Makita 8434D, 8444D, 8414D User Manual

Cordless Percussion-Driver Drill

GB

Instruction Manual

Perceuse percussion-visseuse sans fil

F

Akku-Schlagbohrschrauber

D

Trapano avvitatore percussione a batteria

I

Accu slagboor/schroevedraaier

NL

Taladro atornillador con percusión a batería

E

Berbequim de percussão a bateria

P

Akku-slagboremaskine/skruemaskine

DK

Sladdlös slagborr/skruvmaskin

S

Batteridrevet slagbor med skrutrekker

N

Akkukäyttöinen iskupora/ruuvinväännin

SF

Ασύρµατο κρουστικ κατσαβίδι-τρυπάνι Οδηγίες χρήσεως

GR

Manuel d’instructions

Betriebsanleitung

Istruzioni per l’uso

Gebruiksaanwijzing

Manual de instrucciones

Manual de instruções

Brugsanvisning

Bruksanvisning

Bruksanvisning

Käyttöohje

8414D

8434D

8444D

1

3

2

12

A

4

B

5

34

8

6

7

9

56

10

11

14

15

13

12

78

2

16

18

19

17

910

20

11 12

21

13 14

22

23

3

ENGLISH

Explanation of general view

1Button

2 Battery cartridge

3 Switch trigger

4 Reversing switch lever

5 Speed change lever

6 Action mode change lever

7Arrow

8 Adjusting ring

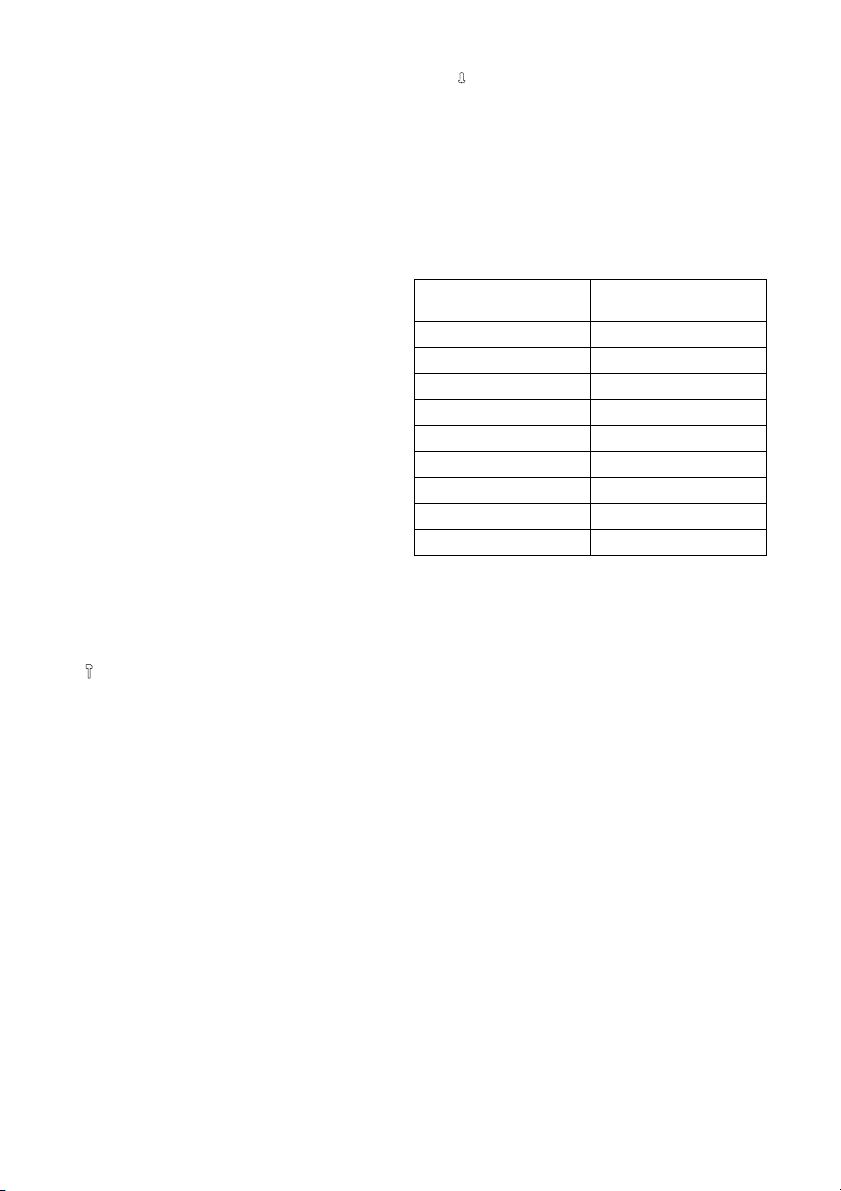

SPECIFICATIONS

Model 8414D 8434D 8444D

Capacities

Concrete............................................... 13 mm 14 mm 16 mm

Steel ..................................................... 13 mm 13 mm 13 mm

Wood.................................................... 45 mm 50 mm 65 mm

Wood screw.......................................... 6 mm x 75 mm 6 mm x 75 mm 10 mm x 89 mm

Machine screw ..................................... 6 mm 6 mm 6 mm

No load speed (min

High (3)................................................. 0 – 1,600 0 – 1,700 0 – 1,700

Medium (2) ........................................... 0 – 550 0 – 600 0 – 600

Low (1) ................................................. 0 – 300 0 – 300 0 – 300

Blows per minute (min

High (3)................................................. 0 –24,000 0 – 25,500 0– 25,500

Medium (2) ........................................... 0 – 8,250 0 – 9,000 0 – 9,000

Low (1) ................................................. 0 – 4,500 0 – 4,500 0 – 4,500

Overall length .......................................... 259 mm 259 mm 259 mm

Net weight ............................................... 2.4 kg 2.5 kg 2.7 kg

Rated voltage .......................................... D. C. 12 V D. C. 14.4 V D. C. 18 V

-1

)

-1

)

9 Graduations

10 Steel band

11 Grip base

12 Side grip

13 Protrusion

14 Groove

15 Sleeve

16 Bit

17 Bit holder

18 Depth rod

19 Clamp screw

20 Blow-out bulb

21 Limit mark

22 Brush holder cap

23 Screwdriver

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for impact drilling in brick, concrete

and stone as well as for drilling without impact in wood,

metal, ceramic and plastic.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

ADDITIONAL SAFETY RULES FOR POWER

TOOL

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to hammer drill safety rules. If you use this power

tool unsafely or incorrectly, you can suffer serious

personal injury.

1. Wear ear protectors with impact drills. Exposure

to noise can cause hearing loss.

2. Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

3. Hold tools by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

4. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

GEB003-1

4

5. Hold the tool firmly with both hands.

6. Keep hands away from rotating parts.

7. Do not leave the tool running. Operate the tool

only when hand-held.

8. Do not touch the bit or the workpiece immediately after operation; they may be extremely hot

and could burn your skin.

9. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS.

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Always cover the battery terminals with the battery cover when the battery cartridge is not

used.

6. Do not short the battery cartridge:

ENC004-1

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

7. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

8. Do not incinerate the battery cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

9. Be careful not to drop or strike battery.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C – 40°C (50°F – 104°F). Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when you do not use it for more than six

months.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the bat-

tery cartridge is removed before adjusting or checking

function on the tool.

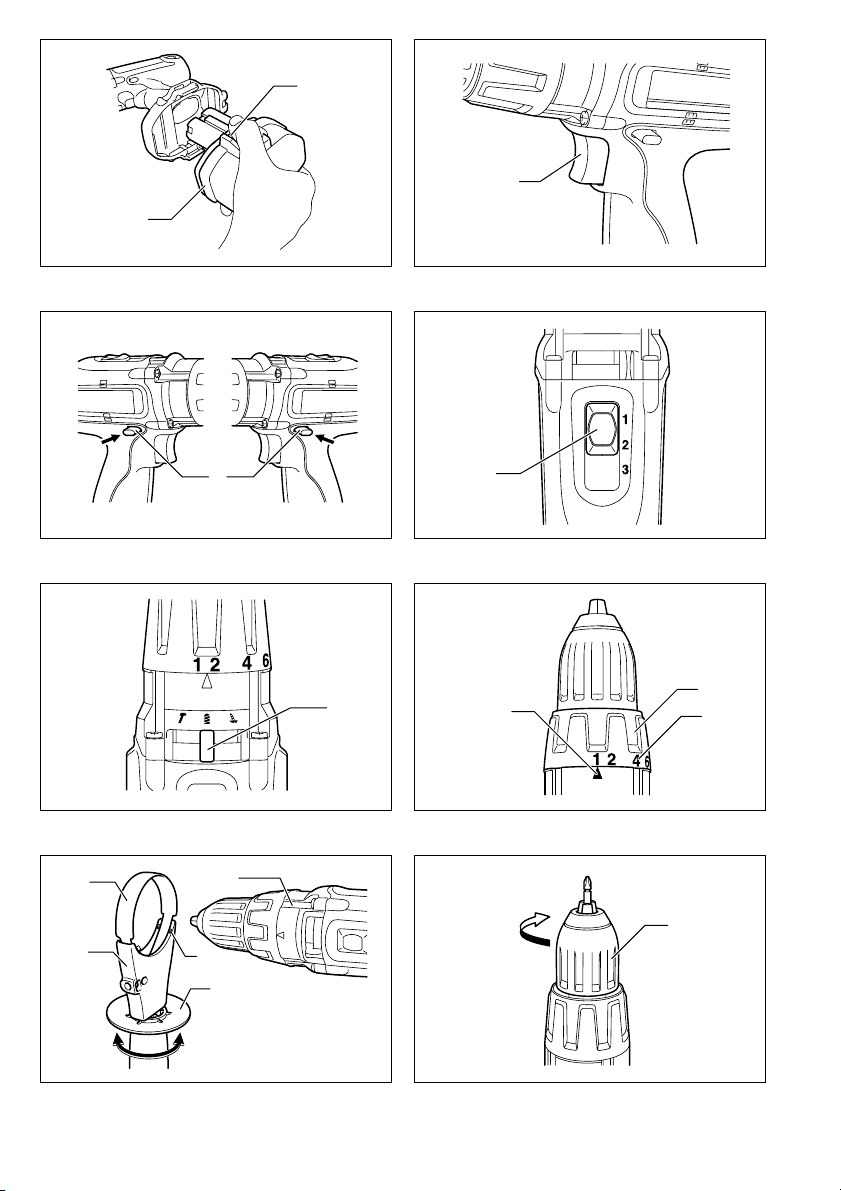

Installing or removing battery cartridge (Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the

tool while pressing the buttons on both sides of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Switch action (Fig. 2)

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

Reversing switch action (Fig. 3)

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the “A”

side for clockwise rotation or from the “B” side for counterclockwise rotation.

When the reversing switch lever is in the neutral position,

the switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

Speed change (Fig. 4)

This tool has a three-gear speed change lever. To

change the speed, first switch off the tool and then slide

the speed change lever to the “1” position for low speed,

“2” position for medium speed or “3” position for high

speed. Be sure that the speed change lever is set to the

correct position before operation. Use the right speed for

your job.

NOTE:

When changing the position from “1” to “3” or from “3” to

“1”, it may be a little difficult to slide the speed change

lever. At this time, switch on and run the tool for a second

at the “2” position, then stop the tool and slide to your

desired position.

CAUTION:

• Always set the speed change lever fully to the correct

position. If you operate the tool with the speed change

lever positioned halfway between the “1” position, “2”

position and “3” position, the tool may be damaged.

• Do not use the speed change lever while the tool is running. The tool may be damaged.

Selecting the action mode (Fig. 5)

This tool employs an action mode changing lever. Select

one of the three modes suitable for your work needs by

using this lever.

For rotation only, slide the lever so that it points toward

the m mark on the tool body.

For rotation with hammering, slide the lever so that it

points toward the mark on the tool body.

For rotation with clutch, slide the lever so that it points

toward the mark on the tool body.

NOTE:

When changing the position from to m, it may be a little difficult to slide the mode change lever. At this time,

switch on and run the tool for a second at the position,

then stop the tool and slide to your desired position.

CAUTION:

Always set the lever correctly to your desired mode mark.

If you operate the tool with the lever positioned halfway

between the mode marks, the tool may be damaged.

Adjusting the fastening torque (Fig. 6)

The fastening torque can be adjusted in 16 steps by turning the adjusting ring so that its graduations are aligned

with the arrow on the tool body. The fastening torque is

minimum when the number 1 is aligned with the arrow,

and maximum when the number 16 is aligned with the

arrow.

Before actual operation, drive a trial screw into your

material or a piece of duplicate material to determine

which torque level is required for a particular application.

5

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work

on the tool.

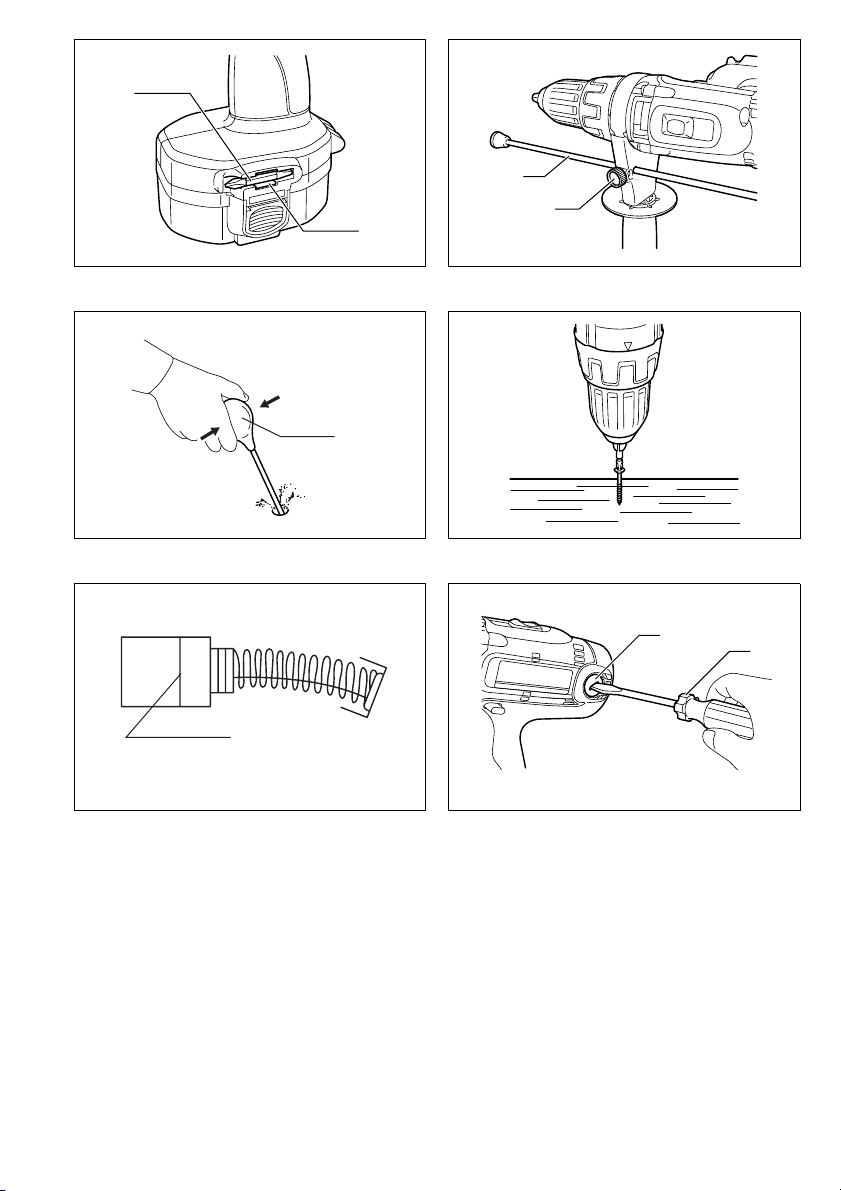

Installing side grip (auxiliary handle) (Fig. 7)

Always use the side grip to ensure operating safety.

Install the side grip so that the protrusions on the grip

base fit in between the grooves on the barrel. Then

tighten the grip by turning clockwise.

Installing or removing driver bit or drill bit

Turn the sleeve counterclockwise to open the chuck jaws.

Place the bit in the chuck as far as it will go. Turn the

sleeve clockwise to tighten the chuck. To remove the bit,

turn the sleeve counterclockwise. (Fig. 8)

When not using the driver bit, keep it in the bit holders.

Bits 45 mm long can be kept there. (Fig. 9)

Adjustable depth rod (Fig. 10)

The adjustable depth rod is used to drill holes of uniform

depth. Loosen the clamp screw, set to desired position,

then tighten the clamp screw.

OPERATION

Hammer drilling operation

CAUTION:

• There is a tremendous and sudden twisting force

exerted on the tool/bit at the time of hole breakthrough, when the hole becomes clogged with chips

and particles, or when striking reinforcing rods embedded in the concrete. Always use the side grip (auxiliary

handle) and firmly hold the tool by both side grip and

switch handle during operations. Failure to do so may

result in the loss of control of the tool and potentially

severe injury.

First, slide the action mode change lever so that it points

to the marking. The adjusting ring can be aligned in

any torque levels for this operation.

Be sure to use a tungsten-carbide tipped bit.

Position the bit at the desired location for the hole, then

pull the switch trigger. Do not force the tool. Light pressure gives best results. Keep the tool in position and prevent it from slipping away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at an

idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out

and normal drilling may be resumed.

Blow-out bulb (optional accessory) (Fig. 11)

After drilling the hole, use the blow-out bulb to clean the

dust out of the hole.

Screwdriving operation (Fig. 12)

First, slide the action mode change lever so that it points

to the marking. Adjust the adjusting ring to the proper

torque level for your work. Then proceed as follows.

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the switch trigger

as soon as the clutch cuts in.

NOTE:

• Make sure that the driver bit is inserted straight in the

screw head, or the screw and/or bit may be damaged.

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting of the workpiece.

See the chart.

Nominal diameter of

wood screw (mm)

3.1 2.0 – 2.2

3.5 2.2 – 2.5

3.8 2.5 – 2.8

4.5 2.9 – 3.2

4.8 3.1 – 3.4

5.1 3.3 – 3.6

5.5 3.6 – 3.9

5.8 4.0 – 4.2

6.1 4.2 – 4.4

NOTE:

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

Recommended size of

pilot hole (mm)

Drilling operation

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole break through. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

First, slide the action mode change lever so that it points

to the m marking. The adjusting ring can be aligned in

any torque levels for this operation. Then proceed as follows.

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide

screw makes drilling easier by pulling the bit into the

workpiece.

6

Loading...

Loading...