Page 1

T

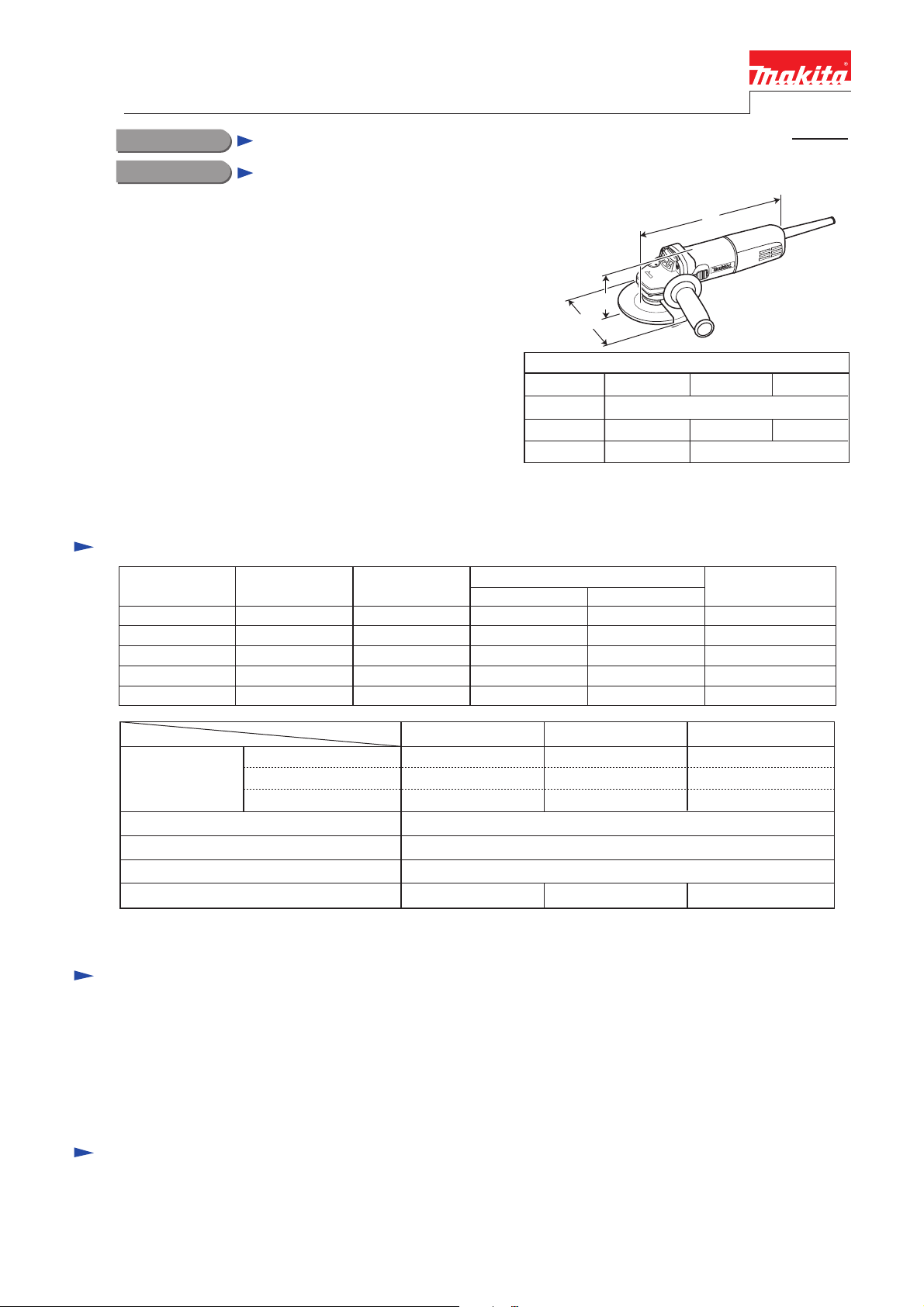

ECHNICAL INFORMATION

Models No.

9556HN, 9557HN, 9558HN

PRODUCT

P 1/ 8

Description

Angle Grinders 100mm (4"), 115mm (4-1/2"), 125mm (5")

CONCEPT AND MAIN APPLICATIONS

These angle grinders have been developed as sister models

of 9556NB series.

Features machined bevel gears more durable than sintered

bevel gears used for 9556NB series models.

9556HN is also available with plastic carrying case as

Model 9556HNK.

9557HN is also available with plastic carrying case or

steel carrying case as Model 9557HNK.

9558HN is also available with steel carrying case as

Model 9558HNK.

AC/DC switch is used for the tools for USA and other

North American countries.

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240

Current (A)

8.0

7.5

4.0

3.8

3.7

50/60

50/60

50/60

50/60

50/60

H

W

Dimensions: mm (")

Model No. 9556HN

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

840

840

840

840

840

118 (4-5/8)

97 (3-13/16)

500

500

500

500

500

L

9557HN

271 (10-5/8)

129 (5-1/8)

106 (4-3/16)

Max. Output (W)

1,000

1,000

1,000

1,000

1,000

9558HN

139 (5-1/2)

Specification

Depressed center wheel

Capacity: mm (")

Protection against electric shock Double insulation

Power supply cord: m (ft)

Net weight*2: kg (lbs)

*1 North America: 10,000

*2 Weight according to EPTA-Procedure 01/2003

Wire cup brush

Abrasive disc

Model No.

9556HN 9557HN 9558HN

100 (4) 115 (4-1/2) 125 (5)

75 (3) 90 (3-1/2) 90 (3-1/2)

100 (4) 115 (4-1/2) 125 (5)

11,000No load speed*1: min.-1 = rpm

Australia, New Zealand: 2.0 (6.6), Other countries: 2.5 (8.2)

1.9 (4.2) 2.1 (4.6)2.0 (4.4)

Standard equipment

9556HN

Depressed center wheel 100-36 .... 1

Lock nut wrench 20 ...................... 1

Grip 36 complete .......................... 1

Plastic or steel carrying case ......... 1 (for 9556HNK, 9557HNK, 9558HNK only)

Note: The standard equipment for the tool shown above may vary by country.

9557HN

Depressed center wheel 115-36 .... 1

Lock nut wrench 28 ...................... 1

Grip 36 complete .......................... 1

9558HN

Depressed center wheel 125-36 .... 1

Lock nut wrench 35 ...................... 1

Grip 36 complete .......................... 1

Optional accessories

Wheel covers, Depressed center wheels, Abrasive discs, Rubber pads (for abrasive discs), Sanding lock nuts,

Cut-off wheels, Super flanges (for 9557HN, 9558HN only), Wire cup brushes, Wire bevel brush (for 9556HN only),

Dust collecting wheel guards

Page 2

P 2/ 8

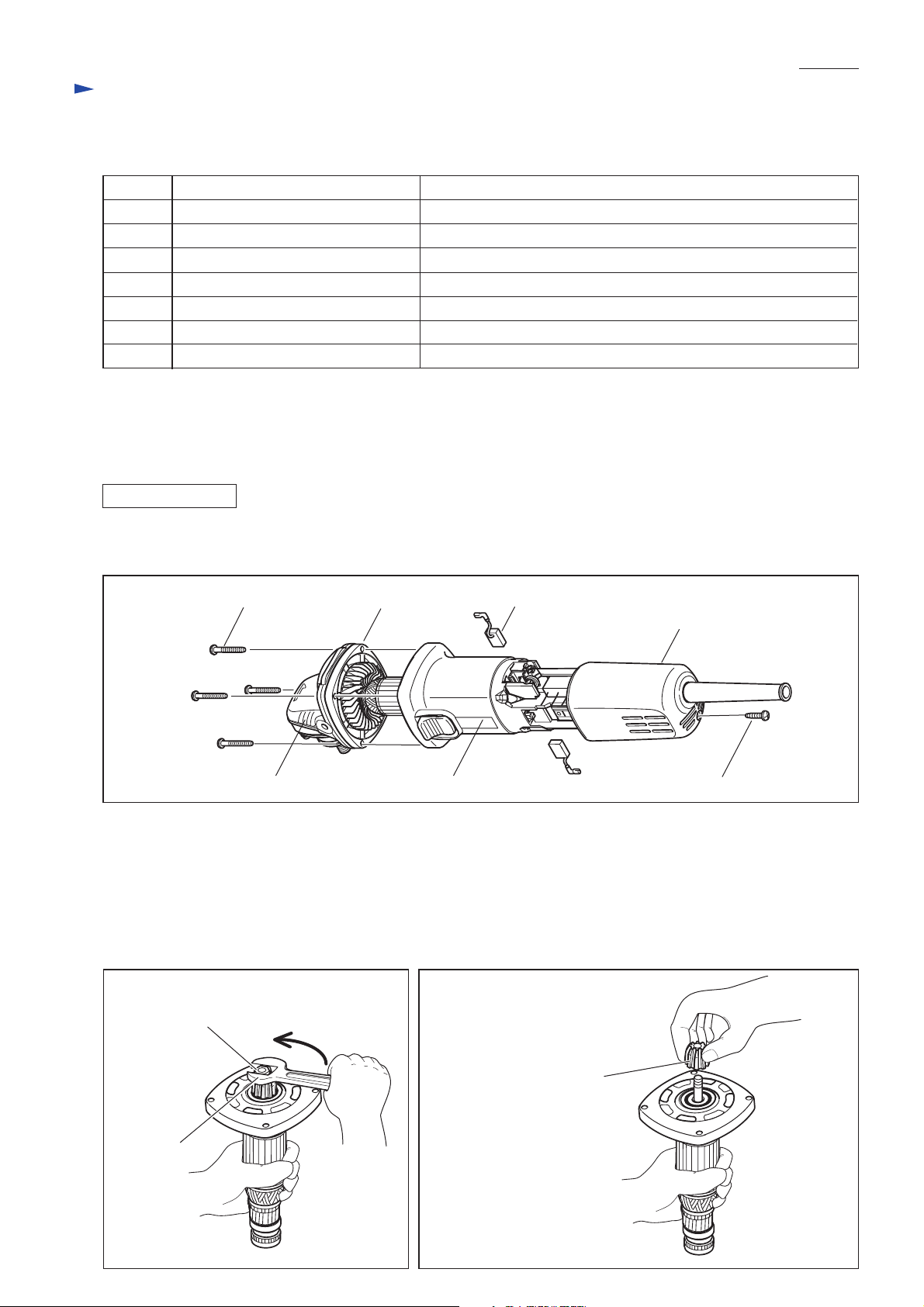

Repair

CAUTION: Disconnect the machine and remove the wheel for safety before repair/maintenance!

[1] NECESSARY REPAIRING TOOLS

Code No. Description

1R028 Bearing Setting Pipe

1R045 Gear Extractor (large)

1R346 Center Attachment for 1R045

1R269 Bearing Extractor Removing Ball bearings

1R291 Retaining Ring S and R Pliers Removing Retaining ring S-12 and R-32

1R343 Retaining Ring Setting Jig

1R----- Bearing Setting Plate (of proper size) Assembling Ball bearing 629LLB and Armature to Gear housing cover

Installing Retaining ring S-12

Removing Spindle from Bearing box

Removing Spindle from Bearing box (for modular use with 1R045)

Installing Retaining ring S-12

Use for

[2] LUBRICATION AND SEALING

Put 7g of Makita Grease N. No.1 into the gear room of Gear housing.

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature and Spiral Bevel Gear 10

DISASSEMBLING

1) Remove 4x18 Tapping screw and separate Rear cover from Motor housing. Then remove Carbon brushes. (Fig. 1)

2) Unscrew four 4x30 Tapping screws and remove the assembled unit of Gear housing and Armature. (Fig. 1)

Fig. 1

Tapping screw 4x30 (4 pcs)

Gear housing cover

Carbon brush (2 pcs)

Rear cover

Gear housing

3) Pull off the assembled unit of Armature and Gear housing cover from Gear housing.

4) Grip Armature securely by gloved hand, then remove Hex nut M6 by turning counterclockwise with wrench 10. (Fig. 2)

5) Remove Spiral bevel gear 10 by gloved hand. (Fig. 3)

If the gear cannot be removed by hand, do the following steps;

1. Spray some lubricant to the contact portion of the gear and Armature shaft.

2. Wrap the gear with wasted cloth for protection of the gear threads, then turn the gear using water pump pliers.

6) Remove Armature from Gear housing cover with Gear Extractor, large (No.1R045).

Fig. 2 Fig. 3

Hex nut M6

Wrench 10

Motor housing

Spiral bevel gear 10

Tapping screw 4x18

Page 3

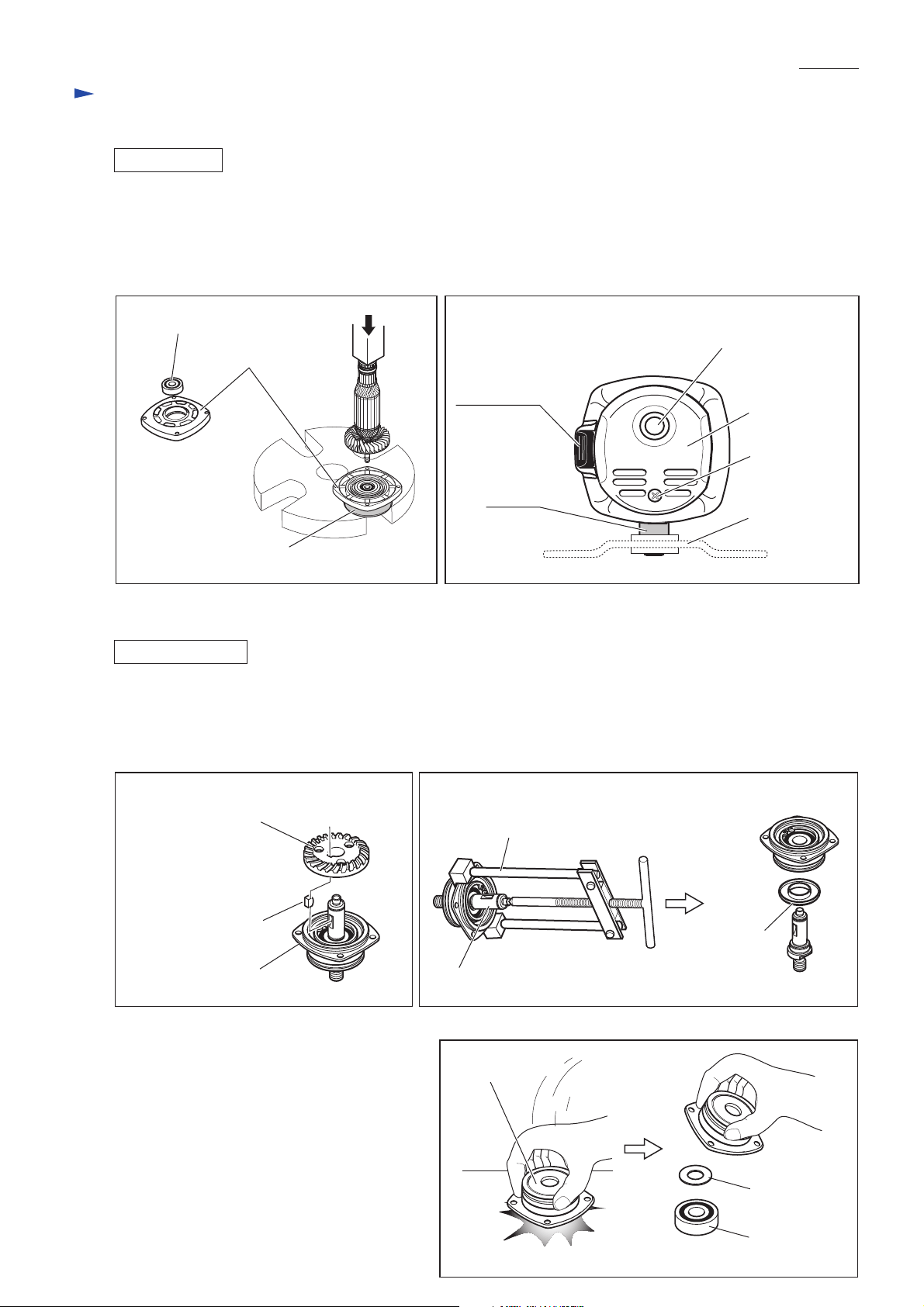

Repair

[3] -1. Armature and Small Spiral Bevel Gear (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note: Use arbor press and Bearing Setting Plate (of proper size ) when fitting Ball bearing 629LLB

in Gear housing cover. (Fig. 4)

Important: Assemble Gear housing to Motor housing so that Switch lever can be operated with right thumb

as illustrated in Fig. 5.

Fig. 4 Fig. 5

P 3/ 8

Ball bearing 629LLB

Gear housing cover

Switch lever

Spindle

Bearing setting plate

(of proper size)

[View from rear cover side]

Power supply cord

Rear cover

Tapping screw

4x18

(Wheel)

[3] -2. Spiral Bevel Gear 37 and Ball Bearing 6201DDW

DISASSEMBLING

1) Remove Bearing box from Gear housing by unscrewing four M4x14 Pan head screws.

2) Remove Retaining ring S-12 and Wave washer 12 from Spindle with Retaining Ring S and R Pliers (No.1R291).

3) Spiral bevel gear 37 can now be removed by hand. Then remove Woodruff key 4. (Fig. 6)

4) Remove Spindle using Gear Extractor, large (No.1R045). Labyrinth ring can now be removed. (Fig. 7)

Fig. 6 Fig. 7

Spiral bevel gear 37

Woodruff key 4

Bearing box

5) Remove Retaining ring R-32 from Bearing box

with Retaining Ring S and R Pliers (No.1R291).

6) By striking Bearing box against the surface of

a work bench, Ball bearing 6201DDW and Flat

washer 12 can be removed from Bearing box

as illustrated in Fig. 8.

If it is difficult to remove the ball bearing,

remove using arbor press.

Gear Extractor, large (No.1R045)

Labyrinth

ring

Spindle

Fig. 8

Bearing box

Flat washer 12

Ball bearing

6201DDW

Page 4

P 4/ 8

Repair

[3] -2. Spiral Bevel Gear 37 and Ball Bearing 6201DDW (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Important: Do not to forget to install Labyrinth ring because it is an important part that prevents dust from entering

into Bearing box. (Fig. 9)

How to fit Retaining ring S-12 in place

See Fig. 10.

After installing Spiral bevel gear 37 and Wave washer 12 on Spindle;

1) Put Retaining ring S-12 on Retaining Ring Setting Jig (No.1R343) from the tapered end of the jig.

2) Put the jig onto Spindle, then put Bearing Setting Pipe 20-12.2 (No.1R028) over the jig.

3) Using arbor press, press down the pipe till the retaining ring is securely fitted in place on Spindle with a snap.

Fig. 9 Fig. 10

Labyrinth ring

Bearing box

Spindle

Retaining

ring S-12

No.1R343

[3] -3. Disassembling/Assembling Shaft Lock Mechanism

DISASSEMBLING

1) Remove Bearing box from Gear housing.

2) Pull off Shoulder pin 4 with pliers while pushing Pin cap with

finger. (Fig. 11)

Note: Do not pull off Shoulder pin 4 without holding Pin cap

because Compression spring 8 would sling Pin cap.

ASSEMBLING

Push Shoulder pin 4 through Gear housing and Compression spring 8

into Pin cap.

Note: Do not reuse removed Pin cap because removal of Shoulder

pin 4 damages the inside surface of Pin cap, producing plastic

dust. Therefore, be sure to use a new Pin cap for replacement

and to remove all the plastic dust on Shoulder pin 4.

Fig. 11

Shoulder pin 4

Compression

spring 8

Pin cap

No.1R028

Retaining

ring S-12

Gear housing

[3] -4. Tightening Tapping Screws That Fasten the Field

Tighten the two tapping screws that fasten Baffle plate and Field to the recommended torque of 1.1 - 1.3 Nm.

Page 5

Circuit diagram

Color index of lead wires' sheath

Black

Red

Clear

Brush holder A

P 5/ 8

Earth terminal (Ground terminal)

on the lead wire of Noise suppressor

Noise suppressor*

Brush holder B

Field

Brush holder A

Power supply

cord

Switch

*Some countries do not use noise suppressor

Brush holder B

Page 6

Wiring diagram

[1] Connecting Lead Wires of Power Supply Cord with Switch

Connect the lead wires with Switch as illustrated in Fig. 12.

Fig. 12

[When Spacer is used] [When Spacer is not used]

Power supply cord

Switch button

Switch

Spacer

P 6/ 8

[2] Wiring of Field Lead Wires in the Rear of Motor Housing

[2] -1. Rear End

Route Field lead wires as illustrated in Figs. 13 - 16.

Fig. 13

[Lead Wires of Field]

Lead wire (black)

Earth terminal on the lead wire (clear)

of Noise suppressor* has to be connected

to this portion.

Field

Lead wire (white)

Switch lever

[Motor Housing with Field]

(view from Rear cover side)

Connect to Brush holder A.

Brush holder A

Lead wire

(black)

Lead wire (white)

Lead wire (black)

Connect to Brush holder B.

Connect to

Switch terminals.

Brush holder B

Spindle

*Some countries do not use noise suppressor.

Page 7

Wiring diagram

[2] Wiring of Field Lead Wires in the Rear of Motor Housing (cont.)

[2] -2. Right Side and Bottom

Fig. 14

Right side view

P 7/ 8

Motor housing

Boss A

Route the lead wire of Power supply cord to

Switch terminal No.2 so that it runs around the boss A.

Boss A Boss A

Noise suppressor*

Switch

Motor housing

Boss A

Bottom view

Switch

Field lead wires

(white)

Motor housing,

viewed from right side

Field lead wire

(black)

Make sure that Field lead wires

are tight in Motor housing.

*Some countries do not use noise suppressor.

Motor housing,

viewed from bottom

Page 8

Wiring diagram

[2] Wiring of Field Lead Wires in the Rear of Motor Housing (cont.)

[2] -3. Left Side

Fig. 15

Earth terminal on the lead wire (clear)

of Noise suppressor* has to be connected

to this portion.

P 8/ 8

Left side view

Make sure that Field lead wires

are tight in Motor housing.

*Some countries do not use noise suppressor.

[2] -4. Top

Fig. 16

Top view

Noise suppressor*

Earth terminal on

the lead wire (clear)

of Noise suppressor*

has to be connected

to this portion.

*Some countries do not use noise suppressor.

**Some countries do not use sensormatic tag.

Noise suppressor*

Sensor-matic tag

(anti-theft tag)

Put Sensor-matic tag** in this space.

Loading...

Loading...