Page 1

GB Angle Grinder Instruction manual

F Meuleuse d’Angle Manuel d’instructions

D Winkelschleifer Betriebsanleitung

I Smerigliatrice angolare Istruzioni per l’uso

NL Haakse slijpmachine Gebruiksaanwijzing

E Esmeriladora Angular Manual de instrucciones

P Esmerilhadeira Angular Manual de instruções

DK Vinkelsliber Brugsanvisning

GR Γωνιακός τροχός Οδηγίες χρήσης

9561CR

9561CVR

9562CR

9562CVR

9564CR

9564CVR

9565CR

9565CVR

009415

Page 2

1

2

1 007358 2 007359

3

4

3 009461 4 009416

2

5

5 001046 6 007360

6

8

7

6

7

8

9

7 009419 8 002980

2

Page 3

8

10

11

12

9 002981 10 010511

13

1

14

11 00 7363 12 005259

15

16

13 005260 14 005261

17

18

AB

15

15 005262 16 007364

3

Page 4

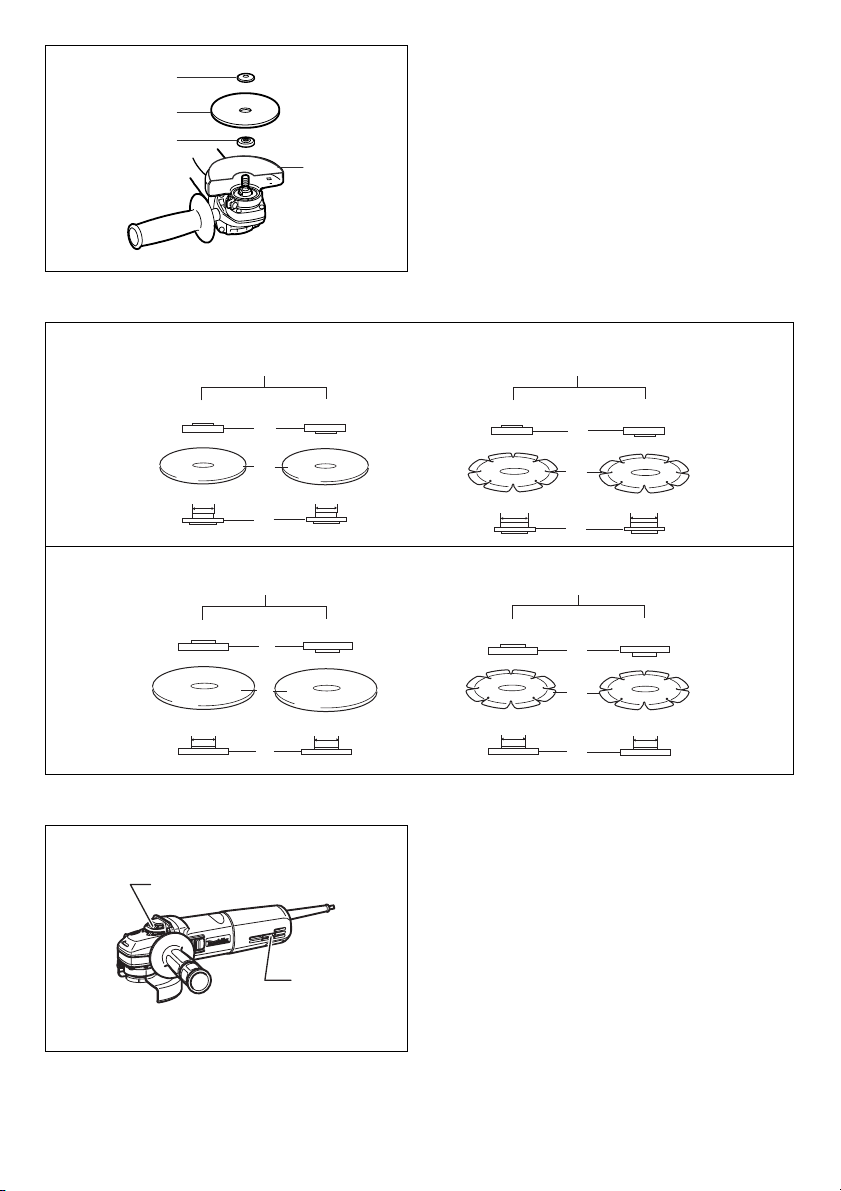

10

19

20

21

17 010855

100 mm (4”)

22

23

24 25 24 25

16 mm (5/8”)

10

22

16 mm (5/8”)

20

20 mm (13/16”)

10

23

20 mm (13/16”)

20

115 mm (4 - 1/2”) / 125 mm (5”)

22

24 25 24 25

22,23 mm (7/8”)

10

22

20

22,23 mm (7/8”)

22,23 mm (7/8”) 22,23 mm (7/8”)

23

10

23

20

18 010848

26

27

19 009417

4

Page 5

ENGLISH (Original instructions)

Explanation of general view

1. Shaft lock

2. Slide switch

3. Indication lamp (speed adjusting

dial)

4. Indication lamp

5. Speed adjusting dial

6. Wheel guard

7. Bearing box

8. Screw

9. Lever

10. Lock nut

11. Depressed center grinding wheel/

Multi-disc

12. Inner flange or super flange

13. Lock nut wrench

14. Marking A

15. Marking B

16. Marking C

17. Pin

18. Vent

19. Abrasive cut-off wheel/diamond

wheel

20. Inner flange

21. Wheel guard for abrasive cut-off

wheel/diamond wheel

22. Abrasive cut-off wheel

23. Diamond wheel

24. Thickness: Less than 4 mm

(5/32”)

25. Thickness: 4 mm (5/32”) or more

26. Exhaust vent

27. Inhalation vent

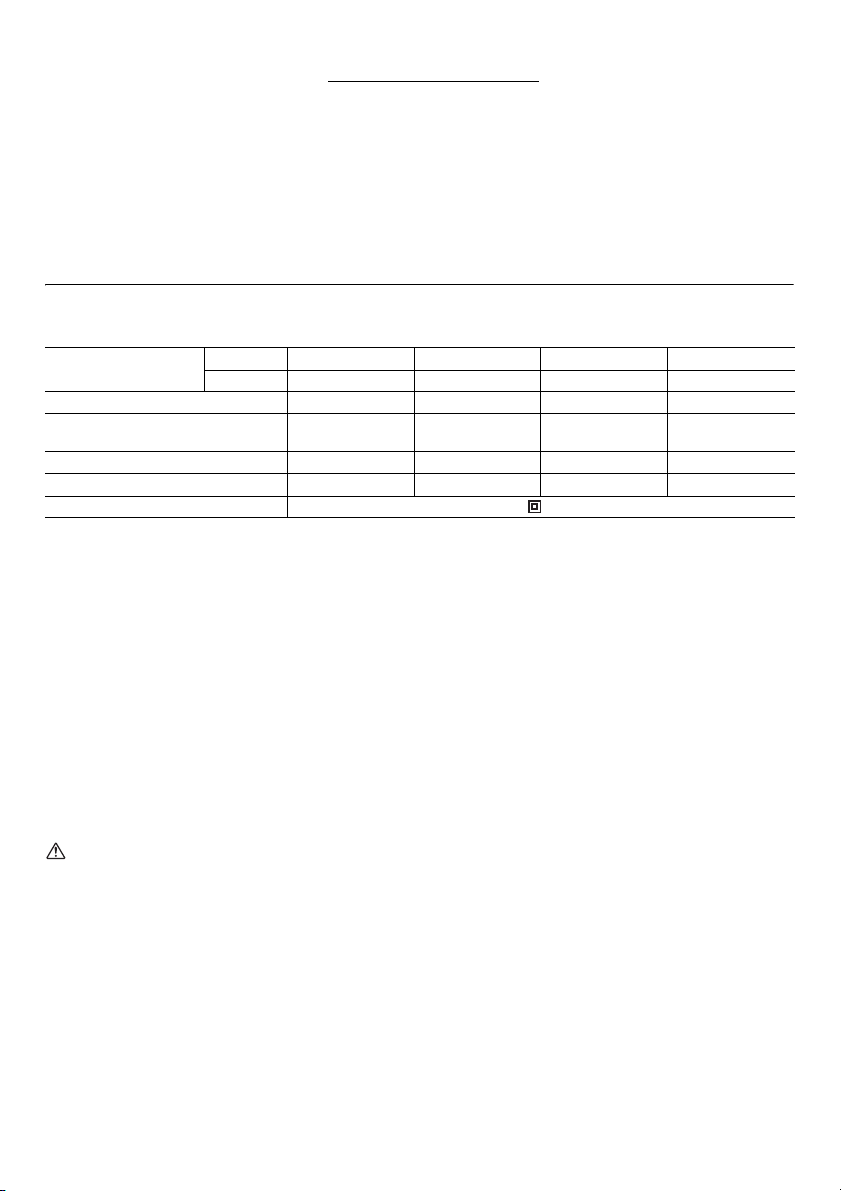

SPECIFICATIONS

Depressed center

wheel diameter

Spindle thread M14 M14 M14 M14

Rated speed (n) / No load speed (

Overall length 289 mm 299 mm 289 mm 299 mm

Net weight 2.2 kg 2.2 kg 2.2 kg 2.2 kg

Safety class /II

• Due to our continuing programme of research and development, the specifications herein are subject to change without

notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for grinding, sanding and cutting of

metal and stone materials without the use of water.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated and can, therefore, also be used from

sockets without earth wire.

General Power Tool Safety

Warnings

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and

instructions for future reference.

GRINDER SAFETY WARNINGS

Safety Warnings Common for Grinding, Sanding,

Wire Brushing, or Abrasive Cutting-Off Operations:

1. This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool. Read all

safety warnings, instructions, illustrations and

specifications provided with this power tool.

115 mm 9561CR 9564CR 9561CVR 9564CVR

125 mm 9562CR 9565CR 9562CVR 9565CVR

n

) 12,000 min

0

-1

ENE048-1

ENF002-2

GEA010-1

GEB033-5

12,000 min

2. Operations such as polishing are not

3. Do not use accessories which are not specifically

4. The rated speed of the accessory must be at least

5. The outside diameter and the thickness of your

6. The arbour size of wheels, flanges, backing pads

7. Do not use a damaged accessory. Before each use

-1

Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal

injury.

designed and recommended by the tool

manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe

operation.

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated

speed can break and fly apart.

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

or any other accessory must properly fit the

spindle of the power tool. Accessories with arbour

holes that do not match the mounting hardware of the

power tool will run out of balance, vibrate excessively

and may cause loss of control.

inspect the accessory such as abrasive wheels for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked

wires. If power tool or accessory is dropped,

2,800 -

12,000 min

-1

2,800 -

12,000 min

-1

5

Page 6

inspect for damage or install an undamaged

accessory. After inspecting and installing an

accessory, position yourself and bystanders away

from the plane of the rotating accessory and run

the power tool at maximum no-load speed for one

minute. Damaged accessories will normally break

apart during this test time.

8. Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable of

stopping flying debris generated by various

operations. The dust mask or respirator must be

capable of filtrating particles generated by your

operation. Prolonged exposure to high intensity noise

may cause hearing loss.

9. Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

10. Hold power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

11. Position the cord clear of the spinning accessory.

If you lose control, the cord may be cut or snagged

and your hand or arm may be pulled into the spinning

accessory.

12. Never lay the power tool down until the accessory

has come to a complete stop. The spinning

accessory may grab the surface and pull the power

tool out of your control.

13. Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into

your body.

14. Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may

cause electrical hazards.

15. Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

16. Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other

accessory. Pinching or snagging causes rapid stalling of

the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction

opposite of the accessory’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel that is entering

into the pinch point can dig into the surface of the material

causing the wheel to climb out or kick out. The wheel may

either jump toward or away from the operator, depending

on direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if

provided, for maximum control over kickback or

torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper

precautions are taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over your hand.

c) Do not position your body in the area where

power tool will move if kickback occurs. Kickback

will propel the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specific for Grinding and Abrasive

Cutting-Off Operations:

a) Use only wheel types that are recommended for

your power tool and the specific guard designed

for the selected wheel. Wheels for which the power

tool was not designed cannot be adequately guarded

and are unsafe.

b) The guard must be securely attached to the

power tool and positioned for maximum safety, so

the least amount of wheel is exposed towards the

operator. The guard helps to protect the operator

from broken wheel fragments, accidental contact with

wheel and sparks that could ignite clothing.

c) Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied to

these wheels may cause them to shatter.

d) Always use undamaged wheel flanges that are

of correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing

the possibility of wheel breakage. Flanges for cut-off

wheels may be different from grinding wheel flanges.

e) Do not use worn down wheels from larger

power tools. Wheel intended for larger power tool is

not suitable for the higher speed of a smaller tool and

may burst.

Additional Safety Warnings Specific for Abrasive

Cutting-Off Operations:

a) Do not “jam” the cut-off wheel or apply

excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the wheel

increases the loading and susceptibility to twisting or

binding of the wheel in the cut and the possibility of

kickback or wheel breakage.

b) Do not position your body in line with and

behind the rotating wheel. When the wheel, at the

point of operation, is moving away from your body, the

6

Page 7

possible kickback may propel the spinning wheel and

the power tool directly at you.

c) When wheel is binding or when interrupting a

cut for any reason, switch off the power tool and

hold the power tool motionless until the wheel

comes to a complete stop. Never attempt to

remove the cut-off wheel from the cut while the

wheel is in motion otherwise kickback may occur.

Investigate and take corrective action to eliminate the

cause of wheel binding.

d) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully re-enter the cut. The wheel may bind, walk

up or kickback if the power tool is restarted in the

workpiece.

e) Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback.

Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near

the line of cut and near the edge of the workpiece on

both sides of the wheel.

f) Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical

wiring or objects that can cause kickback.

Safety Warnings Specific for Sanding Operations:

a) Do not use excessively oversized sanding disc

paper. Follow manufacturers recommendations,

when selecting sanding paper. Larger sanding

paper extending beyond the sanding pad presents a

laceration hazard and may cause snagging, tearing of

the disc or kickback.

Safety Warnings Specific for Wire Brushing

Operations:

a) Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive load to

the brush. The wire bristles can easily penetrate light

clothing and/or skin.

b) If the use of a guard is recommended for wire

brushing, do not allow interference of the wire

wheel or brush with the guard. Wire wheel or brush

may expand in diameter due to work load and

centrifugal forces.

Additional safety warnings:

17. When using depressed centre grinding wheels, be

sure to use only fiberglass-reinforced wheels.

18. NEVER USE Stone Cup type wheels with this

grinder. This grinder is not designed for these types

of wheels and the use of such a product may result in

serious personal injury.

19. Be careful not to damage the spindle, the flange

(especially the installing surface) or the lock nut.

Damage to these parts could result in wheel

breakage.

20. Make sure the wheel is not contacting the

workpiece before the switch is turned on.

21. Before using the tool on an actual workpiece, let it

run for a while. Watch for vibration or wobbling

that could indicate poor installation or a poorly

balanced wheel.

22. Use the specified surface of the wheel to perform

the grinding.

23. Watch out for flying sparks. Hold the tool so that

sparks fly away from you and other persons or

flammable materials.

24. Do not leave the tool running. Operate the tool

only when hand-held.

25. Do not touch the workpiece immediately after

operation; it may be extremely hot and could burn

your skin.

26. Always be sure that the tool is switched off and

unplugged or that the battery cartridge is removed

before carrying out any work on the tool.

27. Observe the instructions of the manufacturer for

correct mounting and use of wheels. Handle and

store wheels with care.

28. Do not use separate reducing bushings or

adaptors to adapt large hole abrasive wheels.

29. Use only flanges specified for this tool.

30. For tools intended to be fitted with threaded hole

wheel, ensure that the thread in the wheel is long

enough to accept the spindle length.

31. Check that the workpiece is properly supported.

32. Pay attention that the wheel continues to rotate

after the tool is switched off.

33. If working place is extremely hot and humid, or

badly polluted by conductive dust, use a shortcircuit breaker (30 mA) to assure operator safety.

34. Do not use the tool on any materials containing

asbestos.

35. Do not use water or grinding lubricant.

36. Ensure that ventilation openings are kept clear

when working in dusty conditions. If it should

become necessary to clear dust, first disconnect

the tool from the mains supply (use non metallic

objects) and avoid damaging internal parts.

37. When use cut-off wheel, always work with the dust

collecting wheel guard required by domestic

regulation.

38. Cutting discs must not be subjected to any lateral

pressure.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product (gained

from repeated use) replace strict adherence to safety

rules for the subject product. MISUSE or failure to

follow the safety rules stated in this instruction

manual may cause serious personal injury.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

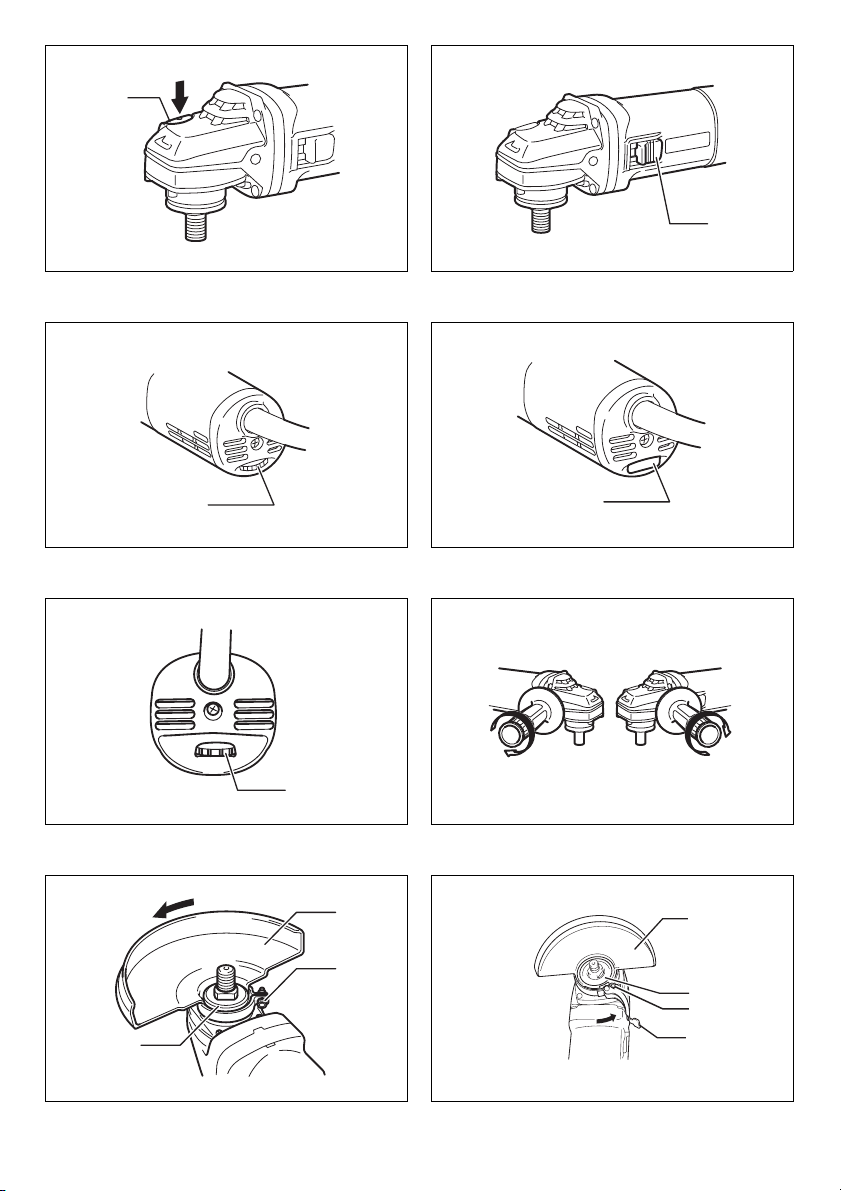

Shaft lock (Fig. 1)

CAUTION:

• Never actuate the shaft lock when the spindle is

moving. The tool may be damaged.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

7

Page 8

Switch action (Fig. 2)

CAUTION:

• Before plugging in the tool, always check to see that

the slide switch actuates properly and returns to the

“OFF” position when the rear of the slide switch is

depressed.

To start the tool, slide the slide switch toward the “I (ON)”

position. For continuous operation, press the front of the

slide switch to lock it.

To stop the tool, press the rear of the slide switch, then

slide it toward the “O (OFF)” position.

Indication lamp

For Models 9561CVR, 9562CVR, 9564CVR, 9565CVR

(Fig. 3)

For Models 9561CR, 9562CR, 9564CR, 9565CR (Fig. 4)

The indication lamp lights up green when the tool is

plugged. If the indication lamp does not light up, the mains

cord or the controller may be defective. The indication

lamp is lit but the tool does not start even if the tool is

switched on, the carbon brushes may be worn out, or the

controller, the motor or the ON/OFF switch may be

defective.

Unintentional restart proof

The tool does not start with the switch being lock-on even

when the tool is plugged.

At this time, the indication lamp flickers red and shows the

unintentional restart proof device is on function.

To cancel the unintentional restart proof, return the slide

switch to “O (OFF)” position, then release it.

Speed adjusting dial

For 9561CVR, 9562CVR, 9564CVR, 9565CVR (Fig. 5)

The rotating speed can be changed by turning the speed

adjusting dial to a given number setting from 1 to 5.

Higher speed is obtained when the dial is turned in the

direction of number 5. And lower speed is obtained when

it is turned in the direction of number 1.

Refer to the below table for the relationship between the

number settings on the dial and the approximate rotating

speed.

Number min

12,800

24,000

36,500

49,000

5 12,000

CAUTION:

• If the tool is operated continuously at low speeds for a

long time, the motor will get overloaded and heated up.

• The speed adjusting dial can be turned only as far as 5

and back to 1. Do not force it past 5 or 1, or the speed

adjusting function may no longer work.

The tools equipped with electronic function are easy to

operate because of the following features.

• Electronic constant speed control

Possible to get fine finish, because the rotating speed

is kept constantly even under the loaded condition.

8

-1

(R.P.M.)

• Soft start feature

Soft start because of suppressed starting shock.

• Overload protector

When the load on the tool exceeds admissible levels,

power to the motor is reduced to protect the motor from

overheating. When the load returns to admissible

levels, the tool will operate as normal.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing side grip (handle) (Fig. 6)

CAUTION:

• Always be sure that the side grip is installed securely

before operation.

Screw the side grip securely on the position of the tool as

shown in the figure.

Installing or removing wheel guard (For

depressed center wheel, multi disc/

abrasive cut-off wheel, diamond wheel)

For tool with locking screw type wheel guard (Fig. 7)

CAUTION:

• The wheel guard must be fitted on the tool so that the

closed side of the guard always points toward the

operator.

Mount the wheel guard with the protrusion on the wheel

guard band aligned with the notch on the bearing box.

Then rotate the wheel guard around 180 degrees

counterclockwise. Be sure to tighten the screw securely.

To remove wheel guard, follow the installation procedure

in reverse.

For tool with clamp lever type wheel guard (Fig. 8 & 9)

Pull the lever in the direction of the arrow after loosening

the screw. Mount the wheel guard with the protrusion on

the wheel guard band aligned with the notch on the

bearing box. Then rotate the wheel guard around 180°.

Fasten it with the screw after pulling lever in the direction

of the arrow for the working purpose. The setting angle of

the wheel guard can be adjusted with the lever.

To remove wheel guard, follow the installation procedure

in reverse.

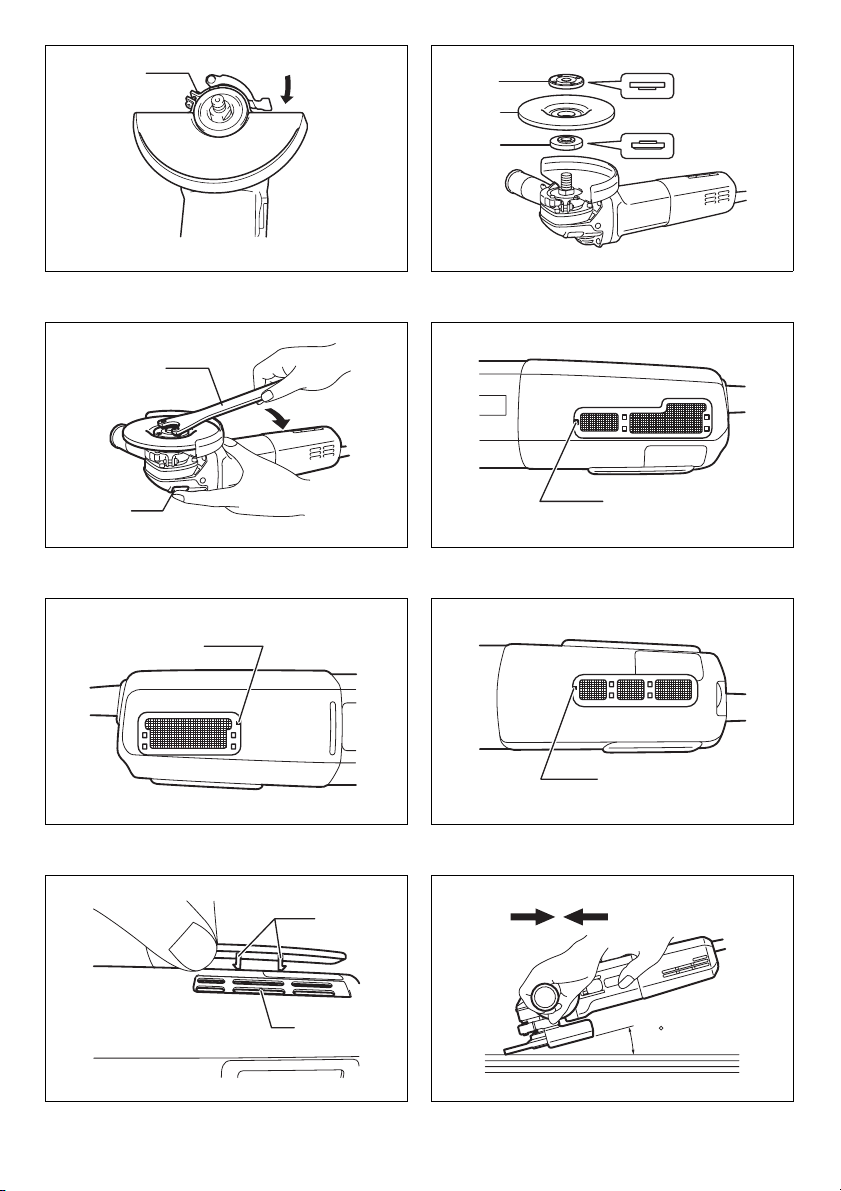

Installing or removing depressed center

grinding wheel/Multi-disc (accessory)

(Fig. 10)

Mount the inner flange onto the spindle. Fit the wheel/disc

on the inner flange and screw the lock nut onto the

spindle.

To tighten the lock nut, press the shaft lock firmly so that

the spindle cannot revolve, then use the lock nut wrench

and securely tighten clockwise. (Fig. 11)

To remove the wheel, follow the installation procedure in

reverse.

Page 9

Super flange

Models with the letter F are standard-equipped with a

super flange. Only 1/3 of efforts needed to undo lock nut,

compared with conventional type.

Installing or removing dust cover

attachment (Optional accessory)

WARNING:

• Always be sure that the tool is switched off and

unplugged before installing or removing the dust cover

attachment. Failure to do so causes damage to the tool

or a personal injury.

There are three types of dust cover attachment and each

is used in one of different positions. (Fig. 12 - 14)

Place the dust cover attachment so that the side of the

dust cover attachment with the marking (A, B or C) faces

towards the tool head. Snap the pins of the dust cover

attachment in the vent. (Fig. 15)

Dust cover attachment can be removed by hand.

NOTE:

• Clean out the dust cover attachment when it is clogged

with dust or foreign matters. Continuing operation with

a clogged dust cover attachment will damage the tool.

OPERATION

WARNING:

• It should never be necessary to force the tool. The

weight of the tool applies adequate pressure. Forcing

and excessive pressure could cause dangerous wheel

breakage.

• ALWAYS replace wheel if tool is dropped while

grinding.

• NEVER bang or hit grinding disc or wheel onto work.

• Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc. This can

cause loss of control and kickback.

• NEVER use tool with wood cutting blades and other

sawblades. Such blades when used on a grinder

frequently kick and cause loss of control leading to

personal injury.

CAUTION:

• After operation, always switch off the tool and wait until

the wheel has come to a complete stop before putting

the tool down.

Grinding and sanding operation

ALWAYS hold the tool firmly with one hand on housing

and the other on the side handle. Turn the tool on and

then apply the wheel or disc to the workpiece.

In general, keep the edge of the wheel or disc at an angle

of about 15 degrees to the workpiece surface.

During the break-in period with a new wheel, do not work

the grinder in the B direction or it will cut into the

workpiece. Once the edge of the wheel has been rounded

off by use, the wheel may be worked in both A and B

direction. (Fig. 16)

Operation with abrasive cut-off/diamond

wheel (optional accessory) (Fig. 17)

The direction for mounting the lock nut and the inner

flange varies by wheel thickness.

Refer to the table below. (Fig. 18)

WARNING:

• When using an abrasive cut-off/diamond wheel, be

sure to use only the special wheel guard designed for

use with cut-off wheels.

• NEVER use cut-off wheel for side grinding.

• Do not “jam” the wheel or apply excessive pressure. Do

not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the

cut and the possibility of kickback, wheel breakage and

overheating of the motor may occur.

• Do not start the cutting operation in the workpiece. Let

the wheel reach full speed and carefully enter into the

cut moving the tool forward over the workpiece surface.

The wheel may bind, walk up or kickback if the power

tool is started in the workpiece.

• During cutting operations, never change the angle of

the wheel. Placing side pressure on the cut-off wheel

(as in grinding) will cause the wheel to crack and break,

causing serious personal injury.

• A diamond wheel shall be operated perpendicular to

the material being cut.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

The tool and its air vents have to be kept clean.

Regularly clean the tool’s air vents or whenever the vents

start to become obstructed. (Fig. 19)

To maintain product SAFETY and RELIABILITY, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by

Makita Authorized Service Centers, always using Makita

replacement parts.

OPTIONAL ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Wheel guard (Wheel cover) For depressed center

wheel/Multi disc

• Wheel guard (Wheel cover) For abrasive cut-off wheel/

diamond wheel

• Depressed center wheels

• Abrasive cut-off wheels

•Multi discs

• Diamond wheels

• Wire cup brushes

• Wire bevel brush 85

• Abrasive discs

• Inner flange

9

Page 10

• Lock nut For depressed center wheel/abrasive cut-off

wheel/multi disc/diamond wheel

• Lock nut For abrasive disc

• Lock nut wrench

• Side grip

• Rubber pad

• Dust cover attachment

NOTE:

• Some items in the list may be included in the tool

package as standard accessories. They may differ

from country to country.

Noise

ENG905-1

The typical A-weighted noise level determined according

to EN60745:

Model 9561CR/CVR, 9562CR/CVR, 9564CR/CVR

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

): 83 dB (A)

pA

): 94 dB (A)

WA

Model 9565CR/CVR

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

): 82 dB (A)

pA

): 93 dB (A)

WA

Wear ear protection.

Vibration

ENG900-1

The vibration total value (tri-axial vector sum) determined

according to EN60745:

Model 9561CR/CVR, 9562CR/CVR

Work mode: surface grinding with normal side grip

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,AG

2

): 8.5 m/s

2

Work mode: surface grinding with anti vibration side

grip

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,AG

2

): 7.5 m/s

2

Model 9564CR/CVR

Work mode: surface grinding with normal side grip

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,AG

2

): 8.0 m/s

2

Work mode: surface grinding with anti vibration side

grip

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,AG

2

): 8.0 m/s

2

Model 9565CR/CVR

Work mode: surface grinding with normal side grip

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,AG

2

): 8.0 m/s

2

Work mode: surface grinding with anti vibration side

grip

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,AG

2

): 7.5 m/s

2

• The declared vibration emission value has been

ENG902-1

measured in accordance with the standard test method

and may be used for comparing one tool with another.

• The declared vibration emission value may also be

used in a preliminary assessment of exposure.

• The declared vibration emission value is used for main

applications of the power tool. However if the power

tool is used for other applications, the vibration

emission value may be different.

WARNING:

• The vibration emission during actual use of the power

tool can differ from the declared emission value

depending on the ways in which the tool is used.

• Be sure to identify safety measures to protect the

operator that are based on an estimation of exposure in

the actual conditions of use (taking account of all parts

of the operating cycle such as the times when the tool

is switched off and when it is running idle in addition to

the trigger time).

For European countries only

ENH101-15

EC Declaration of Conformity

We Makita Corporation as the responsible

manufacturer declare that the following Makita

machine(s):

Designation of Machine:

Angle Grinder

Model No./ Type: 9561CR/CVR, 9562CR/CVR,

9564CR/CVR, 9565CR/CVR

are of series production and

Conforms to the following European Directives:

2006/42/EC

And are manufactured in accordance with the following

standards or standardised documents:

EN60745

The technical documentation is kept by our authorised

representative in Europe who is:

Makita International Europe Ltd.

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, England

30. 1. 2009

Tomoyasu Kato

Director

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

10

Page 11

NEDERLANDS (Originele instructies)

Verklaring van algemene gegevens

1. Asvergrendeling

2. Schuifknop

3. Bedrijfslampje

(snelheidsregelaar)

4. Bedrijfslampje

5. Snelheidsregelaar

6. Beschermkap

7. Lagerhuis

8. Schroef

9. Hendel

10. Borgmoer

11. Slijpschijf/multischijf met

verzonken middengat

12. Binnenflens of superflens

13. Borgmoersleutel

14. Markering A

15. Markering B

16. Markering C

17. Pen

18. Ventilatieopening

19. Doorslijpschijf of diamantschijf

20. Binnenflens

21. Beschermkap voor doorslijpschijf

of diamantschijf

22. Doorslijpschijf

23. Diamantschijf

24. Dikte: minder dan 4 mm

25. Dikte: 4 mm of meer

26. Luchtuitlaatopening

27. Luchtinlaatopening

TECHNISCHE GEGEVENS

Diameter van schijf

met een verzonken

middengat

Asschroefdraad M14 M14 M14 M14

Nominaal toerental (n)/ Nullasttoerental (

Totale lengte 289 mm 299 mm 289 mm 299 mm

Nettogewicht 2,2 kg 2,2 kg 2,2 kg 2,2 kg

Veiligheidsklasse /II

• Als gevolg van ons doorlopende onderzoeks- en ontwikkelingsprogramma, zijn de technische gegevens van dit

gereedschap onderhevig aan veranderingen zonder voorafgaande kennisgeving.

• De technische gegevens kunnen van land tot land verschillen.

• Gewicht volgens EPTA-procedure 01/2003

Gebruiksdoeleinden

Het gereedschap is bedoeld voor het slijpen, schuren en

doorslijpen van metaal en steen zonder gebruik van

water.

Voe din g

Het gereedschap mag uitsluitend worden aangesloten op

een voeding met dezelfde spanning als aangegeven op

het typeplaatje en werkt alleen op enkele-fase

wisselstroom. Het gereedschap is dubbel geïsoleerd en

mag derhalve ook op een niet-geaard stopcontact worden

aangesloten.

Algemene

veiligheidswaarschuwingen voor

elektrisch gereedschap

WAARSCHUWING Lees alle

veiligheidswaarschuwingen en alle instructies

niet volgen van de waarschuwingen en instructies kan

leiden tot elektrische schokken, brand en/of ernstig letsel.

Bewaar alle waarschuwingen en

instructies om in de toekomst te

kunnen raadplegen.

115 mm 9561CR 9564CR 9561CVR 9564CVR

125 mm 9562CR 9565CR 9562CVR 9565CVR

n

) 12.000 min

0

ENE048-1

-1

12.000 min

-1

2.800 -

12.000 min

-1

VEILIGHEIDSWAARSCHUWINGEN

2.800 -

12.000 min

SPECIFIEK VOOR EEN

SLIJPMACHINE

ENF002-2

GEA010-1

. Het

Gemeenschappelijke veiligheidswaarschuwingen

voor slijp-, schuur-, draadborstel- en

doorslijpwerkzaamheden:

1. Dit elektrisch gereedschap is bedoeld voor

gebruik als slijp-, schuur-, draadborstel- of

doorslijpgereedschap. Lees alle

veiligheidswaarschuwingen, instructies,

afbeeldingen en technische gegevens die bij dit

elektrisch gereedschap worden geleverd. Als u

nalaat alle onderstaande instructies te volgen, kan dit

leiden tot een elektrische schok, brand en/of ernstig

letsel.

2. Werkzaamheden zoals polijsten worden niet

aangeraden met dit elektrisch gereedschap.

Werkzaamheden waarvoor dit elektrisch gereedschap

niet is bedoeld kunnen gevaarlijke situaties opleveren

en tot persoonlijk letsel leiden.

3. Gebruik geen accessoires die niet specifiek zijn

ontworpen en aanbevolen door de fabrikant van

het gereedschap. Ook wanneer het accessoire kan

worden bevestigd op uw elektrisch gereedschap, is

een veilige werking niet gegarandeerd.

4. Het nominaal toerental van het accessoire moet

minstens gelijk zijn aan het maximumtoerental

vermeld op het elektrisch gereedschap.

Accessoires die met een hoger toerental draaien dan

hun nominaal toerental kunnen stuk breken en in het

rond vliegen.

-1

GEB033-5

33

Page 12

5. De buitendiameter en de dikte van het accessoire

moet binnen het capaciteitsbereik van het

elektrisch gereedschap vallen. Accessoires met

verkeerde afmetingen kunnen niet afdoende worden

afgeschermd of beheerst.

6. De asdiameter van schijven, flenzen, rugschijven

en andere accessoires moeten goed passen rond

de as van het elektrisch gereedschap. Accessoires

met een asdiameter die niet overeenkomt met de

standaardhardware voor het elektrisch gereedschap

zullen niet in balans draaien, buitensporig trillen en

kunnen tot verlies van controle over het gereedschap

leiden.

7. Gebruik nooit een beschadigd accessoire.

Inspecteer het accessoire vóór ieder gebruik,

bijvoorbeeld een slijpschijf op ontbrekende

schilfers en barsten; een rugschijf op barsten,

scheuren of buitensporige slijtage; en een

draadborstel op losse of gebarsten draden. Nadat

het elektrisch gereedschap is gevallen,

inspecteert u het op schade of monteert u een

onbeschadigd accessoire. Na inspectie en

montage van een accessoire, zorgt u ervoor dat u

en omstanders niet in het rotatie vlak van het

accessoire staan, en laat u het elektrisch

gereedschap draaien op het maximaal, onbelast

toerental gedurende één minuut. Beschadigde

accessoire breken normaal gesproken in stukken

gedurende deze testduur.

8. Gebruik persoonlijke-veiligheidsmiddelen.

Afhankelijk van de toepassing gebruikt u een

gezichtsscherm, een beschermende bril of een

veiligheidsbril. Al naar gelang van toepassing

draagt u een stofmasker, gehoorbeschermers,

handschoenen en een werkschort die in staat zijn

kleine stukjes slijpsel of werkstukfragmenten te

weerstaan. De oogbescherming moet in staat zijn

rondvliegend afval te stoppen dat ontstaat bij de

diverse werkzaamheden. Het stofmasker of

ademhalingsapparaat moet in staat zijn deeltjes te

filteren die ontstaat bij de werkzaamheden.

Langdurige blootstelling aan zeer intens geluid kan

leiden tot gehoorbeschadiging.

9. Houd omstanders op veilige afstand van het

werkgebied. Iedereen die zich binnen het

werkgebied begeeft, moet persoonlijkeveiligheidsmiddelen gebruiken. Fragmenten van

het werkstuk of van een uiteengevallen accessoire

kunnen rondvliegen en letsel veroorzaken buiten de

onmiddellijk werkomgeving.

10. Houd elektrisch gereedschap uitsluitend vast aan

het geïsoleerde oppervlak van de handgrepen

wanneer u werkt op plaatsen waar het

slijpaccessoire met verborgen bedrading of zijn

eigen snoer in aanraking kan komen. Wanneer het

accessoire in aanraking komen met onder spanning

staande draden, zullen de niet-geïsoleerde metalen

delen van het gereedschap onder spanning komen te

staan zodat de gebruiker een elektrische schok kan

krijgen.

11. Houd het snoer goed uit de buurt van het

ronddraaiende accessoire. Als u de controle verliest

over het gereedschap, kan het snoer worden

doorgesneden of bekneld raken, en kan uw hand of

arm tegen het ronddraaiende accessoire worden

aangetrokken.

12. Leg het elektrisch gereedschap nooit neer voordat

het accessoire volledig tot stilstand is gekomen.

Het ronddraaiende accessoire kan de ondergrond

pakken zodat u de controle over het elektrisch

gereedschap verliest.

13. Laat het elektrisch gereedschap niet draaien

terwijl u het naast u draagt. Als het ronddraaiende

accessoire u per ongeluk raakt, kan het verstrikt raken

in uw kleding waardoor het accessoire in uw lichaam

wordt getrokken.

14. Maak de ventilatieopeningen van het gereedschap

regelmatig schoon. De ventilator van de motor zal

het stof de behuizing in trekken, en een grote

opeenhoping van metaalslijpsel kan leiden tot

elektrisch gevaarlijke situaties.

15. Gebruik het elektrisch gereedschap niet in de

buurt van brandbare materialen. Vonken kunnen

deze materialen doen ontvlammen.

16. Gebruik geen accessoires die met vloeistof

moeten worden gekoeld. Het gebruik van water of

andere vloeibare koelmiddelen kan leiden tot

elektrocutie of elektrische schokken.

Terugslag en aanverwante waarschuwingen

Terugslag is een plotselinge reactie op een beknelde of

vastgelopen draaiende schijf, rugschijf, borstel of enig

ander accessoire. Beknellen of vastlopen veroorzaakt een

snelle stilstand van het draaiende accessoire dat op zijn

beurt ertoe leidt dat het elektrisch gereedschap zich

ongecontroleerd beweegt in de tegenovergestelde

richting van de draairichting van het accessoire op het

moment van vastlopen.

Bijvoorbeeld, als een slijpschijf bekneld raakt of vastloopt

in het werkstuk, kan de rand van de schijf die het

beknellingspunt ingaat, zich invreten in het oppervlak van

het materiaal waardoor de schijf eruit klimt of eruit slaat.

De schijf kan daarbij naar de gebruiker toe of weg

springen, afhankelijk van de draairichting van de schijf op

het beknellingspunt. Slijpschijven kunnen in dergelijke

situaties ook breken.

Terugslag is het gevolg van misbruik van het elektrisch

gereedschap en/of onjuiste gebruiksprocedures of omstandigheden, en kan worden voorkomen door goede

voorzorgsmaatregelen te treffen, zoals hieronder vermeld:

a) Houd het gereedschap stevig vast en houdt uw

armen en lichaam zodanig dat u in staat bent een

terugslag op te vangen. Gebruik altijd de extra

handgreep (indien aanwezig) voor een maximale

controle over het gereedschap in geval van

terugslag en de koppelreactiekrachten bij het

starten. De gebruiker kan een terugslag of de

koppelreactiekrachten opvangen indien de juiste

voorzorgsmaatregelen worden getroffen.

b) Plaats uw hand nooit in de buurt van het

draaiende accessoire. Het accessoire kan

terugslaan over uw hand.

c) Plaats uw lichaam niet in het gebied waar het

elektrisch gereedschap naar toe gaat wanneer een

terugslag optreedt. Een terugslag zal het

gereedschap bewegen in de tegenovergestelde

richting van de draairichting van de schijf op het

moment van beknellen.

34

Page 13

d) Wees bijzonder voorzichtig bij het werken met

hoeken, scherpe randen, enz. Voorkom dat het

accessoire springt of bekneld raakt. Hoeken,

scherpe randen of springen veroorzaken vaak

beknellen van het draaiende accessoire wat leidt tot

terugslag of verlies van controle over het

gereedschap.

e) Bevestig geen houtbewerkingsblad van een

zaagketting of getand zaagblad. Dergelijke bladen

leiden vaak tot terugslag of verlies van controle over

het gereedschap.

Veiligheidswaarschuwingen specifiek voor slijp- en

doorslijpwerkzaamheden:

a) Gebruik uitsluitend schijven van het type

aanbevolen voor uw elektrisch gereedschap en de

specifieke beschermkap voor de te gebruiken

schijf. Schijven waarvoor het elektrisch gereedschap

niet is ontworpen, kunnen niet goed worden

afgeschermd en zijn niet veilig.

b) De beschermkap moet stevig worden vastgezet

aan het elektrisch gereedschap en in de maximaal

beschermende stand worden gezet zodat het

kleinst mogelijke deel van de schijf is blootgesteld

in de richting van de gebruiker. De beschermkap

helpt de gebruiker te beschermen tegen afgebroken

stukjes van de schijf, het per ongeluk aanraken van de

schijf en vonken die kleding kunnen doen

ontvlammen.

c) De schijven mogen uitsluitend worden gebruikt

voor de aanbevolen toepassingen. Bijvoorbeeld: u

mag niet slijpen met de zijkant van een

doorslijpschijf. Doorslijpschijven zijn bedoeld voor

slijpen met de rand. Krachten op het zijoppervlak

kunnen deze schijven doen breken.

d) Gebruik altijd onbeschadigde schijfflenzen van

de juiste afmetingen en vorm voor de te gebruiken

schijf. Een goede schijfflens ondersteunt de schijf en

verkleint daarmee de kans op het breken van de

schijf. Flenzen voor doorslijpschijven kunnen

verschillen van flenzen voor slijpschijven.

e) Gebruik geen afgesleten schijven van grotere

elektrische gereedschappen. Schijven die zijn

bedoeld voor grotere elektrische gereedschappen zijn

niet geschikt voor de hogere snelheid van een kleiner

elektrisch gereedschap en kunnen in stukken breken.

Aanvullende veiligheidswaarschuwingen specifiek

voor doorslijpwerkzaamheden:

a) Laat de doorslijpschijf niet vastlopen en oefen

geen buitensporige druk uit. Probeer niet een

buitensporig diepe snede te slijpen. Een te grote

kracht op de schijf verhoogt de belasting en de kans

dat de schijf in de snede verdraait of vastloopt,

waardoor terugslag kan optreden of de schijf kan

breken.

b) Plaats uw lichaam niet in één lijn achter de

ronddraaiende schijf. Wanneer de schijf, op het

aangrijppunt in het werkstuk, zich van uw lichaam af

beweegt, kunnen door de mogelijke terugslag de

ronddraaiende schijf en het elektrisch gereedschap in

uw richting worden geworpen.

c) Wanneer de schijf vastloopt of u het slijpen

onderbreekt, schakelt u het elektrisch

gereedschap uit en houdt u dit stil totdat de schijf

volledig tot stilstand is gekomen. Probeer nooit de

doorslijpschijf uit de snede te halen terwijl de

schijf nog draait omdat hierdoor een terugslag kan

optreden. Onderzoek waarom de schijf is

vastgelopen en tref afdoende maatregelen om de

oorzaak ervan op te heffen.

d) Begin niet met doorslijpen terwijl de schijf al in

het werkstuk steekt. Wacht totdat de schijf de

volle snelheid heeft bereikt en breng daarna de

schijf voorzichtig terug in de snede. Wanneer het

elektrisch gereedschap opnieuw wordt gestart terwijl

de schijf al in het werkstuk steekt, kan de schijf

vastlopen, omhoog lopen of terugslaan.

e) Ondersteun platen en grote werkstukken om de

kans op het beknellen van de schijf en terugslag te

minimaliseren. Grote werkstukken neigen door te

zakken onder hun eigen gewicht. U moet het werkstuk

ondersteunen vlakbij de snijlijn en vlakbij de rand van

het werkstuk aan beide kanten van de schijf.

f) Wees extra voorzichtig bij blind slijpen in

bestaande wanden of op andere plaatsen. De

uitstekende schijf kan gas- of waterleidingen,

elektrische bedrading of voorwerpen die terugslag

veroorzaken raken.

Veiligheidswaarschuwingen specifiek voor

schuurwerkzaamheden:

a) Gebruik geen veel te grote

schuurpapierschijven. Volg de aanwijzingen van

de fabrikant bij uw keuze van het schuurpapier. Te

groot schuurpapier dat uitsteekt tot voorbij de rand

van het schuurkussen levert snijgevaar op en kan

beknellen of scheuren van de schuurpapierschijf of

terugslag veroorzaken.

Veiligheidswaarschuwingen specifiek voor

draadborstelwerkzaamheden:

a) Wees erop bedacht dat ook tijdens normaal

gebruik borsteldraden door de borstel worden

rondgeslingerd. Oefen niet te veel kracht uit op de

borsteldraden door een te hoge belasting van de

borstel. De borsteldraden kunnen met gemak door

dunne kleding en/of de huid dringen.

b) Als het gebruik van een beschermkap wordt

aanbevolen voor draadborstelen, zorgt u ervoor

dat de draadschijf of draadborstel niet in

aanraking komt met de beschermkap. De

draadschijf of draadborstel kan in diameter toenemen

als gevolg van de werkbelasting en centrifugale

krachten.

Aanvullende veiligheidswaarschuwingen:

17. Bij gebruik van een slijpschijf met een verzonken

middengat, mag u uitsluitend met glasvezel

versterkte schijven gebruiken.

18. GEBRUIK NOOIT een stenen komschijf op deze

slijpmachine. Deze slijpmachine is niet ontworpen

voor dit type schijven en het gebruik ervan kan leiden

tot ernstig persoonlijk letsel.

19. Let erop dat u de as, de flens (met name de

montagekant) en de borgmoer niet beschadigt.

Als deze onderdelen beschadigd raken, kan de

schijf breken.

20. Zorg ervoor dat de schijf niet in aanraking is met

het werkstuk voordat u het gereedschap hebt

ingeschakeld.

21. Laat het gereedschap een tijdje draaien voordat u

het werkstuk gaat zagen. Controleer op trillingen

35

Page 14

of schommelingen die op onjuiste montage of een

slecht uitgebalanceerd schijf kunnen wijzen.

22. Gebruik de aangegeven kant van de schijf om mee

te slijpen.

23. Wees alert op rondvliegende vonken. Houd het

gereedschap zodanig vast dat de vonken

wegvliegen van u en andere personen of

brandbare materialen.

24. Laat het gereedschap niet ingeschakeld liggen.

Bedien het gereedschap alleen wanneer u het

vasthoudt.

25. Raak de schijf niet onmiddellijk na gebruik aan.

Deze kan bijzonder heet zijn en brandwonden op

uw huid veroorzaken.

26. Controleer altijd of het gereedschap is

uitgeschakeld en de stekker uit het stopcontact is

getrokken of de accu is verwijderd alvorens enige

werkzaamheden aan het gereedschap te

verrichten.

27. Houd u aan de instructies van de fabrikant voor

juiste montage en gebruik van de schijven.

Behandel en bewaar de schijven zorgvuldig.

28. Gebruik niet afzonderlijke verkleinbussen of

adapterringen om slijpschijven met een groot

middengat te kunnen monteren.

29. Gebruik uitsluitend flenzen die geschikt zijn voor

dit gereedschap.

30. Voor gereedschappen waarop schijven met

schroefdraad in het middengat kunnen worden

gemonteerd, controleert u dat de schroefdraad

van de schijf lang genoeg is voor de lengte van de

as.

31. Controleer dat het werkstuk goed wordt

ondersteund.

32. Wees erop bedacht dat de schijf blijft doordraaien

nadat het gereedschap is uitgeschakeld.

33. Als de werkruimte bijzonder heet en vochtig is, of

sterk vervuild is met geleidend stof, gebruik dan

een kortsluitonderbreker (30 mA) om de veiligheid

van de gebruiker te garanderen.

34. Gebruik het gereedschap niet op materiaal dat

asbest bevat.

35. Gebruik geen water of slijpsmeermiddel.

36. Zorg ervoor dat de ventilatie-openingen niet

verstopt raken bij gebruik in een stoffige

omgeving. Als het noodzakelijk is het stof te

verwijderen, moet u het gereedschap eerst

loskoppelen van de netvoeding (gebruik hiervoor

niet-metalen voorwerpen) en wees voorzichtig

geen inwendige onderdelen te beschadigen.

37. Bij gebruik van een doorslijpschijf, gebruikt u

altijd de stofbeschermkap, zoals vereist door

plaatselijke regelgeving.

38. Doorslijpschijven mogen niet worden blootgesteld

aan enige laterale druk.

BEWAAR DEZE INSTRUCTIES.

WAARSCHUWING:

Laat u NIET misleiden door een vals gevoel van

comfort en bekendheid met het gereedschap (na

veelvuldig gebruik) en neem alle

veiligheidsvoorschriften van het betreffende product

altijd strikt in acht. VERKEERD GEBRUIK of het niet

volgen van de veiligheidsinstructies in deze

gebruiksaanwijzing kan leiden tot ernstig persoonlijk

letsel.

BESCHRIJVING VAN DE

FUNCTIES

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en de stekker uit het stopcontact is getrokken alvorens

de functies van het gereedschap te controleren of af te

stellen.

Asvergrendeling (zie afb. 1)

LET OP:

• Bedien de asvergrendeling nooit terwijl de as nog

draait. Het gereedschap kan hierdoor worden

beschadigd.

Druk op de asvergrendeling om te voorkomen dat de as

kan draaien tijdens het monteren of verwijderen van

schijven of accessoires.

In- en uitschakelen (zie afb. 2)

LET OP:

• Controleer altijd, voordat u het gereedschap aansluit

op het elektriciteitsnet, of de schuifknop op de juiste

manier schakelt en weer terugkeert naar de uit-stand,

wanneer achter op de schuifknop wordt gedrukt.

Start het gereedschap door de schuifknop naar de positie

“I” (aan) te schuiven. Voor doorlopend slijpen, drukt u op

het voorste gedeelte van de schuifknop om hem te

vergrendelen.

Om het gereedschap te stoppen, drukt u op het achterste

gedeelte van de schuifknop en schuift u deze naar de

positie “O” (uit).

Bedrijfslampje

Voor de modellen 9561CVR, 9562CVR, 9564CVR,

9565CVR (zie afb. 3)

Voor de modellen 9561CR, 9562CR, 9564CR, 9565CR

(zie afb. 4)

Het bedrijfslampje gaat branden zodra de stekker van het

gereedschap in een stopcontact wordt gestoken. Als het

lampje niet brandt, kan het netsnoer beschadigd zijn of de

sturing defect. Als het lampje brandt, maar het

gereedschap niet start, zelfs niet wanneer de schuifknop

in de aan-stand wordt gezet, kunnen de koolborstels

versleten zijn, of kunnen de motor, de sturing, of de

schuifknop defect zijn.

Onbedoelde herstartpreventie

Het gereedschap start niet met de schuifknop op aan, ook

niet als de stekker in het stopcontact wordt gestoken.

Op dit moment knippert het bedrijfslampje rood ten teken

dat de onbedoelde herstartpreventie werkt.

Hef de onbedoelde herstartpreventie op door de

schuifknop naar de positie “O” (uit) terug te schuiven en

dan los te laten.

36

Page 15

Snelheidsregelaar

Voor 9561CVR, 9562CVR, 9564CVR, 9565CVR

(zie afb. 5)

U kunt de draaisnelheid veranderen door de

snelheidsregelaar te draaien en in te stellen op een cijfer

van 1 tot 5.

De snelheid verhoogt wanneer u de draaiknop in de

richting van het cijfer 5 draait. De snelheid verlaagt

wanneer u deze in de richting van het cijfer 1 draait.

Raadpleeg onderstaande tabel voor het aantal slagen per

minuut in iedere stand van de draaiknop.

Cijfer min

12.800

24.000

36.500

49.000

5 12.000

LET OP:

• Indien het gereedschap lange tijd achtereen met een

laag toerental wordt gebruikt, raakt de motor overbelast

en oververhit.

• U kunt de snelheidsregelaar alleen tot aan het cijfer 5

draaien en terug naar 1. Forceer de schijf niet voorbij

de 5 of de 1 omdat de snelheidsregeling daardoor

onklaar raakt.

Gereedschappen met elektronische aansturing zijn

dankzij de volgende eigenschappen gemakkelijk te

bedienen.

• Elektronische constante snelheidsregeling

Maakt een onberispelijke afwerking mogelijk omdat de

draaisnelheid zelfs onder belasting constant blijft.

• Zachte-startfunctie

Maakt een zachte start mogelijk door onderdrukking

van de aanloopschok.

• Overbelastingsbeveiliging

Wanneer de toelaatbare belasting van het

gereedschap wordt overschreden, gaat er minder

vermogen naar de motor om deze tegen oververhitting

te beschermen. Wanneer de belasting weer op een

toelaatbaar niveau komt, zal het gereedschap weer

normaal werken.

-1

(RPM)

ONDERDELEN AANBRENGEN/

VERWIJDEREN

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en de stekker uit het stopcontact is getrokken alvorens

enige werk aan het gereedschap uit te voeren.

De zijhandgreep monteren (handvat) (zie

afb. 6)

LET OP:

• Controleer altijd voor gebruik dat de zijhandgreep

stevig vastzit.

Draai de zijhandgreep vast op het gereedschap in een

van de standen aangegeven in de afbeelding.

De beschermkap (accessoire)

aanbrengen en verwijderen (voor schijf

met een verzonken middengat,

multischijf, doorslijpschijf, diamantschijf)

Voor gereedschap met beschermkap type

borgschroef (zie afb. 7)

LET OP:

• De beschermkap moet zodanig op het gereedschap

worden gemonteerd dat de gesloten zijde van de kap

altijd naar de gebruiker is gekeerd.

Monteer de beschermkap met het uitsteeksel op de

beschermkaprand uitgelijnd met de inkeping in het

lagerhuis. Draai vervolgens de beschermkap 180 graden

linksom. Draai tenslotte de schroef stevig vast.

Om de beschermkap te verwijderen, volgt u de procedure

in omgekeerde volgorde.

Voor gereedschap met beschermkap type klemhendel

(zie afb. 8 en 9)

Maak de schroef los en trek de hendel in de richting van

de pijl. Monteer de beschermkap met het uitsteeksel op

de beschermkaprand uitgelijnd met de inkeping in het

lagerhuis. Draai vervolgens de beschermkap rond de

180°.

Trek de hendel in de richting van de pijl en zet de

beschermkap met de schroef vast om ermee te kunnen

werken. U kunt de instelhoek van de beschermkap

aanpassen met de hendel.

Om de beschermkap te verwijderen, volgt u de procedure

in omgekeerde volgorde.

Een slijpschijf/multischijf met een

verzonken middengat (accessoire)

aanbrengen of verwijderen (zie afb. 10)

Breng de binnenflens aan op de as. Monteer de schijf op

de binnenflens en schroef de borgmoer op de as.

Om de borgmoer vast te draaien, drukt u de

asvergrendeling stevig in zodat de as niet kan draaien, en

gebruikt u vervolgens de borgmoersleutel

om de borgmoer stevig rechtsom vast te draaien.

(zie afb. 11)

Om de schijf te verwijderen, volgt u de procedure in

omgekeerde volgorde.

Superflens

Modellen voorzien van de letter F zijn standaard uitgerust

met een superflens. In vergelijking met een conventionele

flens, is hierbij slechts 1/3 van de kracht nodig om de

borgmoer los te draaien.

Stofroosters aanbrengen en verwijderen

(optioneel accessoire)

WAARSCHUWING:

• Controleer altijd of het gereedschap is uitgeschakeld

en de stekker uit het stopcontact is getrokken alvorens

de stofroosters aan te brengen of te verwijderen. Als u

dit niet doet, kan dit leiden tot beschadiging van het

gereedschap of persoonlijk letsel.

Er zijn drie soorten stofroosters die elk in een andere

positie worden gebruikt. (zie afb. 12 - 14)

37

Page 16

Plaats de stofroosters zodanig dat de zijde van het

stofrooster met de markering (A, B of C) naar de voorkant

van het gereedschap is gericht. Klik de pennen van het

stofrooster in de ventilatieopening. (zie afb. 15)

Het stofrooster kan met de hand worden verwijderd.

OPMERKING:

• Maak het stofrooster schoon wanneer het verstopt

raakt met stof en vreemde stoffen. Doorwerken met

een verstopt stofrooster kan het gereedschap

beschadigen.

BEDIENING

WAARSCHUWING:

• Het moet nooit nodig zijn om grote kracht uit te oefenen

op het gereedschap. Het gewicht van het gereedschap

zorgt al voor voldoende druk op het werkstuk. Grote

kracht en hoge druk uitoefenen kunnen ertoe leiden dat

de schijf breekt. Dit is zeer gevaarlijk.

• Vervang de schijf ALTIJD als het gereedschap tijdens

het slijpen is gevallen.

• Stoot of sla NOOIT met de slijpschijf tegen het

werkstuk.

• Voorkom dat de schijf over het werkstuk huppelt of

bekneld raakt tijdens het werken in hoeken, op scherpe

randen, enz. Hierdoor kunt u de controle over het

gereedschap verliezen of kan terugslag worden

veroorzaakt.

• Gebruik het gereedschap NOOIT met zaagbladen en

dergelijke. Als dergelijke zaagbladen op een

slijpmachine worden gebruikt, verspringen ze veelal

waardoor u de controle over het gereedschap verliest

en persoonlijk letsel kan ontstaan.

LET OP:

• Schakel na gebruik altijd het gereedschap uit en wacht

totdat de schijf volledig tot stilstand is gekomen

alvorens het gereedschap neer te leggen.

Slijp- en schuurwerkzaamheden

Houd het gereedschap ALTIJD stevig vast met een hand

op de behuizing en de andere hand aan de zijhandgreep.

Schakel het gereedschap in en breng daarna de schijf in

aanraking met het werkstuk.

In het algemeen geldt: houd de rand van de schijf onder

een hoek van ongeveer 15 graden op het oppervlak van

het werkstuk.

Tijdens de inloopperiode van een nieuwe schijf, mag u de

slijpmachine niet in de richting van pijl B gebruiken omdat

de schijf dan in het werkstuk zal snijden. Nadat de rand

van de schijf is afgerond door gebruik, kunt u de schijf in

de richting van zowel pijl A als B gebruiken. (zie afb. 16)

Gebruik met doorslijpschijf of

diamantschijf (los verkrijgbaar) (zie

afb. 17)

De montagerichting van de borgmoer en binnenflens

verschilt afhankelijk van de dikte van de schijf.

Raadpleeg het onderstaande overzicht. (zie afb. 18)

WAARSCHUWING:

• Wanneer u een doorslijpschijf of diamantschijf gebruikt,

moet u altijd een beschermkap gebruiken die speciaal

ontworpen is voor gebruik met doorslijpschijven.

38

• Gebruik NOOIT een doorslijpschijf om zijdelings mee

te slijpen.

• Laat de schijf niet vastlopen en oefen geen

buitensporige druk uit. Probeer niet een buitensporig

diepe snede te slijpen. Een te grote kracht op de schijf

verhoogt de belasting en de kans dat de schijf in de

snede verdraait of vastloopt, waardoor terugslag kan

optreden, de schijf kan breken of de motor oververhit

kan raken.

• Begin niet met doorslijpen terwijl de schijf al in het

werkstuk steekt. Laat de schijf eerst de volle snelheid

bereiken en breng daarna de schijf voorzichtig in de

snede door het gereedschap naar voren over het

werkstukoppervlak te bewegen. Wanneer het

elektrisch gereedschap wordt gestart terwijl de schijf al

in het werkstuk steekt, kan de schijf vastlopen, omhoog

lopen of terugslaan.

• Tijdens het doorslijpen mag u nooit de hoek van de

schijf veranderen. Door zijdelingse druk uit te oefenen

op de schijf (zoals bij schuren), zal de schijf barsten en

breken waardoor ernstig persoonlijk letsel wordt

veroorzaakt.

• Een diamantschijf moet haaks op het door te slijpen

werkstuk worden gebruikt.

ONDERHOUD

LET OP:

• Zorg er altijd voor dat het gereedschap is

uitgeschakeld en de stekker uit het stopcontact is

getrokken, voordat u een inspectie of onderhoud

uitvoert.

• Gebruik nooit benzine, wasbenzine, thinner, alcohol,

enz. Dit kan leiden tot verkleuren, vervormen of

barsten.

Het gereedschap en de ventilatieopeningen moeten

schoon gehouden worden.

Maak de ventilatieopeningen van het gereedschap

regelmatig schoon of zodra de ventilatieopeningen

verstopt dreigen te raken. (zie afb. 19)

Om de VEILIGHEID en BETROUWBAARHEID van het

gereedschap te handhaven, dienen alle reparaties,

controle en vervanging van de koolborstels, onderhoud en

afstellingen te worden uitgevoerd door een erkend

Makita-servicecentrum, en altijd met gebruikmaking van

originele Makita-vervangingsonderdelen.

VERKRIJGBARE ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita-gereedschap dat in deze

gebruiksaanwijzing wordt beschreven. Het gebruik van

andere accessoires of hulpstukken kan gevaar voor

persoonlijk letsel opleveren. Gebruik de accessoires of

hulpstukken uitsluitend voor de aangegeven

gebruiksdoeleinden.

Mocht u meer informatie willen hebben over deze

accessoires, dan kunt u contact opnemen met uw

plaatselijke Makita-servicecentrum.

• Beschermkap (schijfkap) Voor schijf met een

verzonken middengat, multischijf

• Beschermkap (schijfkap) Voor doorslijpschijf of

diamantschijf

Page 17

• Schijf met een verzonken middengat

• Doorslijpschijven

• Multischijven

• Diamantschijven

• Komvormige draadborstels

• Kegelvormige draadborstel 85

• Slijpschijven

• Binnenflens

• Borgmoer Voor schijf met een verzonken middengat,

doorslijpschijf, multischijf, diamantschijf

• Borgmoer Voor schuurschijf

• Borgmoersleutel

• Zijhandgreep

• Rubberen rugschijf

• Stofscherm

OPMERKING:

• Sommige items op de lijst kunnen zijn inbegrepen in de

doos van het gereedschap als standaard toebehoren.

Zij kunnen van land tot land verschillen.

Geluid

ENG905-1

De typische, A-gewogen geluidsniveaus zijn gemeten

volgens EN60745:

Modellen 9561CR/CVR, 9562CR/CVR en

9564CR/CVR

Geluidsdrukniveau (L

Geluidsvermogenniveau (L

Onzekerheid (K): 3 dB (A)

): 83 dB (A)

pA

WA

): 94 dB (A)

Model 9565CR/CVR

Geluidsdrukniveau (L

Geluidsvermogenniveau (L

Onzekerheid (K): 3 dB (A)

): 82 dB (A)

pA

WA

): 93 dB (A)

Draag gehoorbescherming.

Trillingen

ENG900-1

De totale trillingswaarde (triaxiale vectorsom) zoals

vastgesteld volgens EN60745:

Modellen 9561CR/CVR en 9562CR/CVR

Gebruikstoepassing: slijpen van oppervlakken met

normale zijhandgreep

Trillingsemissie (a

Onzekerheid (K): 1,5 m/s

h,AG

): 8,5 m/s

2

2

Gebruikstoepassing: slijpen van oppervlakken met

trillingsbestendige zijhandgreep

Trillingsemissie (a

Onzekerheid (K): 1,5 m/s

h,AG

): 7,5 m/s

2

2

Model 9564CR/CVR

Gebruikstoepassing: slijpen van oppervlakken met

normale zijhandgreep

Trillingsemissie (a

Onzekerheid (K): 1,5 m/s

h,AG

): 8,0 m/s

2

2

Gebruikstoepassing: slijpen van oppervlakken met

trillingsbestendige zijhandgreep

Trillingsemissie (a

Onzekerheid (K): 1,5 m/s

h,AG

): 8,0 m/s

2

2

Model 9565CR/CVR

Gebruikstoepassing: slijpen van oppervlakken met

normale zijhandgreep

Trillingsemissie (a

Onzekerheid (K): 1,5 m/s

h,AG

): 8,0 m/s

2

2

Gebruikstoepassing: slijpen van oppervlakken met

trillingsbestendige zijhandgreep

Trillingsemissie (a

Onzekerheid (K): 1,5 m/s

h,AG

): 7,5 m/s

2

2

ENG902-1

• De opgegeven trillingsemissiewaarde is gemeten

volgens de standaardtestmethode en kan worden

gebruikt om dit gereedschap te vergelijken met andere

gereedschappen.

• De opgegeven trillingsemissiewaarde kan ook worden

gebruikt voor een beoordeling vooraf van de

blootstelling.

• De opgegeven trillingsemissiewaarde wordt gebruikt bij

veel toepassingen van het elektrisch gereedschap.

Echter, indien het elektrisch gereedschap wordt

gebruikt bij andere toepassingen, dan kan de

trillingsemissiewaarde anders zijn.

WAARSCHUWING:

• De trillingsemissie tijdens het gebruik van het elektrisch

gereedschap in de praktijk kan verschillen van de

opgegeven trillingsemissiewaarde afhankelijk van de

manier waarop het gereedschap wordt gebruikt.

• Zorg ervoor dat veiligheidsmaatregelen worden

getroffen ter bescherming van de gebruiker die zijn

gebaseerd op een schatting van de blootstelling onder

praktijkomstandigheden (rekening houdend met alle

fasen van de bedrijfscyclus, zoals de tijdsduur

gedurende welke het gereedschap is uitgeschakeld en

stationair draait, naast de ingeschakelde tijdsduur).

Alleen voor Europese landen

ENH101-15

EU-verklaring van conformiteit

Wij, Makita Corporation, als de verantwoordelijke

fabrikant, verklaren dat de volgende Makitamachine(s):

Aanduiding van de machine:

Haakse slijpmachine

Modelnr./Type: 9561CR/CVR, 9562CR/CVR,

9564CR/CVR en 9565CR/CVR

in serie zijn geproduceerd en

Voldoen aan de volgende Europese richtlijnen:

2006/42/EC

En zijn gefabriceerd in overeenstemming met de

volgende normen of genormaliseerde documenten:

EN60745

39

Page 18

De technische documentatie wordt bewaard door onze

erkende vertegenwoordiger in Europa, te weten:

Makita International Europe Ltd.

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, Engeland

30. 1. 2009

Tomoyasu Kato

Directeur

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

40

Page 19

Makita Corporation

Anjo, Aichi, Japan

884863D997 www.makita.com

ALA

Loading...

Loading...