Page 1

Models No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

Optional accessories

AC310H

Air Compressor

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 476 (18-3/4)

507 (20)

375 (14-3/4)

W

L

H

This model has been launched as Makita first HP(high pressure) air compressor.

1,500W high output motor generates maximum 2.58MPa air flow performance to

exploit the full potential of HP pneumatic tools such as nailer, stapler, screwdriver

and impact driver.

Four couplers are on the front. The two couplers are for HP pneumatic tools,

the others are for RP (regular pressure) pneumatic tools.

Guard with seven bumpers is equipped to protect their couplers and body.

P 1/ 7

PRODUCT

T

ECHNICAL INFORMATION

Continuous Rating (W)

Voltage (V) Cycle (Hz)

Input Output

Max. Output (W)

120

220-240

13.0

7.0

60

50

---

1,800 1,500

1,500

Current (A)

875

875

Model No.

Specifications

Weight according to EPTA procedure: kg (lbs)

Power supply cord: m (ft)

Tank capacity

Continuous rating output: W

Rated amperage for North America: A

Motor

Horsepower: HP

Type

RPM: min-1

2.5

Air flow performance: L/min at 0.75MPa

90

Noise: dB(A)

tested according to outdoor noise directive

Motor thermal overload protector

Insulation

Max air pressure in Tank: Mpa (psi)

Carrying tool

Air hose assembly

Hose reel

None of Standard equipment

Note: Standard equipment may vary by countries.

Air pressure in Tank when restarting: Mpa (psi)

for high pressure

for regular pressure

Operating air pressure: MPa (psi)

AC310H

2.8 (410)

2.3 (330)

Air pressure

through Coupler: Mpa

0 ~ 2.58

0 ~ 0.91

1,500

4-pole induction motor

90

Yes

by grounding

6.2 (1.6)

1.8 (5.9)

36 (79.4)

0.98~2.26 (140 ~ 320)

13

1,700(60Hz) / 1,420(50Hz)

Standard equipment

Page 2

P 2/ 7

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

[2] REPLACING

[2]-1. Filter

[2]-2. Filter

Fig. 1

Fig. 2

Fig. 4 Fig. 5

Fig. 3

Code No. Description Use for

1R230 1/4" Hex. shank bit for M6 Removing M6 Hex socket head bolt

1R231 1/4" Hex. shank bit for M8 Removing M8 Hex socket head bolt

1) Loosen five M5x10 Pan head screws, then remove Side panel with Side panel cover.

2) Loosen three 4x18 Tapping screws, then remove Filter cover. (Fig. 2)

Filter can be removed as illustrated in Fig. 3.

After removing Side panel with Side panel cover, loosen Cover of Check valve section with box wrench 19. (Fig. 4)

Check valve can be removed. (Fig. 5)

Remove five M5x10 Pan head screws

designated with arrows.

Side panel with Side panel cover

4x18 Tapping screw

(3pcs.)

Filter cover

Filter

Note: Do not loosen two M5x10

Pan head screws in two circles.

Cover of Check valve section

Cover of

Check valve sectionCheck valve

M5x10 Pan head screw

Spring washer 5

Flat washer 5

Page 3

P 3/ 7

Repair

[2] REPLACING

[2]-3. Unloading valve

Fig. 6

Fig. 7

Fig. 8

1) Loosen M8 Ring nut with Spanner 17, then remove Pipe 8 from Elbow 8-R1/4. (Fig. 6)

2) Loosen four M5x10 Pan head screws, then remove Front panel assembly from Frame complete. (Fig. 7)

3) Loosen two Ring nuts 6 with Spanner 13, then remove Pipe 6.

Loosen Screw and Nut (that are components of Switch assembly). Unloading valve can be removed. (Fig. 8)

M8 Ring nutElbow 8-R1/4

Pipe 8

M5x10 Pan head screw

Spring washer 5

Flat washer 5

Frame complete

Pipe 8

Front panel assy (RC1/4)

Ring nut 6 (2pcs.)

Ring nut 6

Switch assembly

Pipe 6

Nut

Unloading valve

Screw

Page 4

P 4/ 7

Repair

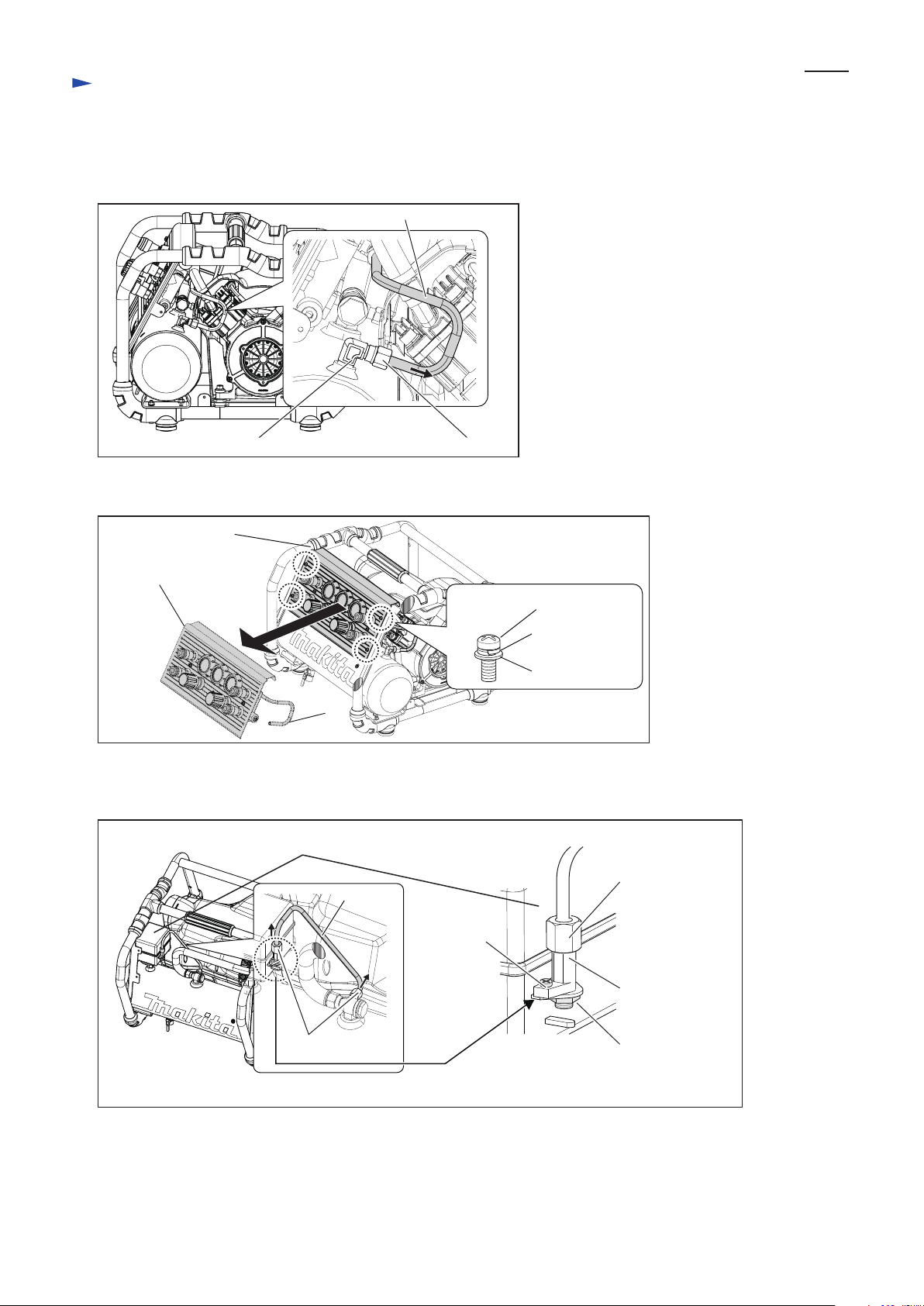

Fig. 9

Fig. 10

Fig. 11

1) After removing Side panel with Side panel cover, loosen two Ring nut 10 and remove Pipe 10. (Fig. 9)

2) Loosen nine 4x18 Tapping screws, then separate Motor cover A complete from Motor cover C. (Fig. 10)

4x18 Tapping screws (9pcs.)

3) Lift up and slide Motor cover A complete along gray arrow direction so that the side of Cylinder head L

faces the reverse of rib of Motor cover A complete. Then remove Motor housing A complete by moving along

black arrow direction. (Fig. 11)

Ring nut 10 (2pcs.)

Pipe 10

side of

Cylinder

head L

rib of

Motor cover

A complete

The side of Cylinder head L faces

the reverse of rib of Motor cover A

complete

Motor cover A complete

Motor cover C

[2] REPLACING

[2]-4. Sheet ring H, Leaf spring H, Wearing H

DISASSEMBLING

Page 5

P 5/ 7

Repair

[2] REPLACING

[2]-4. Sheet ring H, Leaf spring H, Wearing H (cont.)

Fig. 12

Fig. 13

Fig. 14

4) Loosen two Ring nuts 8 with Spanner 17, then remove Pipe 8 from two Elbows 8-R1/4. (Fig. 12)

5) Loosen four M8x70 Hex socket head bolts with Hex wrench 9, then remove Cylinder H section from Crank case. (Fig. 13)

Note: When fastening Cylinder H section to Crank case, tighten M8x70 Hex socket head bolts to fastening torque 18 to

20 N.m.

6) Disassemble Connecting rod H assembly. Sheet ring H, Leaf spring H and Wearing H can be replaced. (Fig. 14)

Elbow 8-R1/4 (2pcs.)

Pipe 8

Ring nut 8 (2pcs.)

M8x70 Hex socket

head bolt (4pcs.)

Spring washer 8

(4pcs.)

Flat washer 8

(4pcs.)

Cylinder H section

Crank case

Connecting rod assembly

Sheet ring H

Leaf spring H

Wearing H

DISASSEMBLING

Page 6

P 6/ 7

Repair

[2] REPLACING

[2]-4. Sheet ring H, Leaf spring H, Wearing H (cont.)

[2]-5. Sheet ring L, Leaf spring L, Wearing L

1) Assemble Wearing H to Piston H. Wear ring H is not directional in assembling.

2) Insert Ring spring H in Sheet ring H so that the clearance of Ring spring H faces the opposite side against the clearance

of Sheet ring H. (Fig. 15)

3) Enlarge a width of the assembled part of Sheet ring H and Ring spring H slightly and fit the assembled part into

the groove of Piston H. (Fig. 16)

4) When Piston H of Connecting rod H assembly is at dead center upper point by turning Fan 195, assemble Cylinder H to

Crank case.

Note: Piston H is not supplied individually. It is supplied as Connecting rod H assembly.

Fig. 15

Fig. 17

Fig. 16

ASSEMBLING

DISASSEMBLING

1) Remove Pipe 8 from two Elbows. (Fig. 12)

2) Loosen four M6x90 Hex socket head bolts with Hex wrench 5, and then remove Cylinder L section from Crank case.

(Fig. 17)

3) Disassembling Connecting rod L assembly in the same manner mentioned for Connecting rod H assembly.

Take the disassembling step in reverse.

Note: 1) Tighten M6x90 Hex socket head bolt to the fastening torque 8 to 10 N.m.

2) Piston L is not supplied individually. It is supplied as Connecting rod L assembly.

M6x90 Hex socket head bolt

(4pcs.)

Flat washer 6 (4pcs.)

Spring washer 6

(4pcs.)

Crank case

ASSEMBLING

Sheet ring H

Ring spring H

Clearance of Ring spring H

Clearance of Sheet ring H Wearing H

Groove of Piston

The assembled part of

Sheet ring H and Ring spring H

Cylinder L section

Page 7

P 7/ 7

Wiring diaphragm

D-1

Note: Fix Lead wires in Motor cover with Band

so as not to sag and interfere with Fan 195.

White or blue Black or brown

Switch assemblyBushing

Cord between Switch assembly

and Motor section

Cord clamp

Overhead view of Switch assembly

Green

A

A

B

B

Power supply cord

Thermal circuit breaker

Polyolefin tube

ø5 Connector

Polyolefin tube

Capacitor

Motor cover

Motor section

Black

Red

Black or

brown

Green

ø6 Connector

White or blue

Three lead wires from Motor section

Black

White

Loading...

Loading...