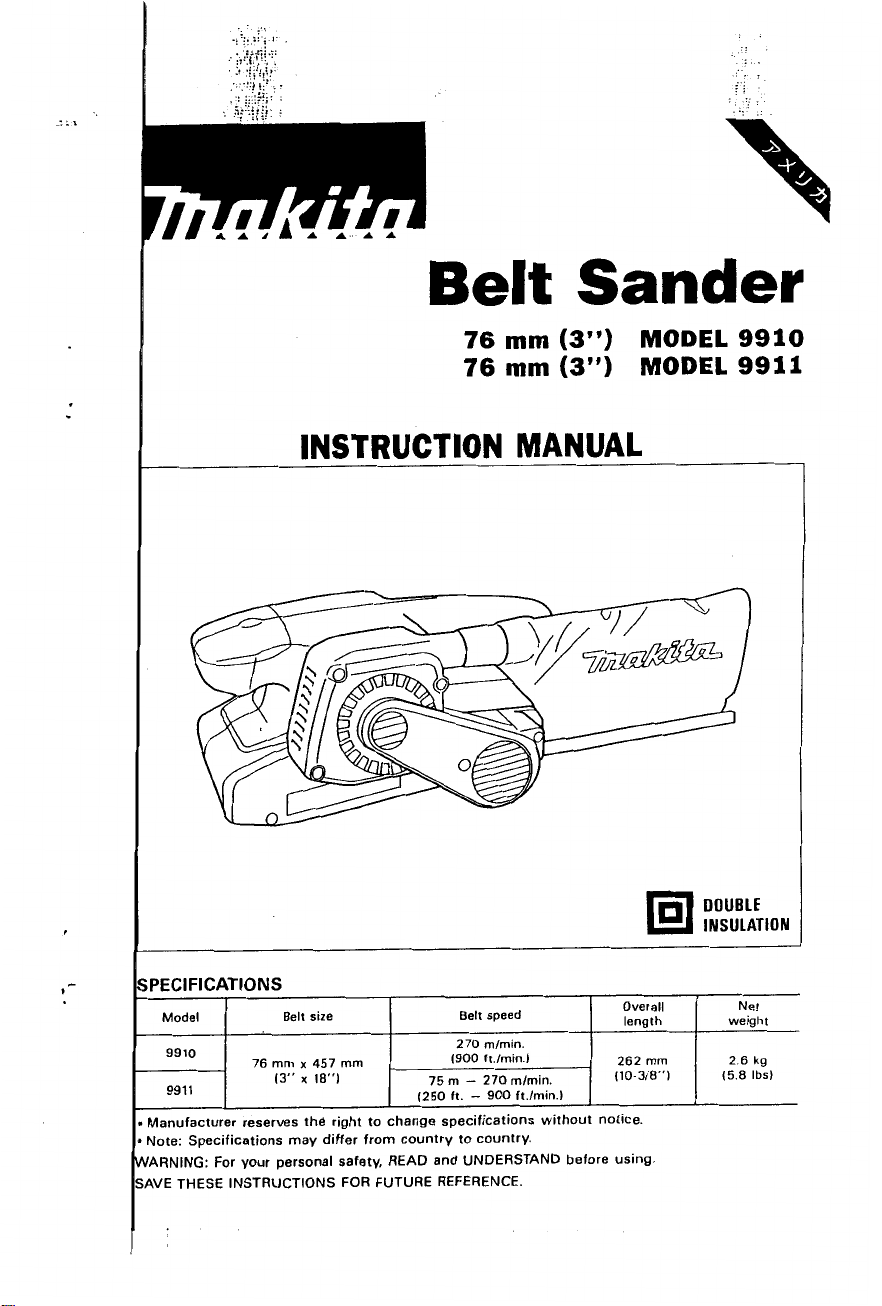

Sander

76

mm

(3”)

76

mm

(3”)

INSTRUCTION MANUAL

MODEL

MODEL

9910

9911

iPEClFlCATlONS

Model Belt size Belt speed

270

9910

9911

Manufacturer reserves the right to change specifications without notice.

Note: Specifications may differ from country to country.

4ARNING: For your personal safety, READ and UNDERSTAND before using.

AVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

76

mm

(3” x 18”)

x

457

mm

1250

mlmin.

1900 ft.lmin.1

75

m

-

270

ft. - 900 ft.lmin.1

mlmin.

Overall

length weight

262

110-318”)

mm

DOUBLE

INSULATION

Net

2

6

kg

15.8

Ibs)

GENERAL SAFETY RULES

(For

WARNING!

to follow

shock, fire and/or serious personal injury.

Read and understand all instructigns.

all

instructions listed below, may result

All

Tools)

Failure

in

electric

SAVE

READ

WORK AREA

1.

2.

3.

EL E CT

4.

5.

6.

7.

8.

PERSONAL SAFETY

9

10

ALL

Keep your work area clean and well

accidents.

Do

not operate power tools

of flammable liquids, gases, or dust. Power

ignite the dust

Keep bystanders, children, and visitors away while Operating a power tool.

Distractions can cause you to loose control.

R I C

Double Insulated tools are equipped

than the other.) This

plug does not fit fully

contact a qualified electrician to install a polarized outlet.

the

wire grounded power cord and grounded power supply system.

Avoid body contact

and refrigerators. There is an increased risk

grounded.

Don't expose power tools to rain or wet conditions. Water entering a power

tool

Do not abuse the cord. Never use the cord to carry the tools or

from an outlet. Keep cord away from heat,

Replace damaged cords immediately. Damaged cords increase the risk

electric shock.

When operating a power tool outside, use an outdoor extension cord marked

"W-A"

of electric shock.

Stay alert, watch what you are doing and use common sense when operatiig

a power tool.

alcohol, or medication.

may result in serious personal injury.

Dress properly.

your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry

or long hair can be caugh

A L SAFETY

pfug

will

or

THESE INSTRUCTIONS

INSTRUCTIONS.

lit.

Cluttered benches and dark areas invite

in

explosive atmospheres, such as

or

fumes.

plug

will fit

in

the outlet, reverse the plug. If

in

any way. Double insulation

with

grounded surfaces such as pipes, radiators, ranges

increase the risk

"W."

These cords are rated for outdoor use and reduce the risk

Do

not use tool while tired or under the influence of drugs,

Do

not wear loose clothing or jewelry. Contain long hair. Keep

of

electric shock.

A

moment of inattention while operating power

in

poving parts.

\,

with

in

a polarized outlet only one way.

tools

create sparks which may

a polarized

@I

eliminates the need

of

oil,

plug

(one blade is wider

it

electric shock if your body is

sharp edges or moving parts.

in

the presence

still does not

Do

not change

for

pull

If

the

fit,

the three

the

plug

of

tools

I

2

..

,.

..

.

.

...

.

I

.1

,

..

.::.::

i.!'

.

.

...

:

;>.y.q+,:

'.

2,

!,

.

..

..

..

..

,

..

.

....

.

..!

i:.

,

:

..

..

.

..:i:.

. .

..

.

_..

.

..

..

..

..

,

.

.

:i:

::*:i

:

.

..

;:.".

1.

Avoid accidental starting. Be sure switch is off before plugging

with

tools

your finger on the switch or plugging

in

tools

that have the switch

in.

Carrying

on invites accidents.

2.

Remove

a key that is left attached to a rotating part of the tool may result

adjusting

keys

or switches before turning the tool on. A wrench or

in

personal

injury.

3.

Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool

&.

Use safety equipment. Always wear eye protection. Dust mask, non-skid

in

unexpected situations.

safety shoes, hard hat, or hearing protection must be used for appropriate

conditions.

)OL

USE AND CARE

5.

Use clamps or other practical way

to

secure and support the workpiece to

a stable platform. Holding the work by hand or against your body is unstable

and may lead to

5.

Do not force tool. Use the correct tool for your application. The correct tool

loss of

will do the job better and safer at the rate for which

7.

Do not use tool if switch does not turn

be controlled with the switch

8.

Disconnect the plug from the power source before making any adjustments,

control.

is

it

is designed.

it

on or off. Any tool that cannot

dangerous and must be repaired.

changing accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

D.

Store idle tools out of reach of children and other untrained persons.

are dangerous

b.

Maintain tools

in

the hands of untrained users.

with

care. Keep cutting tools sharp and clean. Properly

Tools

maintained tools, with sharp cutting edges are less likely to bind and are easier

to control.

.

Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tools operation. If damaged, have

the tool serviced before using. Many accidents are caused by poorly maintained tools.

I.

Use only accessories that are recommended by the manufacturer for

model. Accessories that may be suitable for one tool, may become hazardous

when used on another tool.

RVICE

I.

Tool

service must be performed only by qualified repair personnel. Service

or maintenance performed

by

unqualified personnel could result in a risk

injury.

.

When servicing a tool, use only identical replacement parts. Follow instruc-

in

tions

the Maintenance section of this manual. Use of unauthorized parts

or failure to follow Maintenance Instructions may create a risk of electric shock

or injury.

your

of

3

Specific Safety

1.

Hold tools by insulated gripping surfaces when performing an operation where

the cutting

"live" wire

operator.

2.

Hold

3.

Make sure the belt is not contacting the workpiece before the switch

turned on.

4.

Keep hands away from rotating parts.

5.

Do

not leave the tool

6.

This tool has not been waterproofed,

surface.

tool

may

will

make exposed metal parts

the tool firmly

contact hidden wiring

with

both hands.

running.

Operate the

Rules

or

its own cord. Contact

of

the tool "live" and shock the

tool

only when hand-held.

so

do not use water

on

the workpiece

SAVE THESE INSTRUCTIONS.

with

a

is

4

..

..

.....

....

..

.;

:i

...

.

:I.?.

.

..,!!!.:

....

.....

...

'.

.A!,.!.'

.......

,

.

,

.-,

....

.

-

;:,;.:

::

.'.!.

.........

...

::.:

.:

....

::.

:i:.

:.

:..f

!.

,

:

.

.

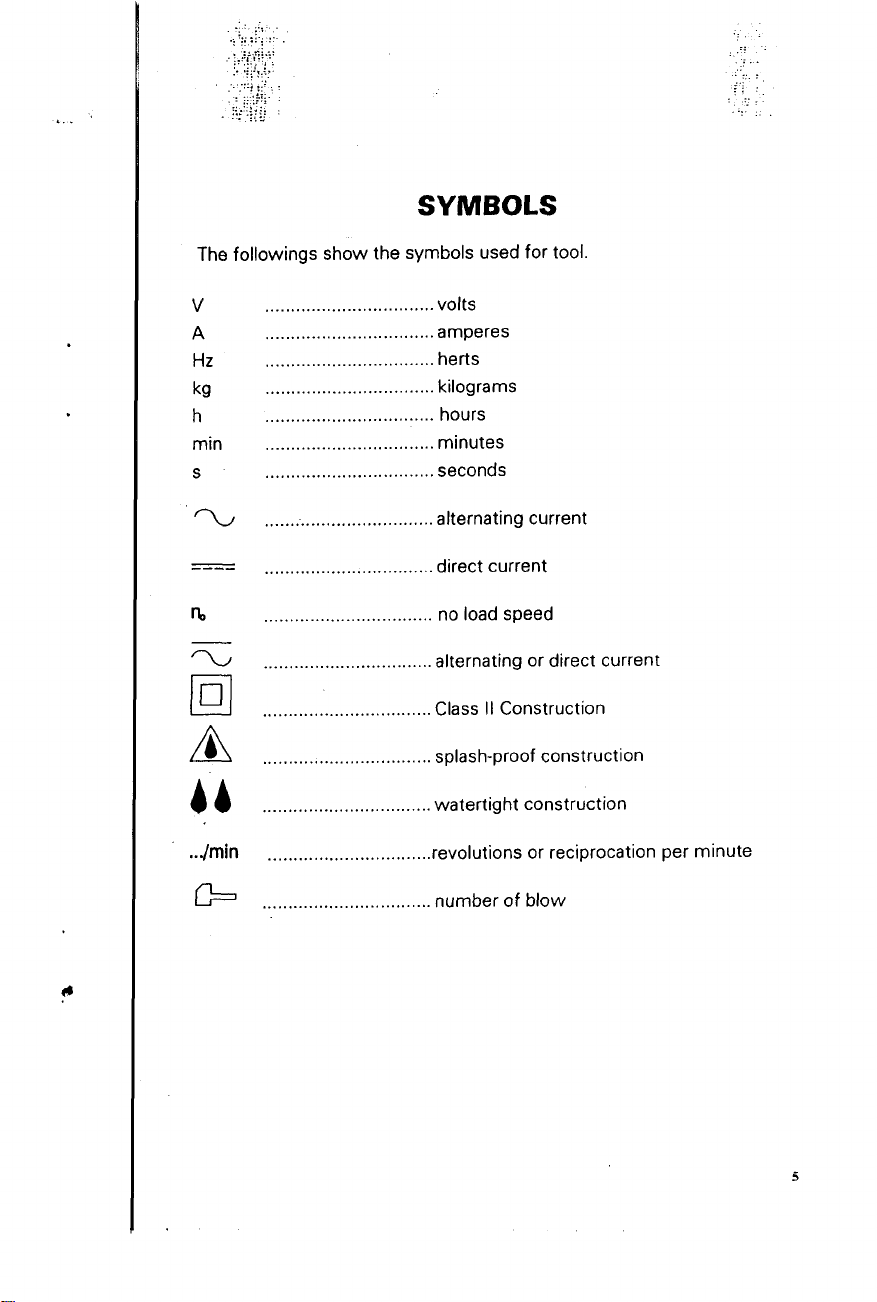

SYMBOLS

The followings show the symbols used for

...........

amperes

.......................

.................................

.................................

.................................

......................

..................

....................

.................

...................

kilograms

hours

minutes

.

seconds

alternating current

..

direct current

....

no load speed

alternating or direct current

Class

II

Construction

......

splash-proof construction

..

watertight construction

tool.

ciprocation per minute

ASSEMBLY

Installing or removing abrasive belt

CAUTION:

Always be sure that the tool is switched off and unplugged before installing or removing

the belt.

Pull the lever all the way out and install the

belt over the rollers, then return the lever

the original position.

to

I

CAUTION:

When installing the belt, make sure that the

direction of the arrow on the back

to

belt corresponds

itself.

Adjusting belt tracking

Switch on the tool and make sure that the

belt is aligned properly.

belt extends beyond the edge of the steel

plate or the edge of the belt retracts more

8

mm

than

the steel plate, use the adjusting screw to

adjust the belt tracking.

(5/16")

the one on the tool

If

the edge of the

away from the edge of

of

the

I

Steel

I

7

I

plate

more

than

8

mm

(Y16")

k

6

..

.

..

.

.

...

.

. ..

.

.

.it::

:;.;

!

,

:.::;.p:

..

_._

.

.l:.

.

..

.,,:,.

.

..

...

.

,

..

.

....

.

._.,:

~

. . ...

..

.

.

.1.

.

.

.

..

..

.:..

.

..

..,

.

:::.:::I

.

.

,

::.-

US~

bag

ttach the dust bag onto the dust spout.

I

Dust

spout

ie dust spout is tapered. When attaching

e

dust bag, push it onto the dust spout

mly as far as it will go to prevent

it

from

ming off during operation.

)r

the best results, empty the dust bag

hen it becomes about half full. tapping

it

lhtfy to remove as much dust as possible.

Dusl

bag

PERATION

witch action

WTION:

3efore plugging in the tool, always check

ind returns to the

"OFF"

position when released.

-he tool should not be in contact with the workpiece surface when you turn the tool

)r off. Otherwise a poor sanding finish

to

see that the switch trigger actuates properly

or

damage of the belt may result.

on

,

start the tool, simply pull the trigger.

?lease the trigger to stop.

For

continuous

Cock

button

,eration, pull the trigger and then push in

e lock button. To stop the tool from the

:ked position, pull the trigger fully, then

lease it.

inding operation

Ad the tool firmly with both hands. Turn the tool on and wait until it attains full speed.

tool

ien gently place the

on the workpiece surface. Keep the belt flush with the work-

xe at all times and move the tool back and forth. Never force the tool. The weight of the

01

applies adequate pressure. Excessive pressure may cause stalling, overheating of the

otor, burning of the workpiece and possible kickback.

Speed adjusting dial

For

9911

only

The belt speed can be infinitely adjusted

between

turning the speed adjusting dial

number setting from

75

m

and

270

m

1

to

6.

Higher speed is

per minute

to

a

given

by

obtained when the dial is turned in the

direction

of

number

6;

lower speed

is

ob-

tained when it is turned in the direction of

number

1.

Select the proper speed for the workpiece

to be sanded.

Speed adjusting dial

'\

CAUTION:

The speed adjusting dial can be turned only as

or

1,

or the speed adjusting function may not longer work.

far

as 6 and back to

1.

Do

not force

it

past

6

..7!.5

.. . .-

,.

.

&.<,?

..,-.

..

...

.

.

.

..

.

.,

.'i'l.::.

.

,

:

.

::a>.:.::

,:.:*.:,

. I ..

.,.:.it

..

.

.. ..

...

..

z;;

...

-.....

.

.

..

.

<..

....

'

,

...

.:

:.

..

,

::.

..

.

.

.

.

MI

ON:

CA

j

be sure that the tool is switched

Alv

tion or maintenance.

ins1

:ing

carbon

Rei

re and check the carbon brushes reg-

Rei

Replace when they wear down to

ular

lit

the

clei

car1

sar

bru

Fir:

usc

hol

bru

the

mark. Keep the carbon brushes

ind free to slip in the holders. Both

brushes should be replaced at the

time.

S.

emove the belt cover from the tool.

screwdriver to remove the brush

caps. Take out the worn carbon

s,

insert the new ones and secure

ish holder caps.

brushes

Use

only identical carbon

off

and unplugged before attempting to perform

Limit

mark

Brush

holder

I

cap

\

ntain product SAFETY and RELIABILITY, repairs, any other maintenance or adjust-

To

hould be performed by Makita Authorized or Factory Service Centers, always using

me

replacement parts.

Ma

9

..

.

4

ACCESSORIES

CAUTION:

These accessories or attachments are recommended for use with your Makita tool specified

manual. The use

The accessories or attachments should be used only in the proper and intended manner.

*Abrasive belts

'Belt

type

AA

-

For wood, iron and steel.

Grit Sheets per pack

M60

AA240

of

any other accessories or attachments might present a risk

*Clamp

and use

Coarse

Medium

10

Fine

(2

I

pcs.)

of

injury

to

in

this

persons.

76

mm

BELT

Model

(3")

SANDER

9910

62

Note:

The

switch and other part configurations

may differ from country to country.

11

MODEL

'LtM

IO

I1

12

13

I4

15

16

I?

I0

19

20

21

22

23

24

25

26

27

20

29

30

31

32

~

..

9910

ED

DESCRIPTION

33

40

41

42

43

44

45

46

4?

48

49

50

51

52

53

54

55

56

57

50

59

60

61

62

83

34

35

36

31

30

39

I

4

1

I

I

I

I

I

I

I

1

1

1

I

1

I

7

1

2

I

1

I

1

1

I

I

I

I

I

I

I

1

1

2

4

I

3

I

4

I

5

6

I

I

1

0

I

9

1

1

1

1

I

1

2

I

2

I

I

I

1

1

I

1

2

2

2

1

I

I

I

I

-

76

mm

BELT

Model

(3")

SANDER

9911

Jan

-20-'98

US

62

Note: The switch and other part configurations

may differ from country to COUntrY.

13

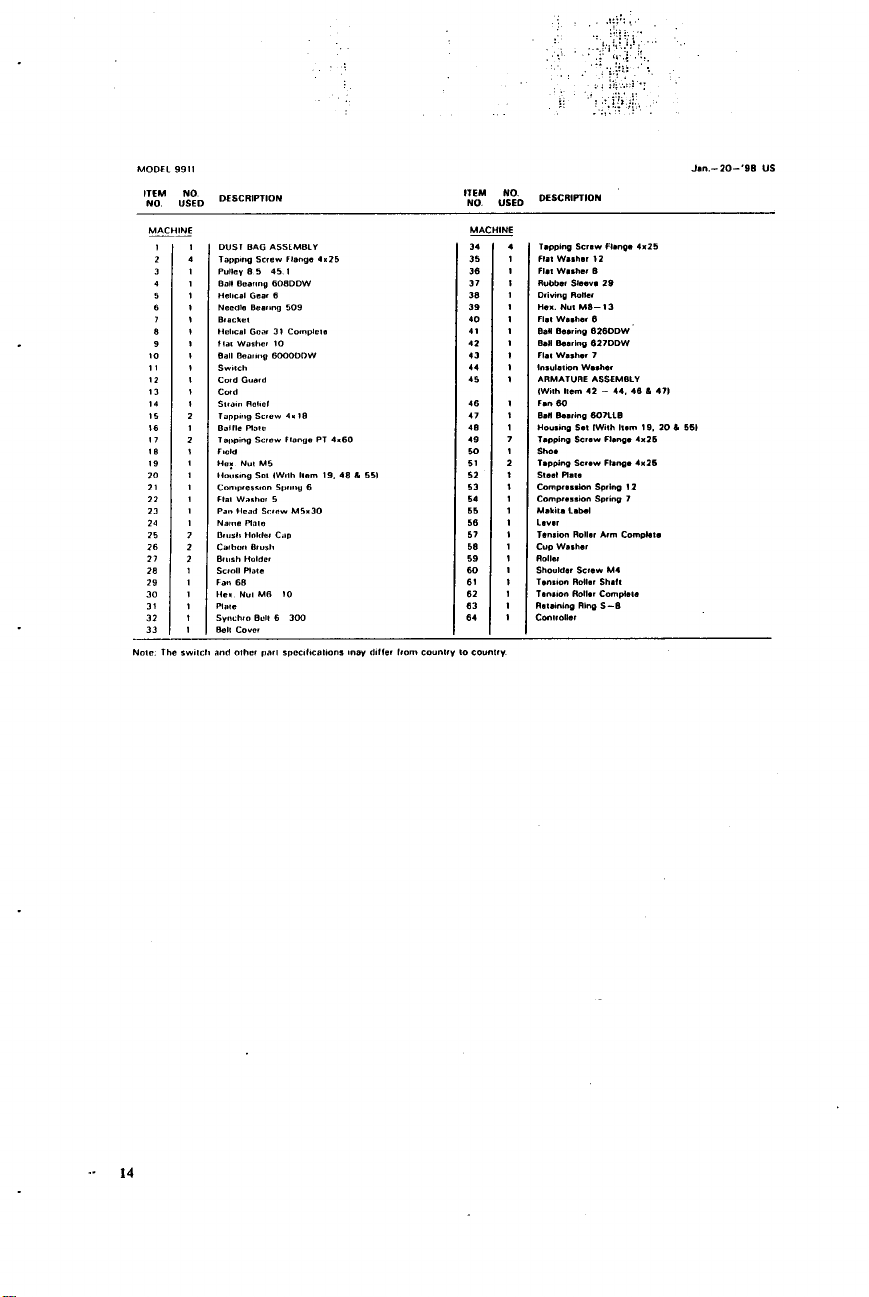

MODEL

ITEM

NO

9911

NO

USED

DESCRIPTIDN

Jan.-ZD-'90

I:","

$$

DESCRIPTION

US

10

II

I2

13

14

15

16

I7

I8

19

in

21

22

23

24

25

26

27

28

29

30

31

32

33

I

1

4

2

3

I

4

1

I

5

6

I

7

I

1

8

I

9

1

I

I

1

I

2

1

2

I

1

I

I

1

I

I

7

2

2

I

I

1

I

1

I

-

34

4

35

1

36

I

37

I

38

1

39

I

40

I

I1

I

41

I

43

1

14

I

45

1

46

I

47 1

40

1

49

7

MI

51

2

52

I

53 1

54

I

66

1

56

I

51

I

56

1

59

1

601

61

I

62

I

63

I

64

1

MAKITA

Every Makita tool is tliorou ily ins ected and tested before leaving the factory.

be free of defects lrom wor&lmanshrp and materials

original purchase. Should any trouble develop during this one-year period. return the COMPLETE

tool, freight prepaid.

the trouble is caused by delective workmanship

replace) without charge.

This Warranty does

repairs have been made

repairs 8re required because

The

tool

has been abused, misused

alterations have been made

IN NO EVENT SllALL MAKITA BE LIABLE FOR ANY INDIRECT. INCIDENTAL

SEQUENTIAL DAMAGES FROM THE SALE

APPLIES BOT11 DURING AND AFTER TIiE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY

WARRANTIES OF “MERCIiANTABILITY” AND “FITNESS

AFTER THE ONE-YEAR TERM

This Warranty gives you specific legal rights, and you may also have other rights which vary lrom

state to state. Some states do not allow the exclusion

damages,

so

limitation on how long an implied warranty lasts.

the above limitation

LIMITED

to

one

of

not

apply where:

or

attempted by others:

of

to

ONE

YEAR WARRANTY

Warranty

Makita’s Factory

normal wea~ and tear:

or

improperly maintained;

the

tool.

FOR

OF

THIS WARRANTY.

or

exclusion may not apply to you. Some states do not allow

Policy

It

lor

the period

of

ONE YEAR lrom the date

or

Authorized Senice Centers.

or

material. Makita will repair

OR

USE OF THE PRODUCT. THIS DISCLAIMER

ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

so

the above limitation may not apply to you.

or

limitation

FOR

A SPECIFIC PURPOSE.”

of

incidental

is warranted lo

If

inspection show

(or

at

or

consequential

our

OR

option,

CON-

1

I

01

Makita

3-1

1-8,

Sumiyoshi-cho,

Anjo,

Aichi

Corporation

446-8502

884138-069

Japan

PRINTED IN JAPAN

1998-

2

-

N

Loading...

Loading...