Page 1

SECTION 1. CHEMICIAL PRODUCT AND COMPANY NAME

Safety Data Sheet

Depressed Centre Grinding Wheel

Flat Cutting- Off Wheel

Complies with the OSHA Hazard

Communication Standard :

29 CFR 1910 1200

Makita U.S.A., Inc.

14930-C Northam Street

La Mirada, CA 90638

Prepared By : Stan Rodrigues

Date Revised: 05/6/2015

EMERGENCY CONTACT INFORMATION

Telephone Number for Information: MAKITA: 1-510-657-9881

Emergency Response

For Chemical Emergency

Spills, Leak, Fire, Exposure, or Accident

Call CHEMTREC Day or Night

Within USA and Canada 1-800-424-9300

SECTION 2. HAZARD IDENTIFICATION

Classification Nomenclature:

Hazards:

Harmfulness:

Environment Effect:

Not applicable to classification criteria

None

No finding available.

No finding available

Health Effect:

Safety Effect:

Possible Emergency Overview:

Physical and Chemical Hazards:

SECTION 3. COMPOSITION, INFORMATION OR INGREDIENTS

Product Groups Product Part No.

Depressed Centre Grinding Wheel

Flat Cutting-Off Wheel

Prolonged absorption of dust generated during grinding operations may induce

pneumoconiosis.

Sparks generated during grinder use may cause burn and fire.

Injury or death accidents due to direct attack on the human body of broken and scattered

grinding wheel fragments

Grinding wheel fragments broken and scattered around during grinding operations, if they

strike the human body, may cause serious injury or death.

A-95956 , A-95956-25 , A-95956-5 , A-95962 , A-95962-25 , A-95962-5

A-95978 , A-95978-25 , A-95978-5 , A-95984 , A-95984-25 , A-95984-5

A-95990 , A-95990-25 , A-95990-5 , A-96001 , A-96001-25 , A-96001-5

B-46143 , B46143-25 , B46159 , B-46159-25 , B-46165 , B-46165-25

1

Page 2

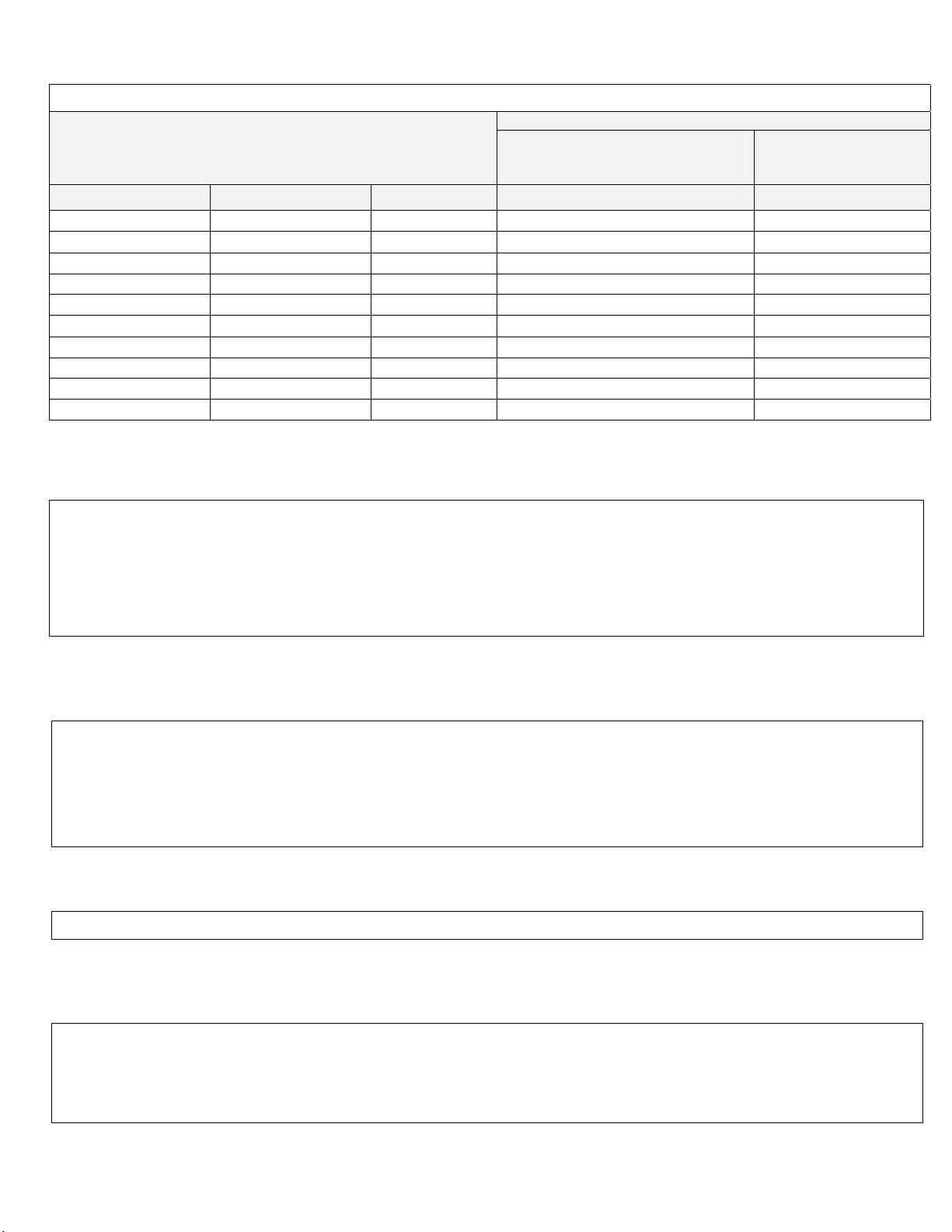

CONTINUED: SECTION 3. COMPOSITION, INFORMATION OR INGREDIENTS

Typical chemical analysis in wt. % (approx.)

Material

Chemical Name Concentration CAS No Concentration % Concentration %

Aluminum Oxide AL2O3 1344-28-1 68.48 – 68.96 40.05 – 42.39

Silicon Dioxide SiO2 7631-86-9 0.10 – 0.11 0.05 – 0.06

Iron Oxide Fe2O3 1309-37-1 0.07 0.02

Titanium Dioxide TiO2 13463-67-7 0.51 – 0.53 0.39 – 0.42

Sodium Oxide Na2O 1313-59-3 - 0.03

Zirconium Oxide ZrO2 1314-23-4 - 10.08 – 10.67

Filler - - 0.78 – 4.05 0.25 – 10.73

Phenolic resin C6H6O-CH2O 9003-35-4 16.39 – 16.63 16.94 – 18.15

GF Reinforcement - - 6.17 – 6.76 8.63 – 9.62

Other - - 2.44 – 3.22 7.52 – 13.53

Depressed Centre Grinding Wheel Flat Cutting-Off Wheel

Product

SECTION 4. FIRST AID MEASURE

Eye Contact:

Skin Contact:

If dust enters the eyes, wash the eyes immediately with clean running water. Do not press hard nor rub

them. Get medical treatment if necessary.

Flush with soapsuds etc. after the end of operations.

Inhalation:

Ingestion:

In the case of dust inhalation, remove the victim immediately to a place of fres h air. Gargle (wash) with

water. Get medical treatment if necessary.

Give large amounts of moisture and induce vomiting. Get medical treatment if necessary.

SECTION 5. FIRE FIGHTING MEASURES

Extinguishing Methods:

Choke extinguishing method. (May be incombustible under normal conditions.)

Use water, powder, carbon dioxide, foam extinguishers, etc. for early-stage fire.

Use water and foam extinguishers to cool and block air for large scale fire.

Gases generated under heating contain hazar do us su bst a nces. Wear respiratory protectors for

firefighting.

SECTION 6. ACCIDENTAL RELEASE MEASURES

Do not use abrasive products near flammable materials.

SECTION 7. HANDLING AND STORAGE

Handling:

(1) Do not drop, (2) do not bump, (3) do no t tur n over during handling.

Before installing on the machine, perform visual tests for grinding wheel crack, breakage, chip, etc.

Make sure that maximum operating peripheral speed, dimensions, etc. conform to the machine.

Do not use in excess of the maximum operating peripheral speed labeled on grinding wheel.

2

Page 3

CONTINUED: SECTION 7. HANDLING AND STORAGE

Handling:

When installing grinding wheel on the flange, use proper flange and do not fasten nuts too tight.

Perform correct installation on the flange.

When installing on the flange, perform visual checkup without fail and make sure the absence of any

abnormality. Perform test runs for 1 minute or more before start of operations for the day and for 3

minutes or more when grinding wheel is installed and/or replaced.

Keep the body from direct contact with grinding wheel under rotation.

Store in a dry place using pigeonholes etc.

Do not store in a place of possible moisture freezing.

Use the designated side only. (Prohibit use of the side face)

Storage:

Absorption of moisture and humidity lowers grinding wheel strength. Store in a dry place of good

ventilation avoiding humidity.

SECTION 8. EXPOSURE CONTROLS AND PERSONAL PROTECTION

Allowable Levels:

Control Levels:

Installation Measures:

Class 2 dust, Inhalable dust = 1 mg/m

Total dust = 4 mg/m

2.9 mg/m

3

(as mineral dust)

3

Japan Society of Industrial Hygiene (1990 Edition)

ACGIH (1990 Edition) 10 mg/m

As dust-proof measures, install dust collectors or arrange general exhaust if necessary. Dust collectors

may generate and absorb sparks and induce fire. Take measures so that they do not absorb sparks

directly

3

3

Protectors:

Operators should wear the following protectors without fail.

Respiratory protectors ... Dust masks passing national tests.

Protective goggles ... Complete protection type dust goggles.

Protective gloves ... Spark-proof gloves.

Protective clothes ... Work clothes of spark-proof materials.

Others ... Soundproof ear plugs, helmets, safety shoes, etc.

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

Appearance:

Physical State:

Boiling Point:

Vapor Pressure:

Volatility:

Ignition Point:

Flash Point:

Melting Point:

Colored molded (yellow-brown, black-brown, red) solid with a slight synthetic resin odor.

Solid with no volatility and sublimation

-

- kPa (20

o

C)

No spontaneous ignition

Flame resistant

-

Density:

Decomposition Point:

Decomposition

Temperature:

Solubility:

-

o

- 300

C or over (hardened phenol resin product)

o

300

C or over (hardened phenol resin pr od uct)

-

3

Page 4

CONTINUED: SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

Odor:

Others:

pH and its Levels:

Alkali Resistance:

-

Solid, not applicable

Strength degradation is accelerated by alkaline grinding fluid.

SECTION 10. STABILITY AND REACTIVITY

Oxidization:

Explosiveness:

Flammability:

Dust Explosiveness:

Stability:

Reactivity:

Conditions to Avoid:

None

None

None

None

Stable in the air

Stable in the air

High temperature, high humidit y

SECTION 11. TOXICOLOGICAL INFORMATION

Skin Corrosiveness:

No finding available.

Irritability:

Sensitivity:

Acute Toxicity:

Chronic Toxicity:

Carcinogenicity:

Mutagenicity:

Reproductive Toxicity:

Teratogenicity:

Others:

Local Effect:

Prolonged inhalation of dust generated during grinding operations may induce pneumoconiosis.

No finding available.

No finding available.

No finding available.

No finding available.

No finding available.

No finding available.

No finding available.

No finding available.

No finding available.

Nothing particular

SECTION 12. ECOLOGICAL INFORMATION

Decomposition:

Accumulation:

Ichthyotoxicity:

Residue/Decomposition:

Bioaccumulation:

Possible Environment

Effect:

No finding available.

No finding available.

No finding available.

No data available

No data available

Grinding wastes (including dust and mist) are discharged in trace amount during cutting, grinding,

etc.

4

Page 5

SECTION 13. DISPOSAL CONSIDERATIONS

Dispose of wastes in accordance with applicable regulations. (Follow national, prefectural and regional laws and regulations.)

Specify the contents and commission the disposal with licensed industrial waste disposers. Classified as "glass wastes and pottery

wastes". Dispose as industrial wastes.

SECTION 14. TRANSPORT INFORMATION

Take care to avoid water soaking and packing case damage.

Place in boxes resistant to some degrees of pressure and shock.

Avoid rough handling to prevent grinding wheel from breakage.

Transport free from turnover, fall, other impact, etc.

"Fragile" Avoid dumping and impact such as fall.

Inform the manufacturer or user when abnormal impact, force, etc. have supposedly been added.

International Regulation: None

UN classification: None

UN No.: None

Domestic Regulation: None

SECTION 15. REGULATORY INFORMATION

Follow regulation and law of each country or region

SECTION 16. OTHER INFORMATION

N/A

5

Loading...

Loading...