Models No.

Description

PRODUCT

T

ECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

P 1/20

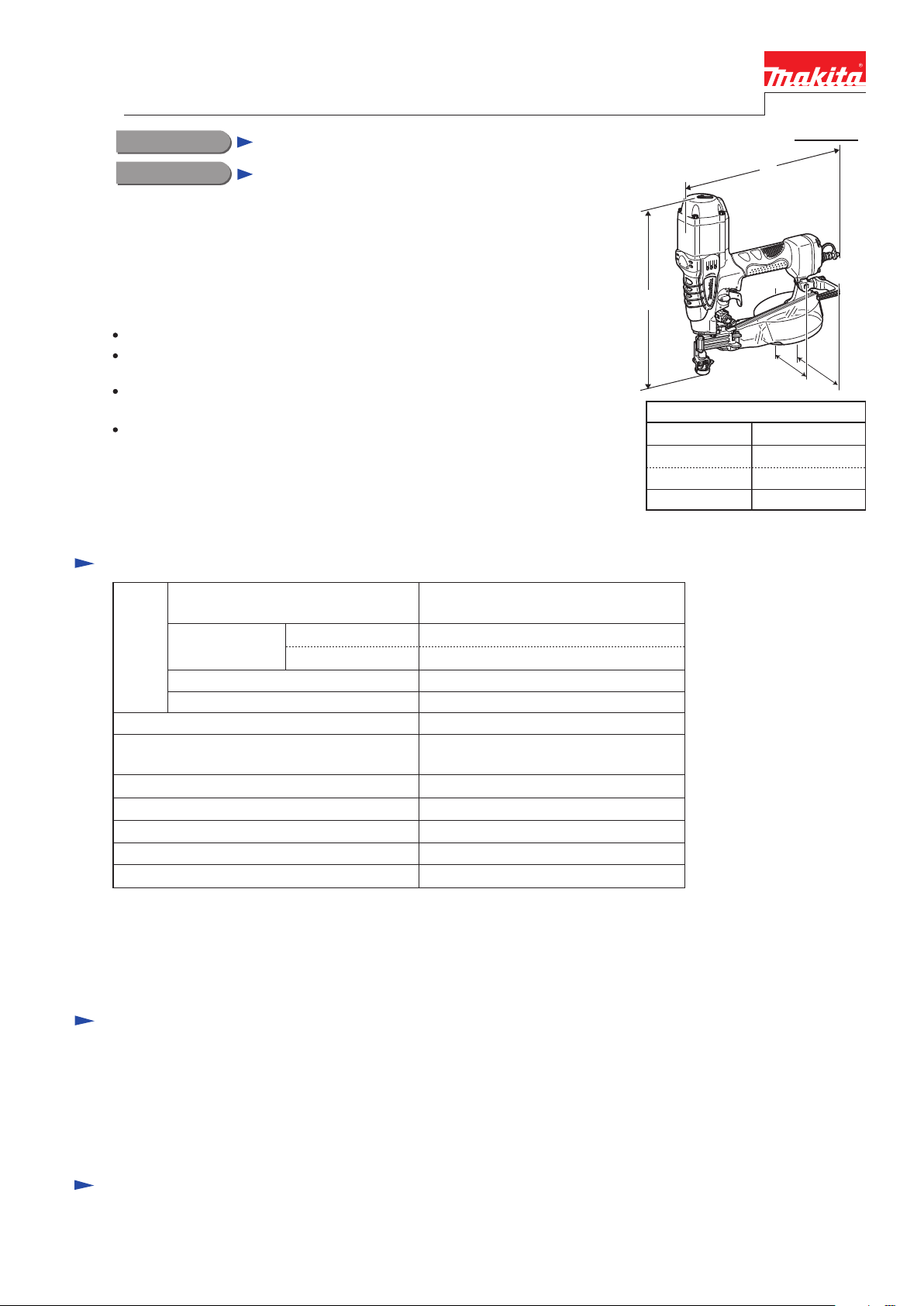

AR410HR

Pneumatic Auto Feed Coil Screwdriver

Model AR410HR is a pneumatic screwdriver powered by high pressure air.

Drives coil type collated drywall screws exactly to depth and fastens plasterboard

securely to wood/metal drywall stud.

Its main benefits are:

Compact body for easy handling and high maneuverability

High power allowing to fasten plasterboard securely to metal stud

of even 0.8mm thick steel plate without unseated screw

Optimum for operation in job sites among residential area

thanks to low-noise air exhaust

Rigid contact arm enabling to make fine finish constantly

Dimensions: mm

Width 2 (W2)

Height (H)

Length (L) 296

142Width 1 (W1)

Width 1: with Hook

Width 2: without Hook

116

305

W2

W1

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

Hook ................................................................. 1

Safety goggles ................................................... 1

Oil supply (containing 30ml of turbine oil) ...... 1

Hex wrench 4 ................................................... 1

Driver bit .......................................................... 1

Plastic carrying case ......................................... 1

Plastic sheet collated drywall screws (coil type)

[3.5mm shank diameter: 25, 28, 41mm; 3.8mm shank diameter: 25, 28, 32, 41mm]

Air hose

Air leak repair set

Screws per coil 100 screws

Net weight: kg

Magazine capacity

Screw

Operating air pressure: MPa

(kgf/cm2)

1.9

100 screws

1.76 - 2.26

(18 - 23)

25, 28, 32, 41

Plastic sheet collated drywall screws

(coil type)

Pressure regulator valve Yes

Length: mm

3.8 (Coarse thread)

3.5 (Fine thread)

Shank diameter:

mm

Wood backing

Metal backing

Screw type

L

H

*1: Screws can be driven one after the other continuously first by pulling Trigger then by

bumping Contact arm against workpiece with the Trigger being pulled.

*2: One screw is driven first by pushing Contact arm against workpiece, then by pulling

Trigger with the Contact arm kept pushed; screw cannot be driven when the steps are

reversed. Another one can be driven by releasing Trigger, then by repeating the steps;

however, cannot be driven if Trigger is not released before repetition of the steps.

Driving depth adjustment

Trigger lock-off function

Fire mechanism

Yes (by dial)

Yes

Bump-fire*1/ Sequential*2

P 2/20

Repair

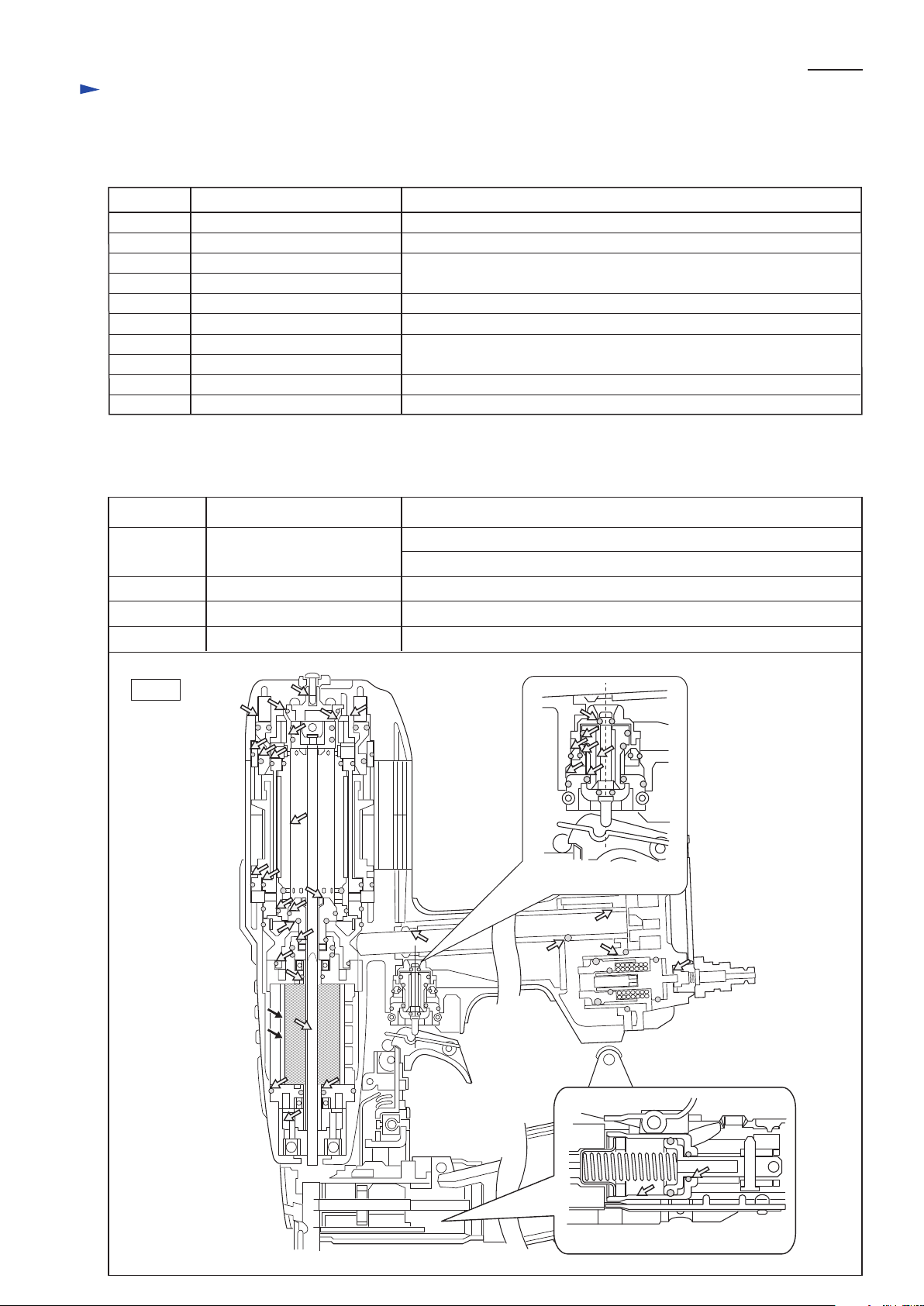

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

Fig. 1

Code No. Description Use for

1R003 Retaining ring S pliers ST-2N Removing Pipe 13

1R027 Bearing setting pipe 18-10.2 Assembling Rotor

1R045 Gear extractor (large)

1R346 Center attachment for 1R045

Disassembling Rotor

1R229 1/4” Hex. shank bit for M5 Screwing/unscrewing M5 Hex socket head bolt

1R266 Spring pin extractor 2 Disassembling Adjuster complete and Adjuster shaft

1R273 Ring spring 26 setting tool B Assembling Air Motor section

1R291 Retaining ring S & R pliers Disassembling/assembling Retaining ring R-24 from/to Feed piston

1R267 Spring pin extractor 2.5

Disassembling Trigger and Idler

1R268 Spring pin extractor 3

Item No.

Apply ISOFLEX NB52 to the portions designated with the white arrow, and apply lubricant VG32 to the portions

designated with black arrow, to protect parts and product from unusual abrasion.

Description Portion to lubricate

CAUTION: Disconnect the air hose from the machine and then remove remaining screws for

safety before repair/ maintenance in accordance with the instruction manual!

Trigger valve section

Inlet section

Drive section

Nail drive section

Trigger valve section

Inlet section Plug, Inlet cap, etc.

Nail feed piston section Cup washer, O rings, etc.

O rings, Trigger valve case, Trigger stem, Pilot valve, etc.

Cylinder, O rings, Driver bit set, etc.

Air Motor (Apply lubricant “VG32” to the Drum portion of Air motor.)

Air motor

Nail feed piston section

P 3/20

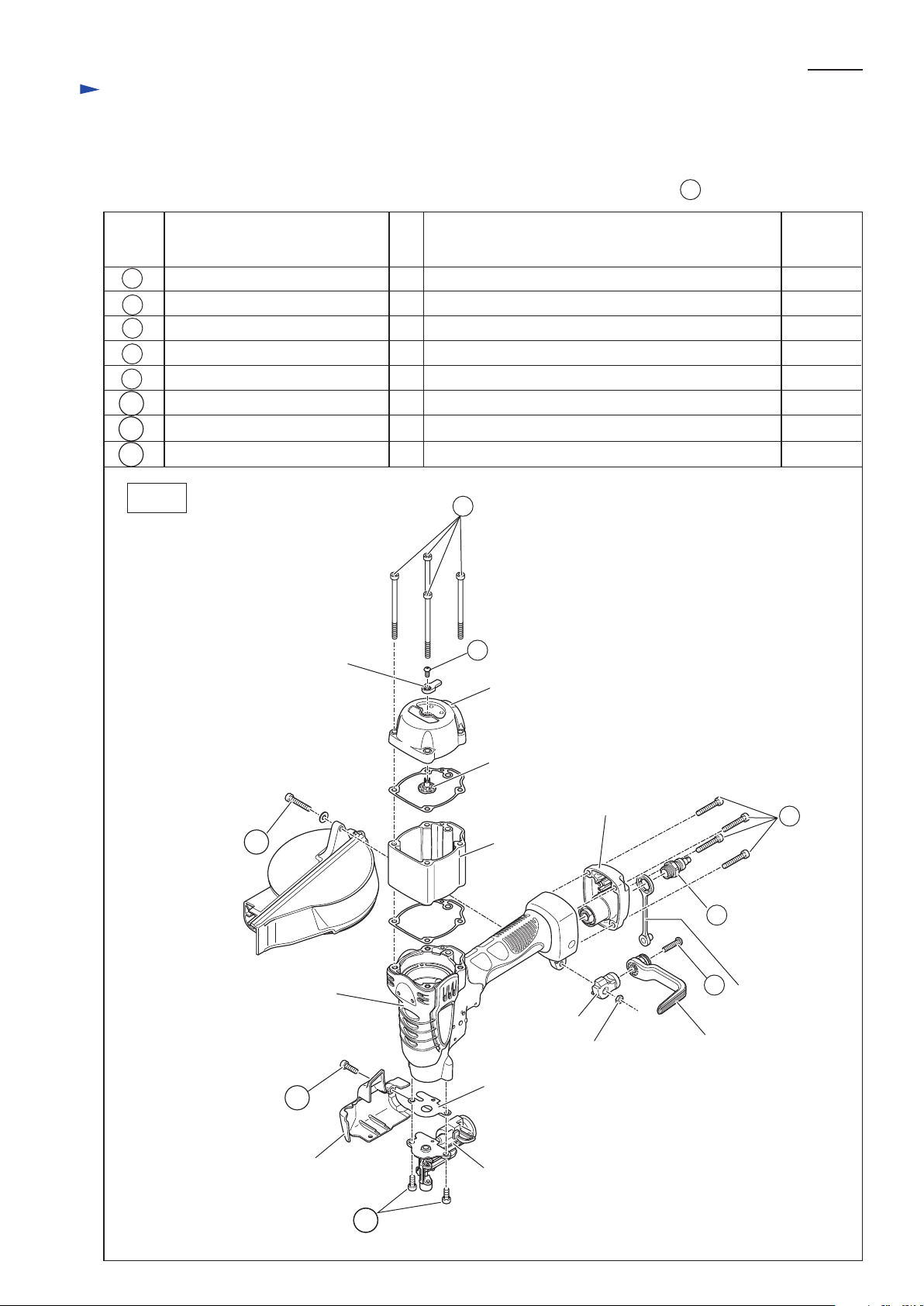

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Fastening Torque for Bolts ans Scerws

Tighten the bolts and scerws to the required fastening torque.

* Apply a little amount of Loctite 242 or Three Bond 1321/1342 to the threaded portion of 77 Plug.

Fig. 2

Item No. Description

M5x80 Hex socket head bolt

M4x8 Hex socket button head bolt

M5x28 Hex socket head bolt

M5x30 Hex socket head bolt

Threaded portion of Plug

M5x22 Pan head screw

M5x16 Hex socket head bolt

M5x12 Hex socket head bolt

Fastening

torque

(N.m)

Q’ty

4

Used for

Fastening Top cap and Top cap spacer to Housing

1 Fastening Knob to Change valve

1 Fastening Magazine and Hook base to Housing

4 Fastening Inlet cap to Housing

1 Fastening Inlet and Inlet cap 9 to Housing

1 Fastening Hook to Hook base

1 Fastening Contact arm cover to Driver guide complete

2

8.0

2.5

2.5

8.0

7.0

2.5

2.5

8.0Fastening Driver guide complete to Housing

1

3

76

Contact arm cover

121

Driver guide complete

Driver guide gasket

Housing

M5 Hex nut

Change valve

Hook base

93

Hook

Cap 9

Inlet cap

Knob

Top cap

Top cap spacer

1

3

128

76

77

93

119

121

121

128

77

119

Compression

spring 4 (8 pcs)

P 4/20

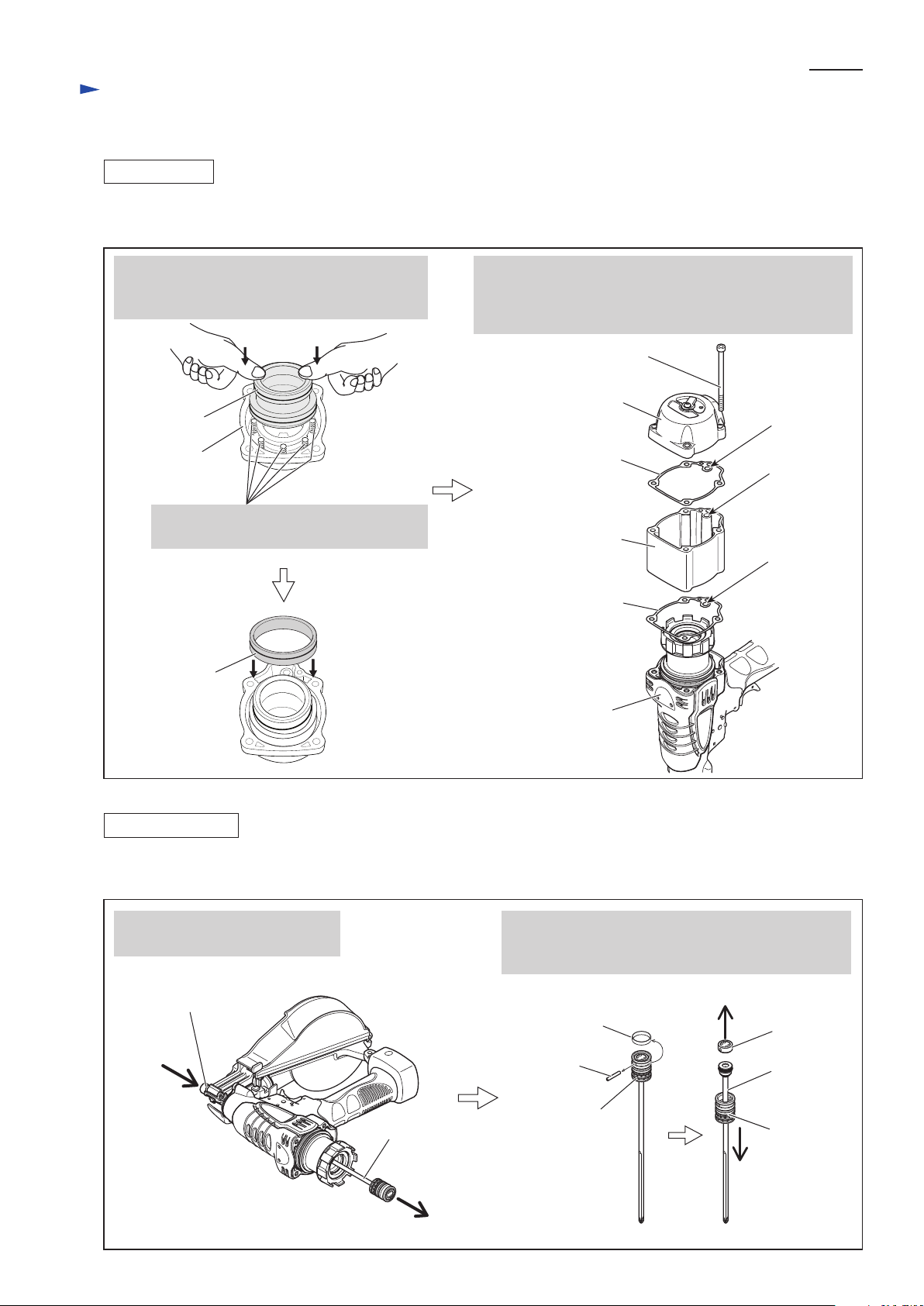

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Top Cap Section

1) After removing Top cap and Top cap spacer from Housing, remove Head valve and Cylinder stay from Top cap

using air duster to blow air into the space between Top cap and Head valve using air pressure. (Fig. 3)

2) Remove Knob from Top cap, then disassemble the other parts from Top cap as illustrated in Fig. 4.

DISASSEMBLING

Cylinder stay

Head valve

1. By removing four M5x80 Hex socket head bolts

using 1R299, separate Top cap, Top cap spacer

and Top cap gasket from Housing. Then remove

Top cap and the other Top cap gasket from

Top cap spacer.

2. Turn Top cap upside down, then press down Head valve

and Cylinder stay firmly into Top cap with your palm

to make the air pressure as possible.

While pressing down Head valve and Cylinder stay,

insert nozzle of air duster into the hole of Top cap.

M4x8 Hex socket

button head bolt

(1 pc)

Cylinder stay

Head valve

Knob

By removing M4x8 Hex socket button head bolt and Knob,

the inner parts can be removed from Top cap as illustrated below.

Conical compression spring 10-15

O Ring 6

Change valve

Fig. 3

Fig. 4

Flat washer 19

Rear cushion

O Ring 22

Seal ring 22

Top cap

M5x80

Hex socket

head bolt

(4 pcs)

Top cap gasket

Top cap spacer

Insert nozzle of air duster

into this hole.

3. By blowing air into the space between Top cap and

Head valve through the hole, Cylinder stay and

Head valve can be separated from Top cap.

Nozzle of air duster

Top cap

P 5/20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Top Cap Section

1) Assemble Top cap section as described in Figs. 5, 6.

2) Assemble O rings to Cylinder stay and Head valve as described in Fig. 7.

ASSEMBLING

Fig. 5

Fig. 6 Fig. 7

click-stop concave

portion

protrusion

Knob

Set Knob on Top cap, with the protrusion on

its back fitting in either click-stop concave

portions on Top cap.

Then assemble O ring 6 to the insertion hole

for Change valve.

Assemble Conical compression spring 10-15 to Top cap

with the small end on Change valve side.

Then assemble Change valve to Top cap.

Note: When assembling Change valve to Top cap, place the

notch on the front side of Top cap as illustrated below

so that Change valve can engage with Knob easily.

Top cap

O Ring 6

Front side

Rear side

Change valve

Conical compression

spring 10-15

Knob

M4x8 Hex socket

button head bolt

Top cap

Seal ring

O Ring 54

Before assembling Cylinder stay and Head valve

to Top cap, mount O rings to them as illustrated

below, then apply such an amount of IDOFLEX

grease that they are covered with a thick layer of

the grease.

After mounting O ring 22 and Flat washer 19 on Rear cushion,

assemble Rear cushion to Top cap, then assemble Seal ring to

Top cap.

Set Compression spring 4 (8 pcs)

in the big diameter holes of Top cap.

Cylinder stay

Head valve

O Ring 47

O Ring 40

O Ring 45

Front side

notch

Rear side

Flat washer 19

Rear cushion

O Ring 22

Top cap

Compression

spring 4

P 6/20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Top Cap Section

3) Assemble Head valve and Cylinder stay to Top cap (left in Fig. 8); assembling of Top cap section is now completed.

Then assemble Top cap section, Top cap spacer and Top cap gasket to Housing as illustrated on right in Fig. 8.

Fig. 8

Head valve

Top cap gasket

Top cap section

M5x80 Hex socket

head Bolt (4 pcs)

Top cap gasket

Housing

Top cap spacer

Assemble Head valve by pressing straight down

into Top cap.

Then assemble Cylinder stay to Top cap.

Top cap

Driver bit

Remove Driver bit by pushing it

from Driver guide complete side.

After removing Rubber ring 19 (white), pull off Pin 3.

Main piston and Piston cap can now be removed

as illustrated below.

Driver guide complete

Rubber ring 19

(white)

Main piston

Piston cap

Pin 3

Driver bit

Main piston

Fig. 9

[3]-3. Driver Bit

1) Disassemble Top cap and Top cap spacer from Housing as described on left in Fig. 3.

2) Disassemble Driver bit as described in Fig. 9.

ASSEMBLING

DISASSEMBLING

Note: Be careful not to fall down the eight

Compression springs set in Top cap.

Cylinder stay

Top cap spacer and two Top cap gaskets are directional

when assembled to Housing.

Make sure that the holes A, B, C are aligned with the hole

of Housing.

A

B

C

Loading...

Loading...