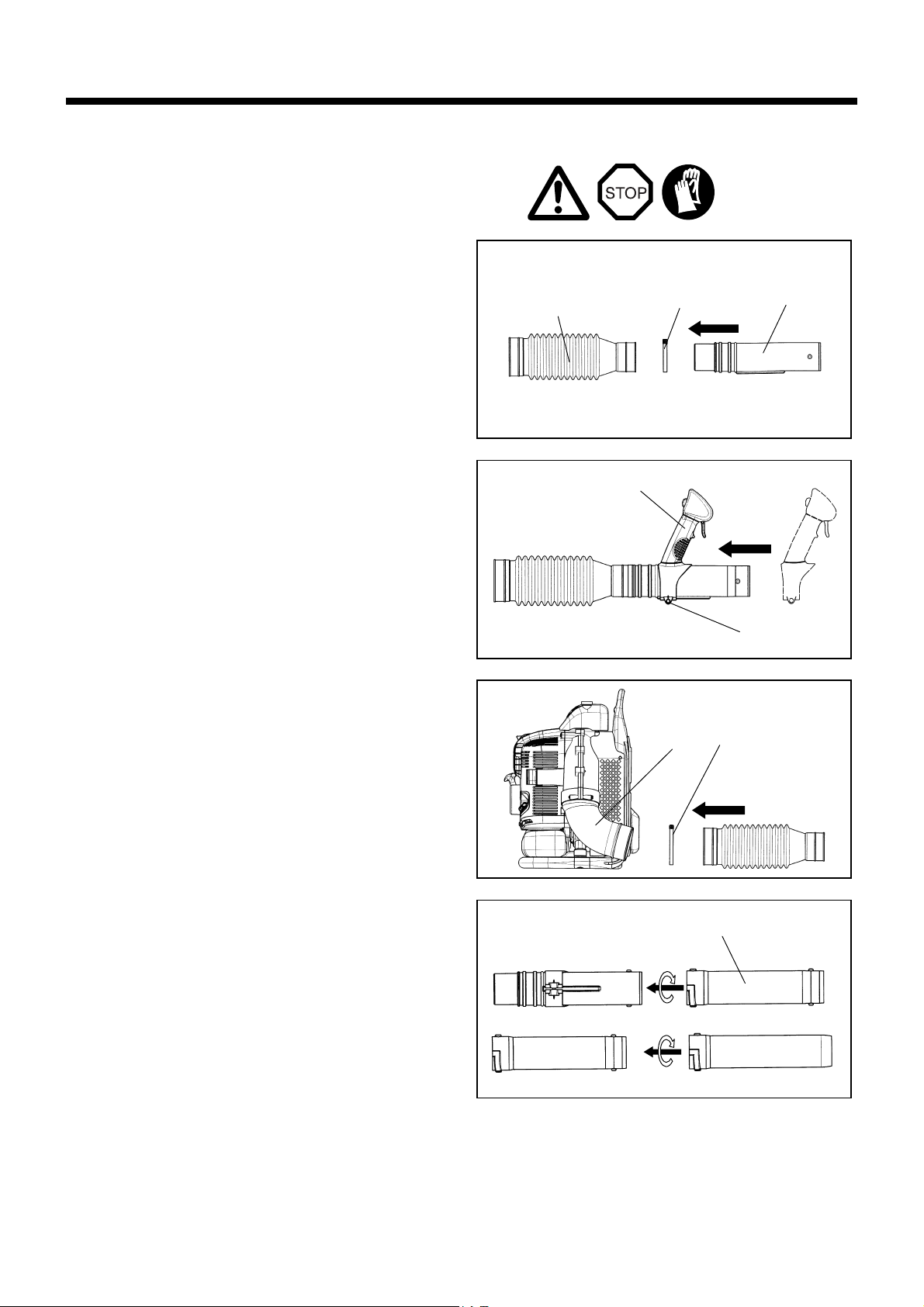

ASSEMBLY OF BLOWER PIPES

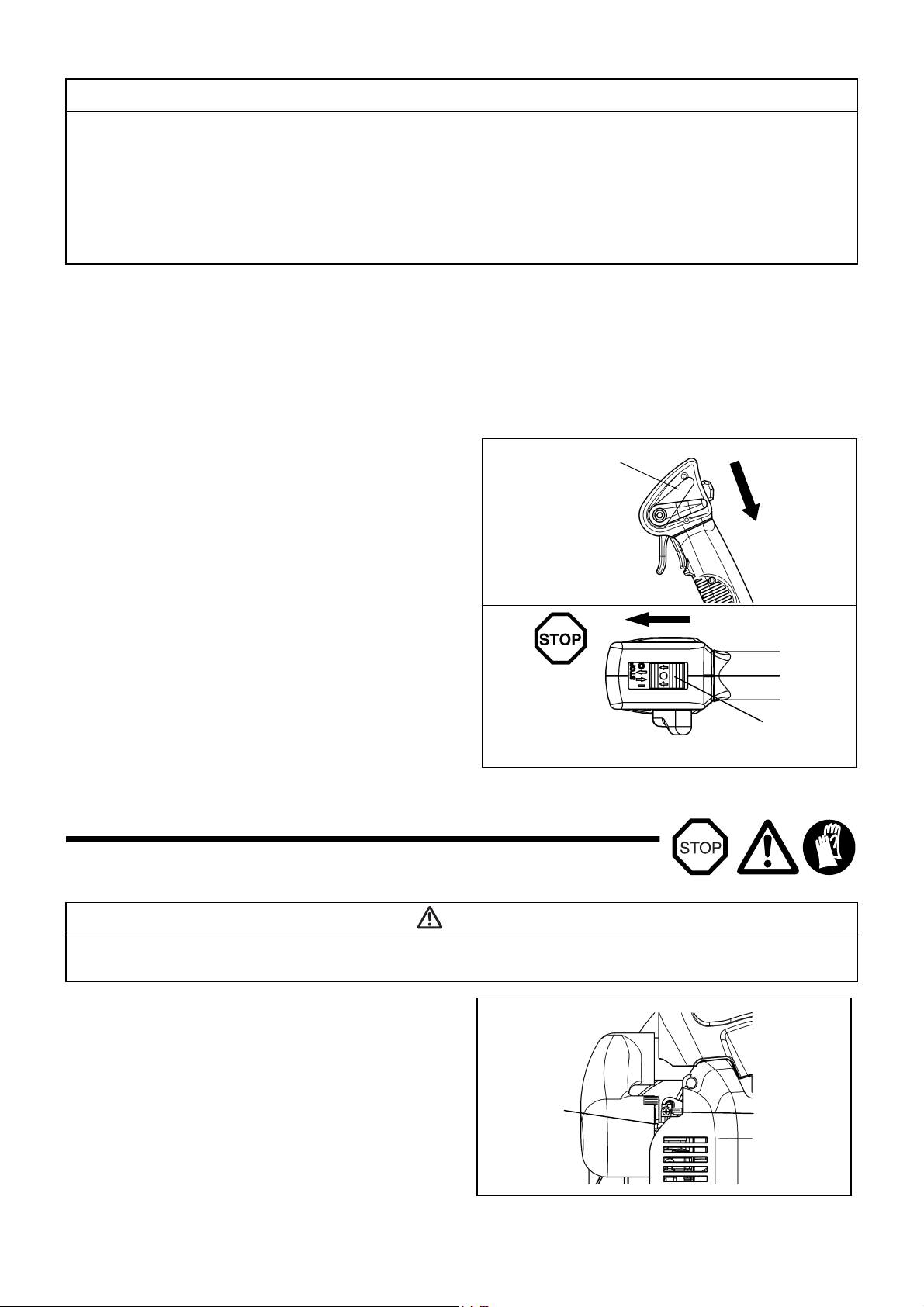

CAUTION : Before performing any work on the blower, always stop

the engine and pull the spark plug connectors off the

spark plug.

Always wear protective gloves!

CAUTION : Start the blower only after having assembled it

1. Assemble straight pipe with swivel (3) into flexible pipe (1) and

tighten hose band ø76 (2).

2. Install control handle (4) onto straight pipe with swivel and tighten

the clamp screw (5).

completely.

3. Assemble flexible pipe to elbow (6) on blower and tighten hose band

ø100 (7).

4. Assemble straight pipe (8) to straight pipe with swivel, turning

straight pipe clockwise to lock it into place.

5. Make sure all clamps are tight.

8

Page 9

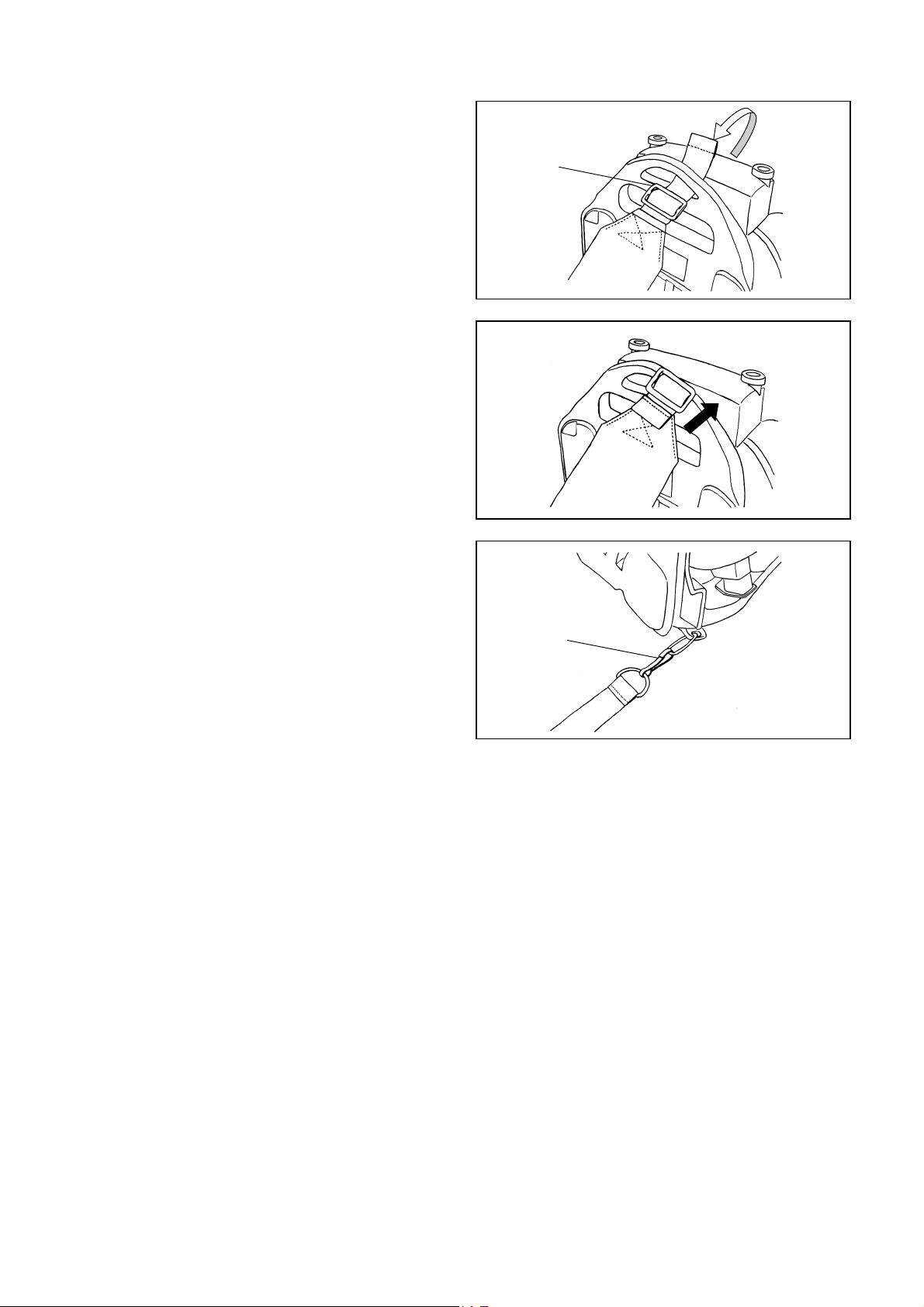

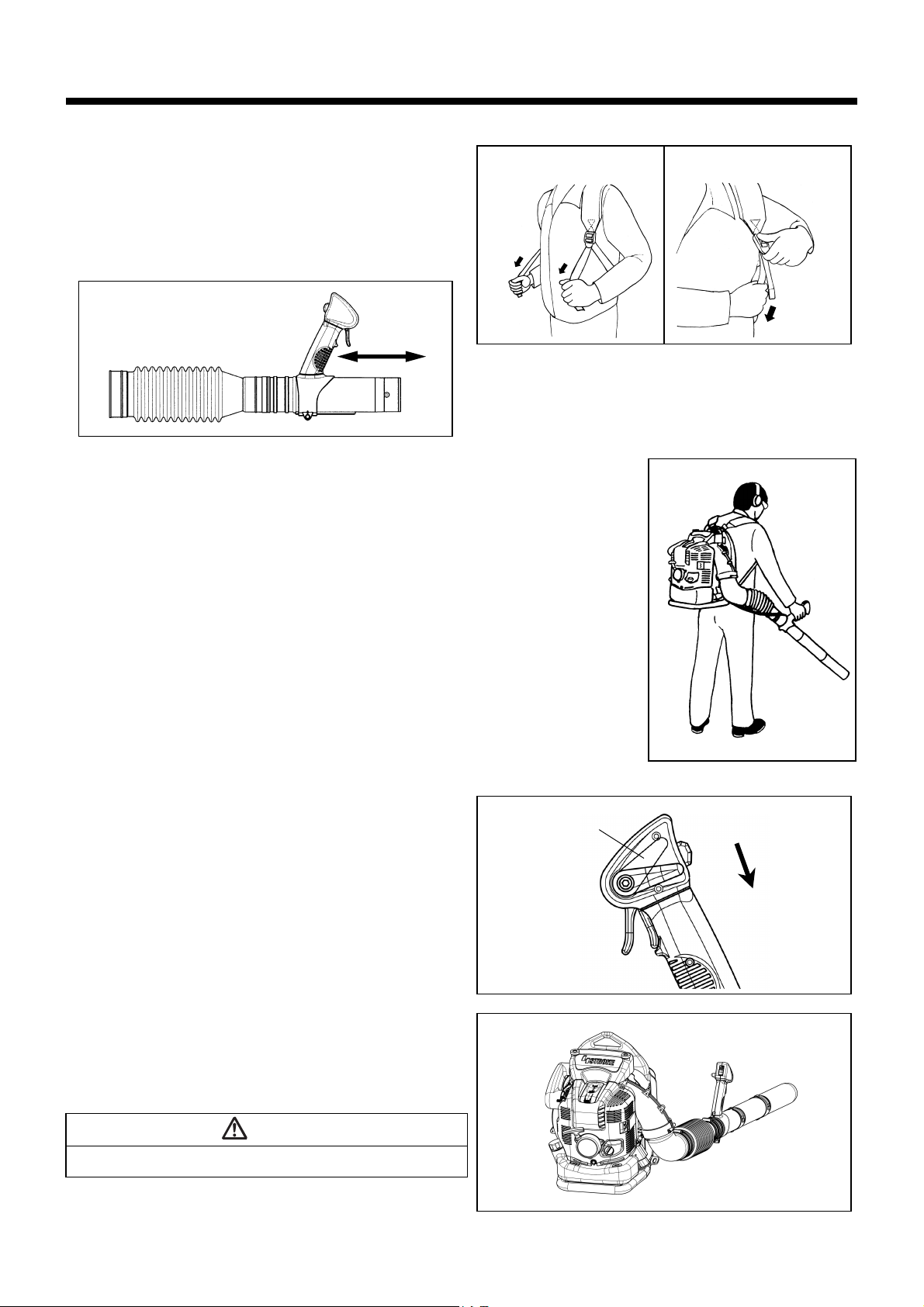

ATTACHING THE SHOULDER STRAP

(1)

Quick-disconnect

spring hook

Attachment Procedure

Attaching the shoulder strap to the blower.

• Loop the end of the strap through the lower part of the hanger as

shown in the figure at right. The side of the strap that has the folded tip

should be facing outwards. Then, bring the end of the strap back over

the hanger and thread the remaining length of the strap through the

buckle (1). Tighten the buckle (1) by pushing it towards the hanger in

the direction of the arrow shown in the drawing while pulling on the

strap in the opposite direction.

• After attaching the strap, tighten the buckle to the hanger. Tug strongly

at the strap to make sure that the strap is secure and will not come

undone.

• Attach the hook at the bottom of the shoulder strap to the ring on the

frame.

• Make sure that the strap is not twisted.

Caution: Please make sure that the strap is attached with the folded tip

facing outwards. If the strap is used with the outside of the strap

facing in, there is the risk that the strap may come loose causing the operator to drop the blower.

9

Page 10

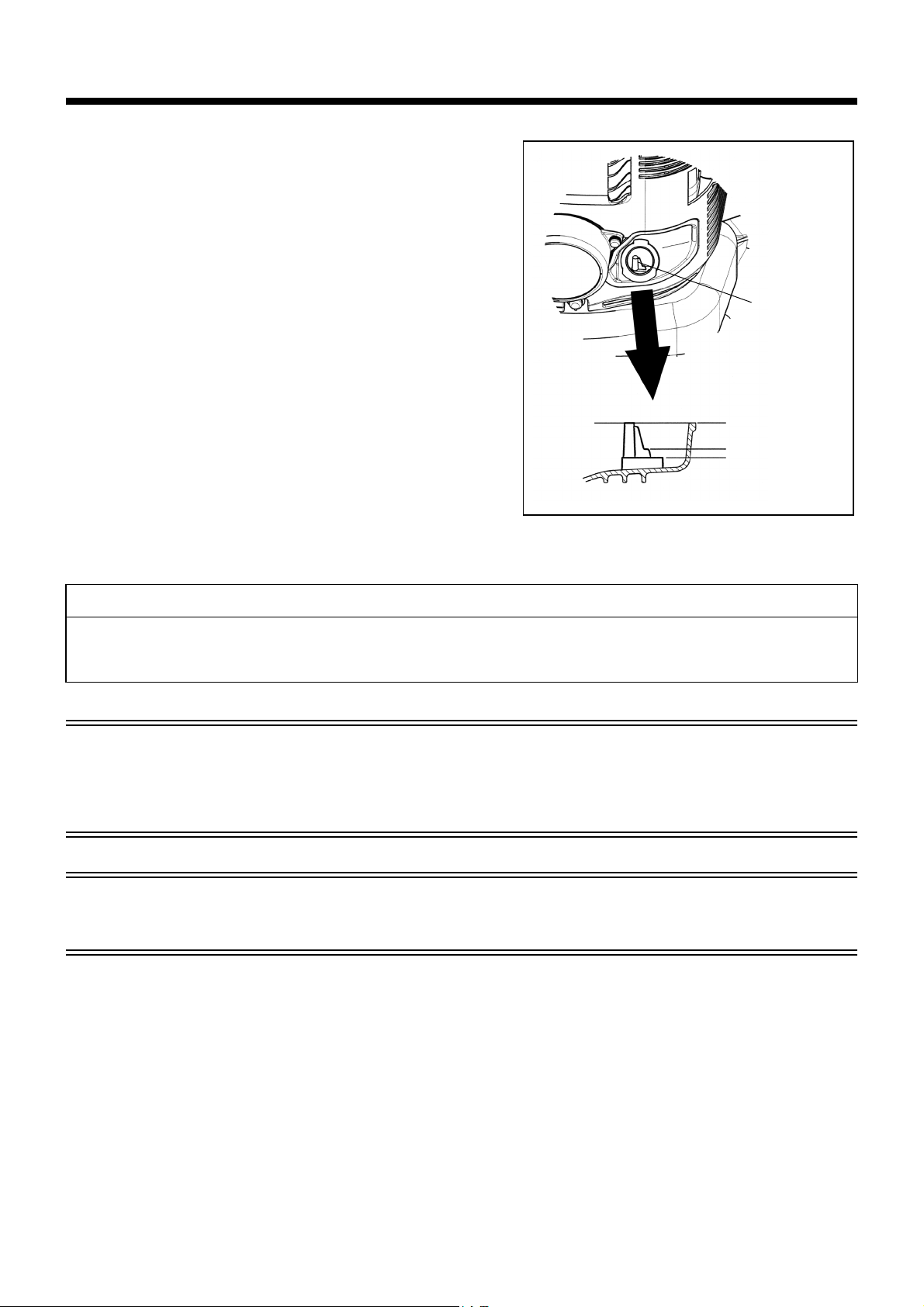

BEFORE STARTING THE ENGINE

Upper limit

Lower limit

Oil level gauge

Remain 100 mL

1. Checking and Refilling Engine Oil

1) Follow the procedure below when the engine oil is cold i.e. the blower has

not been running.

• Inspection:Set the blower down on a level surface and remove the oil cap.

• Adding Oil:Set the blower down on a level surface and remove the oil cap.

2) On average, engine oil normally needs to be added after every 20 hours of

operation. This interval for every change in oil corresponds to refuelling the

blower approximately 10-15 times.

3) Please change the oil whenever it becomes dirty or significantly changes

color. (Refer to p.15 for the oil change procedure and frequency.)

Recommended oil: Makita genuine oil or SAE10W-30 oil of API type SF grade or better (4 stroke motor oil for automobiles)

Oil capacity: Approximately 0.22 L (220 ml)

Make sure that the oil level is within the upper and lower limit

marks on the oil level gauge. If the oil is not up to the 100mL level,

fill up with new oil.

Fill the oil up to the upper limit of the oil level gauge.

CAUTION

• If the blower is not stored in an upright position, the oil may flow from the level gauge into the engine and give a false reading when checking

the oil level. This may result in inadvertently overfilling whenever adding engine oil. Always store in an upright position.

• If the upper oil level limit is exceeded, the oil may become dirty and white smoke may appear due to burning excessive oil.

Check Point #1: The oil cap

• Wipe off dirt and grime around the opening before removing the oil cap.

• Remove the oil cap and place it on a clean surface so that it does not accumulate any sand, dirt, or other foreign materials. These may stick to

the cap and adulterate the engine oil. Dirty oil containing sand, dirt, or foreign materials may cause excessive wear on the engine due to

improper lubrication and cause a breakdown.

Check Point #2: Oil spillage

• Oil spillage on the outside on the blower may cause the engine oil becoming dirty or adulterated. Therefore, please wipe off any oil spillage

before starting the engine.

10

Page 11

2. Fuel supply

WARNING

• When refuelling the unit, be sure to observe the following instructions to prevent ignition or fire:

- Fuel supply must be made in a place free of fire. Never bring the fire (smoking, etc.) near the place of fuel supply.

- Stop the engine and allow the engine to cool down before refuelling.

- Open the fuel tank cap slowly. The fuel may be spilled out under internal pressure.

- Take care not to spill the fuel. Any spilled fuel must be wiped clean.

- Carry out fuel supply in a well-ventilated place.

• Handle the fuel with care.

- Fuel sticking to the skin or entering an eye may cause allergies or irritation. When any physical abnormality is detected, consult the medical

specialist immediately.

• DO NOT put oil in the fuel tank.

STORAGE PERIOD OF FUEL

Fuel should be used within a period of 4 weeks, even if it is kept in a special container in a well-ventilated and shaded area.

Otherwise, fuel may deteriorate in one day.

Storage of machine and refill tank

• Keep the machine and tank at a cool place free from direct sunshine.

• Never keep the fuel in a car.

FUEL

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for Fuel

• Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

• Use of deteriorated oil will cause irregular start-up.

When refuelling, stop the engine and wait for the engine to cool down.

REFUELLING METHOD

• Loosen the tank cap a little to release the tank pressure.

• Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that the refuel port will be oriented upward. DO NOT fill fuel up to the

top of the tank.

• After refuelling, securely tighten the tank cap.

• If there is any flaw or damage on the tank cap, replace it.

• The tank cap wears out in course of time. Replace it every two to three years.

• DO NOT put fuel in the oil fill port.

11

Page 12

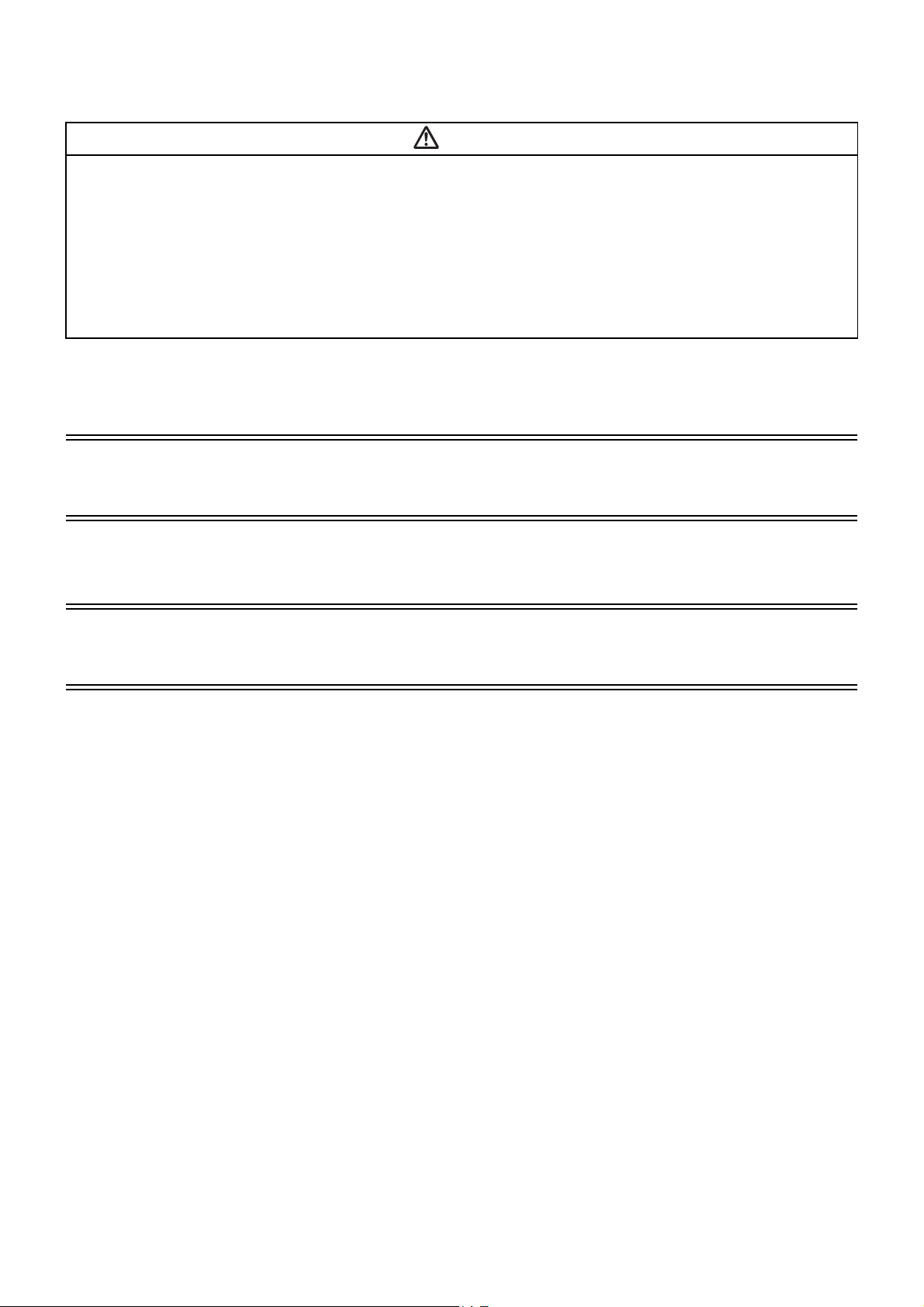

(2)

Stop Switch

Cruise control lever

Open

(3)

Hi-speed

Low-speed

(7)

(8)

Choke lever

Primer pump

Close

(4)

(5)

OPERATION

1. Starting

WARNING

• Never attempt engine start in a place where the fuel has been supplied.

- It may cause ignition or fire. When starting the engine, keep a distance of at least 3 m.

• Exhaust gas from the engine is toxic. Do not operate the engine in a poorly-ventilated place, such as in a tunnel, building, etc.

- Operating the engine in the poorly-ventilated place may cause poisoning by exhaust gas.

• In case of detection of any abnormality in sound, odor, vibration after starting, stop the engine immediately and carry out inspection.

- If the engine is operated without attending such abnormality, an accident may occur.

• Make sure that the engine stops when the stop switch is set to “O” position.

1) When the engine is cold or after refuelling

(1) Set this machine on a flat space.

(2) Set the stop switch to “ I ” position.

(3) Make sure that the cruise control lever is in the low-speed

position.

(4) Continue to push the primer pump until fuel comes into the

primer pump.

• In general, fuel comes into the carburetor by 7 to 10 pushes.

• If the primer pump is pushed excessively, an excess of

gasoline returns to the fuel tank.

(5) Lift the choke lever to the closed position.

(6) Hold the element cover with left hand to prevent the engine

from moving.

(7) Pull out slowly the starter handle till a certain resistance is felt.

Return the starter handle backward once from this position,

then pull it out with force.

• Never pull the rope to the full extension.

• Once the start knob is pulled, never release your hand

immediately. Hold the start knob until it returns to its original

point.

(8) When the engine starts, open the choke lever.

• Open the choke lever fully when checking the engine operation.

• In cold or when the engine is cooled down, never open the

choke lever suddenly. Otherwise, the engine may stop.

(9) Continue warm-up operation for 2 to 3 minutes.

(10) Warm-up is complete when there is quick engine acceleration

from low rpm to full throttle.

12

Page 13

NOTE

Cruise control lever

Hi-speed

Low-speed

Stop Switch

Carburetor

Adjusting screw

• The engine may be damaged if the choke lever is moved further beyond the “CLOSE” position.

• If the engine fires and stops, return this lever to the “OPEN” position and pull the starter handle several times to start the engine again.

• If the operator keeps pulling the starter handle several times with the choke lever left in the “CLOSE” position, the engine may be difficult to

start because of flooding of the fuel.

• In case of flooding of the fuel, remove the spark plug and pull the handle several times rapidly to discharge any excess fuel. Dry the spark

plug electrode.

• When the throttle valve does not return to a position in contact with the idling adjusting screw even if the throttle lever is set to the low speed,

correct the control cable catching state to ensure proper return of the valve.

2) When the engine is warm

(1) Put the engine on a flat ground.

(2) Press the primary pump several times.

(3) Make sure that the choke lever is open.

(4) Hold the element cover with left hand to prevent the engine from moving.

(5) Pull out slowly the starter handle till a certain resistance is felt. Return the starter handle backward once from this position, then pull it

out with force.

(6) When the engine is difficult to start, open the throttle valve by about 1/3.

2. Stopping

1) When the cruise control lever is a Low-speed position.

Release the trigger lever to reduce the engine speed, and set the

stop switch to the “O” position.

2) When the cruise control lever is except a Low-speed

position.

Set the cruise control lever to the Low-speed position, reduce the

engine speed, and set the stop switch to the “O” position.

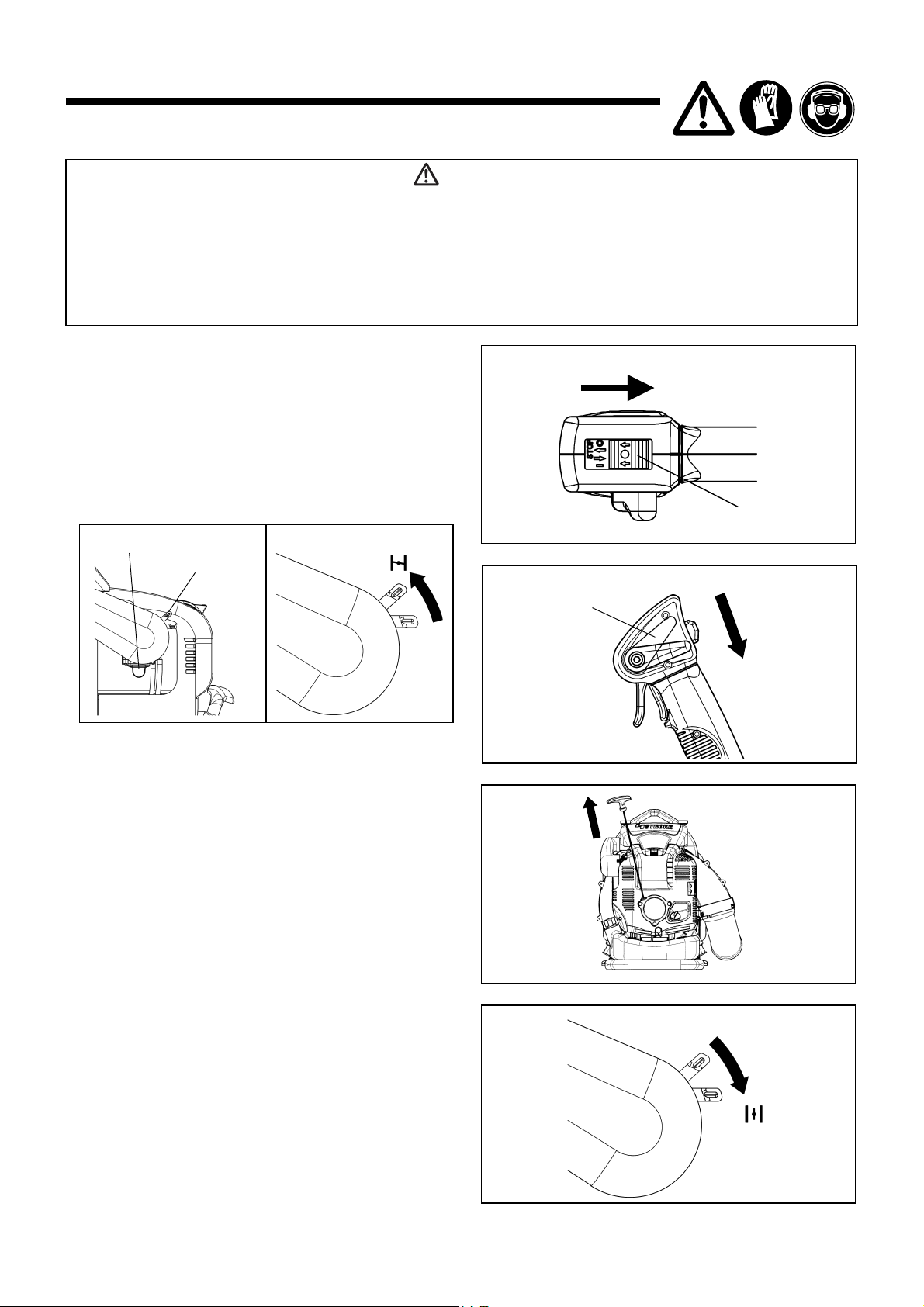

ADJUSTMENT OF IDLING

The carburetor is factory adjusted. Please do not adjust other than idling adjusting. When adjustment becomes necessary, please consult your

dealership or an authorized service agent.

Checkup of low-speed rotation

Set the low-speed rotation to 2800 rpm (/min).

• If it is necessary to change the rotation speed, regulate the adjusting

screw, with Phillips screwdriver.

• Turn the adjusting screw to the right, and the engine speed will

increase. Turn the adjusting screw to the left, and the engine speed will

drop.

DANGER

13

Page 14

OPERATION METHOD

To tighten straps To loosen straps

Cruise control lever

Hi-speed

Low-speed

1. Adjusting Shoulder strap

Adjust the shoulder strap to a length that is comfortable to work while

carrying the blower.

Adjust as shown in the figure.

2. Adjusting the control lever

Move the control handle along the swivel pipe to the most comfortable

position.

3. Blower Operation

While operating the blower, adjust the throttle bar so that the wind force

is appropriate for the work location and conditions.

Low speed: Dried leaves and grass

High speed: Gravel and dirt

The cruise control lever allows the operator to maintain a constant

engine speed without operating the trigger lever.

Lifting the cruise control lever increases engine speed.

Lowering the cruise control lever decreases engine speed.

Adjusting engine speed when the cruise control lever is being used:

When increasing engine speed:

• Pull the trigger lever to increase engine speed. Engine speed returns

to its original setting when the trigger lever is released.

• Increasing the engine speed in this manner also increases the cruise

control setting. The cruise control lever lifts simultaneously as the

trigger lever is pulled, and the new cruise control setting will be maintained at the higher engine speed.

When reducing engine speed:

• Lower the cruise control lever to the low-speed position.

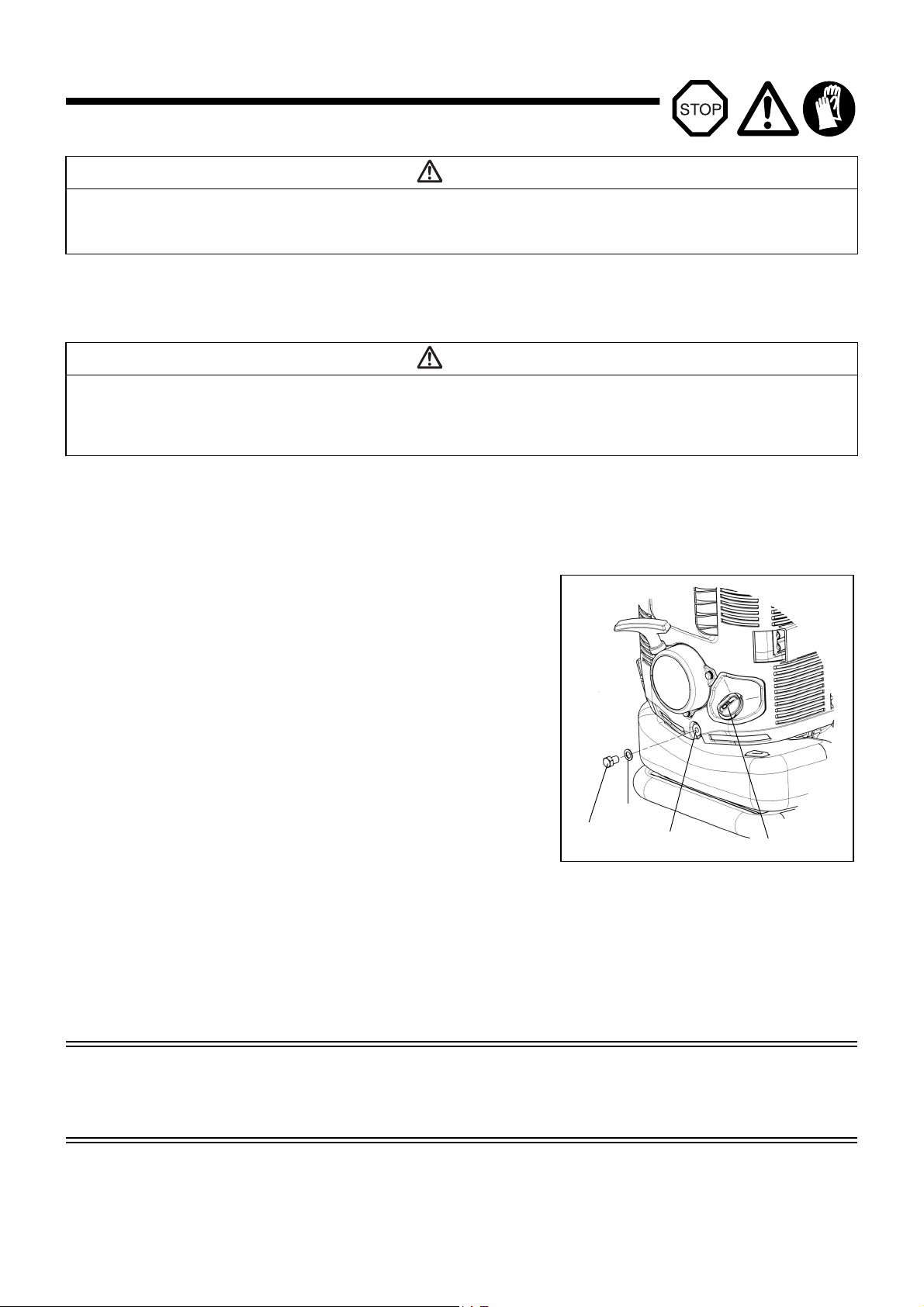

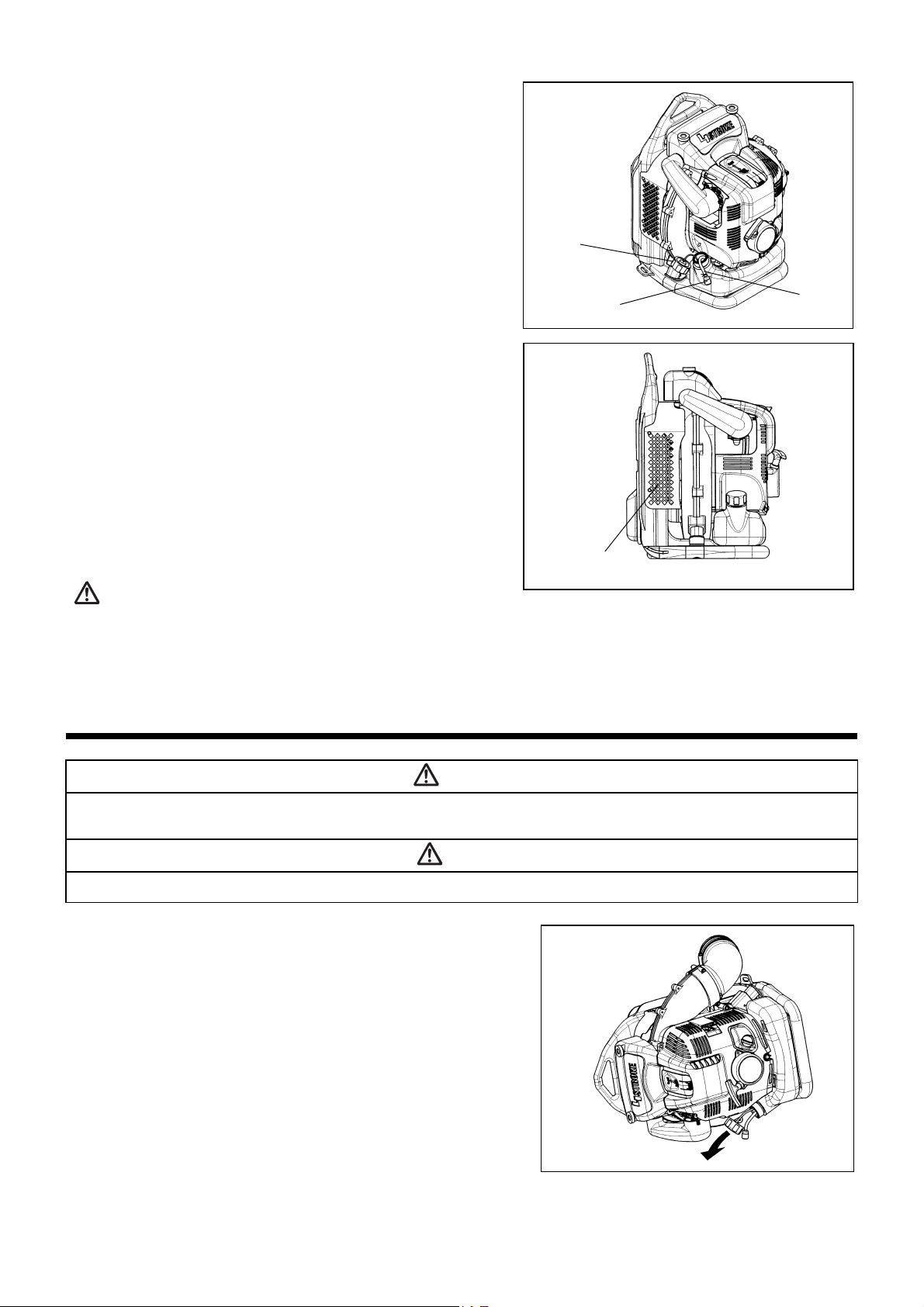

TRANSPORTING AND STORING THE BLOWER

Please maintain the blower in an upright position whenever transporting

or storing. (Refer to Figure at right.)

Transporting or storing in a position that is not upright may cause oil to

spill inside the blower engine. This may result in oil leaks and white

smoke from burning oil, and the air cleaner may become dirty with oil.

DANGER

• When transporting the blower, be sure to stop the engine.

14

Page 15

INSPECTION AND MAINTENANCE

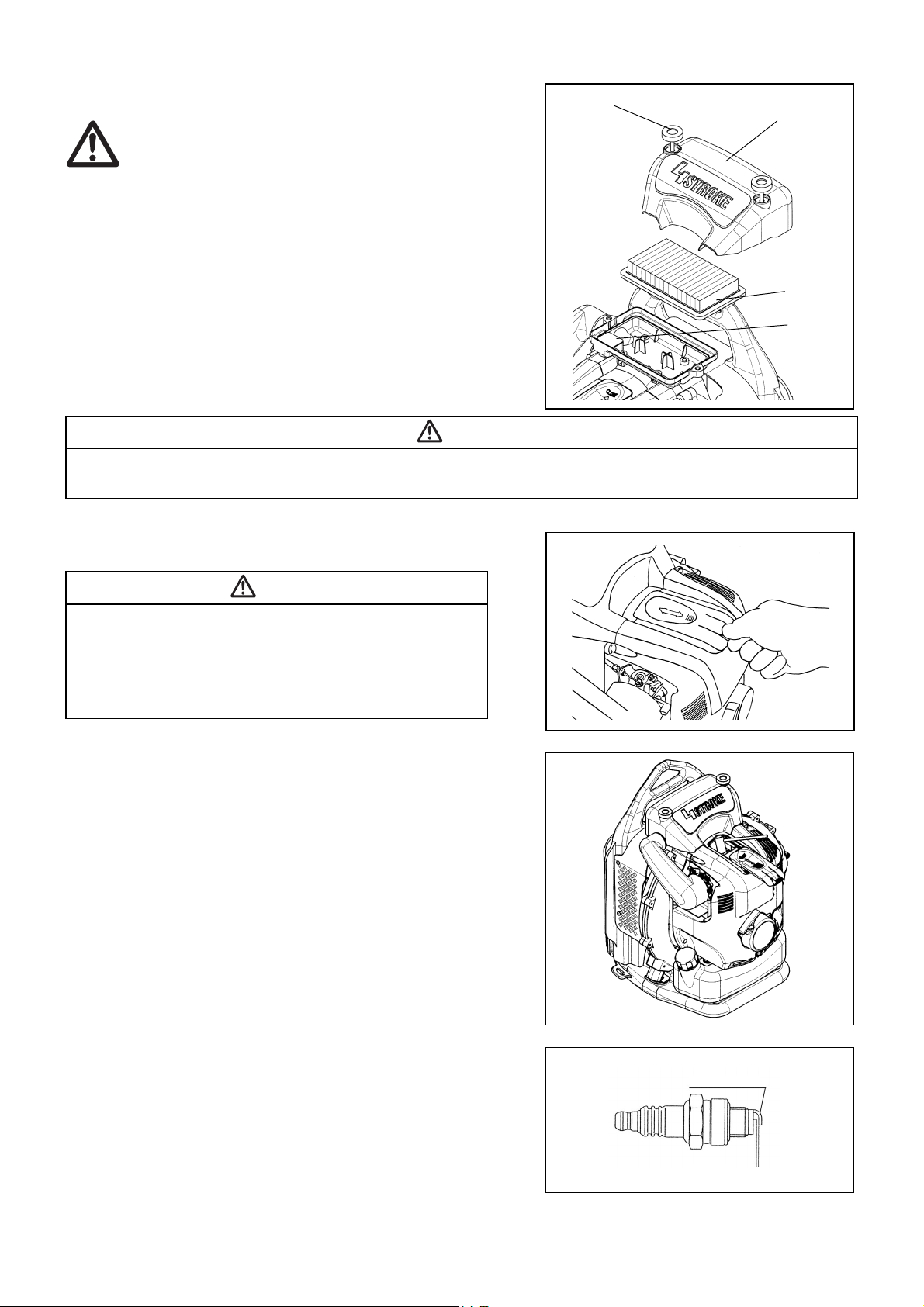

(1)

(2)

(3)

(4)

DANGER

• Before inspection and maintenance, stop the engine and allow it to cool down. Remove the spark plug and plug cap.

- Otherwise the operator may suffer burn or serious injury due to an accidental start-up.

• After inspection and maintenance, make sure that all parts are assembled. Then, proceed to operation.

1. Replacement of engine oil

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of replacement.

DANGER

• In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil, make sure that the

engine main unit and engine oil are sufficiently cooled down. Otherwise, there may remain a risk of scald. Allow sufficient time after stopping

engine for the engine oil to return to the oil tank to ensure accurate reading of the oil level indicator.

• If the oil filled above the limit, it may become dirty or may catch fire with white smoke.

Interval of replacement: After first 20 operating hours, followed by every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classification SF Class or higher (4-stroke engine oil for automobile)

Oil Change Procedure

Please follow these steps when changing the oil:

(1) Set the blower down on a level surface.

(2) Put a waste oil container under the drainage hole (1) to catch the oil as it

drains out. The container should have a capacity of at least 220 ml to be

able to catch all of the oil.

(3) Loosen the oil drain bolt (2) to let the oil drain out. Be careful not to allow oil

to get on the fuel tank or other parts.

Caution: Be careful not to lose the gasket (aluminum washer) (3). Put the

oil drain bolt (2) in a location where it will not accumulate dirt.

(4) Remove the oil cap (4). (Removing the oil cap (4) allows the oil to drain

easily.)

Caution: Be sure to set the oil cap (4) down in a location where it will not

(5) As the level of the oil being drained decreases, tilt the blower over on to the

side with the drain so that the oil will completely drain out.

(6) After the oil has completely drained out, tighten the oil drain bolt (2)

securely. If the bolt is not tightly fastened, this may result in an oil leak.

Caution: Do not forget to put the gasket (aluminum washer) (3) back on

(7) Adding oil during the oil change procedure is performed in the same man-

ner as the separately explained procedure for adding oil whenever the

level is insufficient. Always add oil by filling from the opening under the oil

cap.

(Specified oil level: Approximately 220 ml)

(8) After filling with oil, tighten the oil cap (4) securely to prevent oil leaks.

accumulate dirt.

when reattaching the drain plug.

Points in replacement of engine oil

• Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the relevant

laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

• Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6 months).

15

Page 16

2. Cleaning of air cleaner

Element

Breather

Element cover

Knob bolt

Electrode clearance

0.7 - 0.8 mm

Lateral electrode (–)

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

(1) Loosen the knob bolts.

(2) Remove the air cleaner cover.

(3) Take out the element and remove any dirt from the element with the brush.

Note: The element is a dry type and should not get wet. Never wash with

water.

(4) Replace the element with a new one if it is damaged or very dirty.

(5) Wipe off any oil that has come in to contact with the breather with a rag or

cloth.

(6) Install the element in the cleaner case.

(7) Attach the air cleaner cover and tighten the knob bolt.

DANGER

• Clean the element several times a day, if excessive dust adheres to it.

• If operation continues with the element remaining not cleared of oil, oil in the air cleaner may fall outside, resulting in oil contamination.

3. Checking the spark plug

CAUTION

• When removing the spark plug, clean the spark plug and cylinder head

first, so that no dirt, sand, etc will enter the cylinder.

• You must remove the spark plug after the engine has cooled down in

order to avoid damaging the threaded hole in the cylinder.

• The spark plug must be installed properly into the threaded hole. If

installed at an angle, the threaded hole in the cylinder will get damaged.

(1) Opening/closing the plug cover

To open the plug cover, pull up on the seam of the plug cover projection

and slide in the direction of the “OPEN” indication as shown in the figure at

right.

When closing the cover, slide the cover in the “CLOSE” direction till the

click under the plug cover projection rides over the engine cover. Finally,

push in the projection.

(2) Removing the spark plug

Use an attached box wrench to remove or install the spark plug.

(3) Checking the spark plug

The clearance between two electrodes of spark plug (see the figure left) is

0.7 to 0.8 mm. Adjust to the correct clearance when it is too wide or too

narrow.

Clean thoroughly or replace the spark plug if it has accumulated carbon or

contaminated.

(4) Replacing the spark plug

For replacement, use NGK-CMR6A.

16

Page 17

4. Cleaning the fuel filter

Hose clamp

Fuel filter

Fuel tank cap

Air inlet net

• Clogged fuel filter may cause difficulty of start-up or failure of engine speed

increase.

• Check the fuel filter regularly as follows:

(1) Remove the fuel tank cap, drain the fuel to empty the tank. Check the

tank inside for any foreign materials. If any, wipe clean such materials.

(2) Pull out the fuel filter with wire through the oil filling port.

(3) If the fuel filter surface is contaminated, clean it with gasoline. The gaso-

line used for the cleaning must be disposed of according to the method

specified by each local authority. Excessively contaminated filter must be

replaced.

(4) Reset the fuel filter in the fuel tank and tighten firmly the fuel tank cap. For

replacement, contact your dealership or an authorized service agent.

5. Inspection of bolts, nuts and screws

• Retighten loose bolts, nuts, etc.

• Check for fuel and oil leakage.

• Replace damaged parts with new ones for safety operation.

6. Cleaning of parts

• Keep engine clean by wiping down with a cloth rag.

• Keep the cylinder fins free of dust or dirt. Dust or dirt adhering to the fins will

cause seizure.

• Blowing air is taken in from the air inlet net. When airflow has dropped down

during operation, stop engine and inspect the air inlet net for blocking by

obstacles.

• Such a blockage may cause overheat and damage the engine.

WARNING:

Never use the blower without the net of the blower. Before each use,

check that the net is attached in place and is free from any damage.

7. Replacement of gaskets and packings

Replace gaskets and packings if the engine is disassembled.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agent.

STORAGE

WARNING

• When draining the fuel, stop the engine and wait for the engine to cool down.

- Failure to do so may cause burns or fire.

DANGER

• When you store the machine for a long time, drain all fuel from the fuel tank and carburetor, and keep it at a dry and clean place.

Drain fuel from the fuel tank and carburetor according to the following

procedure:

(1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign materials remaining in the fuel tank, remove it

completely.

(2) Pull out the fuel filter from the refill port using a wire.

(3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

(4) Reset the filter to the fuel tank, and securely tighten the fuel tank cap.

(5) Then, continue to operate the engine until it stops.

(6) Remove the spark plug, and drip several drops of engine oil through the

spark plug hole.

(7) Gently pull the starter handle so that engine oil will spread over the engine,

and attach the spark plug.

(8) Keep the machine with its handle upside.

(9) Keep the drained fuel in a special container in a well-ventilated shade.

17

Page 18

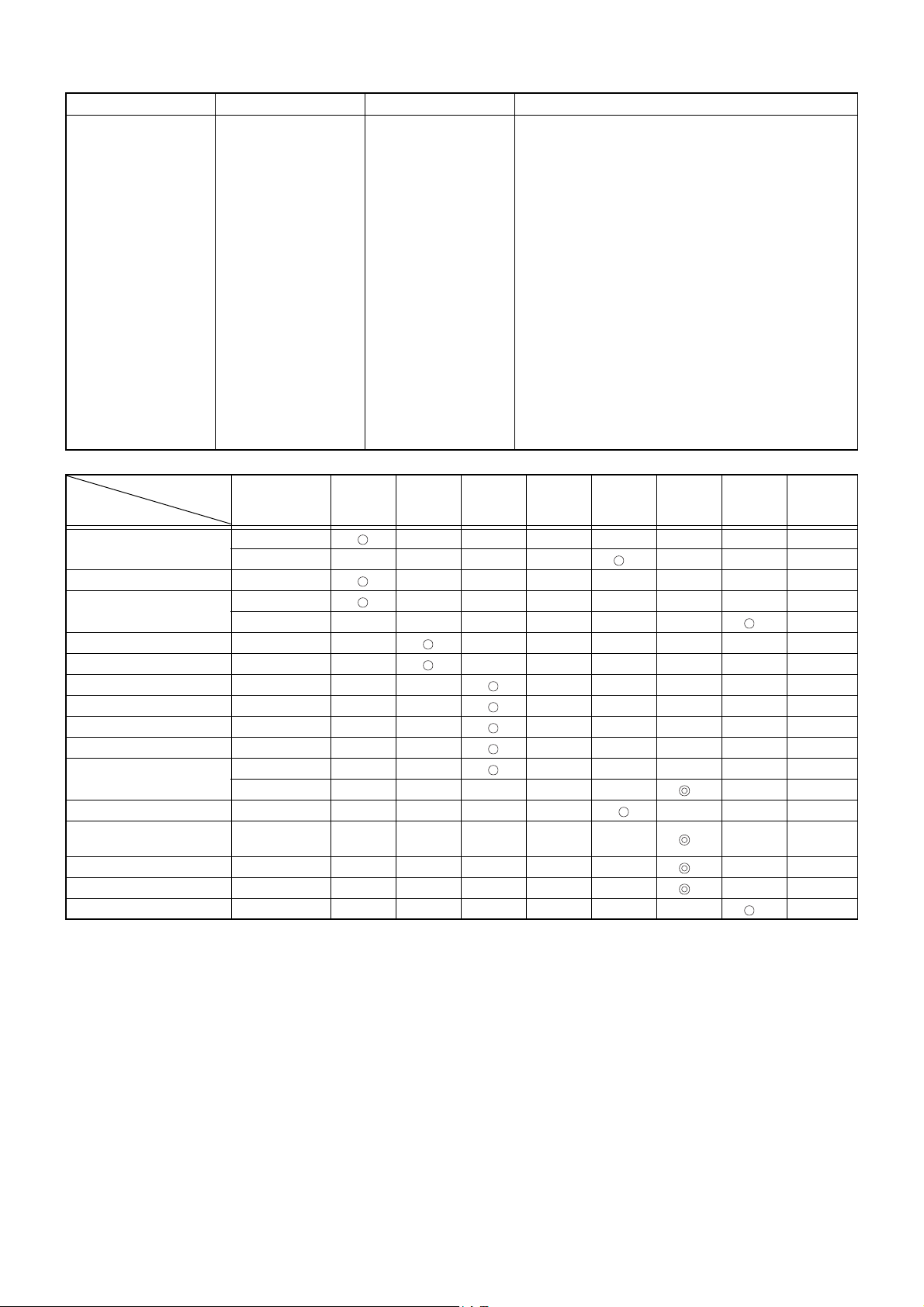

Fault location

Fault System Observation Cause

Engine not starting or

with difficulty

Warm start problems Tank filled ignition spark

Engine starts but dies Fuel supply Tank filled Incorrect idling adjustment, carburetor contaminated

Insufficient performance Several systems may

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark plug

or connector defective, ignition module faulty

Fuel supply Fuel tank filled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty.

Compression No compression when

pulled over

Cylinder bottom gasket defective, crankshaft seals damaged,

cylinder or piston rings defective or improper sealing of spark

plug

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

Carburetor contaminated, have it cleaned

existing

Fuel tank vent defective, fuel supply line interrupted, cable or

STOP-switch faulty

Engine idling poor Air filter contaminated, carburetor contaminated, muffler

simultaneously be

clogged, exhaust duct in the cylinder clogged

affected

3

3

Corre-

sponding

Page

15

17

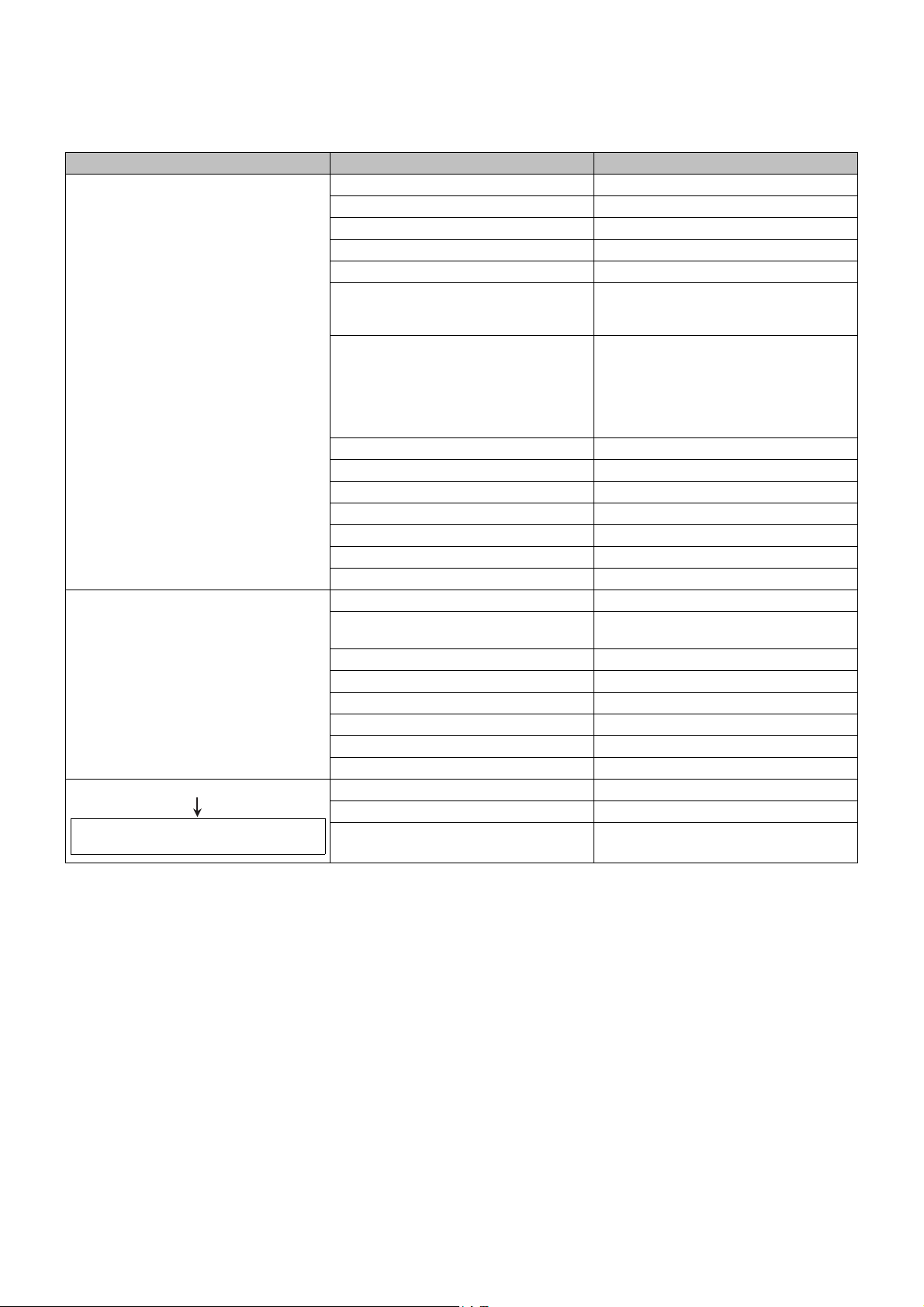

17

Operating time

Item

Engine oil

Tightening parts (bolt, nut) Inspect 17

Fuel tank

Throttle lever Check function –

Stop switch Check function 12

Low-speed rotation Inspect/adjust 13

Air cleaner Clean 16

Ignition plug Inspect 16

Cooling air duct Clean/inspect 17

Fuel pipe

Fuel filter Clean/replace 17

Clearance between air intake

valve and air discharge valve

Oil tube Inspect *

Engine overhaul *

Carburetor Drain fuel *

Inspect/clean 10

Replace *

Clean/inspect –

Drain fuel *

Inspect 17

Replace *

Adjust *

Before

operation

After

lubrication

Daily (10h) 30h 50h 200h

1

Shutdown/

rest

2

2

2

2

–

–

–

–

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

18

Page 19

TROUBLESHOOTING

Run engine at idling, and set choke lever to

CLOSE.

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description of

this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times.

Low pulling speed of starter rope Pull strongly.

Lack of fuel Feed fuel.

Clogged fuel filter Clean

Broken fuel tube Straighten fuel tube

Deteriorated fuel Deteriorated fuel makes starting more difficult.

Replace with new one. (Recommended

replacement: 1 month)

Engine does not start

Engine stops soon

Engine speed does not increase

Excessive suction of fuel Set throttle lever from medium speed to high

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Insufficient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although

engine is warmed up

Clogged fuel filter Clean

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Detached throttle wire Attach securely

speed, and pull starter handle until engine

starts.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specified.

Set to “OPEN”

Engine does not stop. Detached connector Attach securely

Abnormal electric system Make request for inspection and maintenance.

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

19

Page 20

Makita LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to be free of defects from

workmanship and materials for the period of ONE YEAR from the date of original purchase. Should any trouble develop during

this one year period, return the COMPLETE tool, freight prepaid, to one of Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective workmanship or material, Makita will repair (or at our option, replace) without

charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and tear:

the tool has been abused, misused or improperly maintained:

alterations have been made to the tool.

IN NO EVENT SHALL Makita BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE

SALE OR USE OF THE PRODUCT. THIS DISCLAIMER APPLIES BOTH DURING AND AFTER THE TERM OF THIS

WARRANTY.

Makita DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTIES OF

“MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF THIS WARRANTY.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you. Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not

apply to you.

20

Page 21

EMISSION COMPLIANCE PERIOD

Descriptive term Applicable to Emissions Durability Period

Moderate 50 hours (0-80 cc, inclusive)

Intermediate 125 hours (0-80 cc, inclusive)

Extended 300 hours (0-80 cc, inclusive)

For handheld engines : The Emissions Compliance Period referred to on the

Emissions Compliance label indicates the number of operating hours for which

the engine has been shown to meet Federal emission requirements.

Category C=50 hours, B=125 hours, and A=300 hours.

Air Index and durability period information

The Air Index Information hang-tag for this engine is provided in accordance

with the California emission regulations.

The graphical representation of the Air Index on the hang-tag shows the

emissions performance of this engine, and can be used to compare the

emissions performance with other available engines.

The lower the Air Index, the less pollution.

Note: Remove the hang-tag before operating the engine.

The Emissions Durability Period referred to on the hang-tag indicates the

number of operating hours for which the engine has been shown to meet the

California emission requirements.

21

Page 22

FEDERAL EMISSION COMPONENT DEFECT WARRANTY

EMISSION COMPONENT DEFECT WARRANTY COVERAGE - This emission warranty is applicable in all States,

except the State of California

Makita U.S.A., Inc., (herein “Makita”) warrant to the initial retail purchaser and each subsequent owner, that this

utility equipment engine (herein “engine”) was designed, built, and equipped to conform at the time of initial sale to

all applicable regulations of the U.S. Environmental Protection Agency (EPA), and that the engine is free of defects

in materials and workmanship which would cause this engine to fall to conform with EPA regulations during its

warranty period.

For the components listed under PARTS COVERED, the dealer or service center authorized by Makita will, at no

cost to you, make the necessary diagnosis, repair, or replacement necessary to ensure that the engine complies

with applicable U.S. EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the initial purchaser and continues for a period of

2 years.

PARTS COVERED

Listed below are the parts covered by the Emission Component Defect Warranty. Some of the parts listed below may

require scheduled maintenance and are warranted up to the first scheduled replacement point for that part.

1) Fuel Metering System 4) Miscellaneous Items Used in Above Systems

(i) Carburetor and internal parts

(i) Fuel hoses, clamps and sealing gaskets

(ii) Fuel filter, if applicable

(iii) Throttle stopper, if applicable

(iv) Choke System, if applicable

2) Air Induction System 5) Emission-related components for evaporative emission

(i) Air cleaner plate

(ii) Air cleaner case

(iii) Air cleaner element

(i) Fuel Tank

(ii) Fuel Cap

(iii) Fuel line

(iv) Fuel line fitting

(v) Clamps

3) Ignition System

(i) Spark plug

(ii) Flywheel Magneto

(iii) Ignition Coil

22

Page 23

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest Makita Factory Service Center authorized by Makita.

Bring your sales receipts indicating date of purchase for this engine. The dealer or service center authorized by

Makita will perform the necessary repairs or adjustments within a reasonable amount of time and furnish you with a

copy of the repair order. All parts and accessories replaced under this warranty become the property of Makita.

WHAT IS NOT COVERED

* Conditions resulting from tampering, misuse, improper adjustment (unless they were made by the dealer or

service center authorized by Makita during a warranty repair), alteration, accident, failure to use the recommended

fuel and oil, or not performing required maintenance services.

* The replacement parts used for required maintenance services.

* Consequential damages such as loss of time, inconvenience, loss of use of the engine of equipment, etc.

* Diagnosis and inspection charges that do not result in warranty-eligible service being performed.

* Any non-authorized replacement part, or malfunction of authorized parts due to use of non-authorized parts.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s

manual, Makita recommends that you retain all receipts covering maintenance on your engine, but Makita can not

deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled

maintenance.

As the engine owner, you should however be aware that the Makita may deny your warranty coverage if your engine

or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest dealer or service center authorized by Makita when a

problem exists.

If you have any questions regarding your warranty rights and responsibilities, you should contact the Followings:

* For the nearest Makita service center, please visit www.makitatools.com

* For technical support or questions regarding operation of our tools and accessories call: 1-800-4-Makita

* Makita USA Inc. Corporate Office: 14930 Northam St. La Mirada, CA 90638-5753

(For Canada)

* For the authorized service center nearest you please refer to the local yellow pages directory under “tools”, or

contact our customer service department Tel 1-800-263-3734(Canada only), or visit our web site www.makita.ca

* Makita Canada Inc. Head Office & Plant: 1950 Forbes Street, Whitby, ON L1N7B7.

23

Page 24

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY

MAINTENANCE AND REPAIRS

You are responsible for the proper use and maintenance of the engine. You should keep all receipts and

maintenance records covering the performance of regular maintenance in the event questions arise. These receipts

and maintenance records should be transferred to each subsequent owner of the engine. Makita reserves the rights

to deny warranty coverage if the engine has not been properly maintained. Warranty claims will not be denied,

however, solely because of the lack of required maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND

SYSTEMS MAY BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL;

HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A DEALER OR SERVICE

CENTER AUTHORIZED BY Makita. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN

PERFORMANCE AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE

EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON

THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by Makita are used for maintenance replacements or for the repair of components

affecting emission control, you should assure yourself that such parts are warranted by their manufacturer to be

equivalent to the parts authorized by Makita in their performance and durability.

HOW TO MAKE A CLAIM

All repairs qualifying under this limited warranty must be performed by a service dealer authorized by Makita. In

the event that any emission-related part is found to be defective during the warranty period, you shall notify Makita

at the following contacts and you will be advised of the appropriate warranty service dealer or service

providers where the warranty repair can be performed.

* For the nearest Makita service center, please visit www.makitatools.com

* For technical support or questions regarding operation of our tools and accessories call: 1-800-4-Makita

* Makita USA Inc. Corporate Office: 14930 Northam St. La Mirada, CA 90638-5753

(For Canada)

* For the authorized service center nearest you please refer to the local yellow pages directory under “tools”, or

contact our customer service department Tel 1-800-263-3734(Canada only), or visit our web site www.makita.ca

* Makita Canada Inc. Head Office & Plant: 1950 Forbes Street, Whitby, ON L1N7B7.

24

Page 25

CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Makita USA, Inc are pleased to explain the emissions control system’s

warranty on your 2007 and later small off-road engine. In California, new equipment that use small off-engines must

be designed, built, and equipped to meet the State’s stringent anti-smog standards. Makita USA, Inc must warrant

the emissions control system on your small off-road engine for the period listed below provided there has been no

abuse, neglect or improper maintenance of your equipment.

Your emissions control system may include parts such as: carburetors or fuel injection system, ignition system,

catalytic converters, fuel tanks, valves, filters, clamps, connectors, and other associated components. Also, included

may be hoses, belts, connectors, sensors, and other emission-related assemblies.

Where a warrantable condition exists, Makita USA, Inc will repair your small off-road engine at no cost to you

including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emissions-related part on your equipment is

defective, the part will be repaired or replaced by Makita USA, Inc.

OWNER’S WARRANTY RESPONSIBILITIES:

• As the small off-road engine owner, you are responsible for performance of the required maintenance listed in your

owner’s manual. Makita USA, Inc recommends that you retain all receipts covering maintenance on your small

off-road engine, but Makita USA, Inc cannot deny warranty solely for the lack of receipts or your failure to ensure

the performance of all scheduled maintenance.

• As the small off-road engine owner, you should however be aware that Makita USA, Inc may deny you warranty

coverage if your small off-road engine or a part has failed due to abuse, neglect, or improper maintenance or

unapproved modifications.

• You are responsible for presenting your small off-road engine to a Makita Factory Service Center as soon as the

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have a question regarding your warranty coverage, you should contact:

* For the nearest Makita service center, please visit www.makitatools.com

* For technical support or questions regarding operation of our tools and accessories call: 1-800-4-Makita

* Makita USA Inc. Corporate Office: 14930 Northam St. La Mirada, CA 90638-5753

DEFECTS WARRANTY REQUIREMENTS:

(a) The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

(b) General Emissions Warranty Coverage. Makita USA, Inc must warrant to the ultimate purchaser and each

subsequent owner that the engine or equipment is:

(1) Designed, built, and equipped so as to conform with all applicable regulations adopted by the Air

Resources Board; and

(2) Free from defects in materials and workmanship that causes the failure of a warranted part for a period of

two years.

(c) The warranty on emissions-related parts will be interpreted as follows:

25

Page 26

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written

instructions required by subsection (d) must be warranted for the warranty period defined in Subsection

(b)(2). If any such part fails during the period of warranty coverage, it must be repaired or replaced by the

manufacturer according to Subsection (4) below. Any such part repaired or replaced under the warranty

must be warranted for the remaining warranty period.

(2) Any warranted part that is scheduled only for regular inspection in the written instructions required by

subsection (d) must be warranted for the warranty period defined in Subsection (b)(2). A statement in such

written instructions to the effect of “repair or replace as necessary” will not reduce the period of warranty

coverage. Any such part repaired or replaced under warranty must be warranted for the remaining warranty

period.

(3) Any warranted part that is scheduled for replacement as required maintenance in the written instructions

required by subsection (d) must be warranted for the period of time prior to the first scheduled replacement

point for that part. If the part fails prior to the first scheduled replacement, the part must be repaired or

replaced by the engine manufacturer according to Subsection (4) below. Any such part repaired or replaced

under warranty must be warranted for the remainder of the period prior to the first scheduled replacement

point for the part.

(4) Repair or replacement of any warranted part under the warranty must be performed at no charge to the

owner at a warranty station.

(5) Notwithstanding the provisions of Subsection (4) above, warranty services or repairs must be provided at

all manufacturer distribution centers that are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is

in fact defective, provided that such diagnostic work is performed at a warranty station.

(7) The manufacturer is liable for damages to other engine components proximately caused by a failure under

warranty of any warranted part.

(8) Throughout the emissions warranty period defined in Subsection (b)(2), the manufacturer must maintain a

supply of warranted parts sufficient to meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be

provided without charge to the owner. Such use will not reduce the warranty obligations of the

manufacturer.

(10) Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of

any non-exempted add-on or modified parts will be grounds for disallowing a warranty claim. The

manufacturer will not be liable to warrant failures of warranted parts caused by the use of a non-exempted

add-on or modified part.

(11) The manufacturer issuing the warranty shall provide any documents that describe that manufacturer’s

warranty procedures or policies within five working days of request by the Air Resources Board.

(d) Emission Warranty Parts List.

(1) Fuel Metering System

(i) Carburetor and internal parts

(ii) Fuel Filter

(iii) Fuel Tank.

(2) Air Induction System

(i) Air cleaner plate (including choke system)

(ii) Air cleaner cover

(iii) Air cleaner element

26

Page 27

(3) Ignition System

(i) Spark Plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system.

(4) Miscellaneous Items Used in Above Systems

(i) Hoses, Sealing gaskets, belts, connectors, and assemblies.

Makita USA, Inc will furnish with each new engine written instructions for the maintenance and use of the engine by

the owner.

(e) MAINTENANCE STATEMENTS

It is your responsibility to have all scheduled inspection and maintenance services performed at the times

recommended in the 2007 and later Owner’s Manual and to retain proof that inspection and maintenance services

are performed at the times when recommended. Makita USA, Inc will not deny a warranty claim solely because you

have no record of maintenance;

however, Makita USA, Inc may deny a warranty claim if your failure to perform required maintenance resulted in the

failure of warranted part. The proof, which you maintain, should be given to each subsequent owner of the engine.

You are responsible for performing the scheduled maintenance described below based on the procedures specified

in the 2007 and later Owner’s Manual. The scheduled maintenance below is based on the normal engine-operating

schedule.

PROCEDURE INTERVAL

1) Clean engine and check bolts and nuts.

:Every 8 hours(daily)

Retighten if necessary.

2) Check and refill engine oil (4stroke engine

:Every 8 hours(refill daily up to upper limit)

only)

3) Change engine oil (4stroke engine only) :Initial 20 hours and every 50 hours afterward

4) Check clogging of cooling air passage and

:Every 8 hours (daily)

cylinder fins. Remove and clean if necessary.

5) Clean air cleaner. :Every 8 hours (daily)

6) Check spark plug. Clean and adjust if

:Every 8 hours (daily)

necessary.

7) Check muffler exhaust outlet(or port).

:Every 50 hours (monthly)

Clean if necessary.

8) Check fuel filter. If clogged, replace with new

:Every 50 hours (monthly)

one.

9) Adjust valve clearance, if applicable (4stroke

:Every 200 hours (yearly)

engine only).

10) Replace fuel lines. :Every 200 hours (yearly)

11) Clean and inspect the complete engine.

:Every 200 hours

Replace any damaged or worn out parts.

12) Replace packings and gaskets with new

:Every reassembling

ones.

27

Page 28

Français

Vous venez d’acheter un souffleur Makita, fruit d’importants

programmes de développement et de nombreuses années d’études et

d’expérience et nous vous en remercions.

Les modèles BBX7600 / BBX7600CA légers, pratiques et compacts,

allient les avantages d’une technologie de pointe à une conception

ergonomique et sont des outils de professionnels pour de nombreuses

applications.

Lisez soigneusement le manuel, qui traite en détail des différents

points des performances de la machine et vous aidera à en tirer le

meilleur parti possible.

Table des Matières

Symboles ........................................................................................... 28

Consignes de sécurité .................................................................. 29-30

Caractéristiques techniques............................................................... 32

Liste des pièces ................................................................................. 33

Instructions de montage................................................................ 34-35

Avant de démarrer le moteur ........................................................36-37

Fonctionnement ............................................................................38-39

Réglage du ralenti.............................................................................. 39

Mode opératoire................................................................................. 40

Inspection et maintenance ............................................................41-43

Remisage...................................................................................... 43-44

Dépannage ........................................................................................ 45

SYMBOLES

Lors de la lecture de ce manuel, prêtez une attention particulière aux symboles ci-après :

Page

Attention! Danger! Essence et huile

Lire et suivre le manuel de fonctionnement Moteur - Mise en marche manuelle

Interdit Arrêt d’urgence

Interdiction de fumer Premiers secours

Interdiction d’utilisation de produits

inflammables

Port de gants de protection obligatoire Marche

Zone de fonctionnement interdite aux

humains et aux animaux

Recyclage

Arrêt

Port de lunettes de protection et cacheoreilles obligatoire

Surfaces chaudes - Risque de brûlures

Mutilation du doigt ou du bras, Roue mobile

28

Page 29

CONSIGNES DE SECURITE

(1)

(2)

(3)

(4)

(5)

15 mètres

Généralités

• Pour tirer le meilleur parti de votre machine, vous devez lire, assimiler

et respecter les instructions figurant dans ce manuel (1). Les

utilisateurs mal informés risquent, par des manipulations

inappropriées, de se blesser ou de blesser leur entourage.

• Il est conseillé de ne prêter cet appareil qu’aux personnes ayant déjà

une certaine expérience des souffleurs.

• Dans ce cas, leur confier aussi le manuel d’instruction.

• Les utilisateurs qui ne connaissent pas encore le fonctionnement de la

machine devront demander à leur vendeur les explications qui leur

permettront de se familiariser avec le souffleur.

• Les enfants et les adolescents ne doivent pas être autorisés à utiliser

la machine. Au-delà de 16 ans, ils peuvent cependant apprendre à

s’en servir, mais uniquement sous le contrôle direct d’une personne

qualifiée.

• Soyez toujours très prudent.

• N’utilisez la machine que si vous êtes en bonne condition physique.

• Faites très attention à tout ce que vous faites. N’oubliez pas que vous

êtes responsable des autres.

• N’utilisez jamais l’appareil lorsque vous avez bu ou pris des calmants

(2).

• N’utilisez pas l’appareil lorsque vous êtes fatigué.

• Conservez soigneusement ce manuel afin de pouvoir vous y référer

ultérieurement.

Equipements de protection

• Portez des vêtements fonctionnels, c’est-à-dire des vêtements légers,

ne provoquant aucune gêne. Evitez les bijoux, les vêtements ou les

cheveux longs, qui pourraient être happés par l’entrée d’air.

• Pour éviter de vous blesser et vous protéger contre tous les accidents

éventuels, il est conseillé d’utiliser les équipements décrits ci-après.

Prêtez une attention particulière aux consignes

suivantes

• Les vêtements doivent être résistants et moulants, sans toutefois

entraver la liberté de mouvement. Evitez les vestes vagues, les

pantalons à jambes larges, les écharpes, les cheveux longs non

attachés, ou tout ce qui pourrait être happé par l’arrivée d’air. Portez un

bleu de travail ou un pantalon pour protéger vos jambes.

Ne portez pas un pantalon court (4).

• Le bruit de la soufflerie risque de poser des problèmes auditifs. Portez

des cache-oreilles. Si vous utilisez la machine soit régulièrement, soit

pendant de longues périodes, rendez régulièrement visite à un otorhino (3).

• Si possible, portez des gants et évitez les semelles glissantes (4).

• Protégez-vous soigneusement les yeux. Même si l’évacuation ne se

fait pas vers vous, il arrive parfois que le fonctionnement de la machine

entraine des ricochets et des rebonds (3).

• Ne faites jamais fonctionner la machine sans porter des lunettes ou

des verres de sécurité avec protection supérieure et latérale approprié

et conforme à la norme ANSI Z 87.1 (ou à toute norme nationale

applicable).

Mise en route de l’appareil

• Assurez-vous qu’il n’y a personne dans un rayon de 15 mètres (5) de

l’appareil. Ne l’utiliser jamais dans des zones urbaines.

• Avant de le mettre en route, vérifiez toujours la sécurité de la manette

des gaz, qui doit fonctionner facilement et sans à-coup. Vérifiez

également le fonctionnement de son système de verrouillage.

Assurez-vous que les poignées sont propres et sèches et vérifiez le

fonctionnement du commutateur de marche/arrêt.

29

Page 30

Avant de mettre la machine en marche, assurez-vous que toutes les

(6)

(7)

(8)

(9)

3 mètres

• Repos

• Transport

•Plein

• Maintenance

• Remplacement d’outil

instructions sont bien respectées.

N’utilisez pas d’autres méthodes de mise en marche de l’appareil (6).

• N’utilisez la machine et les outils fournis que pour les applications

spécifiées.

• Ne mettez la machine en marche que lorsque tous les accessoires ont

été mis en place. L’appareil ne fonctionne que lorsque tous les

accessoires appropriés y sont fixés.

• En cas de problème, arrêtez immédiatement l’appareil.

• Lorsque vous travaillez avec le souffleur, faites attention à mettre tous

les doigts autour de la poignée, en serrant la poignée de contrôle entre

le pouce et l’index. Gardez la main dans cette position pour avoir le

contrôle de l’appareil à tout moment. Vérifiez que la poignée de

contrôle est en bonne condition et qu’elle n’est pas souillée par de la

moisissure, du goudron, de l’huile ou de la graisse. Tenez-vous

toujours dans une position debout sûre et bien équilibrée.

• Pendant le fonctionnement de l’appareil, évitez toute inhalation de gaz

d’échappement. N’utilisez jamais I’appareil dans des endroits clos (en

raison des riqsues d’étouffement et d’empoisonnement par les gaz

d’échappement). N’oubliez pas que le monoxyde de carbone est un

gaz sans odeur. N’utilisez l’appareil que dans un endroit bien aéré.

• Coupez le moteur pendant les pauses ou lorsque vous laissez le

souffleur sans surveillance. Mettez-le en lieu sûr pour éviter de blesser

l’entourage, de mettre le feu aux matériaux combustibles, ou

d’endommager la machine.

• Ne posez jamais la machine chaude sur de l’herbe sèche ou des

matériaux combustibles.

• Utilisez toujours les éléments de protection fournis avec la machine.

• Ne faites jamais fonctionner la machine si le silencieux pose problème.

• Coupez l’alimentation du moteur pendant le transport (7).

• Pendant le transport, évitez toute fuite de carburant.

• Pendant le transport, assurez-vous que le réservoir de carburant est

totalement vide.

Plein de carburant

• Coupez le moteur (7). Assurez-vous qu’il n’y a aucune flamme à

proximité (8). Ne fumez pas.

• Evitez tout contact avec la peau et les produits dérivés du pétrole.

N’inhalez pas les vapeurs d’essence. Portez toujours des gants de

protection. Changez et nettoyez régulièrement les gants de protection.

• Veillez à ne pas renverser de carburants ou d’huile, pour éviter de

contaminer le sol (protection de l’ environnement). En cas de fuite de

carburant, même légère, nettoyez immédiatement l’appareil. Faites

toujours sécher les chiffons avant de les jeter dans un conteneur

approprié et couvert, pour éviter tout risque de combustion spontanée.

• Evitez tout contact du carburant avec les vêtements. Si nécessaire,

changez immédiatement de vêtement.

• Vérifiez régulièrement le bon fonctionnement du bouchon du réservoir.

• Assurez-vous que le bouchon du réservoir est bien serré, et ne mettez

le moteur en marche qu’à un minimum de 3 m de l’endroit ou vous

avez fait le plein (9).

• Ne faites jamais le plein de carburant dans des pièces fermées : les

vapeurs s’accumulent au niveau du sol (risque d’explosion).

• Ne transportez et ne stockez du carburant que dans des conteneurs

appropriés. Veillez à ce que les enfants n’y aient pas accès.

• Ne faites jamais le plein d’un moteur chaud ou en marche.

30

Page 31

Fonctionnement

(10)

(11)

(12)

• N’utilisez l’appareil que dans des endroits bien éclairés, où la visibilité

est bonne. Pendant les saisons fraiches, évitez les sols glissants ou

humides, la glace et la neige. Ayez toujours une position stable.

• N’utilisez jamais le souffleur sur une surface instable ou sur une pente

abrupte.

• Pour réduire le risque de blessure, n’orientez pas directement le jet

d’air vers les personnes présentes ; la pression élevée de l’air peut

causer une blessure aux yeux ou projeter les petits objets à très

grande vitesse.

• Ne mettez jamais de corps étrangers dans l’arrivée d’air de la machine

ou dans la buse du souffleur, car cela endommagerait le ventilateur et

risquerait de blesser les personnes se trouvant à proximité.

• Tenez compte de la direction du vent, de façon à ne pas travailler

contre le vent.

• Pour éviter de tomber et de perdre le contrôle de l’appareil, ne reculez

jamais pendant son fonctionnement.

• Coupez toujours le moteur avant de nettoyer l’appareil ou de

remplacer certaines de ces pièces.

Maintenance

• Respectez l’environnement; vérifiez notamment le bon réglage du

carburateur pour polluer aussi peu que possible l’atmosphère.

• Vérifiez régulièrement le souffleur, et assurez-vous que ses vis et

écrous sont bien fixés.

• Pendant toutes les opérations de maintenance ou de stockage, évitez

soigneusement la présence de flammes, d’étincelles ou autres (11).

• Stockez toujours l’appareil dans une pièce fermée à clé et bien aérée.

Avant de le stocker, videz soigneusement son réservoir.

Respectez toujours les instructions de prévention d’accidents des

associations professionnelles et des compagnies d’assurances. Ne

modifiez pas l’appareil.

N’effectuez aucune opération de maintenance ou de réparation qui ne

soit pas prévue par ce manuel. Toutes les autres opérations doivent être

effectuées par des représentants autorisés.

N’utilisez-que des pièces et des accessoires d’origine, fournis par

Makita. L’utilisation d’outils et d’accessoires non agréés augmente les

risques d’accident. Makita décline toute responsabilité en cas d’accident

ou de dommage provoqué par l’utilisation d’accessoires ou d’outils non

agréés.

Premiers secours

Veillez à avoir toujours à portée de la main une trousse de premiers

secours respectant les règlementations en vigueur. Assurez-vous que la

trousse est toujours complète.

En cas d’accident, appelez les services de secours et

fournissez-leur les informations suivantes:

• lieu de l’accident

• circonstances de l’accident

• nombre de personnes blessées

• type de blessures

• vos coordonnées

Conditionnement

Le souffleur est livré emballé dans un carton. Le carton est un matériau

de base qui peut donc être réutilisé ou recyclé.

31

Page 32

CARACTÉRISTIQUES TECHNIQUES

Modèle

Poids (sans les tubes) (kg) 10,2

Dimensions (sans les tubes) (L x l x H totales) (mm) 350 × 430 × 495

Vitesse maxi du moteur (min

Vitesse au ralenti (min

Cylindrée totale du moteur (mL) 75,6

Carburant Essence à automobile

Volume du reservoir à carburant (L) 1,9

Huile pour moteur

Volume d’huile à moteur (L) 0,22

Carburateur (Carburateur à diaphragme) WALBRO WYK

Système d’allumage Allumage électronique

Bougie NGK CMR6A

Distance entre électrodes (mm) 0,7 - 0,8

Niveau de bruit (15 metres par ANSI B175-2-2000) (dB(A)) 74

Notes :

1. Utiliser l’huile et la bougie désignés par Makita.

2. La spécification peut être soumise à changement sans avis préalable.

(Pour le Canada)

NOTE : Ce système d’allumage par étincelle de véhicule est conforme à la norme NMB-002 du Canada.

-1

) 7 200

-1

) 2 800

SAE 10W- 30 huile de la classification API, classe SF ou supérieure

(moteur à quatre temps pour automobile)

BBX7600

BBX7600CA

32

Page 33

LISTE DES PIÈCES

Optionnel

Désignation des pièces Désignation des pièces Désignation des pièces Désignation des pièces

1. Interrupteur d’arrêt 8. Levier d’étrangleur 15. Capot de bougie 22. Tube de souffleur

2. Poignée de contrôle 9. Poignée de démarrage 16. Bougie 23. Gicleur de souffleur L=200

3. Déclencheur 10. Réservoir à carburant 17. Bouchon à huile 24. Collier de serrage ø 100

4. Lever du Régulateur de vitesse

5. Pompe d’amorçage 12. Silencieux 19. Coude 26. Gicleur de souffleur L=450

6. Cache élément 13. Bandoulière 20. Tube flexible

7. Boulon du couvercle 14. Filet de la prise d’air 21. Tube rotatif

11. Bouchon du réservoir à

carburant

18. Boulon de vidange d’huile 25. Collier de serrage ø 76

33

Page 34

INSTRUCTIONS DE MONTAGE

(5)

(4)

(1)

(2)

(3)

(6)

(7)

(8)

Montage du tube de soufflante

ATTENTION : Avant toute opération sur le souffleur, coupez

toujours le moteur et débrancher les connecteurs de

bougie.

Portez toujours des gants de protection!

ATTENTION : Ne mettre le souffleur en marche que lorsqu’il est

1. Assembler le tuyau droit pour le raccorder avec la cheville (3) au

tuyau flexible (1) et serrer le tuyau de soufflerie diamètre ø76 (2).

2. Installer la poignée de contrôle (4) sur le tuyau droit avec la cheville

et serrer la vis de raccord (5).

complètement monté.

3. Assembler le tuyau flexible au coude (6) sur le souffleur et serrer le

tuyau de soufflerie diameter ø100 (7).

4. Assembler le tuyau droit (8) au tuyau droit avec la cheville en le

faisant tourner dans le sens des aiguilles d’une montre afin qu’il soit

bien en place.

5. Bien s’assurer que toutes les chevilles sont bien serrées.

34

Page 35

Fixation de la bandoulière

(1)

Crochet ressort détachable

facilement

Procédure de fixation

Fixation de la bandoulière au souffleur.

• Passez le bout de la bandoulière dans la fente de suspension en le

passant par le bas tel qu’indiqué dans la figure à droite. Le côté de la