Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Electronic Sander Polisher

Ponceuse-polisseuse électronique

Lijadora Pulidora

9227C

9227CY

003430

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

Page 2

ENGLISH

SPECIFICATIONS

Model 9227C/9227CY

Max capacities

Spindle thread 5/8”

No load speed (RPM) 0 - 3,000/min.

Overall length 470 mm (18-1/2”)

Net weight 3.0 kg (6.6 lbs)

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Wool pad 180 mm (7”)

Abrasive disc 180 mm (7”)

GENERAL SAFETY RULES

USA001-3

(For All Tools)

WARNING:

Read and understand all instructions.

Failure to follow all instructions listed below,

may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

4. Grounded tools must be plugged into an outlet

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way.

Do not use any adaptor plugs. Check with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should

electrically malfunction or break down, grounding

provides a low resistance path to carry electricity

away from the user.

5. Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refrigera-

tors. There is an increased risk of electric shock if

your body is grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

7. Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric

shock.

8. When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce

the risk of electric shock.

Personal Safety

9. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in

serious personal injury.

10. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

11. Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger

on the switch or plugging in tools that have the

switch on invites accidents.

12. Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

13. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

2

Page 3

enables better control of the tool in unexpected situations.

14. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions. Ordinary eye or sun glasses are NOT eye

protection.

Tool Use and Care

15. Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable and may lead to loss of control.

16. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

17. Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

18. Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such preventive

safety measures reduce the risk of starting the tool

accidentally.

19. Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

20. Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are

easier to control.

21. Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tools operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

22. Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

23. Tool service must be performed only by qualified

repair personnel. Service or maintenance per-

formed by unqualified personnel could result in a risk

of injury.

24. When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unau-

thorized parts or failure to follow Maintenance

instructions may create a risk of electric shock or

injury.

USE PROPER EXTENSION CORD: Use only threewire extension cords that have three-prong grounding-type plugs and three-pole receptacles that

accept the tool's plug. Make sure your extension

cord is in good condition. Replace or repair damaged

or worn cord immediately. When using an extension

cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of

power and overheating. Table 1 shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

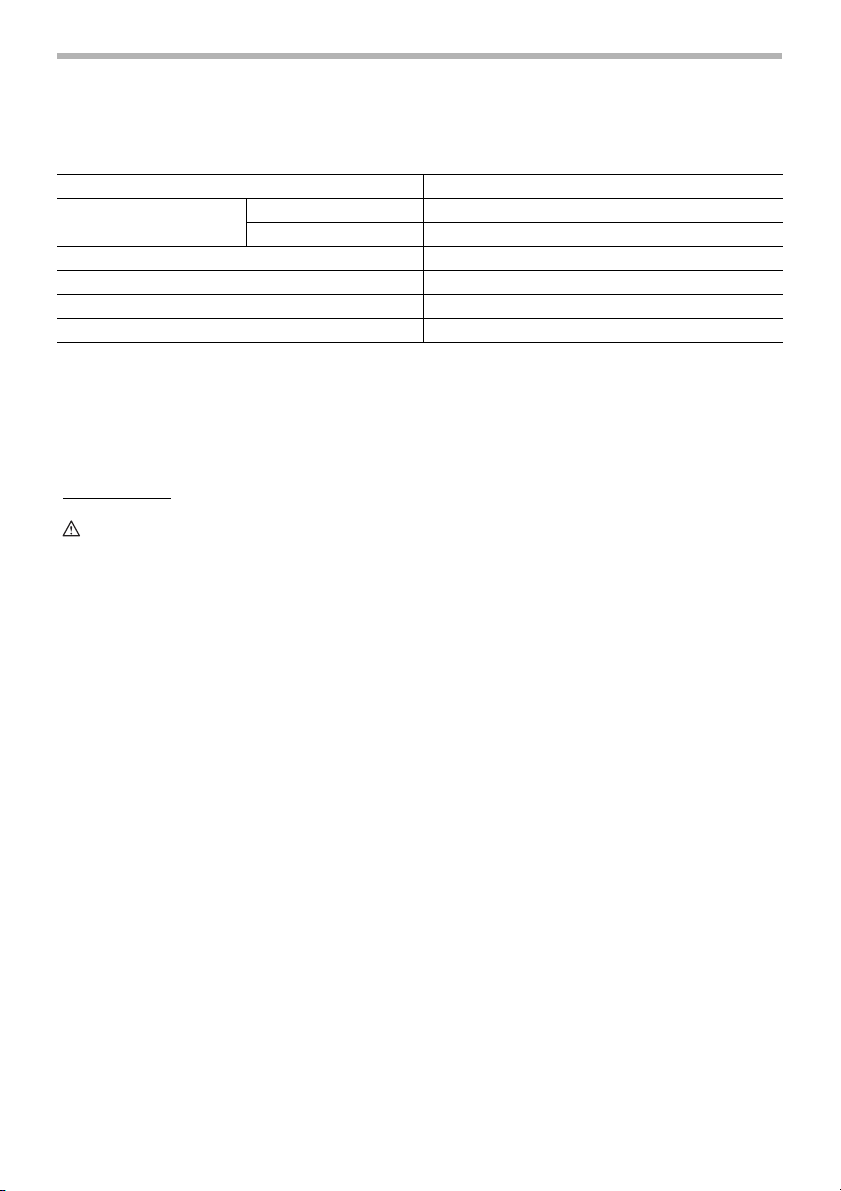

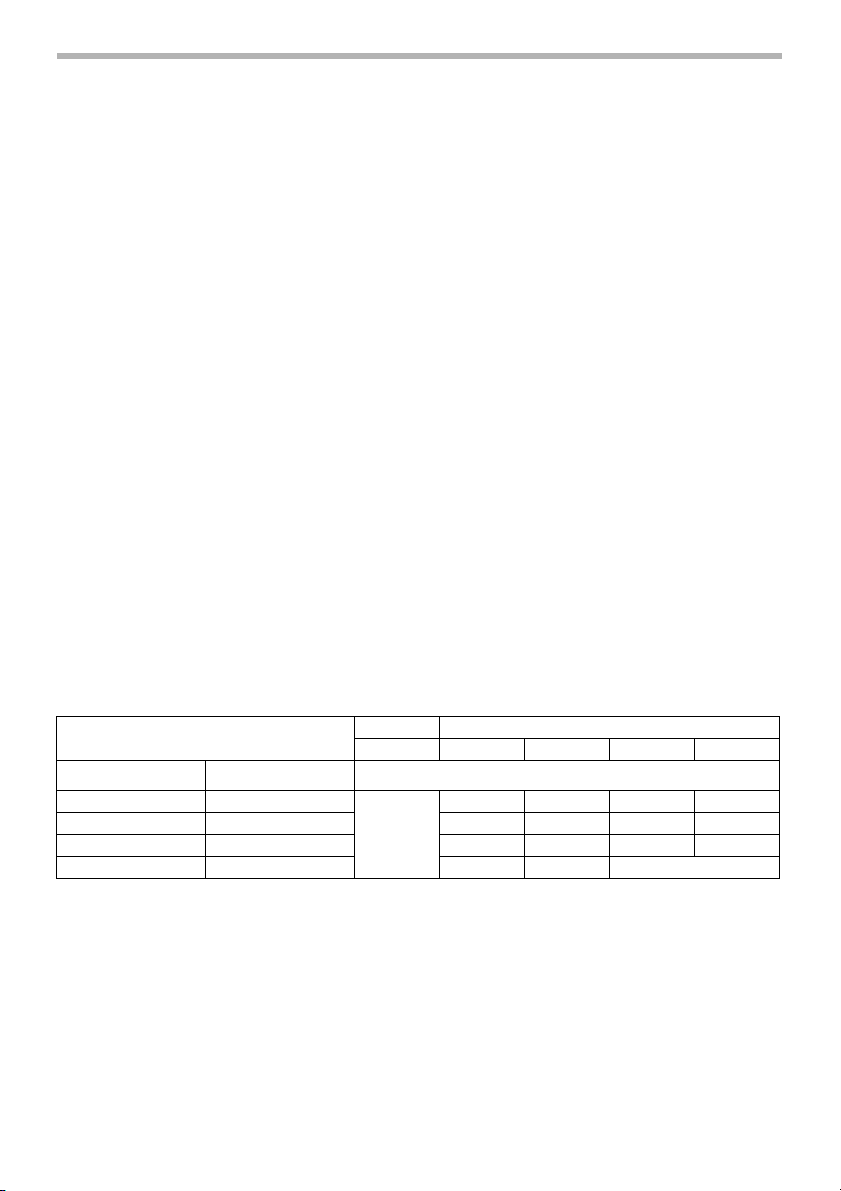

Table 1: Minimum gage for cord

Ampere Rating

Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

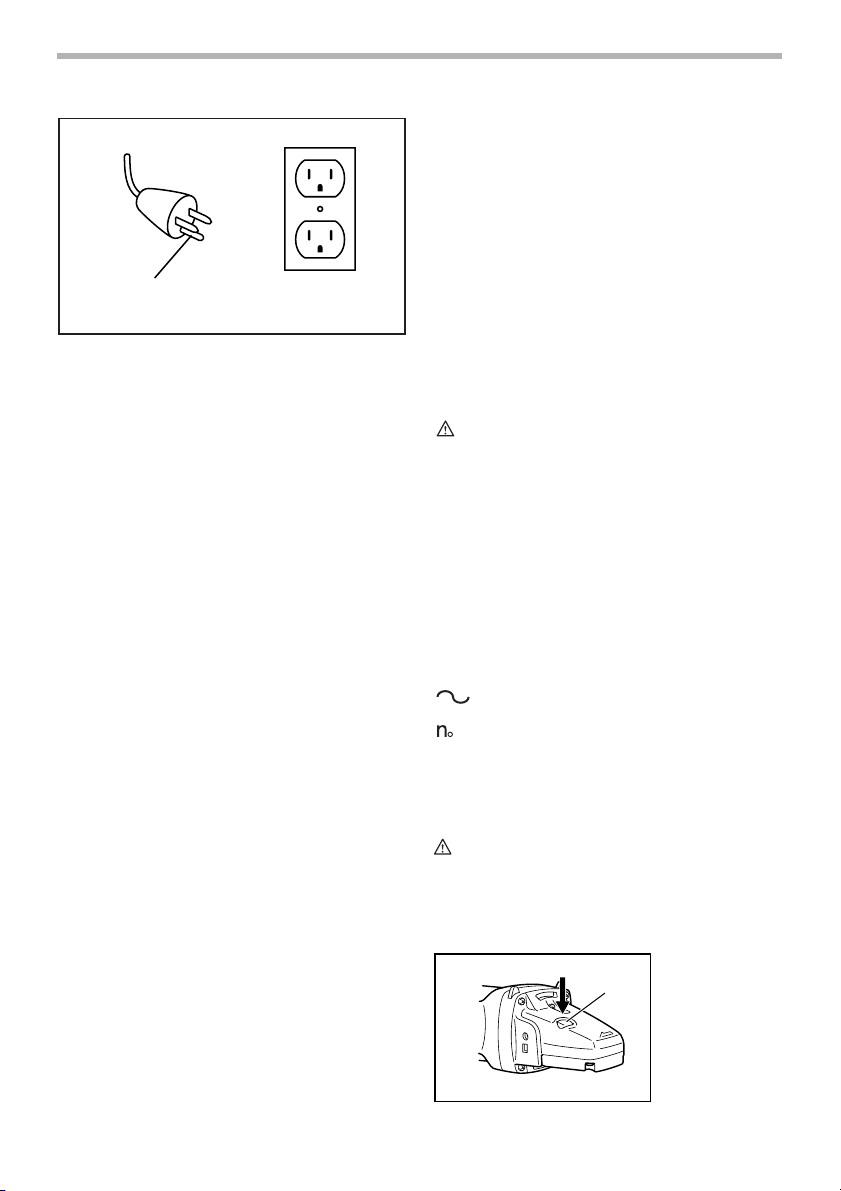

GROUNDING INSTRUCTIONS:

This tool should be grounded while in use to protect

the operator from electric shock. The tool is

equipped with a three-conductor cord and threeprong grounding type plug to fit the proper grounding type receptacle. The green (or green and yellow)

conductor in the cord is the grounding wire. Never

connect the green (or green and yellow) wire to a live

terminal. Your unit is for use on 120 volts and has a

plug that looks like Fig. “A”.

3

Page 4

Fig. A

Grounding

Blade

Cover of Grounded

Outlet Box

SPECIFIC SAFETY RULES

USB047-4

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to polisher

safety rules. If you use this tool unsafely

or incorrectly, you can suffer serious personal injury.

1. Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels

and other accessories running over rated speed can

fly apart and cause injury. Maximum operating

speed of accessories should be higher than the

highest no load speed marked on the tool’s nameplate.

2. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring or its own cord. Con-

tact with a “live” wire will make exposed metal parts

of the tool “live” and shock the operator.

3. Check the backing pad carefully for cracks, damage or deformity before operation. Replace

cracked, damaged or deformed pad immediately.

4. NEVER use tool with wood cutting blades or

other sawblades. Such blades when used on a

polisher frequently kick and cause loss of control leading to personal injury.

5. Hold the tool firmly.

6. Keep hands away from rotating parts.

7. Make sure the abrasive disc or wool bonnet is

not contacting the workpiece before the switch

is turned on.

8. When sanding metal surfaces, watch out for flying sparks. Hold the tool so that sparks fly away

from you and other persons or flammable materials.

9. Do not leave the tool running. Operate the tool

only when hand-held.

10. Do not touch the workpiece immediately after

operation; it may be extremely hot and could

burn your skin.

11. Check that the workpiece is properly supported.

12. Pay attention that the wheel continues to rotate

after the tool is switched off.

13. This tool has not been waterproofed, so do not

use water on the workpiece surface.

14. Ventilate your work area adequately when you

perform sanding operations.

15. Use of this tool to sand some products, paints

and wood could expose user to dust containing

hazardous substances. Use appropriate respiratory protection.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

SYMBOLS

The followings show the symbols used for tool.

V ...........................volts

A...........................amperes

Hz .........................hertz

.................. alternating current

...................... no load speed

.../min ...................revolutions or reciprocation per

minute

USD101-2

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on

the tool.

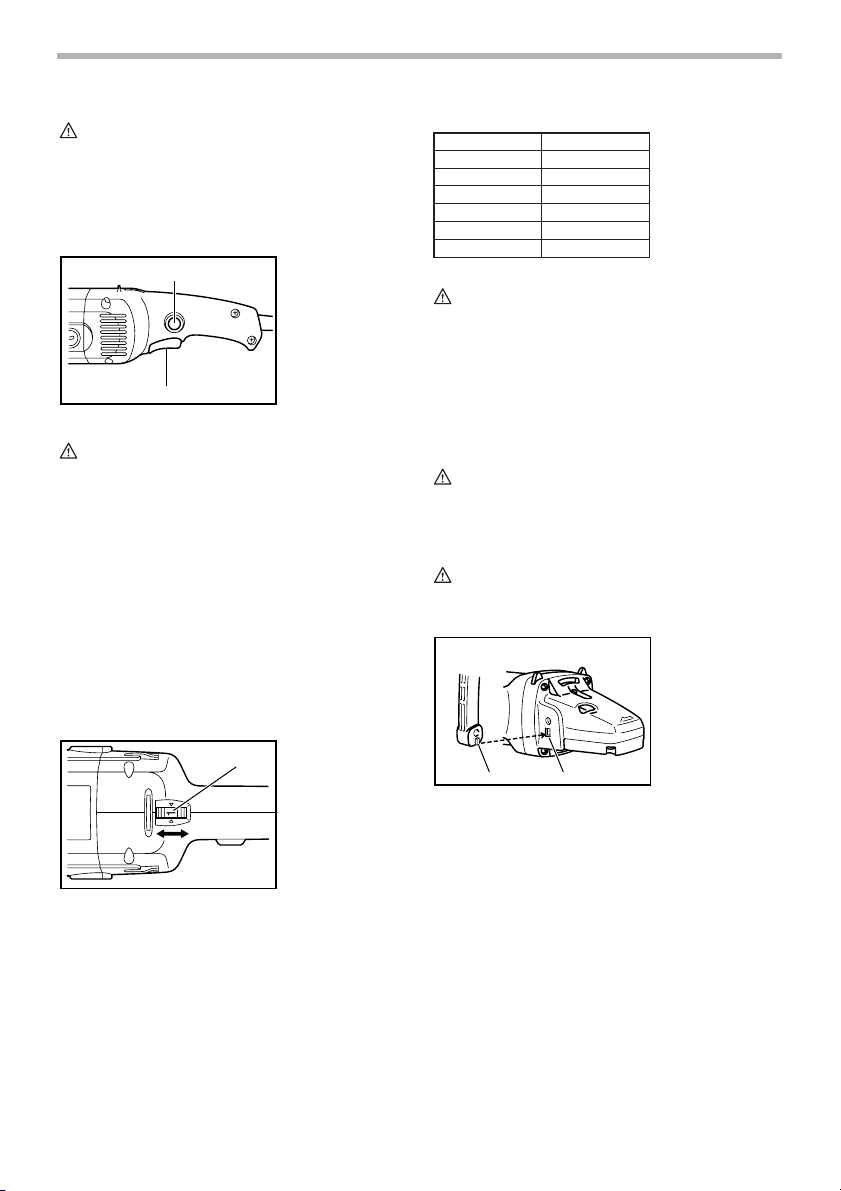

Shaft lock

003432

1. Shaft lock

1

4

Page 5

CAUTION:

• Never actuate the shaft lock when the spindle is

moving. The tool may be damaged.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

Switch action

1

2

003435

1. Lock button

2. Switch trigger

003441

Number

1

2

3

4

5

6

CAUTION:

• If the tool is operated continuously at low speeds for

a long time, the motor will get overloaded, resulting

in tool malfunction.

• The speed adjusting dial can be turned only as far

as 6 and back to 1. Do not force it past 6 or 1, or the

speed adjusting function may no longer work.

min -1 (RPM

)

600

900

1,500

2,100

2,700

3,000

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and returns

to the “OFF” position when released.

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply caution when locking tool in “ON” position and maintain

firm grasp on tool.

To star t the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

For continuous operation, pull the switch trigger and then

push in the lock button.

To stop the tool from the locked position, pull the switch

trigger fully, then release it.

Speed adjusting dial

The tool speed can be changed by turning the speed

adjusting dial to a given number setting from 1 to 6. (At

the time when the switch trigger is fully pulled.)

Higher speed is obtained when the dial is turned in the

direction of number 6. And lower speed is obtained when

it is turned in the direction of number 1.

Refer to the table for the relationship between the number settings on the dial and the approximate tool speed.

003440

1

1. Speed adjusting dial

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing loop handle (For 9227C only)

CAUTION:

• Always be sure that the loop handle is installed

securely before operation.

12

Always install the loop handle on the tool before operation. Hold the tool’s switch handle and the loop handle

firmly with both hands during operation.

Install the loop handle so that its protrusion will fit into the

matching hole in the gear housing.

Install the bolts and tighten them with the hex wrench.

The loop handle can be installed in two different directions as shown in the figures whichever is convenient for

your wor k.

003448

1. Protrusion of

loop handle

2. Matching hole in

gear housing

5

Page 6

003449

1

1. Loop handle

2. Hex wrench

3. Bolt

2

3

003450

11

3

1. Loop handle

2. Bolt

3. Hex wrench

2

Installing side grip (handle) (For 9227CY only)

CAUTION:

• Always be sure that the side grip is installed

securely before operation.

Screw the side grip securely on the position of the tool as

shown in the figure.

003805

Using the sleeve 18 as a positioning guide, install the

wool bonnet on the backing pad with the sleeve 18

inserted through the center hole of the wool bonnet.

Then remove the sleeve 18 from the backing pad.

To remove the wool bonnet, just tear it off the backing

pad. Then unscrew the backing pad while pressing the

shaft lock.

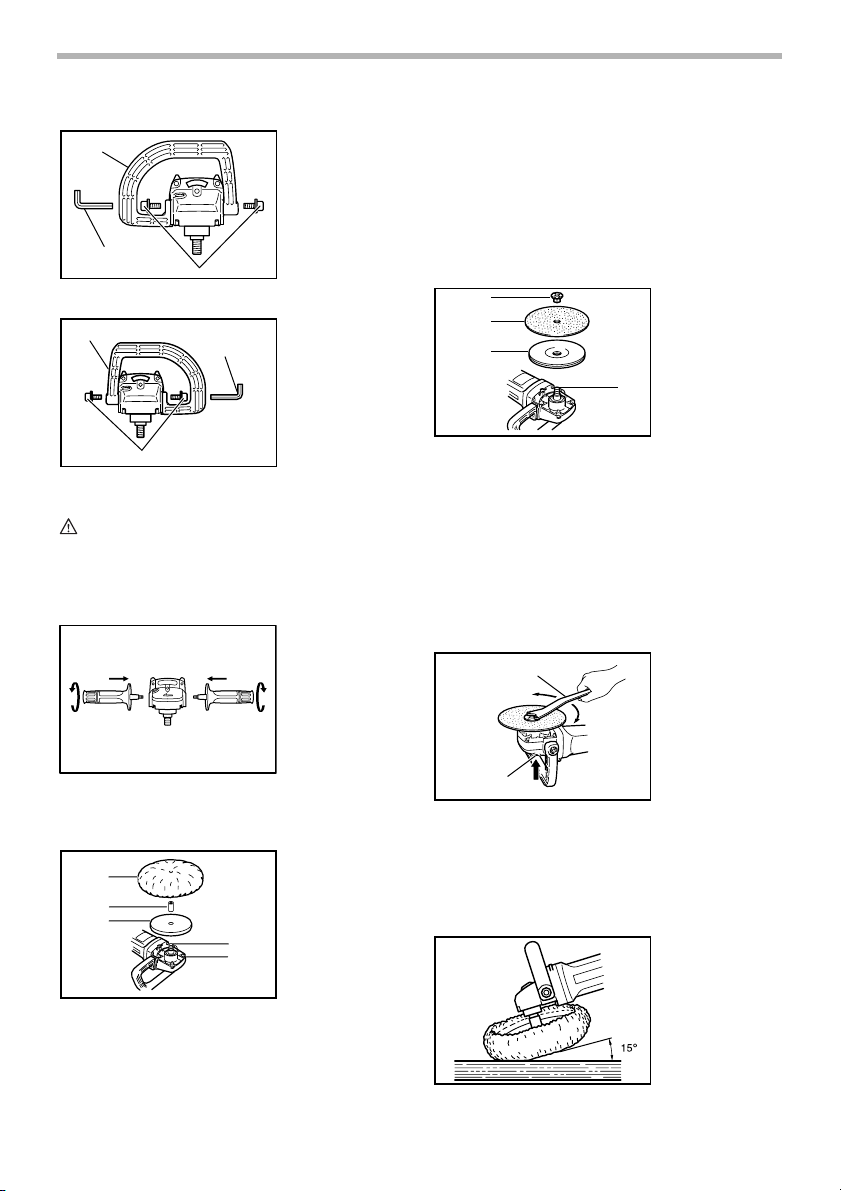

Installing or removing abrasive disc

(optional accessory)

1

2

3

NOTE:

• Use sander accessories specified in this manual.

These must be purchased separately.

Mount the rubber pad onto the spindle. Fit the abrasive

disc on the rubber pad and screw the lock nut onto the

spindle.

To tighten the lock nut, press the shaft lock firmly so that

the spindle cannot revolve, then use the lock nut wrench

and securely tighten clockwise.

1

003457

1. Lock nut

2. Abrasive disc

3. Rubber pad

4. Spindle

4

003458

1. Lock nut wrench

2. Shaft lock

Installing or removing the wool bonnet

(optional accessory)

1

2

3

To install the wool bonnet, first remove all dirt or foreign

matter from the backing pad. Press the shaft lock and

screw the backing pad onto the spindle. Insert the sleeve

18 into the center hole of the backing pad.

003467

4

5

1. Wool bonnet

2. Sleeve 18

3. Backing pad

4. Spindle

5. Shaft lock

2

To remove the disc, follow the installation procedure in

reverse.

OPERATION

Polishing operation

6

003478

Page 7

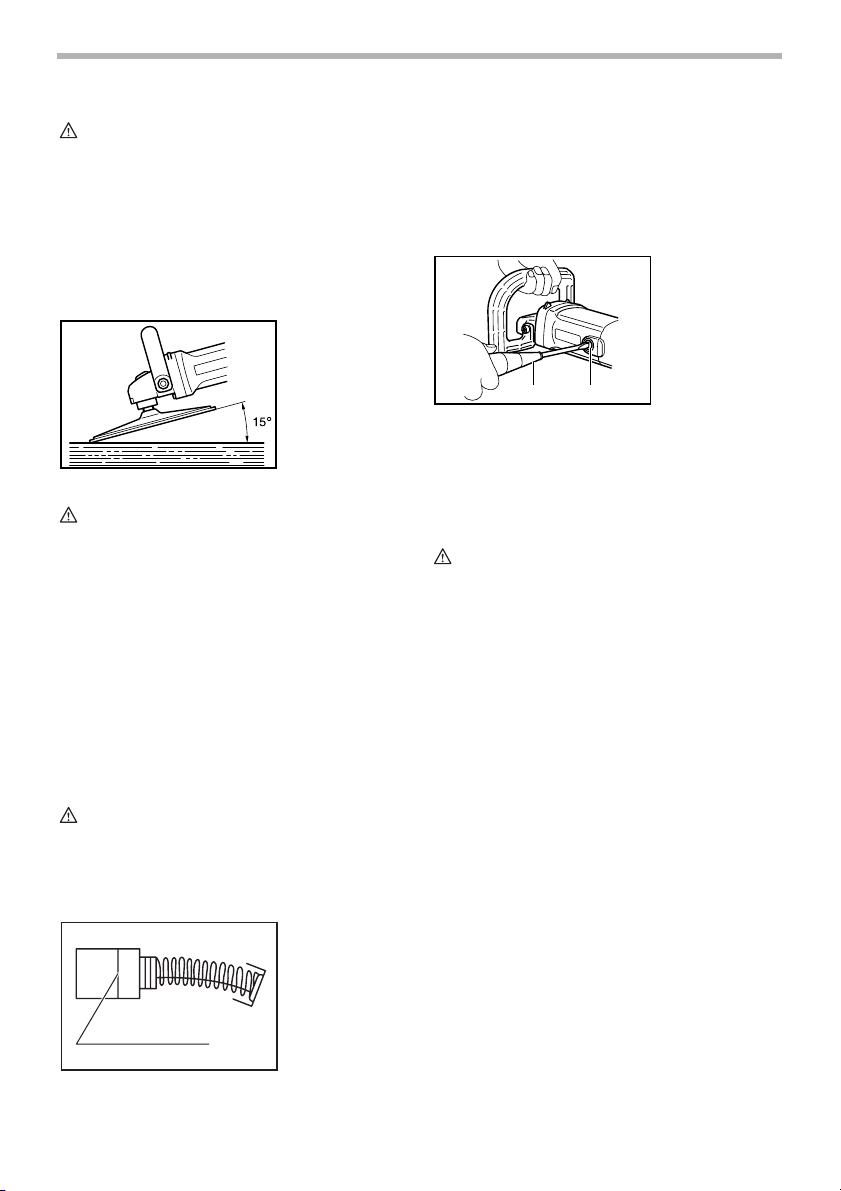

CAUTION:

• Always wear safety glasses or a face shield during

operation.

Hold the tool firmly. Turn the tool on and then apply the

wool bonnet to the workpiece.

In general, keep the wool bonnet at an angle of about 15

degrees to the workpiece surface.

Apply slight pressure only. Excessive pressure will result

in poor performance and premature wear to wool bonnet.

Sanding operation

003473

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

12

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

003483

1. Screwdriver

2. Brush holder

cap

CAUTION:

• Always wear safety goggles or a face shield during

operation.

• Never switch on the tool when it is in contact with

the workpiece, it may cause an injury to operator.

• Never run the tool without the abrasive disc. You

may seriously damage the pad.

Hold the tool firmly. Turn the tool on and then apply the

abrasive disc to the workpiece.

In general, keep the abrasive disc at an angle of about 15

degrees to the workpiece surface.

Apply slight pressure only. Excessive pressure will result

in poor performance and premature wear to abrasive

disc.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

Replacing carbon brushes

001145

1. Limit mark

1

ACCESSORIES

CAUTION:

• These accessories or attachments are recom-

mended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Wool bonnet 180 (Hook & loop)

• Backing pad 165 (Hook & loop)

• Abrasive discs

• Rubber pad 170

• Sanding lock nut 5/8 - 48

• Lock nut wrench 28

• Sleeve 18

• Grip 36

• Loop handle

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

EN0006-1

7

Page 8

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

8

Page 9

FRANÇAIS

SPÉCIFICATIONS

Modèle 9227C/9227CY

Capacités max.

Filetage de l’arbre 5/8”

Vitesse à vide (T/MIN) 0 - 3,000/min.

Longueur totale 470 mm (18-1/2”)

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

Plateau peau de mouton 180 mm (7”)

Disque abrasif 180 mm (7”)

Poids net 3.0 kg (6.6 lbs)

RÈGLES DE SÉCURITÉ

GÉNÉRALES

USA001-3

(Pour tous les outils)

AVERTISSEMENT:

Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel,

des instructions ci-après entraîne un risque

de choc électrique, d’incendie et/ou de

blessures graves.

CONSERVEZ CES

INSTRUCTIONS

Aire de travail

1. Veillez à ce que l’aire de travail soit propre et

bien éclairée. Le désordre et le manque de lumière

favorisent les accidents.

2. N’utilisez pas d’outils électriques dans une

atmosphère explosive, par exemple en présence

de liquides, de gaz ou de poussières

inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières

ou les vapeurs.

3. Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillez avec un

outil électrique. lls pourraient vous distraire et vous

faire une fausse manoeuvre.

Sécurité électrique

4. Les outils mis à la terre doivent être branchés

dans une prise de courant correctement

installée et mise à la terre conformément à tous

les codes et règlements pertinents. Ne modifiez

jamais la fiche de quelque façon que ce soit, par

exemple en enlevant la broche de mise à la terre.

N’utilisez pas d’adaptateur de fiche. Si vous

n’êtes pas certain que la prise de courant est

correctement mise à la terre, adressez-vous à un

électricien qualifié. En cas de défaillance ou de

défectuosité électrique de l’outil, une mise à la terre

offre un trajet de faible résistance à l’électricité qui

autrement risquerait de traverser l’utilisateur.

5. Évitez tout contact corporel avec des surfaces

mises à la terre (tuyauterie, radiateurs,

cuisinières, réfrigérateurs, etc.). Le risque de

choc électrique est plus grand si votre corps est en

contact avec la terre.

6. N’exposez pas les outils électriques à la pluie ou

à l’eau. La présence d’eau dans un outil électrique

augmente le risque de choc électrique.

7. Ne maltraitez pas le cordon. Ne transportez pas

l’outil par son cordon et ne débranchez pas la

fiche en tirant sur le cordon. N’exposez pas le

cordon à la chaleur, à des huiles, à des arêtes

vives ou à des pièces en mouvement.

Remplacez immédiatement un cordon

endommagé. Un cordon endommagé augmente le

risque de choc électrique.

8. Lorsque vous utilisez un outil électrique à

l’extérieur, employez un prolongateur pour

l’extérieur marqué “W-A” ou “W”. Ces cordons

sont faits pour être utilisés à l’extérieur et réduisent

le risque de choc électrique.

Sécurité des personnes

9. Restez alerte, concentrez-vous sur votre travail

et faites preuve de jugement. N’utilisez pas un

outil électrique si vous êtes fatigué ou sous

l’influence de drogues, d’alcool ou de

médicaments. Un instant d’inattention suffit pour

entraîner des blessures graves.

10. Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les

cheveux longs. N’approchez jamais les

cheveux, les vêtements ou les gants des pièces

en mouvement. Des vêtements flottants, des bijoux

9

Page 10

ou des cheveux longs risquent d’être happés par

des pièces en mouvement.

11. Méfiez-vous d’un démarrage accidentel. Avant

de brancher l’outil, assurez-vous que son

interrupteur est sur ARRÊT. Le fait de transporter

un outil avec le doigt sur la détente ou de brancher

un outil dont l’interrupteur est en position MARCHE

peut mener tout droit à un accident.

12. Enlevez les clés de réglage ou de serrage avant

de démarrer l’outil. Une clé laissée dans une pièce

tournante de l’outil peut provoquer des blessures.

13. Ne vous penchez pas trop en avant. Maintenez

un bon appui et restez en équilibre en tout

temps. Un bonne stabilité vous permet de mieux

réagir à une situation inattendue.

14. Utilisez des accessoires de sécurité. Portez

toujours des lunettes ou une visière. Selon les

conditions, portez aussi un masque antipoussière,

des bottes de sécurité antidérapantes, un casque

protecteur et/ou un appareil antibruit. Les lunettes

ordinaires et les lunettes de soleil NE constituent

PAS des lunettes de protection.

Utilisation et entretien des outils

15. Immobilisez le matériau sur une surface stable

au moyen de brides ou de toute autre façon

adéquate. Le fait de tenir la pièce avec la main ou

contre votre corps offre une stabilité insuffisante et

peut amener un dérapage de l’outil.

16. Ne forcez pas l’outil. Utilisez l’outil approprié à

la tâche. L’outil correct fonctionne mieux et de façon

plus sécuritaire. Respectez aussi la vitesse de

travail qui lui est propre.

17. N’utilisez pas un outil si son interrupteur est

bloqué. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux et

doit être réparé.

18. Débranchez la fiche de l’outil avant d’effectuer

un réglage, de changer d’accessoire ou de

ranger l’outil. De telles mesures préventives de

sécurité réduisent le risque de démarrage accidentel

de l’outil.

19. Rangez les outils hors de la portée des enfants

et d’autres personnes inexpérimentées. Les

outils sont dangereux dans les mains d’utilisateurs

novices.

20. Prenez soin de bien entretenir les outils. Les

outils de coupe doivent être toujours bien

affûtés et propres. Des outils bien entretenus, dont

les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

21. Soyez attentif à tout désalignement ou

coincement des pièces en mouvement, à tout

bris ou à toute autre condition préjudiciable au

bon fonctionnement de l’outil. Si vous constatez

qu’un outil est endommagé, faites-le réparer

avant de vous en servir. De nombreux accidents

sont causés par des outils en mauvais état.

22. N’utilisez que des accessoires que le fabricant

recommande pour votre modèle d’outil. Certains

accessoires peuvent convenir à un outil, mais être

dangereux avec un autre.

RÉPARATI ON

23. La réparation des outils électriques doit être

confiée à un réparateur qualifié. L’entretien ou la

réparation d’un outil électrique par un amateur peut

avoir des conséquences graves.

24. Pour la réparation d’un outil, n’employez que

des pièces de rechange d’origine. Suivez les

directives données à la section «ENTRETIEN» de

ce manuel. L’emploi de pièces non autorisées ou le

non-respect des instructions d’entretien peut créer

un risque de choc électrique ou de blessures.

UTLISEZ UN CORDON PROLONGATEUR ADÉQUAT:

N’utilisez que les cordons prolongateurs à trois fils

et munis d’une fiche tripolaire, ainsi que des prises

tripolaires adaptées à la fiche de l’outil. Assurezvous que le cordon prolongateur est en bon état.

Remplacez ou réparez sans tarder tout cordon

endommagé ou usé. Lors de l’utilisation d’un cordon

prolongateur, utilisez sans faute un cordon assez

gros pour conduire le courant que le produit

nécessite. Un cordon trop petit provoquera une

baisse de tension de secteur, résultant en une perte

de puissance et une surchauffe. Le Tableau 1 indique

la dimension appropriée de cordon selon sa

longueur et selon l’intensité nominale indiquée sur la

plaque signalétique. En cas de doute sur un cordon

donné, utilisez le cordon suivant (plus gros). Plus le

numéro de gabarit indiqué est petit, plus le cordon

est gros.

Tableau 1: Gabarit minimum du cordon

Intensité nominale

Volts Longueur totale du cordon en pieds

120 V 25 pi 50 pi 100 pi 150 pi

Plus de Pas plus de Calibre américain des fils

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Non recommandé

10

Page 11

INSTRUCTIONS POUR LA MISE À TERRE:

Cet outil doit être mis à la terre pendant son

utilisation, afin de protéger son utilisateur contre les

chocs électriques. Il est équipé d’un cordon à trois

conducteurs et d’une fiche tripolaire adaptée au type

de prise correspondant. Le conducteur vert (ou vert

et jaune) du cordon est le fil de mise à la terre. Ne

raccordez jamais ce fil vert (ou vert et jaune) à une

borne d’alimentation secteur. Cet appareil doit être

utilisé sur un circuit de 120 volts et sa fiche est telle

qu’illustrée sur la Fig. “A”.

Fig. A

Lame de mise à la terre

Couvercle de la prise

d’alimentation mise à

la terre

RÈGLES DE SÉCURITÉ

PARTICULI ÈRES

USB047-4

NE vous laissez PAS tromper (au fil d’une

utilisation répétée) par un sentiment

d’aisance et de familiarité avec le

produit, en négligeant le respect

rigoureux des consignes de sécurité qui

accompagnent la polisseuse.

L’utilisation non sécuritaire ou incorrecte

de cet outil comporte un risque de

blessure grave.

1. Les accessoires doivent être prévus pour au

moins la vitesse recommandée sur l’étiquette de

mise en garde de l’outil. Les meules et autres

accessoires, s’il tournent au-delà de la vitesse

nominale, risquent d’éclater et de provoquer des

blessures. La vitesse maximale de fonctionnement

des accessoires doit être supérieure à la vitesse

maximale à vide indiquée sur la plaque signalétique

de l’outil.

2. Tenez l’outil par ses surfaces de prise isolées

pendant toute opération où l’outil de coupe

pourrait venir en contact avec un câblage

dissimulé ou avec son propre cordon. En cas de

contact avec un conducteur sous tension, les pièces

métalliques à découvert de l’outil transmettraient un

choc électrique à l’utilisateur.

3. Avant d’opérer, assurez-vous que le plateau

caoutchouc ne présente ni fissure, ni

déformation, ni défaut d’aucune sorte. Si c’était

le cas, changez-le immédiatement.

4. N’utilisez JAMAIS cet outil avec des lames à bois

ou autres lames de scie. Les lames de ce type

sautent fréquemment lorsque utilisées sur une

polisseuse et peuvent alors entraîner une perte

de contrôle pouvant causer des blessures.

5. Tenez votre outil fermement.

6. Gardez les mains éloignées des pièces en

mouvement.

7. Assurez-vous que le disque abrasif ou la peau

de mouton n’entre pas en contact avec la pièce à

travailler avant de mettre l’interrupteur sous

tension.

8. Lors du ponçage de surfaces métalliques, faites

attention aux étincelles. Placez-vous de telle

manière que personne (vous y compris) ne se

trouve sur le trajet des particules

incandescentes. Veillez également à les

maintenir à l’écart de tout produit inflammable.

9. N’abandonnez pas l’outil en fonctionnement : il

ne doit rester en marche que si vous l’avez en

main.

10. La surface qui vient d’être poncée ou polie peut

être très chaude; ne la touchez pas pour ne pas

vous brûler.

11. Vérifiez que la pièce est correctement soutenue.

12. Soyez conscient que la meule continue de

tourner une fois l’outil mis hors tension.

13. Cet outil n’ayant pas été imperméabilisé, la

surface de la pièce à travailler doit être exempte

d’eau lors de son utilisation.

14. Aérez adéquatement l’aire de travail lorsque

vous effectuez des travaux de ponçage.

15. L’utilisation de cet outil pour poncer certains

produits, les surfaces peintes et le bois peut

exposer l’utilisateur à des poussières qui

contiennent des substances dangereuses.

Veuillez porter une protection des voies

respiratoires adéquate.

CONSERVEZ CES

INSTRUCTIONS

AVERTISSEMENT:

LA MAUVAISE UTILISATION de l’outil ou

l’ignorance des consignes de sécurité du

présent manuel d’instructions peut

entraîner une blessure grave.

11

Page 12

SYMBOLES

Les symboles utilisés pour l’outil sont indiqués cidessous.

V............................volts

A ...........................ampères

Hz..........................hertz

..................courant alternatif

.......................vitesse à vide

.../min....................tours par minute

USD101-2

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

débranché avant de l’ajuster ou de vérifier son

fonctionnement.

Blocage de l’arbre

ATTENTION:

• N’activez jamais le blocage de l’arbre alors que

l’arbre bouge. Vous pourriez endommager l’outil.

Appuyez sur le blocage de l’arbre pour empêcher l’arbre

de tourner lors de l’installation ou du retrait des

accessoires.

Interrupteur

1

003432

1. Verrou d’axe

1

003435

1. Bouton de

verrouillage

2. Gâchette

ATTENTION:

• Avant de brancher l’outil, assurez-vous toujours

que la gâchette fonctionne correctement et revient

en position d’arrêt une fois relâchée.

• Pour rendre le travail de l’utilisateur plus confortable

lors d’une utilisation prolongée, l’interrupteur peut

être verrouillé en position de marche. Soyez

prudent lorsque vous verrouillez l’outil en position

de marche, et maintenez une poigne solide sur

l’outil.

Pour mettre l’outil en marche, appuyez simplement sur la

gâchette. La vitesse de l’outil augmente à mesure que

l’on accroît la pression exercée sur la gâchette. Pour

l’arrêter, relâchez la gâchette.

Pour un fonctionnement continu, appuyez sur la gâchette

puis enfoncez le bouton de verrouillage.

Pour arrêter l’outil alors qu’il est en position verrouillée,

appuyez à fond sur la gâchette puis relâchez-la.

Cadran de rélage de vitesse

La vitesse de l’outil peut être modifiée en tournant le

cadran de réglage de la vitesse sur un numéro de

réglage donné, de 1 à 6. (au moment où la gâchette est

tirée à fond)

Une vitesse plus élevée est obtenue lorsque le cadran

est tourné dans le sens du numéro 6. Une vitesse plus

basse est obtenue lorsqu’il est tourné dans le sens du

numéro 1.

Reportez-vous au tableau pour le rapport entre les

réglages numérotés sur le cadran et la vitesse

approximative de l’outil.

Nombre

1

2

3

4

5

6

T/MIN

600

900

1,500

2,100

2,700

3,000

003440

1

003441

1. Cadran de

réglage de la

vitesse

ATTENTION:

• Si l’outil est utilisé de manière continue à vitesse

2

réduite sur une période prolongée, le moteur sera

surchargé et cela entraînera un mauvais

fonctionnement de l’outil.

12

Page 13

• Le cadran de réglage de la vitesse ne peut pas

dépasser le 6 et le 1. Ne le forcez pas à dépasser le

6 ou le 1, sinon la fonction de réglage de la vitesse

risque de ne plus fonctionner.

ASSEMBLAGE

ATTENTION:

• Avant d’effectuer toute intervention sur l’outil,

assurez-vous toujours qu’il est hors tension et

débranché.

Installation de la poignée arceau

(pour 9227C uniquement)

ATTENTION:

• Avant l’utilisation, assurez-vous toujours que la

poignée arceau est solidement installée.

12

Installez toujours la poignée arceau sur l’outil avant le

travail. Tenez la poignée arrière de l’outil et la poignée

arceau fermement à deux mains pendant le

fonctionnement.

Installez la poignée arceau de façon que sa saillie rentre

dans l’orifice correspondant du carter d’engrenages.

Installez les boulons et serrez-les à l’aide de la clé

hexagonale. Vous pouvez installer la poignée arceau

dans deux directions différentes, comme indiqué sur les

figures, en fonction du travail à effectuer.

1

2

003448

1. Partie saillante

de la poignée

arceau

2. Orifice de

couplage dans

le carter

d’engrenages

003449

1. Poignée arceau

2. Clé hexagonale

3. Boulon

3

003450

11

2

3

1. Poignée arceau

2. Boulon

3. Clé hexagonale

Installation de la poignée latérale (poignée)

(pour 9227CY uniquement)

ATTENTION:

• Avant d’utiliser l’outil, assurez-vous toujours que la

poignée latérale est installée de façon sûre.

Vissez la poignée latérale à fond sur la position de l’outil

comme illustré sur la figure.

003805

Installation ou retrait de la peau de mouton

(accessoire en option)

1

2

3

Avant d’installer la peau de mouton, enlevez toute saleté

et tout corps étranger du plateau. Appuyez sur le verrou

d’axe et vissez le plateau de support sur l’arbre. Insérez

le manchon 18 dans l’orifice central du plateau de

support.

En vous servant du manchon 18 comme guide de

positionnement, installez la peau de mouton sur le

plateau de support avec le manchon 18 inséré dans

l’orifice central de la peau de mouton. Puis, retirez le

manchon 18 de la peau.

Pour retirer la peau de mouton, enlevez-la simplement du

plateau. Puis, dévissez le plateau tout en appuyant sur le

verrou d’axe.

003467

4

5

1. Peau de mouton

2. Manchon 18

3. Plateau de

support

4. Arbre

5. Verrou d’axe

13

Page 14

Installation ou retrait du disque abrasif

(accessoire en option)

1

2

3

NOTE:

• Utilisez les accessoires de ponçage recommandés

dans le présent manuel d’instructions. Ces derniers

doivent être achetés séparément.

Placez le plateau de caoutchouc sur l’arbre. Ajustez le

disque abrasif sur le plateau de caoutchouc et vissez le

contre-écrou sur l’arbre.

Pour serrer le contre-écrou, appuyez fermement sur le

blocage de l’arbre pour empêcher l’arbre de tourner, puis

utilisez la clé à contre-écrou en serrant fermement dans

le sens des aiguilles d’une montre.

1

2

Pour retirer le disque, suivez la procédure d’installation

de l’autre côté.

003457

1. Contre-écrou

2. Disque abrasif

3. Plateau de

4. Arbre

4

003458

1. Clé à ergots

2. Verrou d’axe

caoutchouc

UTILISATION

Opération de polissage

003478

Tene z l’outil fermement. Mettez le contact et appliquez

ensuite la peau de mouton sur le matériau.

D’une façon générale, maintenez la peau de mouton

selon un angle d’environ 15 degrés avec la surface du

matériau.

N’appliquez qu’une légère pression ; toute pression

excessive réduit le rendement de l’outil et entraîne une

usure prématurée de la peau de mouton.

Opération de sablage

ATTENTION:

• Portez toujours des lunettes à coques de sécurité

ou un écran facial pendant l’opération.

• Ne mettez jamais l’outil en marche alors qu’il se

trouve en contact avec la pièce à travailler, pour

éviter de vous blesser.

• Ne jamais utiliser l’outil sans le disque abrasif. Vous

risquer de sérieusement endommager le tampon.

Tene z l’outil fermement. Mettez le contact et appliquez

ensuite le disque abrasif sur le matériau.

D’une façon générale, maintenez le disque abrasif selon

un angle d’environ 15 degrés avec la surface du

matériau.

N’appliquez qu’une légère pression ; toute pression

excessive réduit le rendement de l’outil et entraîne une

usure prématurée du disque abrasif.

003473

ENTRETIEN

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

débranché avant d’y effectuer tout travail

d’inspection ou d’entretien.

Remplacement des charbons

001145

1. Trait de limite

d’usure

ATTENTION:

• Portez toujours des lunettes à coques de sécurité

ou un écran facial pendant l’opération.

1

14

Page 15

Retirez et vérifiez régulièrement les charbons.

Remplacez-les lorsqu’ils sont usés jusqu’au trait de limite

d’usure. Maintenez les charbons propres et en état de

glisser aisément dans les porte-charbon. Les deux

charbons doivent être remplacés en même temps.

N’utilisez que des charbons identiques.

Utilisez un tournevis pour retirer les bouchons de portecharbon. Enlevez les charbons usés, insérez-en de

nouveaux et revissez solidement les bouchons de portecharbon.

12

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit,

les réparations, tout autre travail d’entretien ou de

réglage doivent être effectués dans un centre de service

Makita agréé ou un centre de service de l’usine Makita,

exclusivement avec des pièces de rechange Makita.

003483

1. Tournevis

2. Bouchon de

porte-charbon

ACCESSOIRES

ATTENTION:

• Ces accessoires ou pièces complémentaires sont

recommandés pour l’utilisation avec l’outil Makita

spécifié dans ce mode d’emploi. L’utilisation de tout

autre accessoire ou pièce complémentaire peut

comporter un risque de blessure. N’utilisez les

accessoires ou pièces qu’aux fins auxquelles ils ont

été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Peau de mouton 180 (auto-agrippante)

• Plateau de support 165 (auto-aggripant)

• Disques abrasifs

• Plateau de caoutchouc 170

• Contre-écrou pour ponçage 5/8 - 48

• Clé àergots 28

• Manchon 18

• Poignée 36

• Poignée arceau

GARANTIE LIMITÉE D’UN AN MAKITA

EN0006-1

Politique de garantie

Chaque outil Makita est inspecté rigoureusement et testé

avant sa sortie d’usine. Nous garantissons qu’il sera

exempt de défaut de fabrication et de vice de matériau

pour une période d’UN AN à partir de la date de son

achat initial. Si un problème quelconque devait survenir

au cours de cette période d’un an, veuillez retourner

l’outil COMPLET, port payé, à une usine ou à un centre

de service après-vente Makita. Makita réparera l’outil

gratuitement (ou le remplacera, à sa discrétion) si un

défaut de fabrication ou un vice de matériau est

découvert lors de l’inspection.

Cette garantie ne s’applique pas dans les cas où :

• des réparations ont été effectuées ou tentées par

un tiers ;

• des réparations s’imposent suite à une usure

normale ;

• l’outil a été malmené, mal utilisé ou mal entretenu ;

• l’outil a subi des modifications.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ POUR

TOUT DOMMAGE ACCESSOIRE OU INDIRECT LIÉ À

LA VENTE OU À L’UTILISATION DU PRODUIT. CET

AVIS DE NON-RESPONSABILITÉ S’APPLIQUE À LA

FOIS PENDANT ET APRÈS LA PÉRIODE COUVERTE

PAR CETTE GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

À TOUTE GARANTIE TACITE, INCLUANT LES

GARANTIES TACITES DE “QUALITÉ MARCHANDE” ET

“ADÉQUATION À UN USAGE PARTICULIER” APRÈS

LA PÉRIODE D’UN AN COUVERTE PAR CETTE

GARANTIE.

Cette garantie vous donne des droits spécifiques

reconnus par la loi, et possiblement d’autres droits, qui

varient d’un État à l’autre. Certains États ne permettant

pas l’exclusion ou la limitation des dommages

accessoires ou indirects, il se peut que la limitation ou

exclusion ci-dessus ne s’applique pas à vous. Certains

États ne permettant pas la limitation de la durée

d’application d’une garantie tacite, il se peut que la

limitation ci-dessus ne s’applique pas à vous.

15

Page 16

ESPAÑOL

ESPECIFICACIONES

Modelo 9227C/9227CY

Especificaciones eléctricas en México

Capacidades máximas

Rosca del eje 5/8”

Revoluciones por minuto (r.p.m.) 0 - 3 000/min.

Longitud total 470 mm (18-1/2”)

Peso neto 3,0 kg (6,6 lbs)

• Debido a un programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a

cambios sin previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

Disco pulidor de lana 180 mm (7”)

Disco abrasivo 180 mm (7”)

120 V 10 A 50/60 Hz

REGLAS GENERALES DE

SEGURIDAD

USA001-3

(Para todas las herramientas)

AVISO:

Lea y entienda todas las instrucciones.

Si no cumple con las instrucciones aquí

detalladas, se puede producir una descarga

eléctrica, incendio y/o lesiones de gravedad.

GUARDE ESTAS

INSTRUCCIONES

Área de trabajo

1. Mantenga el área de trabajo limpia y bien

iluminada. Las áreas oscuras y mesas de trabajo

desordenadas son propensas a accidentes.

2. No opere herramientas eléctricas en atmósferas

explosivas tales como en presencia de polvo,

gases o líquidos inflamables. Las herramientas

eléctricas producen chispas que puede encender el

polvo o los gases.

3. Mantenga a los niños, espectadores y visitantes

alejados mientras opera la herramienta eléctrica.

Si se distrae, puede perder el control de la

herramienta.

Seguridad en materia de electricidad

4. Las herramientas con toma a tierra deben

enchufarse en un tomacorriente instalado

apropiadamente y conectado a tierra según

todos los códigos y ordenanzas. Nunca retire la

conexión a tierra o modifique la ficha de ninguna

manera. No use fichas para adaptadores.

Verifique con un electricista calificado si tiene

dudas acerca de si el tomacorriente está

conectado a tierra adecuadamente. Si las

herramientas funcionaran mal o fallaran, la conexión

a tierra le brinda un camino de baja resistencia para

llevar la electricidad fuera del usuario.

5. Evite el contacto corporal con superficies a

tierra tales como radiadores, tuberías,

refrigeradores y hornillos. Se corre más riesgo de

sufrir una descarga eléctrica si el cuerpo está a

tierra.

6. No exponga las herramientas eléctricas a la

lluvia o a la humedad. Si ingresa agua en la

herramienta eléctrica, aumenta el riesgo de sufrir

una descarga eléctrica.

7. No tire del cable. Nunca use un cable para

transportar las herramientas ni tire de la ficha

enchufada en un tomacorriente. Mantenga el

cable alejado del calor, aceite, objetos cortantes

o piezas móviles. Reemplace los cables dañados

inmediatamente. Los cables dañados aumentan el

riesgo de sufrir una descarga eléctrica.

8. Cuando opere una herramienta eléctrica al aire

libre, utilice un cable externo marcado “W-A” o

“W”. Estos cables están clasificados para uso

externo y reducen el riesgo de sufrir una descarga

eléctrica.

Seguridad personal

9. Esté atento, preste atención a lo que está

haciendo y utilice su sentido común cuando

opere una herramienta eléctrica. No utilice la

herramienta eléctrica cuando esté cansado o

bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracción

mientras opera herramientas eléctricas puede dar

como resultado heridas personales graves.

16

Page 17

10. Use vestimenta apropiada. No use ropas sueltas

ni joyas. Átese el cabello largo. Mantenga el

cabello, la ropa y los guantes alejados de las

partes móviles. Las ropas sueltas, joyas o el

cabello largo pueden ser atrapados por las partes

móviles.

11. Evite el encendido accidental de la herramienta.

Asegúrese de que el interruptor está en posición

de apagado antes de enchufarla. Tra n spo r t a r

herramientas con su dedo en el interruptor o

enchufar herramientas que tienen el interruptor en la

posición de encendido hacen propensos los

accidentes.

12. Retire las llaves de ajuste o tuercas antes de

encender la herramienta. Si deja alguna de éstas

adherida a una parte giratoria de la herramienta

eléctrica puede sufrir heridas personales.

13. No haga demasiadas cosas al mismo tiempo.

Mantenga la postura y el equilibrio en todo

momento. Una postura y equilibrio apropiados le

permitirán un mejor control de la herramienta en

situaciones imprevistas.

14. Utilice equipos de seguridad. Utilice siempre

protección ocular. Deben utilizarse máscaras para

protegerse del polvo, calzado de seguridad

antideslizante, casco rígido o protección auditiva

para condiciones apropiadas. Los anteojos

comunes o para el sol NO son gafas de seguridad.

Uso y cuidado de la herramienta

15. Utilice abrazaderas u otra forma práctica de

asegurar y soportar la pieza a una plataforma

estable. Sostener la pieza de trabajo con la mano o

contra su cuerpo es instable y puede llevar a una

pérdida del control.

16. No fuerce la herramienta. Utilice la herramienta

correcta para su aplicación. La herramienta

adecuada hará un trabajo mejor y más seguro a la

velocidad para la que ha sido fabricada.

17. No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no pueda

controlarse con el interruptor es peligrosa y debe

repararse.

18. Desconecte la ficha de la fuente de energía antes

de hacer cualquier ajuste, cambiar accesorios o

guardar la herramienta. Dichas medidas

preventivas de seguridad reducen el riesgo de que

la herramienta se opere accidentalmente.

19. Guarde las herramientas que no use fuera del

alcance de los niños y de cualquier otra persona

que no esté familiarizada con el uso de las

mismas. Las herramientas son peligrosas en

manos de personas que no saben operarlas.

20. Cuide sus herramientas. Mantenga las

herramientas de corte limpias y filosas. Si recibe

un mantenimiento adecuado y tiene los bordes

afilados, es probable que la herramienta se atasque

menos y sea más fácil controlarla.

21. Verifique que no esté mal alineada, uniones de

las partes móviles, piezas rotas y demás

condiciones que puedan afectar el

funcionamiento de la herramienta. Si se daña,

repárela antes de usarla. Muchos accidentes son

consecuencia del mal mantenimiento de las

herramientas eléctricas.

22. Utilice sólo accesorios recomendados por el

fabricante para dicho modelo. Los accesorios que

pueden ser adecuados para una herramienta,

pueden ser peligrosos cuando se utilizan en otra

herramienta.

REPARACIÓN

23. Sólo personal calificado deberá realizar la

reparación de la herramienta. La reparación o

mantenimiento realizado por personal no calificado

podría resultar en un riesgo de lesión.

24. Cuando realice reparaciones sólo reemplace por

partes idénticas. Siga las instrucciones de la

sección de Mantenimiento del presente manual.

El uso de partes no autorizadas o la falta de

cumplimiento de las instrucciones de Mantenimiento

podrían crear un riesgo de sufrir una descarga

eléctrica o lesión.

UTILICE UN CABLE DE EXTENSIÓN ADECUADO:

Utilice sólo cables de extensión de tres conductores

que tienen fichas de tres clavijas a tierra y

receptáculos de tres polos que aceptan la ficha de la

herramienta. Asegúrese de que el cable de extensión

esté en buenas condiciones. Reemplace o repare el

cable dañado o gastado inmediatamente. Cuando

use un cable de extensión, asegúrese de que éste

sea lo suficientemente potente como para soportar

la tensión eléctrica que producirá el uso de la

herramienta. Un cable demasiado delgado producirá

una reducción del voltaje, lo que ocasionará una

disminución en la corriente y sobrecalentamiento. La

tabla 1 muestra el tamaño correcto de cable,

dependiendo de la longitud y del rango de amperio

establecido en la placa de fábrica. Si se encuentra en

duda, utilice uno más potente. Cuanto más pequeño

sea el número del calibre, más potente será el cable.

17

Page 18

Tabla 1: Calibre mínimo para el cable

Rango de amperio

Voltios Largo total del cable en centímetros

120 V 762 cm 1.524 cm 3.048 cm 4.572 cm

Más de No más de AWG

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 No se recomienda

INTRUCCIONES PARA CONEXIÓN A TIERRA:

Esta herramienta deberá ser conectada a tierra

mientras está en uso para proteger al operador de

sufrir una descarga eléctrica. La herramienta está

equipada con un cable de tres conductores y una

ficha de tres clavijas para conexión a tierra para

adaptarse al receptáculo apropiado de conexión a

tierra. El conductor verde (o verde y amarillo) en el

cable es el conductor de conexión a tierra. Nunca

conecte el conductor verde (o verde y amarillo) a un

terminal vivo. Su unidad es para usar en 120 voltios y

tiene una ficha igual que la que aparece en la Figura

“A”.

Fig. A

Clavija de conexion a tierra

Cubierta de la caja

del tomacorriente

conectada a tierra

REGLAS ESPECÍFICAS DE

SEGURIDAD

USB047-4

NO permita que la comodidad o

familiaridad con el producto (a causa de

su uso frecuente) substituya el

cumplimiento estricto de las reglas de

seguridad sobre la pulidora. Si usted

utiliza esta herramienta de modo

inseguro o incorrecto, puede sufrir

heridas graves.

1. Los accesorios deben poseer al menos la

velocidad recomendada en la etiqueta de

advertencia que lleva la herramienta. Las ruedas

y demás accesorios que funcionen por encima de la

velocidad estipulada podrían salir volando y causar

heridas. La velocidad máxima de funcionamiento de

los accesorios debe ser mayor a la más alta sin

carga, que aparece en la chapa de la herramienta.

2. Sostenga la herramienta por la superficie de

agarre revestida con aislamiento a la hora de

realizar una actividad en la que la herramienta

de corte pueda estar en contacto con un cable

oculto o con su propio cable de suministro de

energía. El contacto con un cable “vivo” hará que

las partes de metal expuestas de la herramienta

también estén “vivas” y que el operario reciba una

descarga eléctrica.

3. Antes de poner la herramienta en

funcionamiento, asegúrese de que la

almohadilla posterior no esté dañada o

deformada. Reemplace la almohadilla dañada,

quebrada o deformada de inmediato.

4. NUNCA utilice la herramienta con hojas para

cortar madera y demás hojas de sierra. Al

utilizarlas en una pulidora, estas herramientas

con frecuencia retroceden bruscamente y

producen la pérdida de control, lo que ocasiona

heridas personales.

5. Sostenga firmemente la herramienta.

6. Mantenga las manos alejadas de las piezas

giratorias.

7. Asegúrese de que el disco abrasivo o el disco

pulidor de lana no esté en contacto con la pieza

de trabajo antes de encender la herramienta.

8. A la hora de lijar superficies de metal, tenga

cuidado con las chispas voladoras. Sostenga la

herramienta para que las chispas salgan

volando lejos de usted, de otras personas o de

materiales inflamables.

9. No deje la herramienta en funcionamiento.

Opere solamente la herramienta con las manos.

10. No toque la pieza de trabajo inmediatamente

después de operar la herramienta; puesto que

puede estar extremadamente caliente y

quemarle la piel.

11. Verifique que la pieza de trabajo esté

correctamente sostenida.

18

Page 19

12. Tenga cuidado, puesto que la rueda continúa

girando después de apagada la herramienta.

13. Esta herramienta no es a prueba de agua. Por lo

tanto, no utilice agua sobre la superficie de la

pieza de trabajo.

14. Ventile el área de trabajo adecuadamente

cuando realice operaciones de lijado.

15. El uso de esta herramienta para lijar algunos

productos, pinturas y madera podría exponer al

usuario al polvo de sustancias peligrosas.

Utilice protección respiratoria adecuada.

GUARDE ESTAS

INSTRUCCIONES

AVISO:

EL MAL USO o incumplimiento de las

reglas de seguridad descriptas en el

presente manual de instrucciones puede

ocasionar graves lesiones a su persona.

SÍMBOLOS

A continuación se muestran los símbolos empleados

para la herramienta.

V............................voltios

A ...........................amperios

Hz..........................hercios

..................corriente alterna

.......................velocidad en vacío

.../min....................revoluciones por minuto

USD101-2

DESCRIPCIÓN DEL

FUNCIONAMIENTO

PRECAUCIÓN:

• Asegúrese siempre de que la herramienta esté

apagada y desenchufada antes de ajustar o

comprobar cualquier función en la herramienta.

Bloqueo del eje

PRECAUCIÓN:

• No accione nunca el bloqueo del eje cuando este

se esté moviéndo. Podría dañarse la herramienta.

Presione el bloqueo del eje para impedir que este gire

cuando vaya a instalar o desmontar accesorios.

Accionamiento del interruptor

1

2

PRECAUCIÓN:

• Antes de enchufar la herramienta, compruebe

siempre que el gatillo interruptor se acciona

debidamente y que vuelve a la posición “OFF”

(apagado) cuando lo suelta.

• El interruptor puede ser bloqueado en la posición

“ON” (encendido) para mayor comodidad del

operario durante una utilización prolongada. Tenga

precaución cuando bloquee la herramienta en la

posición “ON” (encendido) y sujete la herramienta

firmemente.

Para poner en marcha la herramienta, simplemente

apriete el gatillo. La velocidad de la herramienta

incrementa aumentando la presión en el gatillo. Suelte el

gatillo para parar.

Para una operación continua, apriete el gatillo y después

meta el botón de bloqueo.

Para detener la herramienta estando en la posición

bloqueada, apriete completamente el gatillo y luego

suéltelo.

003432

1

003435

1. Bloqueo del eje

1. Botón de

bloqueo

2. Gatillo

interruptor

19

Page 20

Dial de ajuste de velocidad

Se puede cambiar la velocidad de la herramienta al girar

el control de ajuste de velocidad a un número de

003440

1

1. Dial de

regulación de la

velocidad

regulaciones que varia de 1 a 6. (En el momento en que

el gatillo interruptor se jala por completo)

Se obtiene una velocidad más alta cuando se gira el dial

en dirección al número 6 y se obtiene una velocidad más

baja cuando se lo gira en dirección al número 1.

Consulte la tabla para la relación entre los números de

regulaciones en el dial y la velocidad aproximada de la

herramienta.

Número

1

2

3

4

5

6

min -1 (RPM

003441

)

600

900

1 500

2 100

2 700

3 000

PRECAUCIÓN:

• Si la herramienta es utilizada continuamente a

velocidades bajas durante largo tiempo, el motor se

sobrecargará resultando en un mal funcionamiento

de la herramienta.

• El control de ajuste de velocidad sólo se puede

subir hasta 6 y bajar hasta 1. No lo fuerce más allá

de estas marcas o de lo contrario la función de

ajuste de velocidad podría arruinarse.

MONTAJE

Instalación de la empuñadura

(Para 9227C solamente)

PRECAUCIÓN:

• Asegúrese siempre de que la empuñadura esté

instalada en forma segura antes de comenzar la

operación.

12

Instale siempre la empuñadura en la herramienta antes

de comenzar la operación. Sostenga el mango

interruptor de la herramienta y la empuñadura

firmemente con ambas manos durante la operación.

Instale la empuñadura de manera que su protuberancia

encaje en el agujero de encaje en la tapa de engranaje.

Instale los pernos y apriételos con la llave hexagonal. Se

puede instalar la empuñadura en dos direcciones

diferentes (como se muestra en las figuras) según como

sea conveniente para su trabajo.

1

2

11

003448

1. Protuberancia

de la

empuñadura

2. Agujero de

encaje en la

caja de

engranaje

003449

1. Empuñadura

2. Llave Allen

3. Perno

3

003450

1. Empuñadura

3

2. Perno

3. Llave Allen

PRECAUCIÓN:

• Asegúrese siempre de que la herramienta esté

apagada y desenchufada antes de realizar

cualquier trabajo en la herramienta.

2

20

Page 21

Instalación de la empuñadura lateral (mango)

(Para 9227CY solamente)

PRECAUCIÓN:

• Antes de realizar una operación, asegúrese

siempre de que la empuñadura lateral esté

instalada firmemente.

Rosque la empuñadura lateral firmemente en la posición

de la herramienta mostrada en la figura.

003805

Instalación o desmontaje del disco pulidor de

lana (accesorio opcional)

1

2

3

Para instalar el disco pulidor de lana, primero remueva

toda la suciedad o la materia extraña del disco de

respaldo. Presione el bloqueo del eje y rosque el disco

de respaldo sobre el eje. Inserte la camisa 18 en el

agujero central del disco de respaldo.

Con la utilización de la camisa 18 como guía de

posicionamiento, instale el disco pulidor de lana sobre el

disco de respaldo con la camisa 18 insertado en el

agujero central del disco pulidor de lana. Después,

extraiga la camisa 18 del disco de respaldo.

Para desmontar el disco pulidor de lana, tan sólo

arránquelo del disco de respaldo. Luego, desenrosque el

disco de respaldo mientras presiona el bloqueo del eje.

003467

4

5

1. Disco pulidor de

lana

2. Camisa 18

3. Disco de

respaldo

4. Eje

5. Bloqueo del eje

Instalación o desmontaje de un disco abrasivo

(accesorio opcional)

1

2

3

003457

1. Contratuerca

2. Disco abrasivo

3. Plato de goma

4. Eje

NOTA:

• Utilice accesorios para lijadora especificados en

este manual. Estos deberán ser adquiridos aparte.

Monte la almohadilla de goma sobre el eje. Encaje el

disco abrasivo sobre la almohadilla de goma y enrosque

la contratuerca sobre el eje.

Para apretar la contratuerca, presione el bloqueo del eje

firmemente para que el eje no pueda girar, después

apriete firmemente hacia la derecha utilizando la llave de

contratuerca.

1

2

Para desmontar el disco, siga el procedimiento de

instalación a la inversa.

003458

1. Llave de

contratuerca

2. Bloqueo del eje

OPERACIÓN

Operación de pulido

PRECAUCIÓN:

• Utilice siempre gafas de seguridad o una mascara

facial durante la operación.

Sujete la herramienta firmemente. Encienda la

herramienta y luego ponga el disco pulidor de lana en la

pieza de trabajo.

En general, mantenga el disco pulidor de lana en un

ángulo de aproximadamente 15º de la superficie de la

pieza de trabajo.

Sólo presione ligeramente. La presión excesiva hará que

el disco pulidor de lana tenga un rendimiento pobre y un

desgaste prematuro.

003478

4

21

Page 22

Operación de lijado

003473

Utilice un destornillador para quitar los tapones

portaescobillas. Extraiga las escobillas gastadas, inserte

las nuevas y vuelva a colocar los tapones

portaescobillas.

003483

1. Destornillador

2. Tapa del

portaescobillas

PRECAUCIÓN:

• Póngase siempre gafas de seguridad o máscara

facial durante la operación.

• No encienda nunca la herramienta cuando ésta

esté en contacto con la pieza de trabajo, podría

ocasionar heridas al operario.

• Nunca haga funcionar la herramienta sin el disco

abrasivo. Podría dañar seriamente el disco.

Sujete la herramienta firmemente. Encienda la

herramienta y luego ponga el disco abrasivo en la pieza

de trabajo.

En general, mantenga el disco abrasivo en un ángulo de

aproximadamente 15º de la superficie de la pieza de

trabajo.

Sólo presione ligeramente. La presión excesiva hará que

el disco abrasivo tenga un rendimiento pobre y un

desgaste prematuro.

MANTENIMIENTO

PRECAUCIÓN:

• Asegúrese siempre que la herramienta esté

apagada y desenchufada antes de intentar realizar

una inspección o mantenimiento.

Reemplazo de las escobillas de carbón

001145

1. Marca de límite

12

Para mantener la SEGURIDAD y FIABILIDAD del

producto, las reparaciones, y cualquier otra tarea de

mantenimiento o ajuste deberán ser realizadas en

Centros de Servicio Autorizados por Makita, empleando

siempre repuestos Makita.

ACCESORIOS

PRECAUCIÓN:

• Estos accesorios o acoplamientos están

recomendados para utilizar con su herramienta

Makita especificada en este manual. El empleo de

cualesquiera otros accesorios o acoplamientos

conllevará un riesgo de sufrir heridas personales.

Utilice los accesorios o acoplamientos solamente

para su fin establecido.

Si necesita cualquier ayuda para más detalles en

relación con estos accesorios, pregunte a su centro de

servicio Makita local.

• Disco pulidor de lana 180 (gancho y rulo)

• Disco de respaldo (gancho y anilla)

• Discos abrasivos

• Almohadilla de goma 170

• Contratuerca de lijado 5/8 - 48

• Llave de contratuerca 28

• Camisa 18

• Llave 37

• Empuñadura

1

Extraiga e inspeccione regularmente las escobillas de

carbón. Substitúyalas cuando se hayan gastado hasta la

marca límite. Mantenga las escobillas de carbón limpias

de forma que entren libremente en los portaescobillas.

Ambas escobillas de carbón deberán ser sustituidas al

mismo tiempo. Utilice únicamente escobillas de carbón

originales.

22

Page 23

GARANTÍA LIMITADA MAKITA DE UN AÑO

EN0006-1

Política de garantía

Cada herramienta Makita es inspeccionada y probada

exhaustivamente antes de salir de fábrica. Se garantiza

que va a estar libre de defectos de mano de obra y

materiales por el periodo de UN AÑO a partir de la fecha

de adquisición original. Si durante este periodo de un

año se desarrollase algún problema, retorne la

herramienta COMPLETA, porte pagado con antelación, a

una de las fábricas o centros de servicio autorizados

Makita. Si la inspección muestra que el problema ha sido

causado por mano de obra o material defectuoso, Makita

la reparará (o a nuestra opción, reemplazará) sin cobrar.

Esta garantía no será aplicable cuando:

• se hayan hecho o intentado hacer reparaciones por

otros:

• se requieran reparaciones debido al desgaste

normal:

• la herramienta haya sido abusada, mal usada o

mantenido indebidamente:

• se hayan hecho alteraciones a la herramienta.

EN NINGÚN CASO MAKITA SE HARÁ RESPONSABLE

DE NINGÚN DAÑO INDIRECTO, FORTUITO O

CONSECUENCIAL DERIVADO DE LA VENTA O USO

DEL PRODUCTO.

ESTA RENUNCIA SERÁ APLICABLE TANTO

DURANTE COMO DESPUÉS DEL TÉRMINO DE ESTA

GARANTÍA.

MAKITA RENUNCIA LA RESPONSABILIDAD POR

CUALQUIER GARANTÍA IMPLÍCITA, INCLUYENDO

GARANTÍAS IMPLÍCITAS DE “COMERCIALIDAD” E

“IDONEIDAD PARA UN FIN ESPECÍFICO”, DESPUÉS

DEL TÉRMINO DE UN AÑO DE ESTA GARANTÍA.

Esta garantía le concede a usted derechos legales

específicos, y usted podrá tener también otros derechos

que varían de un estado a otro. Algunos estados no

permiten la exclusión o limitación de daños fortuitos o

consecuenciales, por lo que es posible que la antedicha

limitación o exclusión no le sea de aplicación a usted.

Algunos estados no permiten limitación sobre la

duración de una garantía implícita, por lo que es posible

que la antedicha limitación no le sea de aplicación a

usted.

23

Page 24

< USA only >

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

< USA solamente >

ADVERTENCIA

Algunos tipos de polvo creados por el lijado, serrado, amolado, taladrado, y

otras actividades de la construccion contienen sustancias quimicas

reconocidas por el Estado de California como causantes de cancer, defectos

de nacimiento y otros peligros de reproduccion. Algunos ejemplos de estos

productos quimicos son:

• plomo de pinturas a base de plomo,

• silice cristalino de ladrillos y cemento y otros productos de albanileria, y

• arsenico y cromo de maderas tratadas quimicamente.

El riesgo al que se expone variara, dependiendo de la frecuencia con la que

realice este tipo de trabajo. Para reducir la exposicion a estos productos

quimicos: trabaje en un area bien ventilada, y pongase el equipo de seguridad

indicado, tal como esas mascaras contra el polvo que estan especialmente

disenadas para filtrar particulas microscopicas.

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi 446-8502 Japan

884103-943

Loading...

Loading...