Page 1

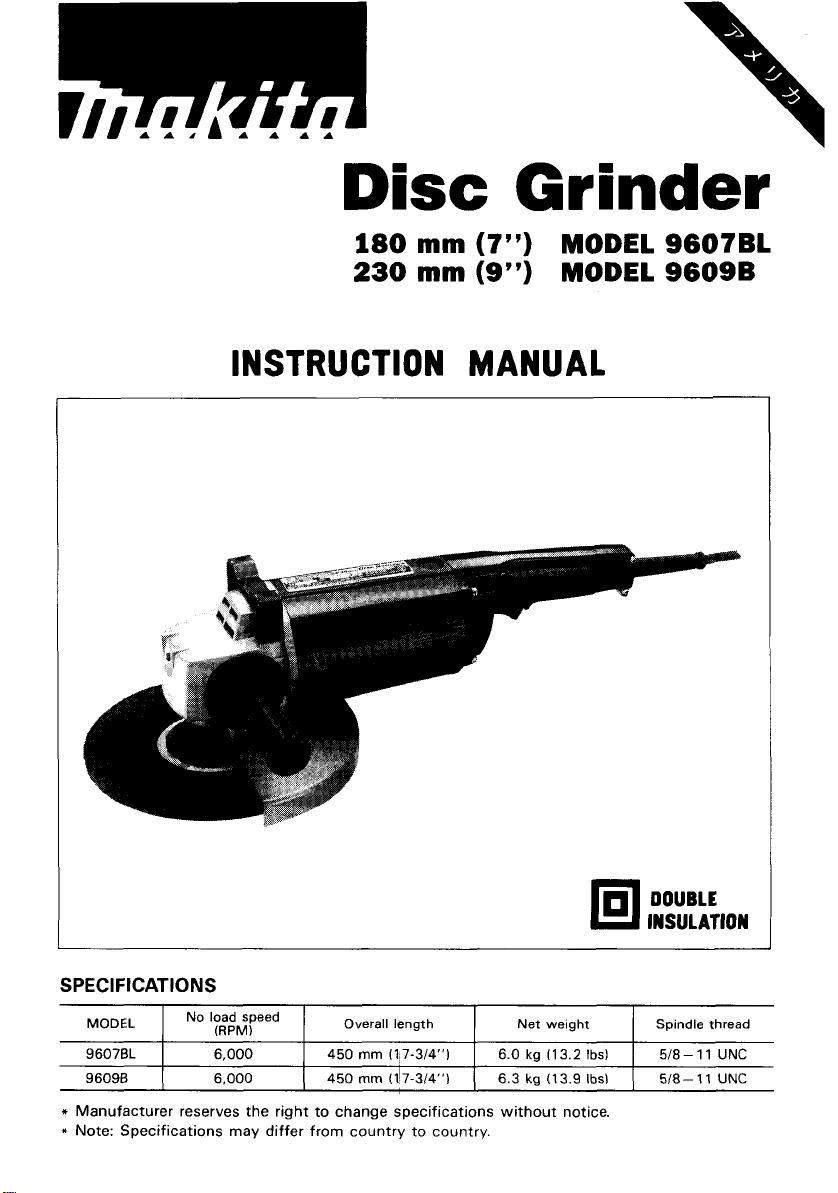

Disc Grinder

180

230

mm

mm

(7”)

(9”)

MODEL

MODEL

INSTRUCTION MANUAL

9607BL

9609B

SPECIFICATIONS

MODEL

9607BL

96098

I

No load speed

I

[

(RPM)

6,000

6,000

1

I

1

450

450

Overall length

mm

(1,7-314“1

mm

(47-314”)

1

I

I

Net weight

6.0

kq

6.3

kg

113.2

(13.9

Ibsl

Ibs)

DOUBLE

INSULATION

I

Spindle thread

I

5/8-11

UNC

518- 11

UNC

Page 2

IMPORTANT

SAFETY INSTRUCTIONS

(For

All

Tools)

WARNING:

WHEN USING ELECTRIC TOOLS, BASIC SAFE-

TY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO

REDUCE THE RISK

OF

FIRE, ELECTRIC SHOCK, AND PER-

SONAL INJURY, INCLUDING THE FOLLOWING:

READ ALL INSTRUCTIONS.

1.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2.

CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp

lit.

or wet locations. Keep work area well

Don‘t use tool

3.

KEEP CHILDREN AWAY. All visitors should be kept away from work area.

Don‘t let visitors contact tool or extension cord.

4.

STORE IDLE TOOLS. When not

or locked-up place

5.

DON’T FORCE TOOL.

it

was intended.

6.

USE RIGHT TOOL. Don‘t force small tool or attachment to do the job of a

heavy-duty tool. Don’t use tool for purpose not intended.

DRESS PROPERLY. Don’t wear loose clothing or jewelry. They can be caught

7.

in moving parts. Rubber gloves and non-skid footwear are recommended

when working outdoors. Wear protective hair covering to contain long hair.

8.

USE SAFETY GLASSES. Also use face or dust mask

dusty.

DON‘T ABUSE CORD. Never carry tool by cord or yank

9.

receptacle. Keep cord from heat, oil, and sharp edges.

SECURE WORK. Use clamps or a vise to hold work. It’s safer than using

IO.

your hand and

11.

DON’T OVERREACH. Keep proper footing and balance at all times.

12.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing accessories. Inspect tool cords periodically and

rized service facility. Inspect extension cords periodically and replace

damaged. Keep handles dry, clean, and free from oil and grease.

13.

DISCONNECT TOOLS. When not

ing accessories, such as blades, bits, cutters.

in

presence of flammable liquids or gases.

in

use, tools should be stored

-

out of reach of children.

It

will

do the job better and safer at the rate for which

it

frees both hands to operate tool.

in

Don’t expose power tools to rain.

in

dry, and high

if

cutting operation is

it

to disconnect from

if

damaged, have repaired by autho-

if

use, before servicing, and when chang-

2

Page 3

14.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning

it

on.

15.

AVOID UNINTENTIONAL STARTING. Don't carry plugged-in tool

on switch. Be sure switch is OFF when plugging

16.

OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only

extension cords intended for use outdoors and

17.

STAY ALERT.

tool when you are tired.

18.

CHECK DAMAGED PARTS. Before further use

part that is damaged should be carefully checked to determine that

operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage

any other conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere

manual. Have defective switches replaced by authorized service center. Don't

use tool if switch does not turn

19.

GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

surfaces. For example; pipes, radiators, ranges, refrigerator enclosures.

20.

REPLACEMENT PARTS. When servicing, use only identical replacement parts.

21.

POLARIZED PLUGS. To reduce the risk of electric shock, this equipment has

a polarized plug (one blade is wider than the other). This plug

polarized outlet only one way. If the

reverse the plug. If

the proper outlet.

Watch

it

Do

what

you

are

doing,

it

still does not fit, contact a qualified electrician to install

not change the plug

use common sense. Don't operate

on and off.

plug

does not fit fully

in

in.

so

marked.

of

the tool, a guard or other

of

parts, mounting, and

in

any way.

with

this instruction

with

will

in

the outlet,

finger

it

will

grounded

fit

in

a

VOLTAGE WARNING: Before connecting the tool to a power source (receptacle,

outlet, etc.) be sure the voltage supplied is the same as that specified on the

with

nameplate of the tool. A power source

in

for the tool can result

the tool. If

voltage less than the nameplate rating is harmful to the motor.

in

doubt,

SERIOUS INJURY to the user - as well as damage to

DO

NOT PLUG IN THE TOOL. Using a power source

voltage greater than that specified

with

3

Page 4

ADDITIONAL SAFETY RULES

1.

Keep guards

2.

Use only wheels having a maximum operating speed at least as high as

Load RPM” marked on the tool’s nameplate.,When using depressed center

wheels, be sure to use only fiberglass-reinforced wheels.

3.

Check the wheel carefully for cracks or damage before operation. Replace

cracked or damaged wheel immediately.

4.

Use only flanges specified for this tool.

5.

Be careful not to damage the spindle, the flange (especially the installing

surface) or the lock

breakage.

6.

Hold the tool firmly.

7.

Keep hands away from rotating parts.

8.

Make sure the wheel is not contacting the workpiece before the switch is

turned on.

9.

Before using the tool on an actual workpiece, let

for vibration or wobbling that could indicate poor installation or a poorly

balanced wheel.

IO.

Use the specified surface of the wheel to perform the grinding.

11.

Watch out for flying sparks. Hold the tool

and other persons or flammable materials.

12.

Do

not leave the tool running. Operate the tool only when hand-held.

13.

Do not touch the workpiece immediately after operation;

hot and could burn your skin.

in

place.

nut.

Damage to these parts could result

it

run for a while. Watch

so

that sparks fly away from you

it

may be extremely

in

“No

wheel

SAVE

4

THESE INSTRUCTIONS.

Page 5

Mount the inner flange onto the spindle.

Lock

Fit the wheel

on

over the inner flange and

nut

screw the lock nut onto the spindle.

Inner

flange

To

remove the wheel, follow the installation procedure in reverse.

I

5

Page 6

Switch action

TO

start

the

tool, simply pull

Release

operation, pull the trigger and then push in

the lock button.

locked position, pull the trigger fully, then

release

the trigger to stop. For continuous

To

stop

it.

the

the

tool from the

trigger.

'

'

Lock

/

button

1

CAUTION

Before plugging in the tool, always check to

and returns to the "OFF" position when released.

Operation

Hold the tool firmly. Turn the tool on and

then apply the wheel or disc to the work-

piece.

In general, keep the edge of the wheel or

disc

piece surface.

During the break-in period with

wheel, do not work the grinder in the

direction or

Once the edge of the wheel has been

rounded off by use, the wheel may be

worked in both A and

WARNING:

If should never be necessary to force the tool. The weight of the tool applies adequate

pressure. Forcing and excessive pressure could cause dangerous wheel breakage.

*Continued use of

injury. Depressed center wheel should not be used after

11

be removed from service and rendered unusable by intentional destruction.

:

at

an angle of about

it

will cut into the workpiece.

5

mm

(4-1/2")

see

that the trigger switch actuates properly

15'

to the work-

a

new

B

B

directions.

a

worn-out wheel may result in wheel explosion and serious personal

it

has been worn down to

in diameter. Use of the wheel after this point

is

unsafe and

it

should

6

Page 7

MAINTENANCE

CAUTION

Always be sure that the tool

inspection or maintenance.

Replacing carbon brushes

Remove and check the carbon brushes

regularly. Replace when they wear down

to the limit mark. Keep the carbon brushes

clean and free to

carbon brushes should be replaced

same time. Use only identical carbon

brushes.

Use

holder caps. Take out the worn carbon

brushes, insert the new ones and secure

the brush holder caps.

:

is

switched off and unplugged before attempting

slip

in the holders. Both

a

screwdriver to remove the brush

at

the

to

perform

Limit mark

To

maintain product SAFETY and RELIABILITY, repairs, any other maintenance or

adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

7

Page 8

ACCESSORIES

CAUTION:

These accessories or attachments are recommended for use with your Makita tool specified in this

manual. The use

accessories or attachments should be used only in the proper and intended manner.

of

any other accessories or attachments might present a risk

of

injury

to

persons. The

0

Wheel cover

Part

NO.

164396-4

164397-2

@

Lock

nut

(For depressed center wheel)

No.

Part

@

Rubber pad

Part

224512-1

No.

743012-7

Size

45

8

In"

180

(7") 9607BL

(9')

230

For Model

9W9B

Inner flange

(For depressed center wheel)

Part

Depressed center wheel

(1 per pkg)

Part

741413-3

7di~ifi-7

741421-4 24 230

741422.2

89

No.

2241 11

No. I Grit

24 180

I

RS

1

36

-9

I

17" x 1/4"x

(9'

Size

In"

x 6 x 22

x 6 x

X

1/4" X 7/8')

7/8")

22

I

For Model

I

9607BL

96096

Page 9

@

Abrasive disc

(1

0

per pkg)

794091 -8

794092-6

794093-4

8-0

79421

794094-2

794095-0

794220-3

794221-1 120

@

Flexible grinding wheel

(IO

per pkg)

794265-1

794233-4 180

794234-2

794235-0

794236-8 120

I

1

16

80

100

(includes

Slze

x

x

1 /8" x 7/8")

(7"

one

Part

No 743027-41

(mml

3

back

180 (7")

x

22

up

pad,@

0

Sanding lock nut

(For abrasive

Part

No.

@

Wire cup brush

Part

743207

743206

743706

0

Lock

nut wrench

No.

Part

No.

Part

0

Grip

37

Part

No.

48

disc)

224517-1

No

2

A

R

Diameter

28

782412-6 (For 9609B)

782413-4 (For 9607BL)

273480-5

4"

6'

0

Urethane washer

14

Part No. 261039-0

When using wire brush, mount urethane

washer 14

spindle.

It

will

to

the

easier to remove wire brush.

make it

9

Page 10

DISC GRINDER

180

mm

(7")

230

mm

(9")

Model

Model

9607BL

9609B

Jan.-26-'90

US

10

Note: The switch and other part configurations

may differ from country to country.

Page 11

MODEL

IT$

9607BL

AiD

96098

DESCRIPTION

AiD

DESCRIPTION

Jan

26-90

US

MACHINE

~

12

21

34

41

51

61

71

91

1

10

1

11

1

12

1

13

3

14

1

15

1

16

AR

17

1

18

4

19

1

20

1

21

1

22

1

23

2

24

2

25

1

26

1

21

1

28

1

29

1

30

1

31

1

32

1

33

Note

The

switch

Pan

Head

Screw

Rest

Head

Housing

Bearing

Bevel

Head

Retainer

Box

Head

Seal

Washpr

Head

Cover

Cover

Flange

Nut

Bevel

other

Screw

Screw

Screw

Key

Screw

5/8-45

M6x16 IWith Washer1

M5x25 IWilh Washer1

R

629LB

9

S - 17

Gear

M5x12 IWith Washerl

48

M5x18 IWith Washer1

4

25

5

M5x16

Holder

89

S-

Gear

part

specifications

Tool

Pan

Retaining Ring

6

Pin

Compression Spring

Gear

Ball

Flat Washer

Spindle Lock Bush

Retaining Ring

Spiral

Pan

Bearing

Ball Bearing 6203LLB

Shim

Bearing

Pan

Pin

6

Woodruff

Spindle

Dust

Spring

Pan

Wheel

Wheel

Inner

Lock

Retaining Ring

Ring 12

Spiral

Ball Bearing 6201LLB

and

MACHINE

~

1

34

35

3

1

36

country

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

58

59

60

61

62

63

64

10

to

1

country

1

I

1

1

1

1

1

1

2

2

2

2

1

1

1

1

I

2

1

2

2

2

1

1

1

2

1

1

12

7

58

12

19

may

dlffer

from

Retainer

Bearing

Pan

Baffle Plate

Woodruff

Fan

ARMATURE ASSEMBLY

IWith

Insulation Washer

Ball

FIELD ASSEMBLY

Band

Rubber Pin 4

Pan

Carbon Brush

Brush

Rivet

Name Plate

Motor

Switch

Dust

Pan

Pan

Handle

Pan

Pan

Pan

Strain Relef

Card

Cord

Pan

Handle

Grip 37

40

Head

Screw

M5x14 IWith Washer)

Key

4

92

Irem

38 - 411

Bearing 6200LB

Head

Screw

M5x85 IWiih Washer & Bond1

Holder

Cap

0-5

Housing

Cover

Head

Screw

M4x25 IWith Washerl

Head

Screw

M6x30 IWith Washerl

Set

IWith Item 641

Head

Screw

M4x25 IWith Washerl

Head

Screw

M4x10

Head

Screw

M4x18 IWith Washerl

Guard

Head

Screw

M6x30 IWith Washer1

Set

IWith Item 551

IWith

Washer1

11

Page 12

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to

be free of defects from workmanship and materials for the period of ONE YEAR from the date of

original purchase. Should any trouble develop during this one-year period, retum the COMPLETE

tool, freight prepaid, to one of Makita’s Factory or Authorized Service Centers. If inspection shows

the trouble is caused by defective workmanship

replace) without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and tear:

The tool has been abused, misused or improperly maintained;

alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER

APPLIES BOTH DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED

WARRANTIES OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,”

AFTER THE ONE-YEAR TERM OF THIS WARRANTY.

This Warranty gives you specific legal rights, and

state to state. Some states do not allow the exclusion

damages,

limitation on how long an implied warranty lasts,

so

the above limitation

or

exclusion may not apply to you. Some states do not allow

or material, Makita

you

may also have other rights which vary from

or

limitation of incidental

so

the above limitation may not apply to

will

repair (or at

or

consequential

our

option,

you.

Makita Corporation

3-11

-8,

Sumiyoshi-cho,

Anjo, Aichi

446

Japan

883085E061

PRINTED IN JAPAN

1992 - 9

-

N

Loading...

Loading...