SECTION 1. CHEMICIAL PRODUCT AND COMPANY NAME

Safety Data Sheet

Depressed Centre Grinding Wheel

Flat Cutting- Off Wheel

Complies with the OSHA Hazard

Communication Standard :

29 CFR 1910 1200

Makita U.S.A., Inc.

14930-C Northam Street

La Mirada, CA 90638

Prepared By : Stan Rodrigues

Date Revised: 05/6/2015

EMERGENCY CONTACT INFORMATION

Telephone Number for Information: MAKITA: 1-510-657-9881

Emergency Response

For Chemical Emergency

Spills, Leak, Fire, Exposure, or Accident

Call CHEMTREC Day or Night

Within USA and Canada 1-800-424-9300

SECTION 2. HAZARD IDENTIFICATION

Classification Nomenclature:

Hazards:

Harmfulness:

Environment Effect:

Not applicable to classification criteria

None

No finding available.

No finding available

Health Effect:

Safety Effect:

Possible Emergency Overview:

Physical and Chemical Hazards:

SECTION 3. COMPOSITION, INFORMATION OR INGREDIENTS

Product Groups Product Part No.

Depressed Centre Grinding Wheel

Flat Cutting-Off Wheel

Prolonged absorption of dust generated during grinding operations may induce

pneumoconiosis.

Sparks generated during grinder use may cause burn and fire.

Injury or death accidents due to direct attack on the human body of broken and scattered

grinding wheel fragments

Grinding wheel fragments broken and scattered around during grinding operations, if they

strike the human body, may cause serious injury or death.

A-95956 , A-95956-25 , A-95956-5 , A-95962 , A-95962-25 , A-95962-5

A-95978 , A-95978-25 , A-95978-5 , A-95984 , A-95984-25 , A-95984-5

A-95990 , A-95990-25 , A-95990-5 , A-96001 , A-96001-25 , A-96001-5

B-46143 , B46143-25 , B46159 , B-46159-25 , B-46165 , B-46165-25

1

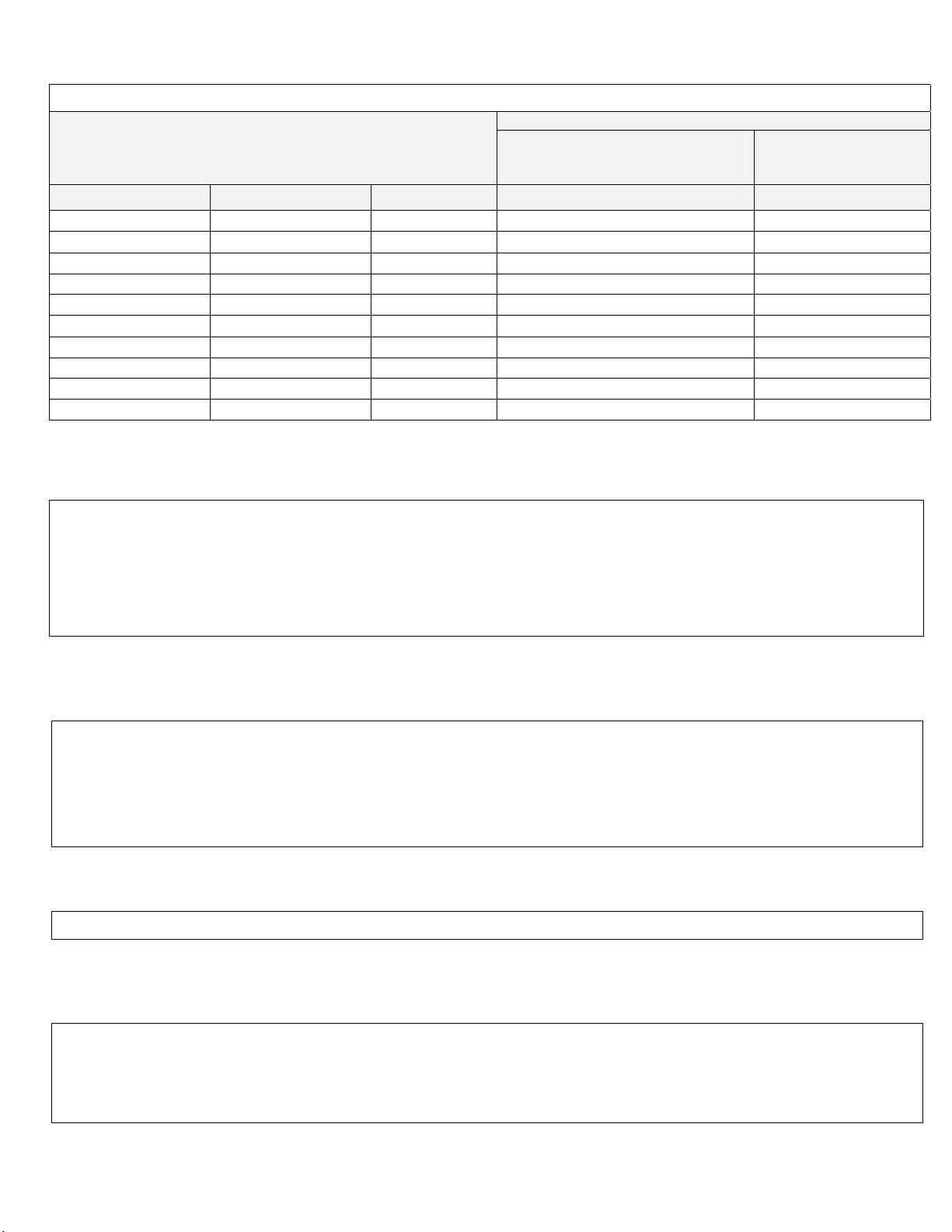

CONTINUED: SECTION 3. COMPOSITION, INFORMATION OR INGREDIENTS

Typical chemical analysis in wt. % (approx.)

Material

Chemical Name Concentration CAS No Concentration % Concentration %

Aluminum Oxide AL2O3 1344-28-1 68.48 – 68.96 40.05 – 42.39

Silicon Dioxide SiO2 7631-86-9 0.10 – 0.11 0.05 – 0.06

Iron Oxide Fe2O3 1309-37-1 0.07 0.02

Titanium Dioxide TiO2 13463-67-7 0.51 – 0.53 0.39 – 0.42

Sodium Oxide Na2O 1313-59-3 - 0.03

Zirconium Oxide ZrO2 1314-23-4 - 10.08 – 10.67

Filler - - 0.78 – 4.05 0.25 – 10.73

Phenolic resin C6H6O-CH2O 9003-35-4 16.39 – 16.63 16.94 – 18.15

GF Reinforcement - - 6.17 – 6.76 8.63 – 9.62

Other - - 2.44 – 3.22 7.52 – 13.53

Depressed Centre Grinding Wheel Flat Cutting-Off Wheel

Product

SECTION 4. FIRST AID MEASURE

Eye Contact:

Skin Contact:

If dust enters the eyes, wash the eyes immediately with clean running water. Do not press hard nor rub

them. Get medical treatment if necessary.

Flush with soapsuds etc. after the end of operations.

Inhalation:

Ingestion:

In the case of dust inhalation, remove the victim immediately to a place of fres h air. Gargle (wash) with

water. Get medical treatment if necessary.

Give large amounts of moisture and induce vomiting. Get medical treatment if necessary.

SECTION 5. FIRE FIGHTING MEASURES

Extinguishing Methods:

Choke extinguishing method. (May be incombustible under normal conditions.)

Use water, powder, carbon dioxide, foam extinguishers, etc. for early-stage fire.

Use water and foam extinguishers to cool and block air for large scale fire.

Gases generated under heating contain hazar do us su bst a nces. Wear respiratory protectors for

firefighting.

SECTION 6. ACCIDENTAL RELEASE MEASURES

Do not use abrasive products near flammable materials.

SECTION 7. HANDLING AND STORAGE

Handling:

(1) Do not drop, (2) do not bump, (3) do no t tur n over during handling.

Before installing on the machine, perform visual tests for grinding wheel crack, breakage, chip, etc.

Make sure that maximum operating peripheral speed, dimensions, etc. conform to the machine.

Do not use in excess of the maximum operating peripheral speed labeled on grinding wheel.

2

Loading...

Loading...