Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Pneumatic Framing Nailer

Cloueuse Pneumatique

Clavador neumático de marcos

AN923

AN943

007004

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

Page 2

ENGLISH

SPECIFICATIONS

Model AN923 AN943

Air pressure

Nail length 50 mm (2”) - 90 mm (3-1/2”)

Nail capacity 64 - 74 pcs. 60 - 84 pcs.

Min. hose diameter 8.5 mm (5/16”)

Dimensions (L X H X W)

Net weight 3.9 kg (8.7 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

559 mm X 347 mm X 109 mm

(22” X 13-11/16” X 4-1/4”)

4.5 - 8.5 kgf/cm2G (65 - 120 PSIG)

455 mm X 365 mm X 109 mm

(17-7/8” X 14-3/8” X 4-1/4”)

IMPORTANT SAFETY

INSTRUCTIONS

USB086-1

WARNING: WHEN USING THIS TOOL,

BASIC SAFETY PRECAUTIONS SHOULD

ALWAYS BE FOLLOWED TO REDUCE

THE RISK OF PERSONAL INJURY,

INCLUDING THE FOLLOWING:

READ ALL INSTRUCTIONS.

1. For personal safety and proper operation and

maintenance of the tool, read this instruction

manual carefully before using the tool.

2. Always wear safety glasses to protect your eyes

from dust or nail injury. The safety glasses

should conform with the requirements of ANSI

Z87.1.

WARNING:

It is an employer's responsibility to enforce the

use of safety eye protection equipment by the

tool operators and by other persons in the immediate working area.

3. Wear hearing protection to protect your ears

against exhaust noise and head protection. Also

wear light but not loose clothing. Sleeves should

be buttoned or rolled up. No necktie should be

worn.

4. Rushing the job or forcing the tool is dangerous.

Handle the tool carefully. Do not operate when

under the influence of alcohol, drugs or the like.

5. General Tool Handling Guidelines:

(1) Always assume that the tool contains fas-

teners.

(2) Do not point the tool toward yourself or any-

one whether it contains fasteners or not.

(3) Do not actuate the tool unless the tool is

placed firmly against the workpiece.

(4) Respect the tool as a working implement.

(5) No horseplay.

(6) Do not hold or carry the tool with a finger on

the trigger.

(7) Do not load the tool with fasteners when any

one of the operating controls is activated.

(8) Do not operate the tool with any power

source other than that specified in the tool

operating/safety instructions.

6. An improperly functioning tool must not be

used.

7. Sparks sometimes fly when the tool is used. Do

not use the tool near volatile, flammable materials such as gasoline, thinner, paint, gas, adhesives, etc.; they will ignite and explode, causing

serious injury.

8. The area should be sufficiently illuminated to

assure safe operations. The area should be clear

and litter-free. Be especially careful to maintain

good footing and balance.

9. Only those involved in the work should be in the

vicinity. Children especially must be kept away at

all times.

10. There may be local regulations concerning noise

which must be complied with by keeping noise

levels within prescribed limits. In certain cases,

shutters should be used to contain noise.

11. Do not play with the contact element: it prevents

accidental discharge, so it must be kept on and

not removed. Securing the trigger in the ON

position is also very dangerous. Never attempt

to fasten the trigger. Do not operate a tool if any

2

Page 3

portion of the tool operating controls is inoperable, disconnected, altered, or not working properly.

12. Operate the tool within the specified air pressure

on the tool label for safety and longer tool life.

Do not exceed the recommended max. operating

pressure. The tool should not be connected to a

source whose pressure potentially exceeds 14.0

2

kgf/cm

G (200 PSIG).

13. Never use the tool with other than compressed

air. If bottled gas (carbon dioxide, oxygen, nitrogen, hydrogen, air, etc.) or combustible gas

(hydrogen, propane, acetylene, etc.) is used as a

power source for this tool, the tool will explode

and cause serious injury.

14. Always check the tool for its overall condition

and loose screws before operation. Tighten as

required.

15. Make sure all safety systems are in working

order before operation. The tool must not operate if only the trigger is pulled or if only the contact element is pressed against the wood. It must

work only when both actions are performed. Test

for possible faulty operation with nails unloaded

and the contact element in fully pulled position.

16. Make sure that the trigger is locked when the

change lever is set to the LOCK position.

17. Check walls, ceilings, floors, roofing and the like

carefully to avoid possible electrical shock, gas

leakage, explosions, etc. caused by striking live

wires, conduits or gas pipes.

18. Use only nails specified in this manual. The use

of any other nails may cause malfunction of the

tool.

19. Do not permit those uninstructed to use the tool.

20. Make sure no one is nearby before nailing. Never

attempt to nail from both the inside and outside

at the same time. Nails may rip through and/or

fly off, presenting a grave danger.

21. Watch your footing and maintain your balance

with the tool. Make sure there is no one below

when working in high locations, and secure the

air hose to prevent danger if there is sudden

jerking or catching.

22. On rooftops and other high locations, nail as you

move forward. It is easy to lose your footing if

you nail while inching backward. When nailing

against perpendicular surface, nail from the top

to the bottom. You can perform nailing operations with less fatigue by doing so.

23. A nail will be bent or the tool can become

jammed if you mistakenly nail on top of another

nail or strike a knot in the wood. The nail may be

thrown and hit someone, or the tool itself can

react dangerously. Place the nails with care.

24. Do not leave the loaded tool or the air compressor under pressure for a long time out in the sun.

Be sure that dust, sand, chips and foreign matter

will not enter the tool in the place where you

leave it setting.

25. Do not point the ejection port at anyone in the

vicinity. Keep hands and feet away from the ejection port area.

26. When the air hose is connected, do not carry the

tool with your finger on the trigger or hand it to

someone in this condition. Accidental firing can

be extremely dangerous.

27. Handle the tool carefully, as there is high pressure inside the tool that can be dangerous if a

crack is caused by rough handling (dropping or

striking). Do not attempt to carve or engrave on

the tool.

28. Stop nailing operations immediately if you

notice something wrong or out of the ordinary

with the tool.

29. Always disconnect the air hose and remove all of

the nails:

(1) When unattended.

(2) Before performing any maintenance or

repair.

(3) Before cleaning a jam.

(4) Before moving the tool to a new location.

30. Perform cleaning and maintenance right after

finishing the job. Keep the tool in tip-top condition. Lubricate moving parts to prevent rusting

and minimize friction-related wear. Wipe off all

dust from the parts.

31. When not operating the tool, always lock the trigger by turning the change lever to the LOCK

position.

32. Do not modify tool without authorization from

Makita.

33. Do not attempt to keep the trigger or contact element depressed with tape or wire. Death or serious injury may occur.

34. Always check contact element as instructed in

this manual. Nails may be driven accidentally if

the safety mechanism is not working correctly.

35. Ask Makita's Authorized service centers for periodical inspection of the tool.

36. To maintain product SAFETY and RELIABILITY,

maintenance and repairs should be performed

by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

3

Page 4

SYMBOLS

The followings show the symbols used for tool.

....................Read and understand tool labels and

manual.

....................Operators and others in work area

must wear safety glasses with side

shields.

....................Keep fingers away from trigger when

not driving fasteners to avoid accidental firing.

INSTALLATION

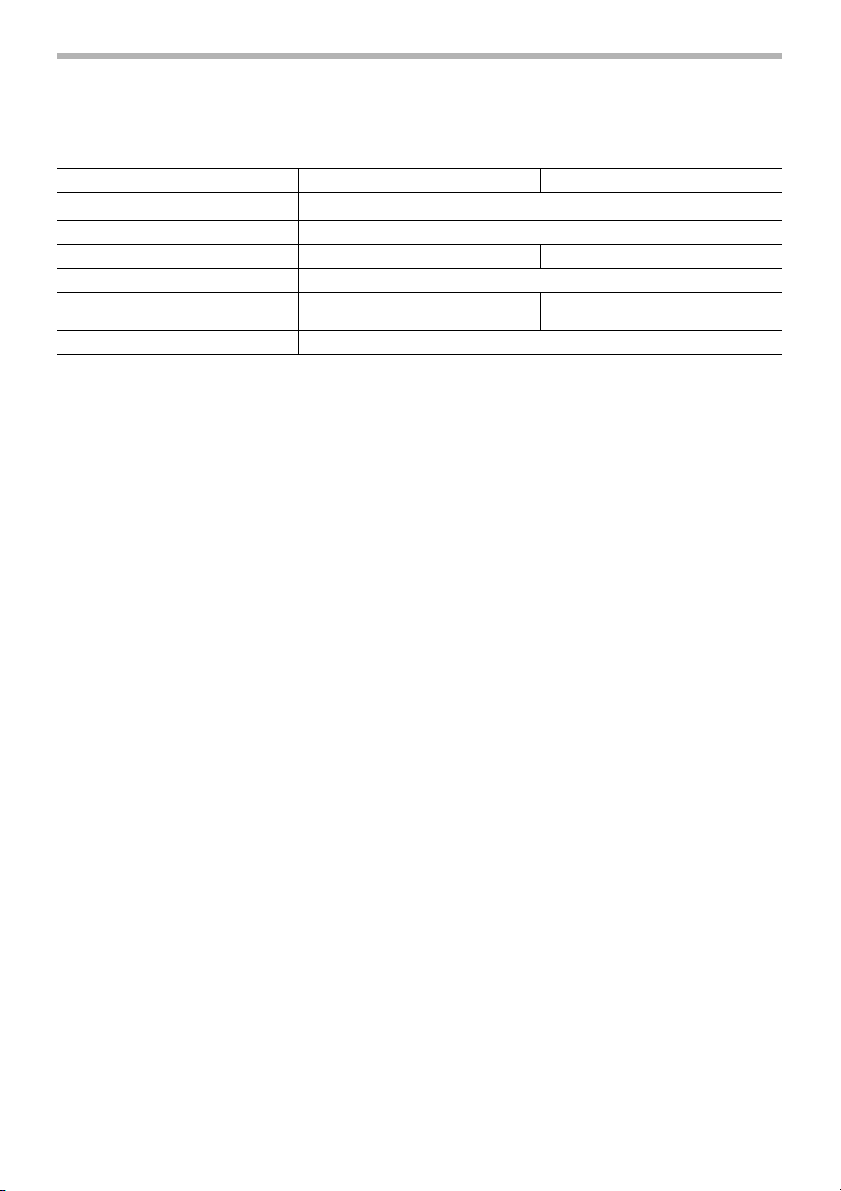

Selecting compressor

3

(ft /min.)

4

3

2

Compressor air output per minute

1

2

8.5kgf/cm G(120PSIG)

7.0kgf/cm G(100PSIG)

4.5kgf/cm G(65PSIG)

005686

2

2

2

6.0kgf/cm G(85PSIG)

USD501-1

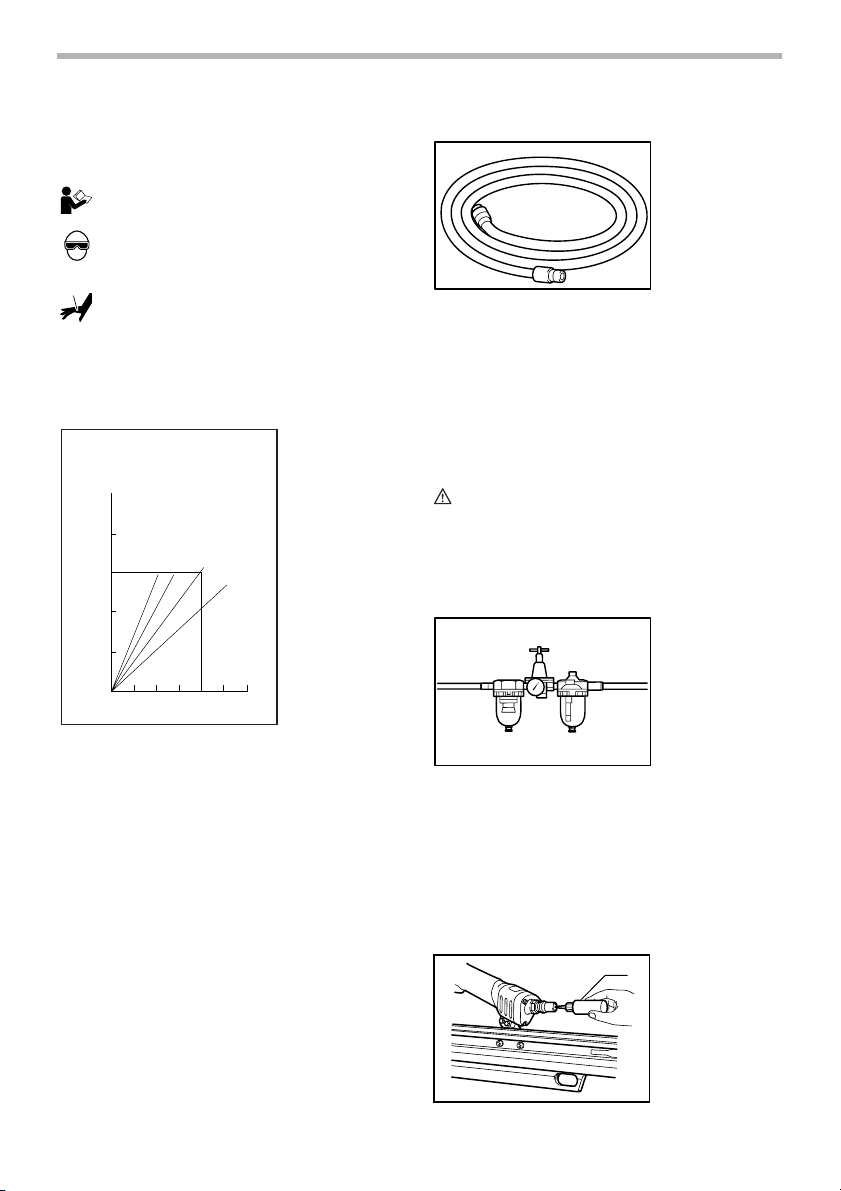

Selecting air hose

Use an air hose as large and as short as possible to

assure continuous, efficient nailing operation. With an air

pressure of 5.0 kgf/cm

internal diameter of over 8.5 mm (5/16”) and a length of

less than 20 m (6.6 ft.) is recommended when the inter-

004294

2

G (70 PSIG), an air hose with an

val between each nailing is 0.5 seconds. Air supply

hoses shall have a minimum working pressure rating of

10.7 kgf/cm

2

G (150 PSIG) or 150 percent of the maximum pressure produced in the system whichever is

higher.

CAUTION:

• Low air output of the compressor, or a long or

smaller diameter air hose in relation to the nailing

frequency may cause a decrease in the driving

capability of the tool.

Lubrication

004295

0102030405060

Nailing frequency (times/min)

The air compressor must comply with the requirements

of ANSI B19.3.

Select a compressor that has ample pressure and air

output to assure cost-efficient operation. The graph

shows the relation between nailing frequency, applicable

pressure and compressor air output.

Thus, for example, if nailing takes place at a rate of

approximately 40 times per minute at a compression of

6.0 kgf/cm

over 3 ft

2

G (85 PSIG), a compressor with an air output

3

/minute is required.

Pressure regulators must be used to limit air pressure to

the rated pressure of the tool where air supply pressure

exceeds the tool’s rated pressure. Failure to do so may

result in serious injury to tool operator or persons in the

vicinity.

To insure maximum performance, install an air set (oiler,

regulator, air filter) as close as possible to the tool. Adjust

the oiler so that one drop of oil will be provided for every

30 nails.

When an air set is not used, oil the tool with pneumatic

tool oil by placing 2 (two) or 3 (three) drops into the air fitting. This should be done before and after use. For

proper lubrication, the tool must be fired a couple of

times after pneumatic tool oil is introduced.

007005

1. Pneumatic tool

1

oil

4

Page 5

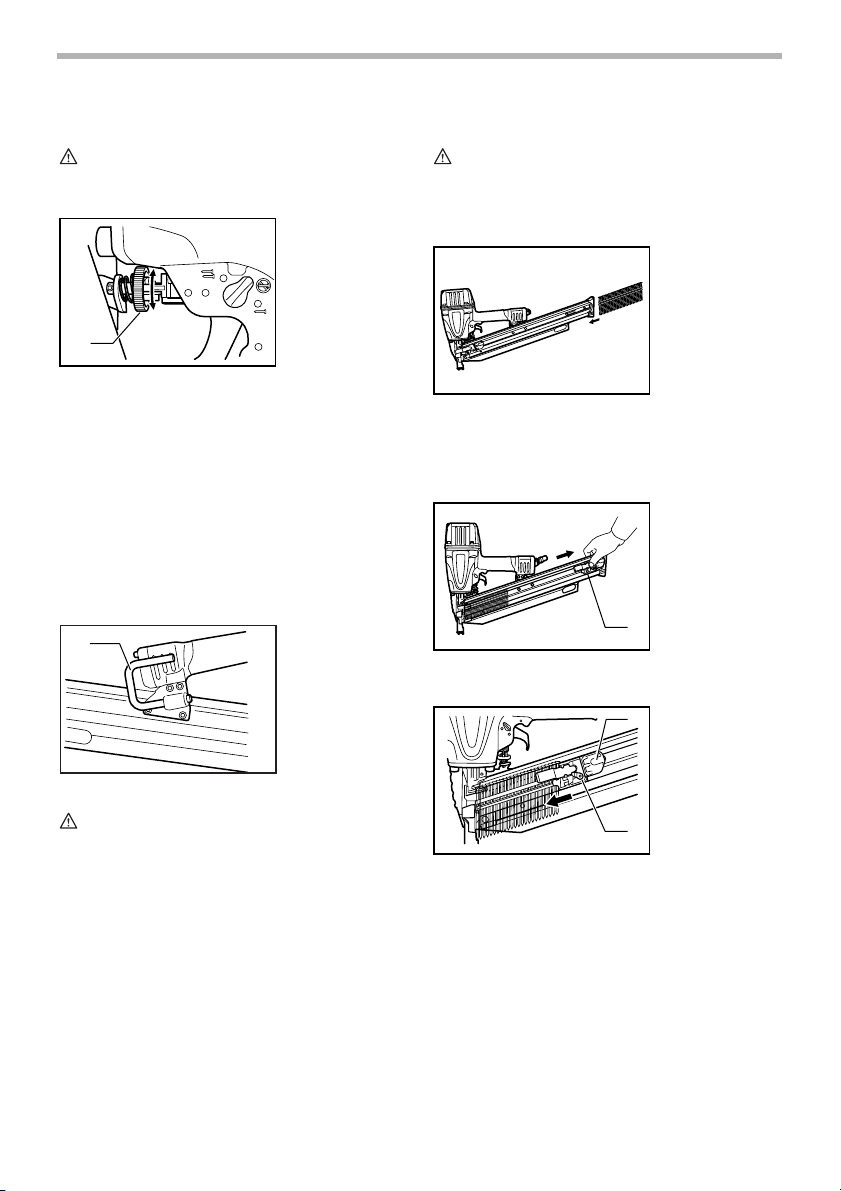

FUNCTIONAL DESCRIPTION

ASSEMBLY

CAUTION:

• Always lock the trigger and disconnect the hose

before adjusting or checking function on the tool.

A

1

To adjust the depth of nailing, turn the adjuster. The

depth of nailing is the deepest when the adjuster is

turned fully in the A direction shown in the figure. It will

become shallower as the adjuster is turned in the B

direction. If nails cannot be driven deep enough even

when the adjuster is turned fully in the A direction,

increase the air pressure. If nails are driven too deep

even when the adjuster is turned fully in the B direction,

decrease the air pressure. Generally speaking, the tool

service life will be longer when the tool is used with lower

air pressure and the adjuster set to a lower depth of nail

driving.

B

Hook

1

007006

1. Adjuster

007062

1. Hook

CAUTION:

• Always lock the trigger and disconnect the hose

before carrying out any work on the tool.

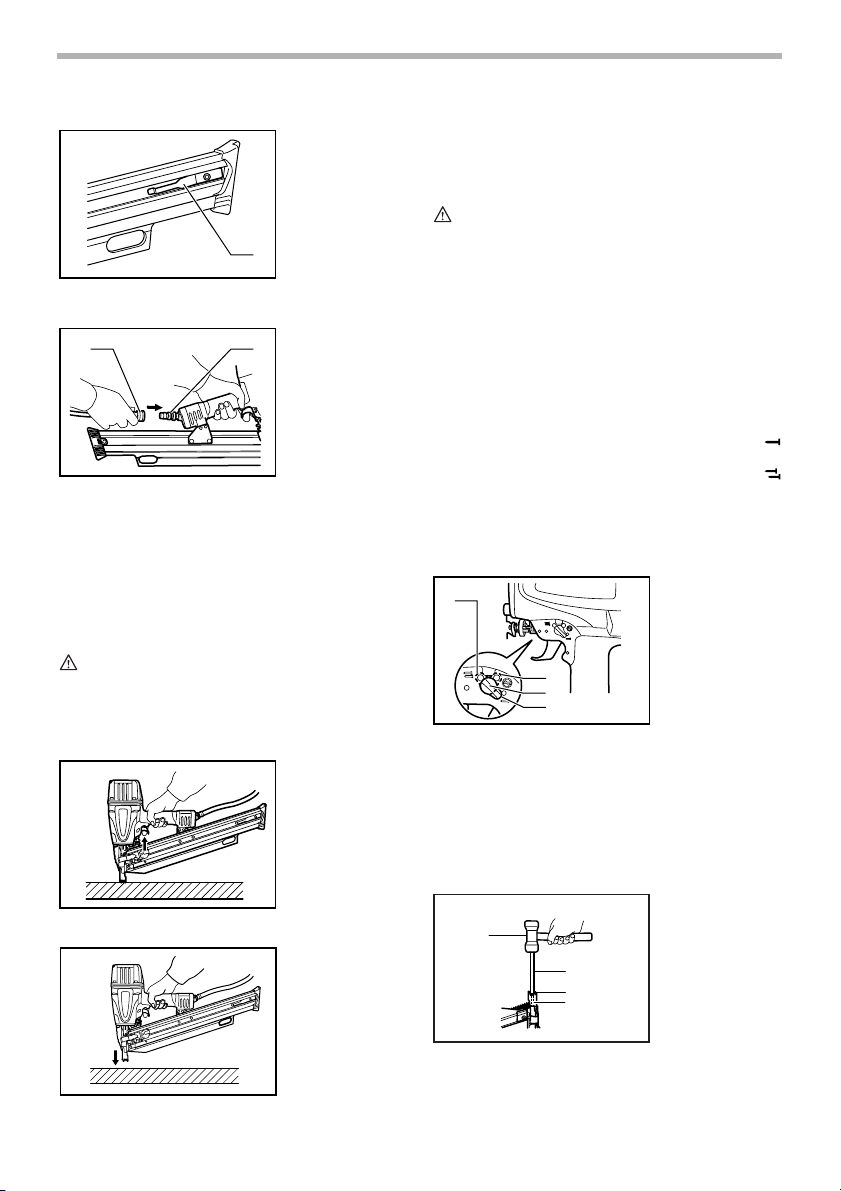

Loading nailer

Select nails suitable for your work. Insert strip of nails

into the magazine.

Pull the pusher lever to the rear to engage the pusher to

the last nail.

Unloading nailer

007007

007008

1

007009

1

1. Pusher

1. Pusher lever

2. Depress

3. Return

CAUTION:

• Always lock the trigger and disconnect the hose

from the tool.

• Never hook the tool at high location or on potentially

unstable surface.

The hook is convenient for hanging the tool temporarily.

To use the hook, simply lift up hook until it snaps into the

open position.

When not in use, always lower hook until it snaps into the

closed position.

3

2

Pull the pusher lever to the rear. Return the pusher lever

back while keeping the pusher depressed to disengage it

from the strip of nails.

Depress the nail stopper and remove the strip of nails

from the magazine.

5

Page 6

007010

1. Nail stopper

1

Connecting air hose

1

007011

2

1. Air socket

2. Air fitting

Lock the trigger. Slip the air socket of the air hose onto

the air fitting on the nailer. Be sure that the air socket

locks firmly into position when installed onto the air fitting. A hose coupling must be installed on or near the tool

in such a way that the pressure reservoir will discharge at

the time the air supply coupling is disconnected.

OPERATION

CAUTION:

• Make sure all safety systems are in working order

before operation.

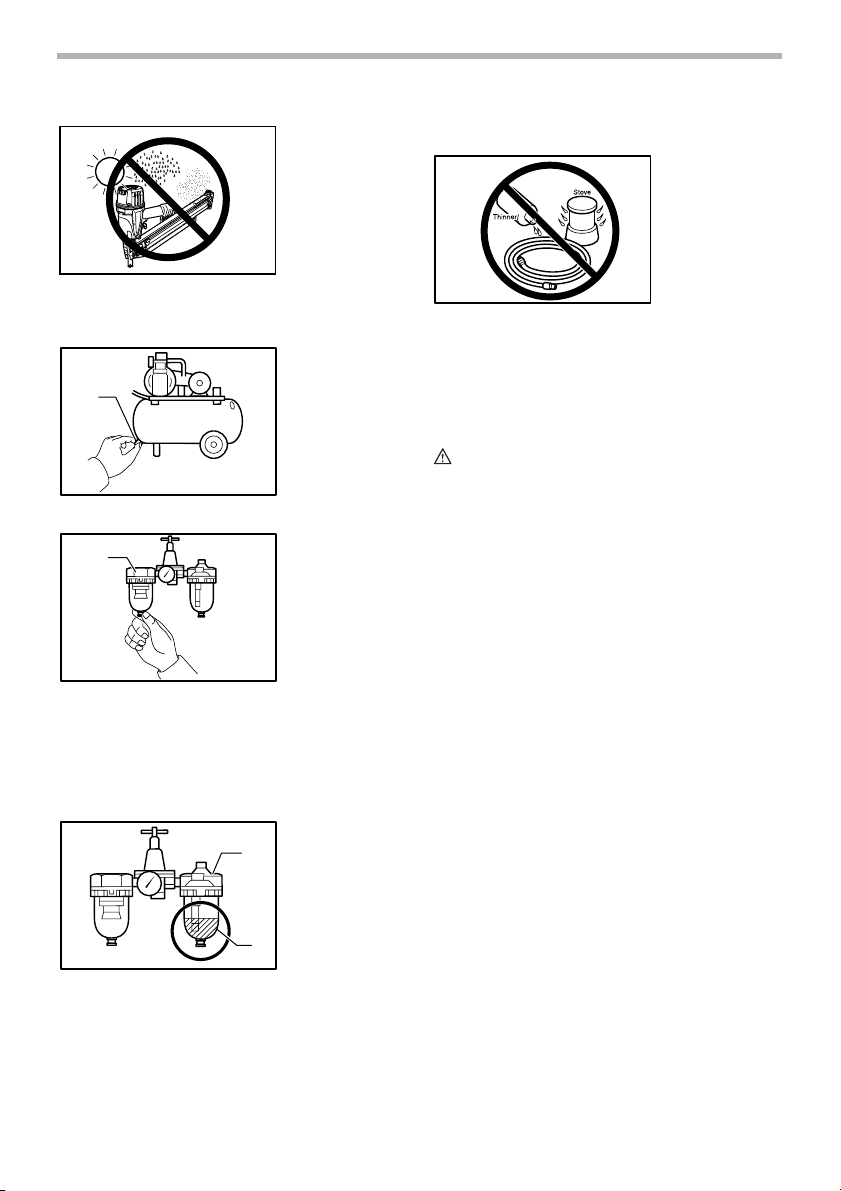

1. To drive a nail, you may place the contact element

against the workpiece and pull the trigger, or

1

2

007012

007013

2. Pull the trigger first and then place the contact ele-

ment against the workpiece.

• No. 1 method is for intermittent nailing, when you

wish to drive a nail carefully and very accurately.

No. 2 method is for continuous nailing.

CAUTION:

• However when the tool is set to the “Intermittent

Nailing” mode, WITH THE TRIGGER HELD IN A

HALF-PULLED POSITION, an unexpected nailing

could occur, if contact element is allowed to re-contact against the workpiece or the other surface

under the influence of recoil.

In order to avoid this unexpected nailing, perform as

follows;

A. Do not place the contact element against the workpiece with excessive force.

B. Pull the trigger fully and hold it on for 1-2 seconds after

nailing.

• For No. 1 method, set the change lever to the

position.

For No. 2 method, set the change lever to the

position.

After using the change lever to change the nailing

method, always make sure that the change lever is

properly set to the position for the desired nailing

method.

1

007014

1. Continuous nailing

2. Trigger lock

3. Lock lever

4. Intermittent nail-

2

3

4

ing

Anti dry fire mechanism

This tool is equipped with an anti dry fire mechanism.

When there are a few nails remaining in the magazine,

the contact arm will be locked in the undepressed position to prevent the tool from being activated. Load more

nails to resume operation.

Jammed nailer

1

004308

1. Hammer

2. Small rod

3. Ejection port

2

3

4

4. Driver

6

Page 7

CAUTION:

• Always lock the trigger, disconnect the hose and

remove the nails from the magazine before clean-

ing a jam.

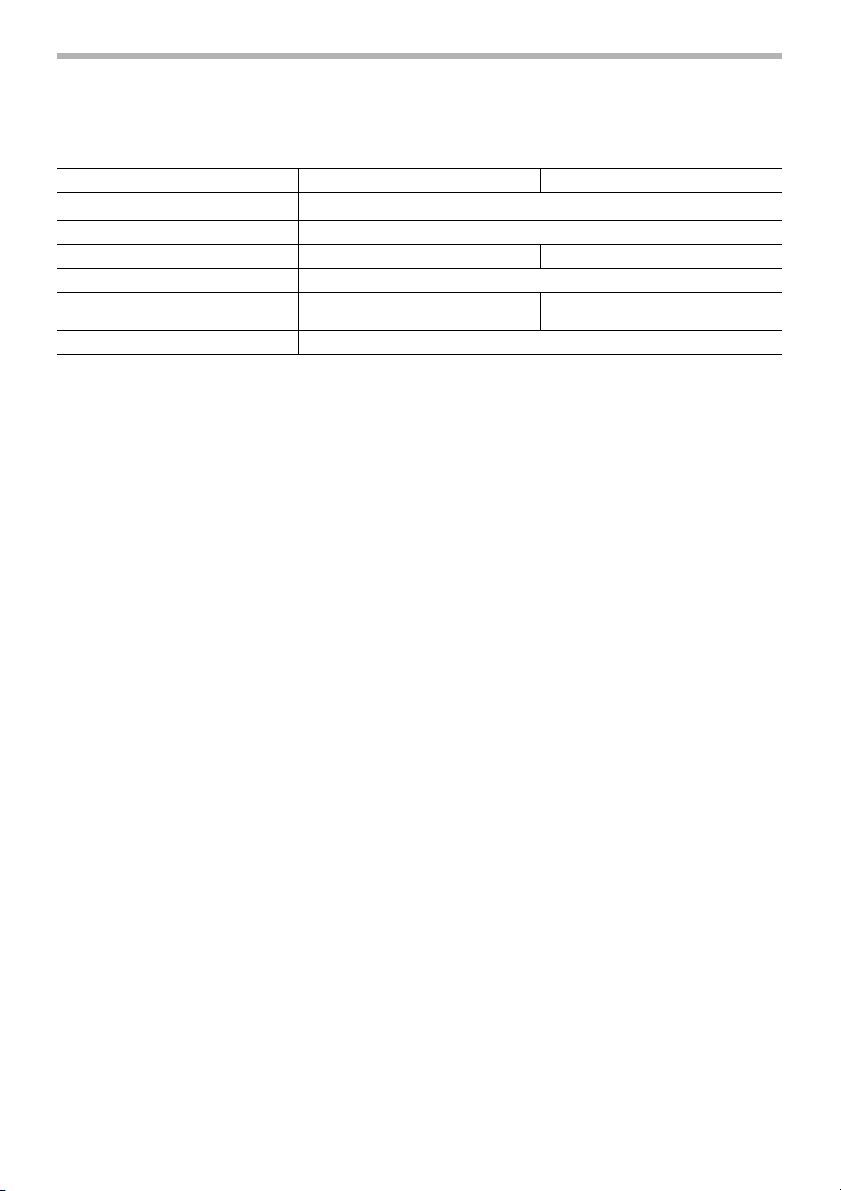

When the nailer becomes jammed, do as follows:

Insert a small rod or the like into the ejection port and tap

it with a hammer to retract the driver.

Use pliers to bend the jammed nail so that the nail head

comes out of the slot in the driver guide. Then remove

the jammed nail.

004309

1. Pliers

2. Slot

1

2

Maintenance of nailer

Always check the tool for its overall condition and loose

screws before operation. Tighten as required.

With tool disconnected, make daily inspection to assure

free movement of the contact element and trigger. Do not

use tool if the contact element or trigger sticks or binds.

007015

007016

Nails

004310

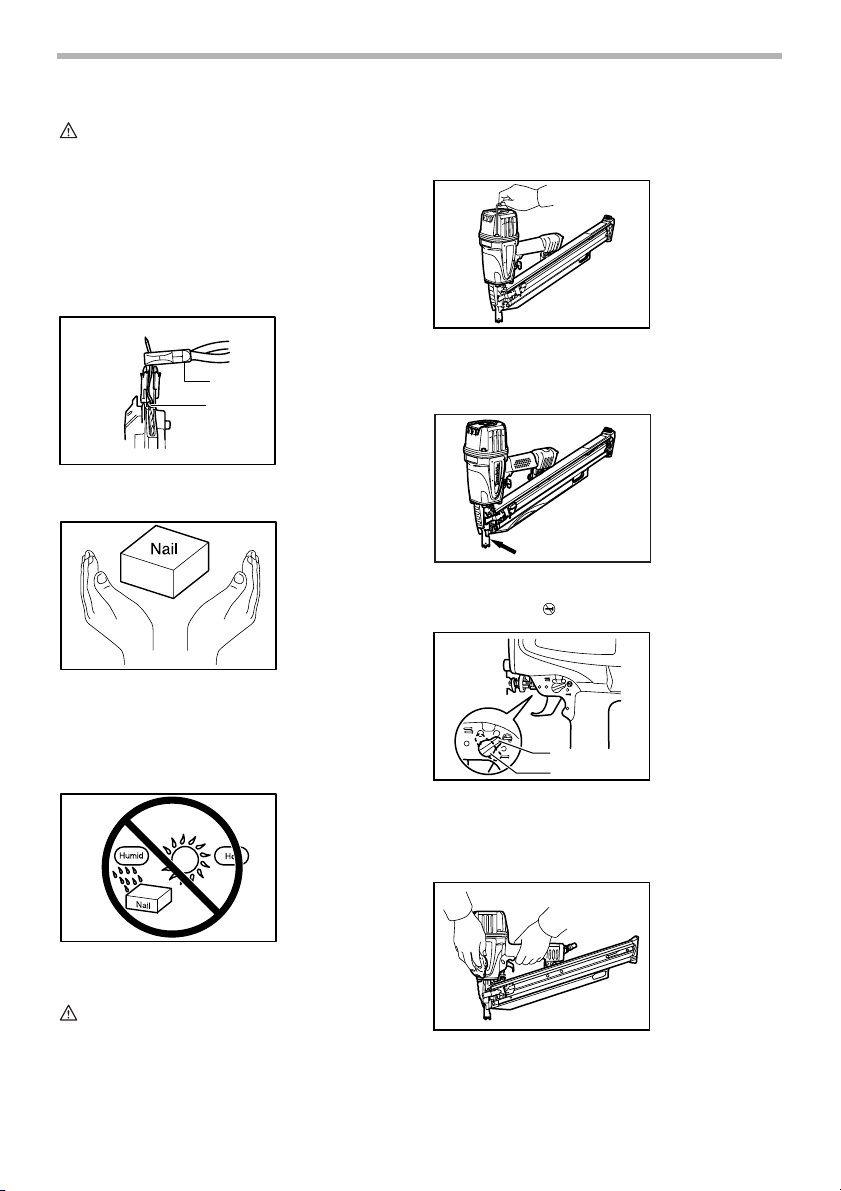

Handle nail coils and their box carefully. If the nail coils

have been handled roughly, they may be out of shape or

their connector breaks, causing poor nail feed.

Avoid storing nails in a very humid or hot place or place

exposed to direct sunlight.

004311

MAINTENANCE

CAUTION:

• Always disconnect the air hose from the tool before

attempting to perform inspection or maintenance.

Make sure that the trigger is locked when the change

lever is set to the position.

007017

1. Trigger lock

2. Change lever

1

2

When the tool is not to be used for an extended period of

time, lubricate the tool using pneumatic tool oil and store

the tool in a safe place. Avoid exposure to direct sunlight

and/or humid or hot environment.

007018

7

Page 8

000219

Maintenance of compressor, air set and air

hose

1

1

004317

1. Drain cock

004318

1. Air filter

Hoses must also be directed away from sharp edges and

areas which may lead to damage or abrasion to the hose.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be per-

004320

formed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recom-

mended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Nails

• Air hoses

• Safety goggles

After operation, always drain the compressor tank and

the air filter. If moisture is allowed to enter the tool, It may

result in poor performance and possible tool failure.

Check regularly to see if there is sufficient pneumatic oil

in the oiler of the air set. Failure to maintain sufficient

lubrication will cause O-rings to wear quickly.

004319

1. Oiler

2. Pneumatic oil

1

2

Keep the air hose away from heat (over 60°C, over

140°F), away from chemicals (thinner, strong acids or

alkalis). Also, route the hose away from obstacles which

it may become dangerously caught on during operation.

8

Page 9

FRANÇAIS

SPÉCIFICATIONS

Modèle AN923 AN943

Pression d’air

Longueur de clou 50 mm (2”) - 90 mm (3-1/2”)

Capacité de clouage 64 - 74 pcs. 60 - 84 pcs.

Diamètre min. du tuyau 8.5 mm (5/16”)

Dimensions (L x H x P)

Poids net 3.9 kg (8.7 lbs)

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

559 mm X 347 mm X 109 mm

(22” X 13-11/16” X 4-1/4”)

4.5 - 8.5 kgf/cm2G (65 - 120 PSIG)

455 mm X 365 mm X 109 mm

(17-7/8” X 14-3/8” X 4-1/4”)

IMPORTANTES CONSIGNES DE

SÉCURITÉ

USB086-1

AVERTISSEMENT : PAR MESURE DE

SÉCURITÉ, DES PRÉCAUTIONS DE

BASE DOIVENT ÊTRE PRISES LORS DE

L’UTILISATION DE CET OUTIL, AFIN DE

RÉDUIRE LES RISQUES DE BLESSURE.

CES MESURES COMPRENNENT LES

SUIVANTES :

LISEZ TOUTES LES INSTRUCTIONS.

1. Par mesure de sécurité personnelle et pour

assurer une utilisation et un entretien adéquats,

veuillez lire attentivement ce manuel

d’instructions avant d’utiliser l’outil.

2. Portez toujours des lunettes de sécurité pour

protéger vos yeux contre toute blessure au

contact de la poussière ou d’un clou. Les

lunettes de sécurité doivent répondre aux

exigences de la norme ANSI Z87.1.

AVERTISSEMENT:

L’employeur a la responsabilité d’imposer le port

d’un dispositif de protection des yeux aux

utilisateurs des outils et à toute personne

présente dans l’aire de travail.

3. Portez une protection d’oreilles pour les

protéger contre le bruit, et portez un casque de

sécurité. Les vêtements portés doivent être

légers et ne doivent pas être amples. Veuillez

boutonner ou rouler vos manches. Ne portez pas

de cravate.

4. Il est dangereux de travailler trop vite ou

d’appliquer une charge de travail excessive à

l’outil. Manipulez l’outil avec prudence. N’utilisez

pas l’outil si vous avez consommé de l’alcool,

des médicaments, etc.

5. Conseils généraux pour l’utilisation de l’outil :

(1) Considérez toujours que l’outil contient des

clous.

(2) QQu’il contienne ou non des clous, l’outil ne

doit jamais être pointé vers vous-même ou

vers une autre personne.

(3) Ne mettez pas l’outil en marche avant qu’il

ne soit fermement placé contre la pièce à

travailler.

(4) Respectez votre outil en tant qu’instrument

de travail.

(5) Évitez tout chahut.

(6) L’outil ne doit jamais être saisi ou transporté

avec le doigt posé sur la gâchette.

(7) Ne mettez jamais de clous dans l’outil alors

que l’une de ses commandes est activée.

(8) Ne branchez jamais l’outil sur une source

d’alimentation autre que celle spécifiée dans

les instructions d’utilisation et consignes de

sécurité qui l’accompagnent.

6. Il ne faut jamais utiliser un outil défectueux.

7. Des étincelles s’échappent parfois de l’outil

pendant son utilisation. N’utilisez pas l’outil près

de substances ou matériaux volatiles ou

inflammables tels que l’essence, le diluant, la

peinture, le gaz, les adhésifs, etc. Ils risqueraient

de prendre feu, d’exploser et de causer une

blessure grave.

8. L’aire de travail doit être suffisamment éclairée

pour assurer la sécurité du travail. L’aire de

travail doit être maintenue propre et exempte de

déchets. Prenez particulièrement soin d’avoir

une bonne assise et une bonne position

d’équilibre.

9

Page 10

9. Seules les personnes qui participent au travail

doivent se trouver dans l’aire de travail. Les

enfants, tout particulièrement, doivent être

maintenus à l’écart en tout temps.

10. Il se peut que des réglementations locales

s’appliquent concernant les niveaux de bruit

permis. Veuillez les respecter. Le cas échéant,

des volets doivent être installés pour réduire le

bruit.

11. Ne modifiez pas l’élément de contact. Il permet

de prévenir les déclenchements accidentels et

doit donc être laissé en place. Il est également

très dangereux de fixer la gâchette en position

de marche. Il ne faut jamais essayer

d’immobiliser la gâchette. N’utilisez jamais un

outil dont une des commandes est inutilisable,

déconnectée, modifiée ou ne fonctionne pas

correctement.

12. Faites fonctionner l’outil sans dépasser la

pression d’air spécifiée sur sa plaque

signalétique pour assurer votre sécurité et une

durée de service plus longue pour l’outil. Ne

dépassez jamais la pression maximale

recommandée. L’outil ne doit pas être connecté

à une source dont la pression potentielle

dépasse 14,0 kgf/cm

13. Cet outil doit être exclusivement utilisé avec de

l’air comprimé. L’utilisation d’une bouteille de

gaz (dioxyde de carbone, oxygène, nitrogène,

hydrogène, air, etc.) ou de gaz combustible

(hydrogène, propane, acétylène, etc.) comme

source de pression de cet outil entraînera une

explosion et risque de causer une blessure

grave.

14. Avant d’utiliser l’outil, assurez-vous qu’il est en

bon état et qu’aucune de ses vis n’est desserrée.

Le cas échéant, serrez les vis.

15. Assurez-vous que tous les dispositifs de

sécurité sont en état de fonctionner avant

d’utiliser l’outil. Il ne faut pas que l’outil s’active

lorsque vous appuyez uniquement sur la

gâchette ou si vous appliquez simplement

l’élément de contact contre le bois. Il ne doit

s’activer que lorsque ces deux actions sont

exécutées. Retirez les clous de l’outil et tirez

complètement l’élément de contact pour vérifier

l’absence de tout vice de fonctionnement.

16. Assurez-vous que la gâchette se verrouille

lorsque vous placez le levier de changement sur

la position LOCK.

17. Pour éviter tout risque de choc électrique, de

fuite de gaz, d’explosion, etc., provoqué par le

contact avec des fils dénudés, des conduites ou

des tuyaux de gaz, vérifiez le mur, le plafond, le

plancher, le toit ou toute autre pièce où vous

clouez.

2

G (200 PSIG).

18. Utilisez uniquement les clous spécifiés dans ce

manuel. L’outil risque de mal fonctionner si vous

utilisez tout autre type de clou.

19. Seules les personnes ayant pris connaissance

du fonctionnement de l’outil doivent être

autorisées à l’utiliser.

20. Avant de procéder au clouage, assurez-vous que

personne ne se trouve près de vous. N’essayez

jamais de clouer une pièce en même temps par

l’intérieur et par l’extérieur. Cela est très

dangereux, puisque les clous risquent alors de

défoncer la pièce ou d’être projetés.

21. Regardez où vous posez les pieds et assurezvous d’un bon équilibre pendant l’utilisation de

l’outil. Assurez-vous qu’il n’y a personne sous

vous lorsque vous travaillez dans un endroit

élevé, et fixez le tuyau d’air de sorte qu’il ne

risque pas de se détacher s’il est brusquement

secoué ou s’il se coince.

22. Sur les toits et autres endroits élevés, clouez en

vous déplaçant vers l’avant. Vous risquez de

perdre pied si vous clouez en vous déplaçant à

reculons. Lorsque vous clouez sur une surface

verticale, faites-le du haut vers le bas. De cette

façon le travail de clouage sera moins exigeant

physiquement.

23. Le clou risque de se plier ou l’outil de se bloquer

si vous clouez par inadvertance dans un nœud

ou sur un autre clou. Le clou risque alors d’être

projeté et de frapper quelqu’un, ou bien l’outil

lui-même risque de réagir de manière

dangereuse. Choisissez l’emplacement des

clous avec soin.

24. N’abandonnez pas pour une période prolongée

un outil chargé ou un compresseur d’air sous

pression exposé au soleil à l’extérieur. Assurezvous de toujours déposer l’outil en un endroit où

la poussière, le sable, les copeaux et corps

étrangers ne risquent pas d’y pénétrer.

25. Ne pointez jamais la sortie d’éjection vers une

personne se trouvant à proximité. Gardez les

mains et les pieds à l’écart de la zone de la sortie

d’éjection.

26. Pour transporter l’outil ou le donner à quelqu’un

alors que le tuyau d’air est raccordé, ne posez

pas le doigt sur la gâchette. Le déclenchement

accidentel de l’outil peut être extrêmement

dangereux.

27. Manipulez l’outil prudemment. La pression

élevée à l’intérieur de l’outil représente un

danger si une fissure est provoquée par une

manipulation brusque (outil échappé ou heurté).

Ne tentez jamais de tailler ou graver une

inscription sur l’outil.

28. Cessez immédiatement le clouage si vous notez

une anomalie ou un fonctionnement inhabituel

de l’outil.

10

Page 11

29. Déconnectez toujours le tuyau d’air et retirez

tous les clous dans les cas suivants :

(1) Lorsque l’outil est laissé sans surveillance.

(2) Avant d’effectuer tout travail d’entretien ou

de réparation sur l’outil.

(3) Avant de retirer un clou coincé dans l’outil.

(4) Avant de déplacer l’outil vers un autre lieu.

30. Procédez au nettoyage et à l’entretien de l’outil

dès votre travail terminé. Maintenez l’outil en

excellente condition. Lubrifiez les pièces

mobiles pour éviter qu’elles ne rouillent et pour

limiter l’usure entraînée par la friction. Retirez

toute poussière déposée sur les pièces.

31. Lorsque vous n’utilisez pas l’outil, verrouillez

toujours la gâchette en tournant le levier de

changement de mode sur la position LOCK.

32. Ne modifiez pas l’outil sans l’autorisation de

Makita.

33. Ne pas essayer de maintenir en position

enfoncée la gâchette ou l’élément de contact

avec un bout de ruban ou de fil. Il y a risque de

décès ou de blessure grave.

34. Vérifiez toujours l’élément de contact, tel

qu’indiqué dans ce manuel. Des clous risquent

d’être projetés par accident si le mécanisme de

sécurité ne fonctionne pas correctement.

35. Confiez régulièrement l’outil à un centre de

service après-vente agréé Makita pour une

inspection.

36. Pour assurer la SÉCURITÉ et la FIABILITÉ du

produit, l’entretien et les réparations doivent être

effectués dans un centre de service après-vente

ou une usine Makita agréé(e), exclusivement

avec des pièces de rechange Makita.

CONSERVEZ CES

INSTRUCTIONS

AVERTISSEMENT:

LA MAUVAISE UTILISATION de l’outil ou

l’ignorance des consignes de sécurité du

présent manuel d’instructions peuvent

entraîner une grave blessure.

SYMBOLES

Les symboles utilisés pour l’outil sont présentés cidessous.

....................Veuillez lire les étiquettes et le

manuel, en vous assurant d’en avoir

bien compris le contenu.

USD501-1

...................L’utilisateur et toute personne

présente dans la zone de travail

doivent porter des lunettes de

sécurité avec protecteurs latéraux.

...................Pour éviter le déclenchement

accidentel de l’outil, ne placez pas les

doigts près de la gâchette lorsque

vous n’êtes pas en train de clouer.

Pose

Sélection du compresseur

3

(pi /min)

2

4

8,5 kgf/cm G (120PSIG)

3

2

1

Sortie d'air du compresseur par minute

0102030405060

Fréquence de clouage (clous par min)

Le compresseur d’air doit répondre aux exigences de la

norme ANSI B19.3.

Choisissez un compresseur dont la capacité de

pressurisation et de sortie d’air assurera un bon rapport

7,0 kgf/cm G (100PSIG)

4,5 kgf/cm G (65PSIG)

qualité/ coût. Le graphique indique la relation entre la

fréquence de clouage, la pression applicable et la sortie

d’air du compresseur.

Ainsi, si par exemple le clouage s’effectue à raison

d’environ 40 fois par minute avec une compression de

6,0 kgf/cm

2

G (85 PSIG), il faudra un compresseur à

sortie d’air supérieure à 3 pi

Un régulateur de pression doit être utilisé si la pression

d’air fournie dépasse la capacité nominale de l’outil.

Autrement, l’utilisateur et les personnes présentes

courent un risque de blessure grave.

Sélection du tuyau d’air

005686

2

2

2

6,0 kgf/cm G (85PSIG)

3

/minute.

004294

11

Page 12

Utilisez un tuyau aussi gros et court que possible pour

assurer un clouage continu et efficace. Avec une

pression d’air de 5,0 kgf/cm

de diamètre supérieur à 8,5 mm (5/16”) et d’une

longueur inférieure à 20 m (6,6 pi) est recommandé si

l’intervalle de clouage est de 0,5 seconde. Le tuyau d’air

doit avoir une pression nominale de travail minimale de

10,7 kgf/cm

maximale produite par le système si cette valeur est

supérieure à la précédente.

• La capacité d’entraînement de l’outil risque de

2

G (150 PSIG) ou de 150 fois la pression

ATTENTION:

diminuer si la sortie d’air du compresseur est faible

ou si le tuyau d’air est trop long ou d’un diamètre

trop petit pour la fréquence de clouage.

Lubrification

Pour assurer une performance maximale, installez une

chambre à air (qui contient le réservoir d’huile, le

régulateur et le filtre à air) le plus près possible de l’outil.

Ajustez le réservoir d’huile de sorte qu’une goutte d’huile

soit fournie à intervalles de 30 clous.

Si vous n’utilisez pas de chambre à air, graissez l’outil en

versant deux (2) ou trois (3) gouttes d’huile pour outil

pneumatique dans le raccord à air. Cette opération doit

être effectuée avant et après l’utilisation. Pour assurer

une lubrification adéquate, il faut faire déclencher l’outil à

quelques reprises après l’insertion de l’huile pour outil

pneumatique.

2

G (70 PSIG), un tuyau d’air

004295

007005

1. Huile pour outil

1

pneumatique

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION:

• Verrouillez toujours la gâchette et débranchez le

tuyau avant de régler l’outil ou de vérifier son

fonctionnement.

A

1

Pour ajuster la profondeur de clouage, tournez le

dispositif de réglage. La profondeur de coupe est plus

grande lorsque le dispositif de réglage est tourné

complètement dans le sens A indiqué sur la figure. Elle

diminue lorsque l’on tourne le dispositif de réglage dans

le sens B. Si les clous ne s’enfoncent pas assez

profondément même lorsque le dispositif de réglage est

tourné complètement dans le sens A, augmentez la

pression d’air. Si les clous s’enfoncent trop profondément

même lorsque le dispositif de réglage est tourné

complètement dans le sens B, réduisez la pression d’air.

En général, la durée de service de l’outil est plus longue

s’il est utilisé avec une pression d’air basse et en plaçant

le dispositif de réglage sur une faible profondeur de

clouage.

B

Crochet

1

007006

007062

1. Dispositif de

réglage

1. Crochet

ATTENTION:

• Verrouillez toujours la gâchette et déconnectez le

tuyau de l’outil.

• Ne suspendez jamais l’outil dans un endroit très

élevé ou sur une surface qui risque d’être instable.

Le crochet est pratique pour suspendre l’outil

temporairement.

Pour utiliser le crochet, il suffit de le soulever jusqu’à ce

qu’il se verrouille en position ouverte.

Lorsque vous n’utilisez pas le crochet, vous devez

l’abaisser jusqu’à ce qu’il se verrouille en position

fermée.

12

Page 13

ASSEMBLAGE

ATTENTION:

• Verrouillez toujours la gâchette et déconnectez le

tuyau avant d’effectuer tout travail sur l’outil.

Chargement de la cloueuse

007007

007010

1. Butée de clou

1

Sélectionnez des clous adéquats pour le type de travail à

effectuer. Insérez une bande de clous dans le magasin.

Tirez le levier-poussoir vers l’arrière pour engager le

poussoir sur le dernier clou.

Vider la cloueuse

007008

1. Poussoir

1

007009

1. Levier-poussoir

1

2. Enfoncer

3. Ramener

3

2

Raccordement du tuyau d’air

1

Verrouillez la gâchette. Glissez la douille à air du tuyau

d’air dans le raccord à air de la cloueuse. Assurez-vous

que la douille à air est verrouillée fermement en position

lorsque vous installez le raccord à air. Un raccord à tuyau

doit être installé sur ou près de l’outil de sorte que le

réservoir de pression se vide au moment de la

déconnexion du raccord d’adduction d’air.

007011

2

1. Douille à air

2. Raccord à air

UTILISATION

ATTENTION:

• Assurez-vous que tous les dispositifs de sécurité

sont en état de fonctionner avant d’utiliser l’outil.

1. Pour clouer, vous pouvez placer l’élément de

contact contre la pièce et appuyer sur la gâchette,

ou

1

007012

Tirez le levier-poussoir vers l’arrière. Remettez le levierpoussoir en position initiale tout en gardant le poussoir

enfoncé pour le dégager de la bande de clous.

Enfoncez la butée de clou et retirez la bande de clous du

magasin.

13

Page 14

007013

2

2. Vous pouvez aussi appuyer d’abord sur la gâchette

puis placer l’élément de contact contre la pièce.

• La méthode 1 est pour le clouage intermittent,

lorsque vous désirez planter un clou avec soin et

précision.

La méthode 2 est pour le clouage continu.

ATTENTION:

• Toutefois, si l’outil est réglé en mode de “clouage

intermittent”, AVEC LA GÂCHETTE MAINTENUE À

MI-COURSE, vous risquez de clouer par

inadvertance si l’élément de contact touche à

nouveau la pièce à travailler ou toute autre surface

sous l’effet du recul.

Pour éviter ce clouage accidentel, procédez

comme suit ;

A. N’appliquez pas une force excessive en plaçant

l’élément de contact contre la pièce.

B. Appuyez à fond sur la gâchette et maintenez-la telle

quelle pendant 1 ou 2 secondes après le clouage.

• Pour la méthode 1, placez le levier de changement

sur la position .

Pour la méthode 2, placez-le sur la position .

Après avoir utilisé le levier de changement pour

changer la méthode de clouage, assurez-vous

toujours que le levier est bien placé sur la position

correspondant à la méthode de clouage désirée.

1

007014

1. Clouage continu

2. Verrou de la

gâchette

3. Levier de

verrouillage

2

3

4

4. Clouage

intermittent

Mécanisme de prévention d’activation à vide

Cet outil est équipé d’un mécanisme de prévention

d’activation à vide. Lorsqu’il ne reste que quelques clous

dans le magasin, le bras de contact se verrouille en

position relevée pour empêcher l’activation de l’outil.

Insérez d’autres clous pour poursuivre votre travail.

Cloueuse bloquée

004308

1. Marteau

1

2

3

4

2. Petite tige

3. Sortie d’éjection

4. Dispositif

d’entraînement

ATTENTION:

• Verrouillez toujours la gâchette, débranchez le

tuyau et retirez les clous du magasin avant de

retirer un clou coincé.

Lorsque la cloueuse se bloque, procédez comme suit :

Insérez une petite tige ou un objet similaire dans la sortie

d’éjection et frappez doucement avec un marteau pour

ramener le dispositif d’entraînement.

Utilisez des pinces pour plier le clou coincé, de sorte que

sa tête sorte de la fente du guide d’entraînement. Retirez

ensuite le clou coincé.

004309

1. Pinces

2. Fente

1

2

Clous

004310

Manipulez avec soin les bandes de clous et les boîtes de

clous. Si un bande de clous est manipulée de manière

brusque, elle risque d’être déformée ou la connexion

entre les clous risque de se détacher, causant une

mauvaise alimentation en clous.

Évitez de ranger les clous dans un endroit très humide

ou chaud, ou dans un endroit exposé directement aux

rayons du soleil.

14

Page 15

004311

ENTRETIEN

ATTENTION:

• Déconnectez toujours le tuyau avant d’effectuer

tout travail d’inspection ou d’entretien sur l’outil.

Entretien de la cloueuse

Avant d’utiliser l’outil, assurez-vous qu’il est en bon état

et qu’aucune de ses vis n’est desserrée. Le cas échéant,

serrez les vis.

Avec l’outil débranché, inspectez-le quotidiennement

pour vous assurer que l’élément de contact et la gâchette

se déplacent librement. N’utilisez pas l’outil si l’élément

de contact ou la gâchette se coince.

007015

007016

Assurez-vous que la gâchette est verrouillée lorsque le

levier de changement est placé en position .

007017

1. Verrou de la

gâchette

2. Levier de

changement

1

2

Si vous prévoyez que l’outil restera inutilisé pendant une

période prolongée, lubrifiez-le avec de l’huile à outil

pneumatique et rangez-le dans un endroit sûr. Évitez de

l’exposer directement aux rayons du soleil et/ou de le

laisser dans un environnement humide ou chaud.

007018

000219

Entretien du compresseur, de la chambre à air

et du tuyau d’air

1

004317

1. Robinet de

vidange

15

Page 16

004318

004319

1

1. Filtre à air

1. Réservoir

d’huile

2. Huile à outil

pneumatique

1

Après l’utilisation, videz toujours le réservoir du

compresseur et le filtre à air. L’outil risque de mal

fonctionner ou de tomber en panne si l’humidité y

pénètre.

Vérifiez régulièrement le chambre à air pour vous

assurer que le réservoir d’huile contient assez d’huile à

outil pneumatique. Les joints toriques s’useront

rapidement s’ils ne sont pas toujours bien graissés.

2

Gardez le tuyau d’air à l’écart de la chaleur (plus de 60°C

ou 140°F) et des produits chimiques (diluant, acides

puissants, substances alcalines). Il faut également faire

courir le tuyau à l’écart des obstacles où il risquerait de

se coincer pendant l’utilisation de l’outil. Les tuyaux

doivent également être placés à l’écart des bords

tranchants et de toute surface pouvant entraîner

l’endommagement ou l’abrasion du tuyau.

004320

ACCESSOIRES

ATTENTION:

• Ces accessoires ou pièces complémentaires sont

recommandés pour l’utilisation avec l’outil Makita

spécifié dans ce mode d’emploi. L’utilisation de tout

autre accessoire ou pièce complémentaire peut

comporter un risque de blessure. N’utilisez les

accessoires ou pièces qu’aux fins auxquelles ils ont

été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Clous

• Tuyau d’air

• Lunettes de sécurité

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit,

les réparations, tout autre travail d’entretien ou de

réglage doivent être effectués dans un centre de service

Makita agréé ou un centre de service de l’usine Makita,

exclusivement avec des pièces de rechange Makita.

16

Page 17

ESPAÑOL

ESPECIFICACIONES

Modelo AN923 AN943

Presión de aire

Longitud del clavo 50 mm (2”) - 90 mm (3-1/2”)

Capacidad de clavos 64 - 74 pcs. 60 - 84 pcs.

Diámetro mínimo de la manguera 8.5 mm (5/16”)

Dimensiones (La x Al x An)

Peso neto 3.9 kg (8.7 lbs)

• Debido a un programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a

cambios sin previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

559 mm X 347 mm X 109 mm

(22” X 13-11/16” X 4-1/4”)

4.5 - 8.5 kgf/cm2G (65 - 120 PSIG)

455 mm X 365 mm X 109 mm

(17-7/8” X 14-3/8” X 4-1/4”)

INTRUCCIONES IMPORTANTES

DE SEGURIDAD

USB086-1

ADVERTENCIA: AL UTILIZAR ESTA

HERRAMIENTA, DEBEN OBSERVARSE

SIEMPRE LAS PRECAUCIONES

BÁSICAS DE SEGURIDAD A FIN DE

REDUCIR EL RIESGO DE SUFRIR

HERIDAS PERSONALES, INCLUYENDO

LAS SIGUIENTES:

LEA TODAS LAS INSTRUCCIONES.

1. Para su seguridad y funcionamiento y

mantenimiento adecuados de la herramienta, lea

este manual de instrucciones en detalle antes de

usar la herramienta.

2. Utilice siempre gafas de seguridad para proteger

sus ojos del polvo o heridas con clavos. Las

gafas de seguridad deben cumplir con los

requisitos de ANSI Z87.1.

ADVERTENCIA:

El empleador tiene la responsabilidad de hacer

que los operarios de las herramientas y demás

personas cercanas al área de trabajo utilicen

equipos de protección para la seguridad de los

ojos.

3. Utilice protección auditiva para proteger sus

oídos de los ruidos de escape y también use

protección en la cabeza. Además, utilice

indumentaria liviana, pero que no le quede

suelta. Las mangas deben estar levantadas o

abotonadas. No utilice corbata.

4. Forzar la herramienta o apurar el trabajo es

peligroso. Manipule la herramienta con cuidado.

No opere la herramienta si usted se encuentra

bajo la influencia de alcohol, drogas o sustancia

similar.

5. Pautas generales para la manipulación de

herramientas:

(1) Siempre dé por sentado que la herramienta

contiene sujetadores.

(2) No apunte la herramienta hacia usted o

hacia otra persona; independientemente de

que la herramienta posea sujetadores o no.

(3) No accione la herramienta salvo que ésta se

encuentre firmemente colocada contra la

pieza de trabajo.

(4) Respete la herramienta como implemento

de trabajo.

(5) No haga "bromas pesadas” con la

herramienta.

(6) No sostenga o transporte la herramienta

con un dedo en el gatillo.

(7) No cargue la herramienta con sujetadores si

alguno de los controles de operación se

encuentra activado.

(8) No opere la herramienta con una fuente de

energía distinta de la especificada en las

instrucciones de funcionamiento/seguridad

de la herramienta.

6. No debe utilizarse una herramienta que funciona

incorrectamente.

7. A veces, salen volando chispas cuando se utiliza

la herramienta. No utilice la herramienta cerca

de materiales volátiles o inflamables como

gasolina, tíner, pintura, gas, adhesivos, etc. ya

que se encenderán y explotarán y provocarán

heridas de gravedad.

8. El área debe estar suficientemente iluminada

para garantizar operaciones seguras. El área

debe estar limpia y sin basura. Tenga

17

Page 18

especialmente cuidado y conserve el equilibrio y

una postura firme.

9. Sólo quienes participen en el trabajo deben

encontrarse en las cercanías. En especial los

niños deben mantenerse alejados en todo

momento.

10. Podría haber regulaciones locales en cuanto al

ruido, que deben cumplirse manteniendo los

límites de ruido dentro de los límites

establecidos. En algunos casos, deberán

utilizarse persianas para contener el ruido

11. No juegue con el elemento de contacto: Este

elemento evita descargas accidentales. Por lo

tanto, debe mantenerse en su lugar y no

retirarse. Asegurar el gatillo en la posición de

encendido ON siempre es muy peligroso. Nunca

intente sujetar el gatillo. No opere la herramienta

si alguna parte de los controles de

funcionamiento de ésta se encuentra

desconectado, inoperable, alterado o si no

funciona correctamente.

12. Opere la herramienta dentro de la presión de aire

especificada en su etiqueta para que la vida útil

sea mayor y segura. No exceda la presión

máxima recomendada de funcionamiento. No

debe conectarse la herramienta a una fuente

cuya presión puede exceder 14,0 kgf/cm

PSIG).

13. Nunca use la herramienta si no es con aire

comprimido. En el caso de que se utilice gas

embotellado (dióxido de carbono, oxígeno,

nitrógeno, aire, hidrógeno, etc.) o gas

combustible (hidrógeno, propano, acetileno,

etc.) como fuente de energía de esta

herramienta, ésta explotará y causará heridas de

gravedad.

14. Siempre verifique el estado general de la

herramienta y que no haya tornillos flojos antes

de utilizarla. Ajuste como sea necesario.

15. Asegúrese de que todos los sistemas de

seguridad funcionen correctamente antes de

operar la herramienta. La herramienta no deberá

funcionar si sólo el gatillo está disparado o si

sólo el elemento de contacto está presionado

contra la madera. Sólo debe funcionar cuando

se realizan ambas acciones. Haga una prueba

para verificar una posible operación defectuosa

con los clavos no cargados y el elemento de

contacto completamente tirado.

16. Asegúrese de que el gatillo se encuentre

trabado cuando la palanca de carga esté en la

posición trabada (LOCK).

17. Revise cuidadosamente paredes, techos, pisos,

cielo rasos y demás para evitar posibles

descargas eléctricas, fugas de gas, explosiones,

etc., que se producen al tocar cables vivos,

conductos o caños de gas.

2

G (200

18. Utilice solamente los clavos especificados en

este manual. Si utiliza otros clavos, la

herramienta puede funcionar incorrectamente.

19. No permita que personas no capacitadas utilicen

la herramienta.

20. Asegúrese de que nadie se encuentre cerca

antes de realizar la acción de clavado. Nunca

intente clavar desde el interior y desde el

exterior al mismo tiempo. Puede que los clavos

se rompan y/o salgan volando causando un

peligro grave.

21. Vigile su postura y conserve el equilibrio con la

herramienta. Asegúrese de que no haya ninguna

persona debajo cuando trabaje en altura y fije la

manguera de aire para evitar daños en caso de

brincos o movimientos bruscos.

22. Cuando se encuentre arriba de techos o en otros

lugares de altura, vaya clavando a medida que

avanza. Es fácil perder la postura si clava

mientras se mueve hacia atrás. Cuando va

clavando contra superficies perpendiculares,

clave desde arriba hacia abajo. Usted puede

clavar clavos fatigándose menos si lo hace de

este modo.

23. Si por error usted clava un clavo arriba de otro o

le pega a un nudo en la madera, se podrá doblar

un clavo o atorarse la herramienta. Puede que el

clavo salga volando y lastime a alguna persona

o que la herramienta reaccione en forma

peligrosa. Coloque los clavos con cuidado.

24. No deje la herramienta cargada o el compresor

de aire bajo presión bajo el sol por tiempo

prolongado. Asegúrese de que el polvo, arena,

astillas y demás materiales extraños no ingresen

en la herramienta en el lugar donde usted la dejó

colocada.

25. No apunte el puerto de expulsión hacia una

persona que se encuentre cerca. Mantenga las

maños y pies alejados del área del puerto de

expulsión.

26. Cuando la manguera de aire esté conectada, no

transporte la herramienta con el dedo en el

gatillo ni se la dé a otra persona de esta manera.

Un disparo accidental puede resultar

extremadamente peligroso.

27. Manipule la herramienta con cuidado ya que hay

presión alta dentro de ésta que puede ser

peligrosa si se produce una grieta por

manipularla fuertemente (en caso de que se

caiga o golpee). No intente grabar ni hacer

surcos en la herramienta.

28. Deje de clavar inmediato si nota que algo

funciona mal o que hay algo fuera de lo común

con la herramienta.

29. Siempre desconecte la manguera de aire y retire

todos los clavos:

18

Page 19

(1) Cuando la herramienta se encuentra sin

supervisión.

(2) Antes de realizar cualquier reparación o

mantenimiento.

(3) Antes de limpiar algo que quedó atascado.

(4) Antes de mover la herramienta a otro lugar.

30. Realice la limpieza y el mantenimiento de la

herramienta después de realizado el trabajo.

Mantenga la herramienta en estado óptimo.

Lubrique las partes móviles para evitar que se

oxiden y minimizar así el desgaste ocasionado

por la fricción. Limpie todo el polvo de las

piezas.

31. Cuando no opera la herramienta, siempre trabe

el gatillo girando la palanca de cambio a la

posición LOCK.

32. No modifique la herramienta sin la autorización

de Makita.

33. No intente mantener el gatillo o elemento de

contacto presionado con cinta o cable. Podrían

ocasionarse heridas de gravedad o muerte.

34. Siempre verifique el elemento de contacto, como

figura en este manual. Los clavos pueden

accionarse accidentalmente si el mecanismo no

funciona correctamente.

35. Solicite en los centros autorizados de servicio

Makita la inspección periódica de la

herramienta.

36. Para mantener la SEGURIDAD y CONFIABILIDAD

del producto, las reparaciones y mantenimiento

deberán realizarse a través de los Centros

Autorizados de Servicio o de los Centros de

Servicio de Fábrica Makita, que siempre utilizan

piezas de repuesto Makita.

GUARDE ESTAS

INSTRUCCIONES

AVISO:

EL MAL USO o incumplimiento de las

reglas de seguridad descriptas en el

presente manual de instrucciones puede

ocasionar graves lesiones a su persona.

SÍMBOLOS

A continuación se muestran los símbolos utilizados para

la herramienta.

....................Lea y entienda el manual y las

etiquetas de la herramienta.

....................Los operarios y demás personas que

se encuentran en el área de trabajo

USD501-1

deben usar gafas de seguridad con

protección lateral.

...................Mantenga los dedos alejados del

gatillo cuando no esté clavando los

sujetadores a fin de evitar un disparo

accidental.

INSTALACIÓN

Cómo elegir un compresor

3

(pies /min.)

2

4

8,5 kgf/cm G (120PSIG)

3

2

1

Salida de aire del compresor por minuto

0102030405060

Frecuencia de clavado (veces/ min.)

El compresor de aire debe cumplir con los

requerimientos de ANSI B19.3.

Seleccione un compresor que tenga presión amplia y

salida de aire para garantizar una operación económica.

El gráfico muestra la relación entre la frecuencia de

clavado, la presión aplicable y la salida del compresor de

aire.

Así, por ejemplo, si el clavado se realiza a una velocidad

de aproximadamente 40 veces por minuto a una

compresión de 6,0 kgf/cm

compresor con una salida de aire superior a 3 pies

minuto.

Los reguladores de presión deben usarse para limitar la

presión de aire a la presión nominal de la herramienta

donde la presión del aire suministrado excede la presión

nominal de la herramienta. Si no lo hiciere, podrían

ocurrir graves daños al operador de la herramienta o las

personas que se encuentren en las proximidades del

lugar.

7,0 kgf/cm G (100PSIG)

4,5 kgf/cm G (65PSIG)

005686

2

2

2

6,0 kgf/cm G (85PSIG)

2

G (85 PSIG), se requiere un

3

/

19

Page 20

Cómo seleccionar una manguera de aire

004294

007005

1

1. Aceite para

herramienta

neumática

Use una manguera de aire tan larga y tan corta como

fuera posible para garantizar un clavado continuo y

eficiente. Con una presión de aire de 5,0 kgf/cm

recomienda una manguera de aire con un diámetro

interno superior a 8,5 mm (5/16”) y una longitud menor

de 20 m (6,6 pies) cuando el intervalo entre cada clavado

es de 0,5 segundos. Las mangueras de suministro de

aire deberán tener una escala de presión de

funcionamiento mínima de 10,7 kgf/cm

de 150 por ciento de la máxima presión producida en el

sistema, cualquiera sea la mayor.

PRECAUCIÓN:

• La baja salida de aire del compresor o una

manguera de aire de mayor o menor diámetro en

relación con la frecuencia de clavado puede causar

una disminución en la capacidad de manejo de la

herramienta.

Lubricación

Para garantizar un máximo rendimiento, instale un juego

de aire (lubricador, regulador, filtro de aire) lo más cerca

posible de la herramienta. Ajuste el lubricador de forma

tal que suministre una gota de aceite cada 30 clavos.

Cuando no se use el juego de aire, lubrique la

herramienta con aceite para herramientas neumáticas,

colocando 2 (dos) o 3 (tres) gotas en el adaptador de

aire. Esto deberá realizarse antes y después de cada

uso. Para una lubricación adecuada, la herramienta debe

dispararse un par de veces después de introducir el

aceite para herramientas neumáticas.

004295

2

G (150 PSIG) o

2

, se

DESCRIPCIÓN DEL

FUNCIONAMIENTO

PRECAUCIÓN:

• Siempre trabe el gatillo y desconecte la manguera

antes de ajustar o controlar el funcionamiento en la

herramienta.

A

B

1

Para ajustar la profundidad del clavado, gire el ajustador.

La profundidad del clavado está a su punto máximo

cuando el ajustador está completamente girado hacia la

dirección A que se muestra en la figura. A medida que el

ajustador se gire hacia la posición B se hará menos

profundo. Si los clavos no están penetrando a una

profundidad suficiente incluso cuando se está

completamente en la dirección A, aumente la presión del

aire. Si los clavos están penetrando con demasiada

profundidad incluso cuando el ajustador está

completamente en la dirección B, disminuya la presión

del aire. En general, la vida útil de la herramienta será

mayor cuando ésta es utilizada a menor presión y el

ajustador está puesto a una menor profundidad para la

operación de clavado.

Gancho

1

007006

1. Ajustador

007062

1. Gancho

20

Page 21

PRECAUCIÓN:

• Siempre bloquee el gatillo y desconecte la

manguera de la herramienta.

• Nunca enganche la herramienta en un lugar

elevado o en una superficie potencialmente

inestable.

El gancho resulta conveniente a la hora de colgar la

herramienta en forma temporaria.

Para usar el gancho, simplemente levántelo hasta que

enganche en la posición abierta.

Cuando no se utilice, siempre baje el gancho hasta que

enganche en la posición cerrada.

MONTAJE

PRECAUCIÓN:

• Siempre trabe el gatillo y desconecte la manguera

antes de realizar cualquier trabajo con la

herramienta.

Cómo cargar una clavadora

007007

Descarga del clavador

Jale la palanca del propulsor hacia atrás. Retorne el

propulsor mientras lo mantiene presionado para

desengranarlo de la tira de clavos.

Presione el bloqueador de clavos y extraiga la tira de

clavos de la recámara de clavos.

007009

1. Palanca del

1

propulsor

2. Presionar

3. Retornar

3

2

007010

1. Bloqueador de

clavos

1

Escoja clavos que sean adecuados para su trabajo.

Inserte la tira de clavos en la recámara de clavos.

Jale la palanca del propulsor hacia atrás para engranar

el propulsor hasta el último clavo.

007008

1. Propulsor

1

Cómo conectar la manguera

1

Trabe el gatillo. Deslice el receptáculo de aire de la

manguera de aire dentro del adaptador de aire en la

clavadora. Asegúrese de que el receptáculo de aire

quede trabado firmemente en su lugar cuando lo instale

en el adaptador de aire. Debe instalarse un

acoplamiento de manguera en la herramienta o cerca de

la misma de manera tal que el depósito de presión se

descargue en el momento que se desconecte el

acoplamiento de suministro de aire.

007011

1. Enchufe de aire

2

2. Adaptador de

aire

OPERACIÓN

PRECAUCIÓN:

• Asegúrese de que todos los sistemas de seguridad

funcionen adecuadamente antes de utilizar la

herramienta.

21

Page 22

1. Para impulsar un clavo, puede colocar el elemento

de contacto contra la pieza de trabajo y tirar del

gatillo o

007012

1

007013

2

2. Tirar del gatillo primero y luego colocar el elemento

de contacto contra la pieza de trabajo.

• El método No.1 se usa para un clavado

intermitente, cuando desea cuidadosamente

controlar un clavo de forma muy precisa.

El método No.2 es para el clavado continuo.

PRECAUCIÓN:

• Sin embargo, cuando la herramienta se encuentra

en el modo “Clavado intermitente”, SI MANTIENE

EL GATILLO DISPARADO A LA MITAD, podría

ocurrir un clavado inesperado, si permite que el

elemento de contacto vuelva a ponerse en contacto

contra la pieza de trabajo u otra superficie bajo la

influencia del rebote.

A fin de evitar este clavado inesperado, siga el

siguiente procedimiento:

A. No coloque el elemento de contacto contra la pieza de

trabajo con demasiada fuerza.

B. Tire del gatillo por completo y sosténgalo por 1-2

segundos después de clavar.

• Para el método No.1, ponga la palanca de cambio

en la posición .

Para el método No.2, ponga la palanca de cambio

en la posición .

Después de usar la palanca de cambio para

modificar el método de clavado, siempre asegúrese

de que la palanca de cambio está puesta en la

posición del método de clavado deseado.

007014

1

1. Clavado

continuo

2. Seguro del

gatillo

3. Palanca de

2

3

4

bloqueo

4. Clavado

intermitente

Mecanismo anti disparador en seco.

Esta herramienta está equipada con un mecanismo anti

disparador en seco. Cuando quedan unos cuantos

clavos en la recámara para clavos, el brazo de contacto

estará bloqueado en posición no presionada para evitar

que la herramienta sea accionada. Cargue más clavos y

continúe con la operación.

Clavadora atascada

1

PRECAUCIÓN:

• Siempre trabe el gatillo, desconecte la manguera y

retire los clavos de la recámara antes de

desatascar la herramienta.

Cuando la clavadora se atasca, haga lo siguiente:

Inserte una varilla pequeña o algo similar en el puerto de

eyección y golpee ligeramente con un martillo para

retractar el controlador.

Use tenazas para doblar el clavo atascado para que la

cabeza salga de la ranura en la guía del controlador.

Luego extraiga el clavo atascado.

004308

1. Martillo

2. Varilla pequeña

3. Puerto de

2

3

4

004309

expulsión

4. Controlador

1. Tenazas

2. Ranura

1

2

22

Page 23

Clavos

004310

Clavo

Manipule las bobinas de clavos y sus cajas con cuidado.

Si las bobinas de clavos se manipulan sin cuidado,

pueden perder la forma o romperse sus conectores,

teniendo como resultado una alimentación escasa de

clavos.

Evite guardar clavos en un lugar húmedo o caluroso o

colocarlos expuestos a la luz solar directa.

Húmedo

Clavo

004311

CalurosoCaluroso

MANTENIMIENTO

PRECAUCIÓN:

• Desconecte siempre la manguera de aire de la

herramienta antes de intentar hacer una inspección

o mantenimiento.

Mantenimiento de la clavadora

Verifique siempre el estado general de la herramienta y

afloje los tornillos antes de ponerla en funcionamiento.

Ajuste según lo requerido.

007015

007016

Asegúrese de que el gatillo está bloqueado cuando la

palanca de cambio está puesta en la posición .

007017

1. Seguro del

gatillo

2. Palanca de

cambio

1

2

Cuando la herramienta no se use durante un largo

tiempo, lubríquela usando aceite para herramientas

neumáticas y guarde la herramienta en un lugar seguro.

Evite exponerla a la luz solar directa y/ o al calor o

humedad ambiental.

007018

000219

Con la herramienta desconectada, realice una

inspección diaria para garantizar un movimiento libre del

elemento de contacto y el gatillo. No use la herramienta

si el elemento de contacto o el gatillo queda trabado o

atascado.

23

Page 24

Mantenimiento del compresor, juego de aire o

manguera de aire

1

1

Luego de utilizarla, vacíe siempre el tanque del

compresor y el filtro de aire. Si permite que la humedad

entre en la herramienta, esto podría ocasionar un mal

funcionamiento y la posible falla de la misma.

Verifique regularmente para ver si hay suficiente aceite

neumático en el lubricador del juego de aire. La falta de

mantenimiento de una lubricación suficiente ocasionará

el desgaste rápido de los aros.

004317

1. Llave de drenaje

004318

1. Filtro de aire

004319

1. Lubricador

2. Aceite

1

neumático

004320

Horno

Diluyente

Para mantener la SEGURIDAD y FIABILIDAD del

producto, las reparaciones, y cualquier otra tarea de

mantenimiento o ajuste deberán ser realizadas en

Centros de Servicio Autorizados por Makita, empleando

siempre repuestos Makita.

ACCESORIOS

PRECAUCIÓN:

• Estos accesorios o acoplamientos están

recomendados para utilizar con su herramienta

Makita especificada en este manual. El empleo de

cualesquiera otros accesorios o acoplamientos

conllevará un riesgo de sufrir heridas personales.

Utilice los accesorios o acoplamientos solamente

para su fin establecido.

Si necesita cualquier ayuda para más detalles en

relación con estos accesorios, pregunte a su centro de

servicio Makita local.

• Clavos

• Mangueras de aire

• Gafas de seguridad

2

Mantenga la manguera de aire fuera del calor (más de

60°C, más de 140°F), lejos de las sustancias químicas

(diluyente, ácidos fuertes o álcalis). Además, encamine

la manguera fuera de los obstáculos dado que podría

quedar peligrosamente atrapada durante el

funcionamiento. Las mangueras deben también dirigirse

lejos de bordes filosos y áreas que podrían dañarlas o

desgastarlas.

24

Page 25

252627

Page 26

Page 27

Page 28

< USA only >

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

< USA solamente >

ADVERTENCIA

Algunos tipos de polvo creados por el lijado, serrado, amolado, taladrado, y

otras actividades de la construccion contienen sustancias quimicas

reconocidas por el Estado de California como causantes de cancer, defectos

de nacimiento y otros peligros de reproduccion. Algunos ejemplos de estos

productos quimicos son:

• plomo de pinturas a base de plomo,

• silice cristalino de ladrillos y cemento y otros productos de albanileria, y

• arsenico y cromo de maderas tratadas quimicamente.

El riesgo al que se expone variara, dependiendo de la frecuencia con la que

realice este tipo de trabajo. Para reducir la exposicion a estos productos

quimicos: trabaje en un area bien ventilada, y pongase el equipo de seguridad

indicado, tal como esas mascaras contra el polvo que estan especialmente

disenadas para filtrar particulas microscopicas.

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi 446-8502 Japan

884653-948

Loading...

Loading...